Professional Documents

Culture Documents

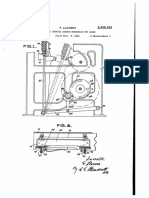

Sept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-Sheet

Uploaded by

Lucas Raiths0 ratings0% found this document useful (0 votes)

10 views4 pagesOriginal Title

US3466911

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views4 pagesSept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-Sheet

Uploaded by

Lucas RaithsCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Sept. 16, 1969 J.

MARCOVC- 3,466,911

MASS PRODUCTION OF STANDARDISED COMPONENTS

Filed day l, 1967 2 Sheets-Sheet

/wa/72e

e/acoa A7%cop/7ca/

ass/ Žeta- 14%-ou

arry-1s.

Sept. 16, 1969 J. MARCOVITCH 3,466,911

MASS PRODUCTION OF STANDARDISED COMPONENTS

Filed May 1, 1967 2. Sheets-Sheet 2

United States Patent Office 3,466,911

Patented Sept. 16, 1969

2

3,466,911

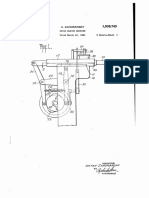

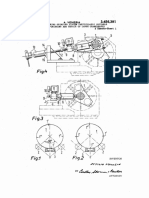

FIGURE 1 is a vertical section through the machine,

MASS PRODUCTION OF STANDARDISED FIGURE 2 is a view, partly in section, on the line

COMPONENTS 2-2 of FIGURE 1,

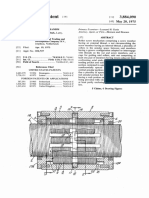

Jacob Marcovitch, Johannesburg, Transvaal, Republic of FIGURE 3 is a fragmentary sectioned view on the line

South Africa, assignor to Rotary Profile Anstalt, Vaduz, 3-3 of FIGURE 1, on an enlarged scale,

Liechtenstein FIGURE 4 is a fragmentary sectional view of a known

Filed May 1, 1967, Ser. No. 634,944 machine, and

Claims priority, application Republic of South Africa, FIGURE 5 is a fragmentary sectional view of the ma

May 5, 1966, 2,614/66 chine of FIGURES 1 to 3, corresponding to the view of

nt. C. B21b 5/00 FIGURE 4.

U.S. C. 72-91 2 Claims 10

The machine illustrated in FIGURES 1, 2, 3 and 5 con

sists essentially of an annular roller 10, within the cavity

ABSTRACT OF THE DISCLOSURE of which is mounted a solid roller 12. The outer roller

is rotatably mounted in any suitable manner, for instance

A metal band is passed through the throat defined 15 on rollers 13, rotating about fixed axes, while the inner

between the inner surface of a hollow roller and the roller is carried on a shaft 14 that is journalled in bear

circumference of a roller mounted eccentrically within ings 15.

the cavity of the hollow roller, the opposed roller surfaces The inner roller is mounted eccentrically with respect

defining between them a series of dies which profile the to the outer roller, and the eccentricity is such that a

band to form a line of articles separated by rupturable convergent-divergent throat 16 is defined between the

webs. Direction-changing means are provided to lead the inner face of the outer roller and the periphery of the

band to and from the throat. inner roller.

The opposed faces of the two rollers are shaped to act

as a series of dies. The cavity of each die 18 is provided

This invention relates to the mass production of stand 25 partly by one roller and partly by the other; or wholly

ardised articles from blank material such as strip, bar, by one or other of the rollers. In the embodiment illus

rod or individual pieces. The articles are continuously trated, each roller provides one part of the die. In order

fabricated as a ribbon in which a multiplicity of the that the two parts 20, 22 of each die should be in reg

articles is joined by webs which are ruptured to free the ister on every revolution of the inner roller, the two roll

individual articles. 30 ers are geared together. To this end, the shaft 14 has

In apparatus hitherto proposed, a blank is passed mounted on it a spur wheel 26 that engages with a ring

through the throat defined by parallel, juxtaposed rollers gear 24 fast with the outer roller. The shaft 14 is driven

which are suitably profiled to act as dies and to impose through a spur gear 28. If, however, the die is sunk en

the required shape on the blank. The objection to this tirely within one of the rollers, the other roller having

arrangement is that the rollers are virtually in line con 3.5 a smooth surface, it is then not essential for the rollers

tact with the blank, with the result that the die cavities to be mechanically coupled, since there is then continu

defined between the juxtaposed rollers are not completely ous register of the die.

enclosed during the formation of each article. The mate One roller may be recessed circumferentially to receive

rial of the blank is therefore not fully entrapped and is the other, so that the die cavity is closed off at each side.

extruded from the die cavity to some extent, as the rollers 40 This is seen in FIGURE 3.

rotate, so that the articles tend to lack precision. If the blank to be passed through the throat were of

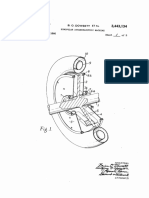

The object of the present invention is to provide appa such short length and manoeuvrability that it be intro

ratus in which the difficulty discussed above is minimised. duced into the crescent 30 of the machine and have one

According to the invention, the throat is defined be end offered to the throat 16, then the machine so far

tween two rollers of which one is hollow and the other described would be complete. However, if the blank is

is located within its cavity. lengthy, means must be provided to pass it into the cres

The rollers are rotated for their peripheral speeds at cent and remove it therefrom. In the preferred form, the

the throat to be the same. If one face of the finished means consists of direction-changing guides or pulleys

article is to be smooth, there need be no co-ordination 32, 34 (FIGURES 1 and 2) to lead the workpiece into

between the rollers. Indeed, the smooth-peripheral roller 50 parallelism with the throat and guide it out of the cres

may be frictionally driven by the blank. However, if the cent.

profile to be imposed on the blank is partly imposed by The operation of the machine is self-evident. A lengthy

one and partly by the other roller, then the rollers must blank 38 is passed around the pulley 32 and its end is

be geared together to run in unison, so that the profiles offered to the throat 16. Rotation of the rollers draws the

are in register with one another. 55 blank into and through the throat. As the throat con

The rollers are arranged for their peripheries to be verges, so is the blank reduced in thickness and the ma

as close together as is possible. This ensures that webs terial flows plastically into each die cavity to fill it. Be

joining or surrounding the shapes formed in the blank tween the dies, the blank is flattened to a thin ribbon

are as thin as is practicable. This not only saves material, which constitutes an easily rupturable web 40 between

but facilitates severance of the webs to liberate the indi 60 the components.

vidual articles. It was observed earlier on that known machines hav

It must be pointed out that the machine of the inven ing externally juxtaposed rollers had the inherent dis

tion has the disadvantage over known machines that a advantage that the material within the die was incom

lengthy rod, bar or other blank cannot be led directly pletely entrapped. An examination of FIGURE 4 will

into the throat, as the outer roller is in the way, whereas 65

make this evident. There is no position during the pas

in the known form there is no such difficulty. For short sage of the blank through the throat between the rollers

blanks this need not matter, but for long ones, it does. A 42, 44, when a die 46 forms an enclosed space: the cavity

manner of overcoming this problem is described later.

The machine may be associated with a device for lib is always open either at the rear, as it approaches the nar

erating the components from the webs. rowest part of the throat, or at the front as it leaves it, and

A machine made in accordance with the invention is material within the cavity can extrude through the gap.

illustrated in the accompanying drawings, in which: As seen in FIGURE 5, however, the geometry of the ma

3,466,911.

3. 4.

chine of the invention produces a throat of considerably through which the blank passes, a series of die cavities

longer length and correspondingly more gradual con for standardized articles defined jointly by the rollers

vergence and divergence than in the case of the known and disposed in the confronting circumferential surfaces

machine with externally juxtaposed rollers. This allows of the rollers, and means to rotate the rollers in the

the material pressed into each die to be completely en 5 same direction with the die cavities in register.

trapped as the die proceeds through the narrowest part 2. The machine of claim 1 in which the blank mate

of the throat, resulting in the production of components rial is lengthy, and including direction-changing means

of greater precision and uniformity than is possible with to guide the blank into the crescent defined between the

known machines. rollers and into parallelism with the throat, and to guide

A multiplicity of components may be made abreast of 0. it from the throat to the outside of the crescent.

each other or of one another, to increase the output of

the machine. References Cited

When the end product of the machine is a ribbon of UNITED STATES PATENTS

components, divided by the rupturable webs 40, means

may be incorporated with the machine to separate the 5 596,899 1/1898 Merriam ----------- 72-186

components from the ribbon. In other cases the finished 607,015 7/1898 Brisben -------------- 72-7

articles are formed individually from separate blanks. 958,010 5/1910 Richards ------------- 72-91

I claim: 1,217,748 2/1917 Greenfield ----------- 72-91

1. A machine for mass-producing standardized articles 2,421,011 5/1947 Chevigny ------------- 72-71

from blank material, consisting of two rollers, one of '0 CHARLES W. LANHAM, Primary Examiner

which is hollow and the other of which is contained

within its cavity with its axis parallel with the axis of L. A. LARSON, Assistant Examiner

the hollow roller, but displaced from it to provide be U.S. C. X.R.

tween the inner face of the hollow roller and the pe

riphery of the inner roller a convergent-divergent throat 25 72-198

You might also like

- 8.hydraulics of Tangential Vortex Intake For Urban DrainageDocument11 pages8.hydraulics of Tangential Vortex Intake For Urban Drainageローズ サンティアゴNo ratings yet

- Installation Manual - Galileo - EgyptDocument65 pagesInstallation Manual - Galileo - EgyptAhmed ElarabyNo ratings yet

- Kathryn Paulsen - Witches Potions and Spells Cd7 Id2119482802 Size5047Document33 pagesKathryn Paulsen - Witches Potions and Spells Cd7 Id2119482802 Size5047yuukosan83100% (2)

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Document4 pagesA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJNo ratings yet

- US Patent 3884090Document5 pagesUS Patent 3884090sthollanderNo ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- Web Separator US3463377Document5 pagesWeb Separator US3463377chupalaNo ratings yet

- Bag cutting mechanism for adjustable bag lengthDocument3 pagesBag cutting mechanism for adjustable bag lengthJhonnatan E Avendaño Florez100% (1)

- Us3432107 PDFDocument3 pagesUs3432107 PDFasssssNo ratings yet

- US2447117Document6 pagesUS2447117MahnooshNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- US2182002Document5 pagesUS2182002Jhonnatan E Avendaño FlorezNo ratings yet

- Mixing Mill Accumulating Shelf for Intimately Mixing Large BatchesDocument5 pagesMixing Mill Accumulating Shelf for Intimately Mixing Large BatchesEduardo Fernandez DazaNo ratings yet

- Braiding MachineDocument7 pagesBraiding Machinejojaberi100% (1)

- Us2218783 PDFDocument4 pagesUs2218783 PDFlandagoNo ratings yet

- Rail Transporting MachineDocument7 pagesRail Transporting MachineAkashNo ratings yet

- Us2018240 PDFDocument4 pagesUs2018240 PDFPolygrapack SA DE CVNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Us 1893840Document6 pagesUs 1893840Robert BercovitzNo ratings yet

- M2 HB Bolt Side Change US2529391Document4 pagesM2 HB Bolt Side Change US2529391apoorva singhNo ratings yet

- US1952501 Drum WeirDocument12 pagesUS1952501 Drum WeirSlađana RadovanovićNo ratings yet

- A BY - 4 The: May 23, 1961 B. J. Parmele 2,985,391Document5 pagesA BY - 4 The: May 23, 1961 B. J. Parmele 2,985,391Eloquent EloquentNo ratings yet

- Removable Francis Turbine SealsDocument4 pagesRemovable Francis Turbine SealsmachevelNo ratings yet

- Self-Centering Grinding System for CrankshaftsDocument5 pagesSelf-Centering Grinding System for CrankshaftsMahnooshNo ratings yet

- Us 3443134Document4 pagesUs 3443134Diego T. FranceschiNo ratings yet

- Easily removable fertilizer spreader metering mechanismDocument5 pagesEasily removable fertilizer spreader metering mechanismVijayakumar G VNo ratings yet

- Thompson Proto US1425810Document4 pagesThompson Proto US1425810apoorva singhNo ratings yet

- Us 3090578Document3 pagesUs 3090578mohamad zareNo ratings yet

- BYY "So: June 7, 1966 M, A Brown 3,254,776Document7 pagesBYY "So: June 7, 1966 M, A Brown 3,254,776Yu YangNo ratings yet

- Knot Tying MachineDocument10 pagesKnot Tying MachineSun And youNo ratings yet

- Patent conversion device rotates wire linearlyDocument7 pagesPatent conversion device rotates wire linearlyRockerss RockerssNo ratings yet

- Sept. 11, 1951 B. B. Scott 2,567,735: His AttorneyDocument3 pagesSept. 11, 1951 B. B. Scott 2,567,735: His AttorneyTri PujiyantoNo ratings yet

- Us 2425103Document6 pagesUs 2425103Muhamad HasanNo ratings yet

- Cementing Patent 2Document3 pagesCementing Patent 2Lara CitlalliNo ratings yet

- Adjustable jaw crusher with replaceable platesDocument4 pagesAdjustable jaw crusher with replaceable platescarrialdiNo ratings yet

- US4335764Document7 pagesUS4335764Jorge ArbelaezNo ratings yet

- US3580211-Method of Shaft Alignment of A Main Engine Shaft in ShipbuildingDocument3 pagesUS3580211-Method of Shaft Alignment of A Main Engine Shaft in ShipbuildingMahnooshNo ratings yet

- BY WWW/a : April 12, 1960v A. Witte - 2,932,081Document3 pagesBY WWW/a : April 12, 1960v A. Witte - 2,932,081PrasadNo ratings yet

- Us 2543888Document5 pagesUs 2543888Juan Sebastian PrietoNo ratings yet

- April 28, 1970 K. Kohl 3,508,419: Filed June 25, 1968Document3 pagesApril 28, 1970 K. Kohl 3,508,419: Filed June 25, 1968Sher Hai HamNo ratings yet

- Feb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3Document7 pagesFeb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3ValBMSNo ratings yet

- Automatic roll changing system for metal rolling millsDocument6 pagesAutomatic roll changing system for metal rolling millsPooria1989No ratings yet

- Dec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoDocument4 pagesDec. 14, 1948. O. G. Reske 2,456,446: - 2Z 2. 77zzvezzoAngelica Mae LargaNo ratings yet

- Dec. 13, 1960 I, Tubbs 2,964,084: Z2S SLDocument5 pagesDec. 13, 1960 I, Tubbs 2,964,084: Z2S SLstv ravaNo ratings yet

- Neckel's 1940 patent for improved stacking of folded flat articlesDocument4 pagesNeckel's 1940 patent for improved stacking of folded flat articlesMary HullNo ratings yet

- Fabric load lifting sling patent from 1966Document7 pagesFabric load lifting sling patent from 1966Paballo MontleNo ratings yet

- T Red.: 3. Sheets-Sheet LDocument6 pagesT Red.: 3. Sheets-Sheet LThyagaraj A HNo ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- Nov. 22, 1932. W. D. Lpps. 1888,353Document12 pagesNov. 22, 1932. W. D. Lpps. 1888,353AGUAVIVANJNo ratings yet

- Nov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Document3 pagesNov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Karin AndersonNo ratings yet

- US2228469Document4 pagesUS2228469George AcostaNo ratings yet

- Us 4476409Document7 pagesUs 4476409Shankar PediredlaNo ratings yet

- QZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Document3 pagesQZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Galo YambayNo ratings yet

- Feb. 11, 1969 O. Sahm 3,426,395: Otto Sa/2772Document3 pagesFeb. 11, 1969 O. Sahm 3,426,395: Otto Sa/2772Fiqri AnraNo ratings yet

- Filed Sept. 30, 1963: C. C. BrownDocument8 pagesFiled Sept. 30, 1963: C. C. BrownyasamanNo ratings yet

- Method and Machine for Manufacturing Paperboard Tubes by Helical WindingDocument8 pagesMethod and Machine for Manufacturing Paperboard Tubes by Helical WindingUvxtalNo ratings yet

- O/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231Document5 pagesO/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231VyacheslavNo ratings yet

- US2126920Document10 pagesUS2126920Jhonnatan E Avendaño FlorezNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- E.I. ZS: Else ADocument5 pagesE.I. ZS: Else ABelay ShibruNo ratings yet

- 2004 - ICPR Agard Kusiak PDFDocument9 pages2004 - ICPR Agard Kusiak PDFFadly Ahmad KNo ratings yet

- Wren Minibike PlansDocument7 pagesWren Minibike PlansJim100% (5)

- The Impact of Standardization and Standards On InnovationDocument33 pagesThe Impact of Standardization and Standards On InnovationTamara RadicNo ratings yet

- Standardisation and Regulatory Context of Machine-to-Machine CommunicationDocument7 pagesStandardisation and Regulatory Context of Machine-to-Machine CommunicationLucas RaithsNo ratings yet

- Standardization and Innovation PDFDocument258 pagesStandardization and Innovation PDFGabriela SterianNo ratings yet

- Rapport Final CensurDocument131 pagesRapport Final CensurLucas RaithsNo ratings yet

- Progress Towards Standardisation of Ball CrateringDocument13 pagesProgress Towards Standardisation of Ball CrateringLucas RaithsNo ratings yet

- 049 - Standardization and Standards As Research and Innovation Indicators: Current Opportunities and Future ChallengesDocument13 pages049 - Standardization and Standards As Research and Innovation Indicators: Current Opportunities and Future ChallengesOECDInnovationNo ratings yet

- Chalk ClockDocument1 pageChalk ClockLucas RaithsNo ratings yet

- Standard and InterchangeDocument25 pagesStandard and InterchangeBibin Baby100% (1)

- Gearabc A1 PDFDocument19 pagesGearabc A1 PDFjinriNo ratings yet

- Boss Digital Recorder Micro BRDocument132 pagesBoss Digital Recorder Micro BRLucas RaithsNo ratings yet

- Automating SolidWorks with Visual BasicDocument20 pagesAutomating SolidWorks with Visual BasicLucianNo ratings yet

- The Locked Book of Magical SecretsDocument507 pagesThe Locked Book of Magical SecretsEstormehelsingNo ratings yet

- Colibri SampleDocument26 pagesColibri SampleGergő Attila TóthNo ratings yet

- Inventor Professional Detail Bro Us1 PDFDocument32 pagesInventor Professional Detail Bro Us1 PDFLucas RaithsNo ratings yet

- 0916 AgmaDocument4 pages0916 AgmaLucas RaithsNo ratings yet

- Gear Guide2Document50 pagesGear Guide2Anonymous fQAeGFNo ratings yet

- Agma 1103 h07 Tooth Proportions For Fine Pitch Spur and Helical Gearing Metric Edition PDFDocument32 pagesAgma 1103 h07 Tooth Proportions For Fine Pitch Spur and Helical Gearing Metric Edition PDFLucas RaithsNo ratings yet

- What Wood Whisper To ItselfDocument93 pagesWhat Wood Whisper To ItselfLucas RaithsNo ratings yet

- Double Flank TestingDocument8 pagesDouble Flank TestingLucas RaithsNo ratings yet

- Taper Chart 1Document3 pagesTaper Chart 1alim fakihNo ratings yet

- Hous1998 O9801042Document52 pagesHous1998 O9801042John Barry Leonard JrNo ratings yet

- Catalogue: A C Ompan y of Ha Wle German y GR OupDocument62 pagesCatalogue: A C Ompan y of Ha Wle German y GR OupAlvin TombarevicNo ratings yet

- SDS22 00 00Document26 pagesSDS22 00 00János RédeiNo ratings yet

- Bonney Forge Catalogue PDFDocument105 pagesBonney Forge Catalogue PDFGustavo TorresNo ratings yet

- METRIC THREAD TABLEDocument22 pagesMETRIC THREAD TABLEВлад ГреськоNo ratings yet

- Iit-Jam Full Length Test - 01Document15 pagesIit-Jam Full Length Test - 01Sneha SuriNo ratings yet

- Time Dilation: The Theory of RelativityDocument8 pagesTime Dilation: The Theory of RelativityJashwanth saiNo ratings yet

- GED Physics Motion ForcesDocument4 pagesGED Physics Motion ForcesShahadat Hussain Parvez100% (2)

- H Section JIS G 3192Document9 pagesH Section JIS G 3192Sudath KularathnaNo ratings yet

- ABB Medium Voltage SwitchgearDocument36 pagesABB Medium Voltage Switchgearap00100% (1)

- Why The Interest in Hybrid Technology?: Bryan Nelson - Caterpillar, IncDocument11 pagesWhy The Interest in Hybrid Technology?: Bryan Nelson - Caterpillar, IncAnoj pahathkumburaNo ratings yet

- ASME High Pressure Boiler QuizDocument36 pagesASME High Pressure Boiler Quizmen100% (1)

- CFD Pro 14.5 L08 IntroCFD CFXDocument27 pagesCFD Pro 14.5 L08 IntroCFD CFXMahir SoyerNo ratings yet

- Minera Yanacocha SRL Project Specification 000.250.50003 Yanacocha GSA - Project Date 03 Aug 2005 Contract 53229802 Page 1 of 12Document12 pagesMinera Yanacocha SRL Project Specification 000.250.50003 Yanacocha GSA - Project Date 03 Aug 2005 Contract 53229802 Page 1 of 12Pedro FalconNo ratings yet

- R950 Tunnel StageIV GB PI 2015 04 - 15990 0 PDFDocument12 pagesR950 Tunnel StageIV GB PI 2015 04 - 15990 0 PDFma6070No ratings yet

- K58L XRZ: Truck-Mounted Concrete Boom PumpDocument2 pagesK58L XRZ: Truck-Mounted Concrete Boom PumpAhmed RashadNo ratings yet

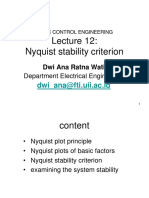

- DSK NyquistDocument19 pagesDSK NyquistRahmat Wahyu PratamaNo ratings yet

- Chaypy V NotchDocument5 pagesChaypy V NotchGherNo ratings yet

- Model E & Pe Series Two-Stage ConvertersDocument5 pagesModel E & Pe Series Two-Stage ConverterswritetobjNo ratings yet

- Lab 3 - Hydrostatic Forces On Plane and Curved SurfacesDocument5 pagesLab 3 - Hydrostatic Forces On Plane and Curved SurfacesAlyssa Suzanne TafallaNo ratings yet

- Turbinas Evaporativas de GasDocument158 pagesTurbinas Evaporativas de GasluijamurNo ratings yet

- BE Mechanical Engg Scheme of Exam For I To VIII SemDocument16 pagesBE Mechanical Engg Scheme of Exam For I To VIII SemAlok ShamkuwarNo ratings yet

- Exam 5: PH 111-01: General Physics 1Document5 pagesExam 5: PH 111-01: General Physics 1Jessica Leigh SmealNo ratings yet

- Produk Catalog AC Multi V LGDocument274 pagesProduk Catalog AC Multi V LGarif_bagusNo ratings yet

- Introduction In: Rotating EquipmentDocument57 pagesIntroduction In: Rotating EquipmentAhmed ZNo ratings yet

- SPM General CatalogDocument40 pagesSPM General CatalogNailuth García100% (1)

- XI Physics IMP Short QuestionsDocument4 pagesXI Physics IMP Short QuestionsAshfaque Memon100% (1)