Professional Documents

Culture Documents

Types and Properties of Lubricants

Uploaded by

aeronautical rajasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Types and Properties of Lubricants

Uploaded by

aeronautical rajasCopyright:

Available Formats

CHAPTER 2

TYPES AND

PROPERTIES OF

LUBRICANTS

WS Robertson CEng MlnstF This chapter outlines the main types oflubricants and covers

Esso Petroleum Company Ltd some of the more important lubricant properties and tests,

finishing with engine tests. With each test description there

is a note on any relevant additives or classification systems.

TYPES OF LUBRICANTS

Lubricants can be fluids (gases or liquids) or solids.

Fluids

Gases are not always considered as lubricants, but air

lubricated bearings are becoming increasingly important.

However, air for specialist applications may not be a cheap

lubricant. For hydrostatic spindIe bearings on machine

tools, for instance. air cleaned and dried to adequate

standards can cost as much as three times as much as

lubricating oil.

Lubricating oil-hydrocarbon oil produced from cmde

petroleum-is of course the most common of alllubricants.

Hydrocarbon oils are used because:

a. They are widely available in a range of viscosities that

gives a wide choice of load. speed and temperature con-

ditions to the designer,

b. They give a low, consistent coefficient of friction and

have low compressibility.

c. They are reasonably effective in carrying away heat

from bearing surfaces.

d. They are inexpensive lubricants.

Hydrocarbon lubricating oils fall into two main cate-

gones:

Paraffinic oils have high pour points (because of the wax

they contain), high viscosity indices, and good resistance

to oxidation.

Naphthenic oils have low pour points and relatively low

viscosity indices and oxidation stability.

The above properties are described later in the chapter,

Synthetic lubricants (esters, phosphates, silicones) may

cost up to ten times as much as hydrocarbon oils but they

are necessary for some specialised applications, like aircraft

gas turbines where resistance to degradation at tempera-

tures of up to perhaps 300°C is necessary.

G. G. Evans et al. (eds.), Lubrication in Practice 15

© Esso Petroleum Company Limited and the Macmillan Press Limited 1972

LUBRICATION IN PRACTICE

Water is much better at carrying away heat than are However, tests that indicate the presence of particular

hydrocarbon oils, but its low viscosity and its relatively types of oil or additives still need to be supplemented by

high freezing point and low boiling point greatly limits its performance tests. Tests for composition are really most

use as a lubricant. useful for process control in ensuring that, once a specifica-

tion has been established for a lubricant. the lubricant is

Solids and semi-solids always produced with as near the same composition as is

Grease is the most important solid or semi-solid lubricant, necessary.

and it is normally made from hydrocarbon oils thickened

Tests and specifications

with metallic soaps, in consistencies ranging from slightly

There are two kinds of specifications for lubricants:

tbickened liquid to block-hard (see Chapter 12). Although

manufacturing specifications just mentioned above, set

grease will not carry heat away from a bearing as liquid

up by makers to keep their products consistent in composi-

lubricant will, it can be an effective seal against dirt and

tion, and therefore in quality; and performance specifica-

water reaching the bearing surfaces. It can also provide a

tions set up by standards institutions like the British

reservoir of lubricant in a bearing lubricated at long

Standards Institution, by equipment makers like Cater-

intervals, or even sealed for life.

pillar or F ord, or by govemments, primarily for military

Other solid lubricants, functioning in a different way.

use.

include molybdenum disulpbide and graphite. These

Performance specifications range from the Society of

may be used on their own or in combination with oils and

Automotive Engineers crankcase and gear oil classifica-

greases. Chemical coatings on bearing metals and bearing-.

tions, wbich only specify a range ofviscosities, to advanced

made from plastics such as PTFE can also be included in

military specifications like MIL-L-2104C for engine oils.

this category.

Specifications of this last kind are built up from standard

The remainder of tbis chapter is concemed only with

laboratory and engine tests. Tests on lubricants have to be

conventional industriallubricants made from hydrocarbon

carefully standardised because few of the tests measure

oils, either alone or with additives to enhance their natural

fundamental properties independent of the test method.

properties.

If the method or the equipment used for the test is changed,

the result will change too.

Specifications will always give either an upper or lower

PROPERTIES OF LUBRICANTS

limit or a range of properties for each test result, because

The first, obvious, property of a lubricant is its ability to no production lubricant can be made to give exactly the

keep moving surfaces apart, in all the conditions of pressure, same results every time, nor are the tests used capable of

temperature, the presence of contaminants and so on, to exact repeatability every time- there must be a range

which they may be subjected. within wh ich the results can fall.

Secondly, most lubricants also need to cool, by carrying

away heat generated at the bearing surfaces or reaching

them from an outside source (as the heat of combustion of

SPECIFIC TESTS ON LUBRICANTS

a gas turbine reaches the turbine bearings). Various standard tests are mentioned in this section.

Thirdly, a lubricant should be stable enough to keep None are described in detail because full technical in-

on doing its job for its designed lifetime, whether that is formation on all of them can be found in the relevant

seconds on a once-through mist lubricated bearing or Institute of Petroleum 1 and the American Society for

ten or more years in a steam turbine. Lastly, the lubricant Testing and Materials publications 2 • and in other publica-

should protect the surfaces with which it comes in contact tions 3 • 4 that describe the significance of tests more fully

against corrosion from the atmosphere, or from corrosive than is possible in this chapter.

products generated in the equipment. like acid gases from

Viscosit)'

an IC engine.

Viscosity and lubrication theory has been covered in

Chapter 1. Some basic points are repeated here to lead into

a description of viscosity test methods.

TESTS ON LUBRICANTS Viscosity, a measure of resistance to flow in a fluid. is

Purpose of tests the most important of all lubricant properties. Viscosity

Measurement of the properties of lubricants can show increases with increasing molecular weight and changes

lubricant composition and can indicate, to some extent, rapidly with changes in temperature. Heating lubricating

lubricant performance, but hydrocarbon oils are too oillowers and cooling raises its viscosity.

complex for this type of testing to be at all a complete guide Design calculations require knowledge of dynamic

to behaviour in practice. Laboratory engine tests and, viscosity. In streamline flow conditions, dynamic vis-

finally, controlled field trials in the actual equipment to be cosity is defined as the tangential force on unit area of

lubricated are needed to prove the suitability of a particular one of two planes parallel to each other, separated by unit

oil for a particular use. distance, and moving with uniform unit velocity relative to

The chemical composition of the oil makes a great each other, the space between being filled with fluid. The

difference to lubricant performance, and the additives SI unit is Nsjm 2 but the centipoise (10- 3 Nsjm 2 ) is normally

used with the oils also considerably affect performance. used.

16

You might also like

- Onboard Maintenance SystemsDocument61 pagesOnboard Maintenance SystemsCaroline Xiaoxi71% (7)

- Material Alloy KHR32CDocument2 pagesMaterial Alloy KHR32CKHNo ratings yet

- 11.1.26 AOAC of Fi Cial Method 974.27 Cad Mium, Chro Mium, Cop Per, Iron, Lead, Mag Ne Sium, Man Ga Nese, Sil Ver, and Zinc in Wa TerDocument2 pages11.1.26 AOAC of Fi Cial Method 974.27 Cad Mium, Chro Mium, Cop Per, Iron, Lead, Mag Ne Sium, Man Ga Nese, Sil Ver, and Zinc in Wa Termttla100% (1)

- EG' Histology (5th Ed.) Bookmarks and SearchableDocument325 pagesEG' Histology (5th Ed.) Bookmarks and SearchableCHRISTOPHER JOHN MANINGASNo ratings yet

- FWC Air Cooled Exchanger PDFDocument49 pagesFWC Air Cooled Exchanger PDFdinakaranpatelNo ratings yet

- Re-Refining of Used Lubricating OilsDocument30 pagesRe-Refining of Used Lubricating OilsJaydeep TayadeNo ratings yet

- Diesel Emissions - A Breath of Fresh Air P2Document10 pagesDiesel Emissions - A Breath of Fresh Air P2STEVENNo ratings yet

- Re-Refining of Used Lubricating OilsDocument30 pagesRe-Refining of Used Lubricating OilsJaydeep TayadeNo ratings yet

- ECL - Choosing A GreaseDocument13 pagesECL - Choosing A GreaseJako MishyNo ratings yet

- White Paper: LubrisenseDocument8 pagesWhite Paper: Lubrisensecarlos trilloNo ratings yet

- Specialty LubricantsDocument2 pagesSpecialty Lubricantshumayun121No ratings yet

- TI - LubricationDocument5 pagesTI - LubricationAlex LinsNo ratings yet

- Submarine Main Propulsion Diesels - Chapter 7Document32 pagesSubmarine Main Propulsion Diesels - Chapter 7Michael ChungNo ratings yet

- Natural Refrigerants WhitepaperDocument10 pagesNatural Refrigerants WhitepaperDiptarghya KunduNo ratings yet

- Everything You Always Wanted To Know About Oil: But Were Afraid To AskDocument12 pagesEverything You Always Wanted To Know About Oil: But Were Afraid To AskLogist ChinaNo ratings yet

- Lubrication TechnologyDocument15 pagesLubrication TechnologyDillibabu RNo ratings yet

- Lubrication: Md. Al Amin Hossain Lecturer (ME)Document8 pagesLubrication: Md. Al Amin Hossain Lecturer (ME)SaHaria SajibNo ratings yet

- Lubricating Oils: 3-1. Oil RefiningDocument7 pagesLubricating Oils: 3-1. Oil RefiningJerome Christopher Gacusan IdioNo ratings yet

- Lubricants: Increase Service Life For Rail Wheel Bearings-A Review of Grease Lubrication For This ApplicationDocument18 pagesLubricants: Increase Service Life For Rail Wheel Bearings-A Review of Grease Lubrication For This ApplicationManish PatilNo ratings yet

- Compressor Oils: Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Min. Description / ApplicationDocument2 pagesCompressor Oils: Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Min. Description / ApplicationmdkhandaveNo ratings yet

- Introduction To Refining 3-1Document4 pagesIntroduction To Refining 3-1Mohamed GhareebNo ratings yet

- WINSEM2017-18 - MEE2009 - TH - GDN109 - VL2017185003149 - Reference Material I - 5.lubricationDocument39 pagesWINSEM2017-18 - MEE2009 - TH - GDN109 - VL2017185003149 - Reference Material I - 5.lubricationUTKARSH SHARMANo ratings yet

- 1.2. BTR - Lubrication NotesDocument17 pages1.2. BTR - Lubrication Notesvishnu vishnu G.T.No ratings yet

- Lube Base OilDocument14 pagesLube Base OilzibaNo ratings yet

- DTS Report Lubrication EditDocument16 pagesDTS Report Lubrication EditPrathamesh RaneNo ratings yet

- LubricantsDocument42 pagesLubricantsNo Mercy GamingNo ratings yet

- Converting Used Engine Oil into Lubricating GreaseDocument19 pagesConverting Used Engine Oil into Lubricating GreasemohamedNo ratings yet

- Qunfeng Zeng The Lubrication Performance and ViscosityDocument8 pagesQunfeng Zeng The Lubrication Performance and ViscosityMarcelinus RanggaNo ratings yet

- Function of A Lubricant: Ref To Page 48 Diesel Engines 3rd Edition, A J WhartonDocument11 pagesFunction of A Lubricant: Ref To Page 48 Diesel Engines 3rd Edition, A J Whartonapi-3701567No ratings yet

- Kluber Lubricants For Gas Compressors ManualDocument24 pagesKluber Lubricants For Gas Compressors ManualJon GNo ratings yet

- Lubrication Oils and AdditivesDocument12 pagesLubrication Oils and AdditivesavciayNo ratings yet

- TT Electric Motor Bearing Lubrication GuideDocument7 pagesTT Electric Motor Bearing Lubrication GuidepatipanpanitanNo ratings yet

- PELUMASANDocument7 pagesPELUMASANAndri Indra GunawanNo ratings yet

- Make Bearings Live Longer.: Plain Bearing Lubrication: Product Selection and TipsDocument24 pagesMake Bearings Live Longer.: Plain Bearing Lubrication: Product Selection and TipsMario MullerNo ratings yet

- Amity - Lubricants - Why So DumbDocument17 pagesAmity - Lubricants - Why So DumbAbhimanyu Singhal100% (2)

- LubricationDocument49 pagesLubricationAdel KlkNo ratings yet

- Grease 2Document4 pagesGrease 2arunNo ratings yet

- Delta Lube 06 (PDB) - en - GB TechnicalDocument3 pagesDelta Lube 06 (PDB) - en - GB TechnicalRezk SifeNo ratings yet

- Tech Data: Compro™ C FDocument4 pagesTech Data: Compro™ C FJeremias UtreraNo ratings yet

- E_4486_1 - 3.3.5 LO MGO-MDODocument5 pagesE_4486_1 - 3.3.5 LO MGO-MDODennis Alexander Oseguera OsegueraNo ratings yet

- SKF Bearings With Solid OilDocument8 pagesSKF Bearings With Solid OilLuisSilvaNo ratings yet

- chapter Four Lubrication and Corrosion-convertedDocument32 pageschapter Four Lubrication and Corrosion-convertedTemesgen GetaNo ratings yet

- 2018.11.25 Grease Book FuchsDocument18 pages2018.11.25 Grease Book FuchsnghiaNo ratings yet

- Shell Gas Compressor Oil S4 PV 190 (En) TDSDocument2 pagesShell Gas Compressor Oil S4 PV 190 (En) TDSrehan7777No ratings yet

- Shell Gas Compressor Oil S4 PN 220 TDS - UnlockedDocument2 pagesShell Gas Compressor Oil S4 PN 220 TDS - UnlockedOmer IkhlasNo ratings yet

- LUBRICANTS: CLASSIFICATION AND PROPERTIESDocument25 pagesLUBRICANTS: CLASSIFICATION AND PROPERTIESSiontan GhoshNo ratings yet

- 2.5 Lubrication System - NotesDocument6 pages2.5 Lubrication System - NotesAustin ChechecheNo ratings yet

- 6481-6482 Product InfoDocument8 pages6481-6482 Product InfoNima FakherNo ratings yet

- TDS - Total - Lubrilam Cleaner - Nqa - 201412 - enDocument1 pageTDS - Total - Lubrilam Cleaner - Nqa - 201412 - enVelibor KaranovicNo ratings yet

- BECHEM Special Lubricants Chain Oils EN 02Document7 pagesBECHEM Special Lubricants Chain Oils EN 02Alfonso Florez MartinezNo ratings yet

- Shell Air Tool S2 A 32: Performance, Features & BenefitsDocument2 pagesShell Air Tool S2 A 32: Performance, Features & Benefitssergio26sotoNo ratings yet

- Mobil Rarus 800 Series FactsheetDocument2 pagesMobil Rarus 800 Series FactsheetSiswantoro Adi WibowoNo ratings yet

- Refining of Used Oil POSTER (4489)Document1 pageRefining of Used Oil POSTER (4489)Movies EraNo ratings yet

- Fuel Oil Quality: General Considerations Combustion QualityDocument2 pagesFuel Oil Quality: General Considerations Combustion QualityAtanasio PerezNo ratings yet

- Nu-Calgon Product Bulletin: Emkarate RL LubricantsDocument4 pagesNu-Calgon Product Bulletin: Emkarate RL Lubricantsusna1970No ratings yet

- Fuel and Lube PropertiesDocument18 pagesFuel and Lube PropertiesGonzales Frank Lioyd Bhong100% (1)

- Grease Life in Ball Bearings - The Effect of Temperatures - TLT Article - Oct10Document7 pagesGrease Life in Ball Bearings - The Effect of Temperatures - TLT Article - Oct10khairulNo ratings yet

- Journal PublishersDocument9 pagesJournal PublishersSai ReddyNo ratings yet

- Tech Data: Compro XL-S Compressor FluidDocument4 pagesTech Data: Compro XL-S Compressor FluidRoberto Alfaro EspinozaNo ratings yet

- BECHEM Special Lubricants Cement Industry Open Cast Mining and Mineral Processing 03Document7 pagesBECHEM Special Lubricants Cement Industry Open Cast Mining and Mineral Processing 03Sergey MedvedevNo ratings yet

- Chevron - PDS - Compressor Oils - CetusDE - v0920Document2 pagesChevron - PDS - Compressor Oils - CetusDE - v0920Santhosh DhandapaniNo ratings yet

- lp51 lp62Document6 pageslp51 lp62aeronautical rajasNo ratings yet

- lp87 lp98Document7 pageslp87 lp98aeronautical rajasNo ratings yet

- lp99 lp100Document2 pageslp99 lp100aeronautical rajasNo ratings yet

- lp63 lp74Document7 pageslp63 lp74aeronautical rajasNo ratings yet

- IMA System Interrupts and Shared ResourcesDocument7 pagesIMA System Interrupts and Shared Resourcesaeronautical rajasNo ratings yet

- lp51 lp62Document6 pageslp51 lp62aeronautical rajasNo ratings yet

- IMA System Interrupts and Shared ResourcesDocument7 pagesIMA System Interrupts and Shared Resourcesaeronautical rajasNo ratings yet

- lp63 lp74Document7 pageslp63 lp74aeronautical rajasNo ratings yet

- lp41 lp50Document6 pageslp41 lp50aeronautical rajasNo ratings yet

- lp51 lp62Document6 pageslp51 lp62aeronautical rajasNo ratings yet

- LP 02Document3 pagesLP 02aeronautical rajasNo ratings yet

- lp99 lp100Document2 pageslp99 lp100aeronautical rajasNo ratings yet

- Fluid Mechanics Chapter 2 Pascal's Law and PressureDocument3 pagesFluid Mechanics Chapter 2 Pascal's Law and Pressureaeronautical rajasNo ratings yet

- lp87 lp98Document7 pageslp87 lp98aeronautical rajasNo ratings yet

- Introduction To Fluids Background: A Fluid Is A Substance Which Conforms Continuously Under The Action of Shearing ForcesDocument3 pagesIntroduction To Fluids Background: A Fluid Is A Substance Which Conforms Continuously Under The Action of Shearing Forcesaeronautical rajasNo ratings yet

- Current and Voltage Distribution on AntennasDocument3 pagesCurrent and Voltage Distribution on Antennasaeronautical rajasNo ratings yet

- General: Bombardier Challenger 605 - LightingDocument23 pagesGeneral: Bombardier Challenger 605 - Lightingaeronautical rajasNo ratings yet

- Concept of Fluid and FlowDocument4 pagesConcept of Fluid and Flowaeronautical rajasNo ratings yet

- LP 87Document12 pagesLP 87aeronautical rajasNo ratings yet

- Information Systems IntroductionDocument4 pagesInformation Systems Introductionaeronautical rajasNo ratings yet

- 1 3Document2 pages1 3aeronautical rajasNo ratings yet

- Chapter 15 RADocument8 pagesChapter 15 RAaeronautical rajasNo ratings yet

- Cockpit and Passenger Compartment PresentationDocument8 pagesCockpit and Passenger Compartment Presentationaeronautical rajasNo ratings yet

- GPS BasicsDocument45 pagesGPS BasicsahmednppNo ratings yet

- Bombardier CRJ 200-Lighting PDFDocument30 pagesBombardier CRJ 200-Lighting PDFmamon113No ratings yet

- Air Traffic ManagementDocument16 pagesAir Traffic Managementaeronautical rajasNo ratings yet

- Escape Facilities and Crew Rest Compartment PresentationDocument9 pagesEscape Facilities and Crew Rest Compartment Presentationaeronautical rajasNo ratings yet

- Acars: Aircraft Communications Addressing and Reporting SystemDocument21 pagesAcars: Aircraft Communications Addressing and Reporting Systemaeronautical rajas100% (1)

- LEVEL III - ATA 45 Onboard Maintenance SystemDocument186 pagesLEVEL III - ATA 45 Onboard Maintenance Systemwagdi100% (3)

- Drilling and Completion Fluids OverviewDocument10 pagesDrilling and Completion Fluids OverviewSuta VijayaNo ratings yet

- Earth and Planetary Science Letters: Konstantin D. Litasov, Anton Shatskiy, Eiji OhtaniDocument13 pagesEarth and Planetary Science Letters: Konstantin D. Litasov, Anton Shatskiy, Eiji OhtaniLuan TrigoliNo ratings yet

- A Guide To Glycols - DowDocument58 pagesA Guide To Glycols - DowvoromarNo ratings yet

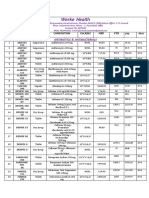

- Werke HealthDocument23 pagesWerke Healthganga ippltdNo ratings yet

- Prior Austen It e Grain SizeDocument39 pagesPrior Austen It e Grain SizePearl MassanNo ratings yet

- DD Cen TS 12037-2003Document34 pagesDD Cen TS 12037-2003DoicielNo ratings yet

- Wheatland Tube Company Wheatland Galvanized Rigid Metal Conduit (RMC) - SteelDocument2 pagesWheatland Tube Company Wheatland Galvanized Rigid Metal Conduit (RMC) - SteelAnya RumeserNo ratings yet

- Chemical Equilibrium Part 2Document26 pagesChemical Equilibrium Part 2adityayadav18julyNo ratings yet

- Kolor Kut Paste PDFDocument1 pageKolor Kut Paste PDFjohar MohammadNo ratings yet

- Analisis Risisko Kesehatan Pajanan Benzena Di Industri Percetakan X Kota SemarangDocument8 pagesAnalisis Risisko Kesehatan Pajanan Benzena Di Industri Percetakan X Kota SemarangAyunda SaputriNo ratings yet

- Sarnacol®-2170: Product Data SheetDocument3 pagesSarnacol®-2170: Product Data SheetAhmed MontashNo ratings yet

- Occupational Asthma: Current Concepts in Pathogenesis, Diagnosis, and ManagementDocument19 pagesOccupational Asthma: Current Concepts in Pathogenesis, Diagnosis, and ManagementIrina Luciana DumitriuNo ratings yet

- Biostimulatory Effects of Polydioxanone, Poly, Lactic Acid, and Polycaprolactone Fillers in Mouse ModelDocument7 pagesBiostimulatory Effects of Polydioxanone, Poly, Lactic Acid, and Polycaprolactone Fillers in Mouse ModelAlan CasoteNo ratings yet

- Astm D3242Document6 pagesAstm D3242Difany tsabitaNo ratings yet

- A Special Selection From Infinite Energy Magazine: Selected Articles From Issues 1 - 45 March/April 1995 - September/October 2002Document117 pagesA Special Selection From Infinite Energy Magazine: Selected Articles From Issues 1 - 45 March/April 1995 - September/October 2002DsgmmmmNo ratings yet

- D) 3 AlcoholDocument9 pagesD) 3 AlcoholJessicaNo ratings yet

- REVIEWER FOR ChE COMPRE 07082018Document352 pagesREVIEWER FOR ChE COMPRE 07082018Ahe BeongNo ratings yet

- Biomedx BEV Manual LCD ModelDocument21 pagesBiomedx BEV Manual LCD ModelbiomedxNo ratings yet

- LGLT 2: SKF Product Data SheetDocument1 pageLGLT 2: SKF Product Data SheetRahul SharmaNo ratings yet

- Free Ebook - Microbiology Review Notes by MedpgnotesDocument103 pagesFree Ebook - Microbiology Review Notes by Medpgnotesdr dixit100% (1)

- Book Ispst 2020Document52 pagesBook Ispst 2020SakhaviTVNo ratings yet

- Unit 4 Applied Chemistry CsitDocument9 pagesUnit 4 Applied Chemistry CsitBUDDHARAJU G GOPALA KRISHNAM RAJU 122062404010No ratings yet

- Material Safety Data Sheet: 1 Identification of SubstanceDocument7 pagesMaterial Safety Data Sheet: 1 Identification of SubstanceHermanHalimNo ratings yet

- Types of Titration CurvesDocument63 pagesTypes of Titration CurvesVibhinn SinghalNo ratings yet

- Azbil, Single Seated Control Valve (GLOBE)Document2 pagesAzbil, Single Seated Control Valve (GLOBE)Rangga TaufiqurahmanNo ratings yet

- Abs - Basf - Gp22Document2 pagesAbs - Basf - Gp22Marcio NovoNo ratings yet