Professional Documents

Culture Documents

Klüber Summit Varnasolv: Compressor Varnish Cleaner

Uploaded by

anon_925307644Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Klüber Summit Varnasolv: Compressor Varnish Cleaner

Uploaded by

anon_925307644Copyright:

Available Formats

Klüber Summit Varnasolv

Compressor Varnish Cleaner

Protect and optimise your compressors Your benefits at a glance

Mineral oil-based compressor oils can cause lacquer-like residues – Effective and time-saving cleaning during operation

and carbon build-up in oil-injected screw-type and rotary vane – Reduced maintenance and down-time costs

compressors that may form deposits in the entire oil circuit.

– Reduced operating temperature of the compressor, resulting

This often results in increased energy consumption, increase

in reduced energy costs

temperature, clogged oil lines and filters, and high maintenance

– Optimised oil life after cleaning

costs and downtime.

Your requirements - our solution

Klüber Summit Varnasolv is a fluid cleaning concentrate designed

to dissolve sticky residues, varnish and carbon build-up during

operation and keep them suspended in the oil.

It is a concentrated conditioner fluid containing synthetic ester oil

and cleaning additives. It is miscible with mineral oils, synthetic

hydrocarbons, ester oils and polyglycols. It is especially developed

for cleaning rotary screw compressors, vane compressors,

hydraulic systems, gears and other oil circulating systems.

Cleaning the compressor increases its efficiency.

The field test shows that power consumption decreased by 5% on average

when using Klüber Summit Varnasolv

Klüber Summit Varnasolv

Compressor Varnish Cleaner

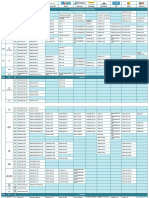

Easy compressor cleaning without downtime Oil sampling and observation for residues

Klüber Summit Varnasolv is a highly effective concentrated Oil samples collected after a cleaning operation. They are left for

conditioner. Approximately 60 hours before an oil change is due, some time to observe for settlement of varnish and carbon.

the conditioner is added to the oil fill in a concentration of 10%.

While the compressor continues to operate, Klüber Summit Cleaning: After cleaning:

Varnasolv dissolves the residues on the surfaces and keeps Compressor oil mixed with Fresh compressor oil after 2

them in dissolved condition. The residues are then flushed out in Klüber Summit Varnasolv, hours

the course of the oil change. This method is more effective than after 36 hours in operation

flushing the compressor with a normal compressor oil.

Results:

Varnish and carbon residues removed with Klüber Summit

Varnasolv

Before After

Outcome: Outcome:

Carbon residual settlement Carbon residual settlement re-

found at the bottom duced significantly after cleaning

Good practice tips: Conclusion:

To protect and optimise your compressor, you should clean your After only a short cleaning time with Klüber Summit Varnasolv, your

compressors one to two times per year. compressor is clean again and runs reliably with the Klüber Summit

oil.

It is our aim to offer you high-quality speciality lubricants and services around the globe along with the high technical competence

Klüber Lubrication is known for. We meet this aim through our worldwide network of production and sales companies, and our highly

specialised local experts are ready to respond to your individual requirements.

Contact our specialists now to learn more about our solutions or write an email to: sales@my.klueber.com

Publisher and Copyright:

Klüber Lubrication (Malaysia) Sdn Bhd

Unit 3-5, Level 3, Tower 9, UOA Business Park

No. 1, Jalan Pengaturcara U1/51A,

40150 Shah Alam, Selangor, Malaysia.

www.klueber.com

You might also like

- OilSafe Catalog 201304 PDFDocument38 pagesOilSafe Catalog 201304 PDFFernandoPelozioNo ratings yet

- Operator Manual HL MODELO 90-5000 Ingerson-IntermediaDocument37 pagesOperator Manual HL MODELO 90-5000 Ingerson-IntermediaRafael Agustin Menchaca MarinNo ratings yet

- RENOLIT LST 00 Technical Data SheetDocument1 pageRENOLIT LST 00 Technical Data SheetQuoc HungNo ratings yet

- Manual UsuarioDocument140 pagesManual UsuarioGetse VargasNo ratings yet

- Omega Fluid PDFDocument2 pagesOmega Fluid PDFapatzinfedNo ratings yet

- R5 BrochureDocument6 pagesR5 BrochureALEXNo ratings yet

- 06 - Lubricants Competition Grade Leaflet - 04-03-14 PDFDocument2 pages06 - Lubricants Competition Grade Leaflet - 04-03-14 PDFSriraghuraman Gopal RathnamNo ratings yet

- Visco SinDocument2 pagesVisco SinSyeda Fatima ali100% (1)

- Gardner Denver - GDX Modular Adsorption DryersDocument16 pagesGardner Denver - GDX Modular Adsorption DryerskuraimundNo ratings yet

- New Oil Lubricated Compressors 90-132 KW Updated January 2020Document34 pagesNew Oil Lubricated Compressors 90-132 KW Updated January 2020abdurohmanNo ratings yet

- NE700 Valve PositionerDocument9 pagesNE700 Valve Positionersteve@air-innovations.co.zaNo ratings yet

- CF SeriesDocument60 pagesCF SeriesKatya FirsenkoNo ratings yet

- Lubricants Brochure 2016Document8 pagesLubricants Brochure 2016luisNo ratings yet

- GA 90 160 Fixed Speed WS IPM CorrDocument44 pagesGA 90 160 Fixed Speed WS IPM CorrAldhair Perseo Oliva EscobedoNo ratings yet

- Tabela de Similaridade de Lubrificantes Industriais DocxDocument4 pagesTabela de Similaridade de Lubrificantes Industriais Docxjulioebc2014100% (1)

- Dynalub Lubricant 510 Eng R0 SafetyDocument4 pagesDynalub Lubricant 510 Eng R0 Safetysteelpro1No ratings yet

- ZS 4 - ZS 4 VSD - ZS 4 VSD+ - enDocument28 pagesZS 4 - ZS 4 VSD - ZS 4 VSD+ - enMichael Lagundino100% (1)

- PC Nirvana Contact Cooled - FormDocument1 pagePC Nirvana Contact Cooled - Formjohn vickers100% (1)

- Flyer Sewage Sludge DryingDocument6 pagesFlyer Sewage Sludge Dryingkosmc123No ratings yet

- Industrial Lubrication Solutions for Sugar MillsDocument15 pagesIndustrial Lubrication Solutions for Sugar MillsAnibal RiosNo ratings yet

- P37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Document12 pagesP37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Jozsef MagyariNo ratings yet

- 95105780-Technical-Manual-SABROE Compresor Pistones PDFDocument288 pages95105780-Technical-Manual-SABROE Compresor Pistones PDFAnonymous NYymdHgyNo ratings yet

- Aeon PD PDFDocument4 pagesAeon PD PDFAlex NavarreteNo ratings yet

- Shell Albida EMS2Document1 pageShell Albida EMS2Muhammad Haris BaigNo ratings yet

- CPF-175-200-CPVS-200-250 ManualDocument28 pagesCPF-175-200-CPVS-200-250 ManualEvandro Jva compressoresNo ratings yet

- Atlas Copco Roto Inject Fluid JECDocument2 pagesAtlas Copco Roto Inject Fluid JECアラファト イスラム教No ratings yet

- E10777 1 03 15 - Filteruebersicht PDFDocument76 pagesE10777 1 03 15 - Filteruebersicht PDFshekharNo ratings yet

- FX 400-2000Document8 pagesFX 400-2000francisco jose arruda de sousaNo ratings yet

- Sabroe-Oil-Recommendation en 2012-11Document56 pagesSabroe-Oil-Recommendation en 2012-11john smithNo ratings yet

- Low Wear Carbon Filled PTFE for Air and Gas CompressionDocument1 pageLow Wear Carbon Filled PTFE for Air and Gas CompressionТатьяна ВасильеваNo ratings yet

- MYCOM VR Series Screw Compressor Overhaul ManualDocument51 pagesMYCOM VR Series Screw Compressor Overhaul ManualWai LaiNo ratings yet

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Document2 pagesSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniNo ratings yet

- Commissioning Report CD390 1050 Antwerp 2946068800Document3 pagesCommissioning Report CD390 1050 Antwerp 2946068800Naveedullah AwanNo ratings yet

- Atlas Copco ZS Blowers PDFDocument20 pagesAtlas Copco ZS Blowers PDFwacsii ccasullaNo ratings yet

- Lubricantes LSCDocument22 pagesLubricantes LSCAndres PozoNo ratings yet

- Danfoss Scrolls, H-Series Residential and Light Commercial: Application GuidelinesDocument44 pagesDanfoss Scrolls, H-Series Residential and Light Commercial: Application GuidelinesMechanical Power100% (1)

- Shell Omala Oils: Premium Lead-Fee EP Gear OilDocument3 pagesShell Omala Oils: Premium Lead-Fee EP Gear Oilsamar209100% (1)

- Atlas Copco gearbox teardownDocument2 pagesAtlas Copco gearbox teardownKopral JonoNo ratings yet

- Lancer EXDocument13 pagesLancer EXspydaman4u100% (1)

- Catálogo Elmo RietschleDocument12 pagesCatálogo Elmo RietschleEdgarNo ratings yet

- Angus Model S1: Standard Response SprinklerDocument1 pageAngus Model S1: Standard Response SprinklerAhamed KyanaNo ratings yet

- Api 54Document2 pagesApi 54almandhari33100% (1)

- EVO BrochureDocument6 pagesEVO BrochureHassanNo ratings yet

- Catalogo Gas BSPDocument51 pagesCatalogo Gas BSPFernando Gonzales HNo ratings yet

- Ultra Coolant Lubricant PDFDocument3 pagesUltra Coolant Lubricant PDFvictorNo ratings yet

- Bray ValvesDocument6 pagesBray ValvesiksajidscribdNo ratings yet

- Recomendation Parts U190 PACE - CompressorDocument1 pageRecomendation Parts U190 PACE - CompressorFrans MetinNo ratings yet

- Compressor Roto InjectDocument2 pagesCompressor Roto InjectJeremias UtreraNo ratings yet

- Diagrama Elétrico CPE 100-150Document15 pagesDiagrama Elétrico CPE 100-150Emerson Rodrigues100% (1)

- Technical Documentation: SAB 163 Screw Compressor UnitsDocument2 pagesTechnical Documentation: SAB 163 Screw Compressor UnitsHenry100% (1)

- Sonic Scan DatasheetDocument4 pagesSonic Scan DatasheetChandravadanNo ratings yet

- Grundfosliterature 145813Document2 pagesGrundfosliterature 145813Sudhakar Murugesan100% (1)

- HydroPure Vesta Hydraulic Oils H (AW) SeriesDocument2 pagesHydroPure Vesta Hydraulic Oils H (AW) SeriesdnoaisapsNo ratings yet

- Meh Flyer Produkt TZW-50 TZW-60 TZW-70 2014-07 en MailDocument2 pagesMeh Flyer Produkt TZW-50 TZW-60 TZW-70 2014-07 en MailMartín Baeza100% (2)

- KL Über Air Compressor NewDocument6 pagesKL Über Air Compressor NewВасилий ЗотовNo ratings yet

- Varnasolv Ficha TécnicaDocument2 pagesVarnasolv Ficha TécnicaKevin SantosNo ratings yet

- Oil Mist Lubrication TrainingDocument70 pagesOil Mist Lubrication TrainingDelfinsh100% (3)

- MAN Genuine Oil for Maximum EfficiencyDocument5 pagesMAN Genuine Oil for Maximum Efficiencyabdallah harrab100% (1)

- Slop Oil 1197 ENDocument6 pagesSlop Oil 1197 ENsasankar_yhNo ratings yet

- Palm Oil RefiningDocument10 pagesPalm Oil Refiningharrison_sNo ratings yet

- Distillation Column Diameter Calculation - Reference TrybalDocument7 pagesDistillation Column Diameter Calculation - Reference TrybalNitin Kurup100% (1)

- Calculation of Coefficients of Contraction, Velocity, and Discharge of A Circular Orifice Using A Hydraulic BenchDocument4 pagesCalculation of Coefficients of Contraction, Velocity, and Discharge of A Circular Orifice Using A Hydraulic BenchFran CarnaceNo ratings yet

- Implement Tap Locations: 938H / IT38H Wheel Loader Hydraulic SystemDocument2 pagesImplement Tap Locations: 938H / IT38H Wheel Loader Hydraulic SystemGonzalo Abarzua BaezaNo ratings yet

- Gary Goforth - Historical and Present Flows in The Caloosahatchee RiverDocument14 pagesGary Goforth - Historical and Present Flows in The Caloosahatchee RiverNews-PressNo ratings yet

- SBIInstructionManual17 03 2014Document11 pagesSBIInstructionManual17 03 2014ramon duldulaoNo ratings yet

- EPC Engineering Sequence PDFDocument1 pageEPC Engineering Sequence PDFveenaNo ratings yet

- Spe 113903 Pa PDFDocument7 pagesSpe 113903 Pa PDFPOOL SERVICES & SUPLLIESNo ratings yet

- CE Board Nov 2020 - Hydraulics - Set 18Document1 pageCE Board Nov 2020 - Hydraulics - Set 18Justine Ejay MoscosaNo ratings yet

- Hydraulics For Engineers - F. C. Lea PDFDocument594 pagesHydraulics For Engineers - F. C. Lea PDFsayhigaurav07No ratings yet

- 2 Fluid StaticsDocument20 pages2 Fluid StaticsRomolus H. ValenciaNo ratings yet

- Fluid Mechanics Theory Shell Momentum Balance DerivationDocument89 pagesFluid Mechanics Theory Shell Momentum Balance Derivationneerajtrip1230% (2)

- EHD LubricationDocument28 pagesEHD Lubricationfeni4kaNo ratings yet

- Performance Analysis and Comparison of High Lift Airfoil For Low-Speed Unmanned Aerial VehicleDocument6 pagesPerformance Analysis and Comparison of High Lift Airfoil For Low-Speed Unmanned Aerial VehicleMd Abdullah Al KhosruNo ratings yet

- BOQ Water Curtain Vertical - FixDocument3 pagesBOQ Water Curtain Vertical - FixAnton PermanaNo ratings yet

- DesignManualIssueMay2012 PDFDocument57 pagesDesignManualIssueMay2012 PDFKlich77No ratings yet

- Karman Institute: For Fluid DynamicsDocument27 pagesKarman Institute: For Fluid DynamicsMarcelo MartinezNo ratings yet

- Material Balance Equations PresentationDocument9 pagesMaterial Balance Equations PresentationDeddy NurfaqihNo ratings yet

- Assignment Turbomachinery Made by Akita Sukhdave 2K19/THE/01Document9 pagesAssignment Turbomachinery Made by Akita Sukhdave 2K19/THE/01Raunak KumarNo ratings yet

- Instrumentation ListDocument2 pagesInstrumentation ListGiuseppeNo ratings yet

- Roughness Body Reynolds-Number: The Effect of Surface of The High FlowDocument11 pagesRoughness Body Reynolds-Number: The Effect of Surface of The High FlowLuizNo ratings yet

- Principles of Design of Water SupplyDocument5 pagesPrinciples of Design of Water SupplyShubham SrivastavaNo ratings yet

- Calculo Venteo API 2000Document3 pagesCalculo Venteo API 2000Produccion Vegetal100% (1)

- Series N45B-EZ-M1 Installation InstructionsDocument2 pagesSeries N45B-EZ-M1 Installation InstructionsWattsNo ratings yet

- V-Flo Screw PumpDocument88 pagesV-Flo Screw PumpVuong BuiNo ratings yet

- Sewage Design Template 2011Document27 pagesSewage Design Template 2011joechengshNo ratings yet

- Resistance Coefficient KDocument14 pagesResistance Coefficient KNestor S. ReEyesNo ratings yet

- Formula KircshmerDocument4 pagesFormula Kircshmerhabibi_fiestaNo ratings yet

- FAT SPLITTING PFD ANALYSIS AND KEY METRICSDocument1 pageFAT SPLITTING PFD ANALYSIS AND KEY METRICSrizky efrinaldoNo ratings yet

- Bernoulli Chapter 3Document45 pagesBernoulli Chapter 3Izzudin HusseinNo ratings yet

- 09 - Standard WBM TESTING 2013Document45 pages09 - Standard WBM TESTING 2013Slim.BNo ratings yet