Professional Documents

Culture Documents

Pipe and Tube Railings

Pipe and Tube Railings

Uploaded by

Akber Hassan0 ratings0% found this document useful (0 votes)

5 views12 pagesOriginal Title

05521 - PIPE AND TUBE RAILINGS

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document0 ratings0% found this document useful (0 votes)

5 views12 pagesPipe and Tube Railings

Pipe and Tube Railings

Uploaded by

Akber HassanYou are on page 1of 12

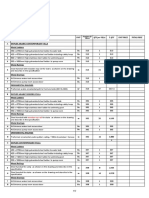

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION, May 2013,

SECTION 05521 - PIPE AND TUBE RAILINGS

PART I -GENERAL

A

13

PIPE AND TUBE RAILINGS

RELATED DOCUMENTS

Drawings and general provisions of the Contract, including Conditions of Contract and

Division 1 Specification Sections, apply to

SUMMARY

This Section includes the following:

1, Aluminum pipe and tube handrails and railings.

2. Stainless-steel pipe and tube handrails and railings.

3. Steel pipe and tube handrails and railings.

Related Sections include the following:

1. Division 5 Section "Metal Stairs" for steel pipe handrails and railings included with

metal stairs

2. Division S Section "Ornamental Metal” for omamental metal handrails and railings

fabricated from custom components.

3. Division 5 Section "Ornamental Handrails and Railings" for omamental_ metal

handrails and railings fabricated from stock components.

4. Division 10 Section "Access Flooring" for handrails and railings included with access

flooring

PERFORMANCE REQUIREMENTS.

General: In engineering handrails and railings to withstand structural loads indicated,

determine allowable design working stresses of handrail and railing materials based on the

following:

1. Aluminum: AA 30, "Specifications for Aluminum Structures."

2. Stainless Steel: ASCE 8, "Specification for the Design of Cold-Formed Stainless

Steel Structural Members,

3. Structural Steel: AISC $335, "Specification for Structural Steel Buildings Allowable

Stress Design and Plastic Design with Commentary."

4. Cold-Formed Structural Steel: AISI SG-673, Part l, "Specification for the Design of

Cold-Formed Steel Structural Members.”

Structural Performance of Handrails and Railings: Provide handrails and railings capable of

withstanding structural loads required by ASCE 7 without exceeding allowable design

working stresses of materials for handrails railings, anchors, and connections.

‘Thermal Movements: Provide handrails and railings that allow for thermal movements

resulting from the following maximum change (range) in ambient and surface temperatures

by preventing buckling, opening of joints, overstressing of components, failure of

month me [SP]

ISSUED FOR TENDER

05521 Page 112

RAYADAH HOUSING COMPLEX (RHO)

PACKAGE 3 - BUILDINGS.

PROJECT STANDARD SPECIFICATION May 2013,

15

connections, and other detrimental effects. Base engineering calculation on surface

temperatures of materials due to both solar heat gain and nighttime-sky heat loss.

1. Temperature Change (Range): 67 deg. C, ambient; 100 deg. C, material surfaces,

Control of Corrosion: Prevent galvanic action and other forms of corrosion by insulating

‘metals and other materials from direct contact with incompatible materials.

SUBMITTALS

Product Data: For the following:

1, Manufacturer's product lines of mechanically connected handrails and railings,

2. Grout, anchoring cement, and paint products.

Shop Drawings: Show fabrication and installation of handrails and railings. Include plans,

elevations, sections, component details, and attachments to other Work.

1. For installed handrails and railings indicated to comply with design loads, include

structural analysis data signed and sealed by the qualified professional engineer

responsible for their preparation.

‘Samples for Initial Selection: Manufacturer's color charts showing the full range of colors

available for products with factory-applied color finishes.

‘Samples for Initial Selection: Short sections of railing or flat, sheet metal samples showing

available mechanical finishes.

Samples for Verification: For each type of exposed finish required, prepared on

‘components indicated below and of same thickness and metal indicated for the Work. If

finishes involve normal color and texture variations, include sample sets showing the full

range of variations expected.

1. 150 mm long sections of each distinctly different linear railing member, including

handrails, top rails, posts, and balusters.

2. Fittings and brackets.

3. Assembled sample of railing system, made from full-size components, including top

rail, post, handrail, and infill. Show method of finishing members at intersections.

‘Sample need not be full height.

Qualification Data: For firms and persons specified in the "Quality Assurance" Article to

demonstrate their capabilities and experience. Include lists of completed projects with

project names and addresses, names and addresses of architects/engineers and owners, and.

other information specified.

Product Test Reports: From a qualified testing agency indicating products comply with

requirements, based on comprehensive testing of current products,

Product Test Reports: From a qualified testing agency indicating handrails and railings

‘comply with ASTM E 985, based on comprehensive testing of current products.

QUALITY ASSURANCE

PIPE AND TUBE RAILINGS

‘05521 - Page T12

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION. May 2013,

A. Quality System: Comply with ISO 9001/9002 Quality System as a minimum. Incorporate all

the standard procedures supplied by the Engineer and the Employer.

Professional Engineer Qualifications: A professional engineer who is legally registered and

qualified to practice in jurisdiction where Project is located and who is experienced in

providing engineering services of the kind indicated. Engineering services are defined as

those performed for installations of handrails and railings that are similar to those indicated

for this Project in material, design, and extent,

C. Testing Agency Qualifications: An independent testing agency, acceptable to the Engineer,

with the experience and capability to conduct the testing indicated, as documented

according to ASTM E 548.

D. —Souree Limitations: Obtain each type of handrail and railing through one source fom a

single manufacturer.

16 STORAGE

A. Store handrails and railings in a dry, well-ventilated, weathertight place, and protect from

damage.

1.7 PROJECT CONDITIONS

‘A. Field Measurements: Verify handrail and railing dimensions by field measurements before

fabrication and indicate measurements on Shop Drawings. Coordinate fabrication schedule

with construction progress to avoid delaying the Work.

18 COORDINATION

A. Coordinate installation of anchorages for handrails and railings. Furnish setting drawings,

templates, and directions for installing anchorages, including sleeves, concrete inserts,

anchor bolts, and items with integral anchors, that are to be embedded in conerete or

‘masonry. Deliver such items to Project site in time for installation.

19 SCHEDULING

A. Schedule installation so handrails and railings are mounted only on completed walls. Do

not support temporarily by any means that does not satisfy structural performance

requirements.

PART 2 - PRODUCTS

2.1 METALS

A. General: Provide metal free from pitting, seam marks, roller marks, stains, discolorations,

and other imperfections where exposed to view on finished units.

megasore [65]

ISSUED FOR TENDER

PIPE AND TUBE RAILINGS ‘05521 - Page S12

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3 - BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013

B, Aluminum: Alloy and temper recommended by aluminum producer and finisher for type of

use and finish indicated, and with not less than the strength and durability properties of alloy

and temper designated below for each aluminum form required

Extruded Bar and Tube: ASTM B 221M, alloy 6063-T5/TS2,

Extruded Structural Pipe and Tube: ASTM B 429, alloy 6063-T6,

Drawn Seamless Tube: ASTM B 210M, alloy 6063-1832,

Plate and Sheet: ASTM B 209M, alloy 6061-76

Die and Hand Forgings: ASTM B 247M, alloy 6061-T6.

Castings: ASTM B 26/B 26M, alloy A356-T6.

C. Stainless Steel: Grade or type designated below for each form required:

Tubing: ASTM A 554, Grade MT 304.

Pipe: ASTM A 312/A 312M, Grade TP 304,

Castings: ASTM A 743/A 743M, Grade CF 8 or CF 20,

CPlate: ASTM A 666, Type 304

Plate: ASTM A 666, Type 316L.

peepee

D. Steel and Iron: Provide steel and iron in the form indicated, complying with the following.

requirements:

1. Steel Pipe: ASTM A 33; finish, type, and weight class as follows:

4. Black finish, unless otherwise indicated.

b. Galvanized finish for exterior installations and where indicated.

c. Type, or Type S, Grade A, standard weight (Schedule 40), unless another

‘grade and weight are required by structural loads.

Steel Tubing: Cold-formed steel tubing, ASTM A 500, Grade A, unless another

trade is required by structural loads.

3. Steel Plates, Shapes, and Bars: ASTM A 36/A 36M.

4, Iron Castings: Malleable iron complying with ASTM A 47M, Grade 22010.

Brackets, Flanges, and Anchors: Cast or formed metal of same type of material and finish

as supported rails, unless otherwise indicated,

WELDING MATERIALS, FASTENERS, AND ANCHORS

A. Welding Electrodes and Filler Metal: Provide type and alloy of filler metal and electrodes

as recommended by producer of metal to be welded and as required for color match,

strength, and compatibility in fabricated items.

B. Fasteners for Anchoring Handrails and Railings to Other Construction: Select fasteners of

type, grade, and class required to produce connections suitable for anchoring handrails and

railings to other types of construction indicated and capable of withstanding design loads.

1. For aluminum handrails and railings, use fasteners fabricated from Type 304 ot

‘Type 316 stainless steel,

2. For stainless-steel handrails and railings, use fasteners fabricated from Type 304 or

‘Type 316 stainless steel,

3. For steel handrails. railings, and fitings, wse plated fasteners complying, with

ASTM B 633, Class Fe/Zn "

(05521 = Page 412

PIPE AND TUBE RAILINGS ¢

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3 - BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013,

23

24

Fasteners for Interconnecting Handrail and Railing Components: Use fasteners fabricated

from same basic metal as fastened metal, unless otherwise indicated. Do not use metals that

are corrosive or incompatible with materials joined.

1. Provide concealed fasteners for interconnecting handrail and railing components and

for attaching them to other work, unless otherwise indicated.

2. Provide concealed fasteners for interconnecting handrail and railing components and

for attaching them to other work, unless exposed fasteners are unavoidable or are the

standard fastening method for handrails and railings indicated.

3. Provide Phillips flat-head machine screws for exposed fasteners, unless otherwise

indicated.

Cast-in-Place and Postinstalled Anchors: Anchors of type indicated below, fabricated from

corrosion-resistant materials with capability to sustain, without failure, a load equal to six

times the load imposed when installed in unit masonry and equal to four times the load

imposed when installed in concrete, as determined by testing per ASTM E 488 conducted

by a qualified independent testing agency acceptable to the Engineer.

1. Cast-in-place anchors.

2. Chemical anchors.

3. Expansion anchors.

PAINT

Shop Primers: Provide primers to comply with applicable requirements in Division 9

Section "Painting."

Shop Primer for Ferrous Metal: Fast-curing, lead- and chromate-free, universal modified-

alkyd primer complying with performance requirements in FS TT-P-664; selected for good

resistance to normal atmospheri¢ corrosion, compatibility with finish paint systems

indicated, and capability to provide a sound foundation for field-applied topcoats despite

prolonged exposure.

Shop Primer for Galvanized Steel: Zinc-dust, zine-oxide primer formulated for priming

zine-coated steel and for compatibility with finish paint systems indicated, and complying

with SSPC-Paint 5.

Bituminous Paint: Cold-applied asphalt mastic complying with SSPC-Paint 12, except

containing no asbestos fibers, or cold-applied asphalt emulsion complying with

ASTM D 1187,

GROUT AND ANCHORING CEMENT

Nonshrink, Nonmetallic Grout: Premixed, fuactory-packaged, nonstaining, noncorrosive,

nongascous grout complying with ASTM C 1107. Provide grout specifically recommended

by the manufacturer for interior and exterior applications.

Interior Anchoring Cement: Factory-packaged, nonshrink, nonstaining, hydraulic~

controlled expansion cement formulation for mixing with water at Project site to create

pourable anchoring, patching, and grouting compound, Use for interior applications only.

seaman cm [er

OBST Page TD

PIPE AND TUBE RAILINGS

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013

c

25

G.

PIPE AND TUBE RAILINGS

Erosion-Resistant Anchoring Cement: — Factory-packaged, nonshrink, nonstaining,

hydraulie-controlied expansion cement formulation for mixing with water at Project site 10

create pourable anchoring, patching, and grouting compound. Provide formulation that is

resistant to erosion from water exposure without needing protection by a sealer or

waterproof coating and that is recommended by the manufacturer for exterior use.

FABRICATION

General: Fabricate handrails and railings to comply with requirements indicated for design,

dimensions, member sizes and spacing, details, finish, and anchorage, but not less than that

required to support structural loads

Assemble handrails and railings in the shop to greatest extent possible to minimize field

splicing and assembly. Disassemble units only as necessary for shipping and handling

limitations. Clearly mark units for reassembly and coordinated installation, Use

connections that maintain structural value of joined pieces.

Form changes in direction of railing members as follows:

1. As detailed.

Form simple and compound curves by bending members in jigs to produce uniform

curvature for each repetitive configuration required; maintain cylindrical cross section of

member throughout entire bend without buckling, twisting, cracking, or otherwise

«deforming exposed surfaces of handrail and railing components.

Welded Connections: Fabricate handrails and railings for connecting members by welding.

Cope components at perpendicular and skew connections to provide close fit, or use fittings

designed for this purpose. Weld connections continuously to comply with the following:

1. Use materials and methods that minimize distortion and develop strength and

corrosion resistance of base metals.

2. Obtain fusion without undercut or overlap.

3. Remove flux immediately.

4. At exposed connections, finish exposed surfaces smooth and blended so that no

roughness shows after finishing and welded surface matches contours of adjoining

surfaces,

Nonwelded Connections: Fabricate handrails and railings by connecting members with

concealed mechanical fasteners and fittings, unless otherwise indicated, Fabricate members

and fittings to produce flush, smooth, rigid, hairline joints.

1. Pabricate splice joints for field connection using an epoxy structural adhesive where

this is manufacturers standard splicing method.

Welded Connections for Aluminum Pipe: Fabricate pipe handrails and railings to

interconnect members with concealed internal welds that eliminate surface grinding, using

manufacturer's standard system of sleeve and socket fittings.

Brackets, Flanges, Fittings, and Anchors: Provide wall brackets, flanges, miscellaneous

fittings, and anchors to interconnect handrail and railing members to other work, unless

otherwise indicated

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3 - BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013,

L

Provide inserts and other anchorage devices for connecting handrails and railings to

concrete or masonry work. Fabricate anchorage devices capable of withstanding loads

imposed by handrails and railings. Coordinate anchorage devices with supporting structure.

For niling posts set in concrete, provide preset sleeves of steel not less than 150 mm long

with inside dimensions not less than 12 mm greater than outside dimensions of post, and

steel plate forming bottom closure.

For removable railing posts, fabricate slip-fit sockets from steel tube whose ID is sized for a

close fit with posts; limit movement of post without lateral load, measured at top, 10 not

more than one-fortieth of post height. Provide socket covers designed and fabricated to

resist being dislodged.

1. Provide chain with eye, snap hook, and staple across gaps formed by removable

railing sections at locations indicated. Fabricate from same metal as railings.

Shear and punch metals cleanly and accurately. Remove burrs from exposed cut edges.

Ease exposed edges to a radius of approximately 1 mm, unless otherwise indicated. Form

bbent-metal comers to smallest radius possible without causing grain separation or otherwise

impairing the Work.

Cut, reinforce, drill, and tap components, as indicated, to receive finish hardware, screws,

and similar items,

0. Provide weep holes or other means to drain entrapped water in hollow sections of handrail

and railing members that are exposed to exterior or to moisture from condensation or other

sources.

P. Fabricate joints that will be exposed to weather in a watertight manner.

Q. Close exposed ends of handrail and railing members with prefabricated end fittings.

Provide wall returns at ends of wall-mounted handrails, unless otherwise indicated. Close

ends of returns, unless clearance between end of railing and wall is 6 mm or less.

S. Toe Boards: Where indicated, provide toe boards at railings around openings and at edge of

open-sided floors and platforms. Fabricate to dimensions and details indicated.

T. Fillers: Provide fillers made from steel plate, or other suitably crush-resistant material,

where needed to transfer wall bracket loads through wall finishes to structural supports

Size fillers to suit wall finish thicknesses and to produce adequate bearing area to prevent

bracket rotation and overstressing of substrate

2.6 FINISHES, GENERAL

A. Comply with NAAMM’s "Metal Finishes Manual for Architectural and Metal Products" for

recommendations for applying and designating finishes

B. Protect mechanical finishes on exposed surfaces from damage by applying a strippable,

temporary protective covering before shipping.

PIPE AND TUBE RAILINGS semesssormr (E¥or] Naname Page TE

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3 - BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013,

©

27

28

G.

PIPE AND TUBE RAILINGS

Appearance of Finished Work: Variations in appearance of abutting or adjacent pieces are

acceptable if they are within one-half of the range of approved Samples. Noticeable

variations in the same piece are not acceptable. Variations in appearance of other

components are acceptable if they are within the range of approved Samples and are

assembled or installed to minimize contrast.

Provide exposed fasteners with finish matching appearance, including color and texture, of

handrails and railings.

ALUMINUM FINISHES

Finish designations prefixed by AA comply with system established by the Aluminum

Association for designating aluminum finishes.

Mechanical Finish: AA-M12 (Mechanical Finish: nonspecular as fabricated).

Class I, Color Anodic Finish: AA-M12C22A42/A44 (Mechanical Finish: nonspecular as

fabricated; Chemical Finish: etched, medium matte; Anodic Coating: Architectural Class I,

integrally colored or electrolytically deposited color coating 0.018 mm or thicker)

complying with AAMA 606.1 or AAMA 608.1.

1. Color: As selected by the Engineer from the full range of industry colors and color

densities.

Polyester Powder Coating: approved type to meet the requirements of AAMA 603

consisting of powder particles of resinous material and additives to improve performance.

The coating is to be electrostatically sprayed on the object to produce a hard, durable

coating:

1. Surface Finish: As indicated,

2. Minimum Dry Film Thickness: 60 microns.

3. Color and Surface Finish: As selected by the Engineer from manufacturer's full

range.

STAINLESS-STEEL FINISHES

Remove or blend tool and die marks and stretch lines into finish.

Grind and polish surfaces to produce uniform, directionally textured polished finish

indicated, free of cross scratches. Run grain with long dimension of each piece.

180-Grit Polished Finish: Oil-ground, uniform, textured finish,

320.Grit Polished Finish: Oil-ground, uniform, smooth finish,

Polished and Buffed Finish: Oil-ground, 180-grt finish followed by buffing.

Bright, Directional Polish: No. 4 finish.

When polishing is completed, passivate and rinse surfaces. Remove embedded foreign

matter and leave surfaces chemically clean,

(O5521 - Page WI

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013,

2.9 STEEL FINISHES

A. Galvanized Handrails and Railings: Hot-dip galvanize exterior steel and iron handrails and

railings to comply with ASTM A 123. Hot-lip galvanize hardware for exterior steel and

iron handrails and railings to comply with ASTM A 153/A 153M.

Galvanizing: Hot-dip galvanize items as indicated to comply with applicable standard listed

below:

1, ASTM A 123, for galvanizing steel and iron produets.

2. ASTM A 153/A 153M, for galvanizing steel! and iron hardware.

Fill vent and drain holes that will be exposed in finished Work, unless indicated to remain as

‘weep holes, by plugging with zine solder and filing off smooth

For galvanized handrails and railings, provide galvanized fittings, brackets, fasteners,

sleeves, and other ferrous components.

For nongalvanized steel handrails and railings, provide nongalvanized ferrous-metal fittings,

brackets, fasteners, and sleeves, except galvanize anchors to be embedded in exterior

‘concrete or masonry.

Preparation for Shop Priming: After galvanizing, thoroughly clean handrails and railings of

‘grease, dirt, oil, flux, and other foreign matter, and treat with metallic-phosphate process.

Preparation for Shop Priming: Prepare uncoated ferrous-metal surfaces to comply with

minimum requirements indicated below for SSPC surface-preparation specifications and

environmental exposure conditions of installed handrails and railings:

1, Exteriors (SSPC Zone 1B): SSPC-SP 6, "Commercial Blast Cleaning.”

2. Interiors (SSPC Zone 1): SSPC-SP 7, *Brush-off Blast Cleaning."

Apply shop primer to prepared surfaces of handrail and railing components, unless

‘otherwise indicated. Comply with requirements in SSPC-PA 1, "Paint Application

Specification No. 1," for shop painting. Primer need not be applied to surfaces to be

embedded in concrete or masonry.

1. Donot apply primer to galvanized surfaces.

2. Stripe paint edges, comers, crevices, bolts, and welds.

Polyester Powder Coating: approved type to meet the requirements of AAMA 603

consisting of powder particles of resinous material and additives to improve performance.

‘The coating is to be electrostatically sprayed on the object to produce produces a hard,

durable coating:

1, Surface Finish: As indicated.

2. Minimum Dry Film Thickness: 60 microns.

3. Color and Surface Finish: As selected by the Engineer from manufacturer's full

range.

PIPE AND TUBE RAILINGS

‘5521 Page O12

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROJECT STANDARD SPECIFICATION May 2013

2.10 EXAMINATION

‘A. Examine plaster and gypsum board assemblies, where reinforced to receive anchors, to

verify that locations of concealed reinforcements have been clearly marked for Installer.

Locate reinforcements and mark locations if not already done,

2.11 INSTALLATION, GENERAL

A. Fit exposed connections together to form tight, hairline joints,

B. Perform cutting, drilling, and fitting required to install handrails and railings. Set handrails

and railings accurately in location, alignment, and elevation; measured trom established

lines and levels and free from rack.

1. Do not weld, cut, or abrade surfaces of handrail and railing components that have

been coated or finished after fabrication and that are intended for field connection by

mechanical or other means without further cutting or fitting.

Set posts plumb within a tolerance of 2 mm in I m,

3. Align rails so that variations from level for horizontal members and from parallel

‘with rake of steps and ramps for sloping members do not exceed 5 mm in 3m,

Corrosion Protection: Coat concealed surfaces of aluminum that will be in contact with

‘rout, concrete, masonry, wood, or dissimilar metals with a heavy coat of bituminous paint.

D. Adjust handrails and railings before anchoring to ensure matching alignment at abutting

Joints. Space posts at interval indicated, but not less than that required by structural loads.

E, Fastening to In-Place Construction: Use anchorage devices and fasteners where necessary

for securing handrails and railings and for properly transferring loads to in-place

construction,

2.12. RAILING CONNECTIONS

A. Nonwelded Connections: Use mechanical or adhesive joints for permanently connecting

railing components. Use wood blocks and padding to prevent damage to railing members

and fittings. Seal recessed holes of exposed locking screws using plastic cement filler

colored to match finish of handrails and railings.

B, Welded Connections: Use fully welded joints for permanently connecting railing

‘components. Comply with requirements for welded connections in "Fabrication" Article

‘whether welding is performed in the shop or inthe field.

C. Expansion Joints: Install expansion joints at locations indicated but not farther apart than

required to accommodate thermal movement. Provide slip-joint internal sleeve extending

50 mm beyond joint on either side, fasten internal sleeve securely to one side, and locate

joint within 150 mm of post.

2.13 ANCHORING POSTS

A. Use steel pipe sleeves preset and anchored into concrete for installing posts. After posts

have been inserted into sleeves, fill annular space between post and sleeve with the

PIPE AND TUBE RAILINGS RSS EE 05521 Page 1072

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHO)

PACKAGE 3 - BUILDINGS.

PROJECT STANDARD SPECIFICATION. May 2013,

244

PIPE AND TUBE RAILINGS

following anchoring material, mixed and placed to comply with anchoring material

‘manufacturer's written instructions:

Form or core-drill holes not less than 125 mm deep and 20 mm larger than OD of post for

installing posts in concrete. Clean holes of loose material, insert posts, and fill annular

space between post and conerete with the following anchoring material, mixed and placed to

comply with anchoring material manufacturer's written instructions:

1. Nonshrink, nonmetallic grout or anchoring cement.

Cover anchorage joint with flange of same metal as post, attached to post as follows:

1. Welded to post after placing anchoring material,

2. Bysset screws,

Leave anchorage joint exposed; wipe off surplus anchoring material; and leave 3 mm build-

up, sloped away from post.

Anchor posts to metal surfaces with oval flanges, angle type, of floor type as required by

conditions, connected to posts and to metal supporting members as follows:

1. For aluminum pipe railings, attach posts as indicated using fittings designed and

engineered for this purpose.

2. For stainless-steel pipe railings, weld flanges to post and bolt to metal supporting

surfaces.

3. For steel pipe railings, weld flanges to post and bolt to metal supporting surfaces.

Install removable railing sections, where indicated, in stip-fit metal sockets cast in concrete.

ANCHORING RAILING ENDS

Anchor railing ends into concrete and masonry with round flanges connected to railing ends

and anchored into wall construction with postinstalled anchors and bolts.

Anchor railing ends to metal surfaces with flanges bolted to metal surfaces.

1. Weld flanges to railing ends.

2 Connect flanges to railing ends using nonwelded connections.

ATTACHING HANDRAILS TO WALLS

Attach handrails to wall with wall brackets, Provide bracket with 38 mm clearance from

inside face of handrail and finished wall surface.

Locate brackets as indicated of, if not indicated, at spacing required to support structural

loads.

‘Secure wall brackets to building construction as follows:

1. For concrete and solid masonry anchorage, use drilled-in expansion shields and

hanger or lag bolts

2. For hollow masonry anchorage, use toggle bolts,

cae WaT Fag

ISSUED FOR TENDER

RAYADAH HOUSING COMPLEX (RHC)

PACKAGE 3- BUILDINGS

PROMI

STANDARD SPECIFICATION May 2013,

217

3. For wood stud partitions, use hanger or lag bolts set into wood backing between

studs. Coordinate with carpentry work to locate backing members.

4, For steel-framed gypsum board assemblies, fasten brackets directly to steel framing

or concealed reinforcements using selfapping serews of size and type required to

support structural loads.

CLEANING

Clean aluminum and stainless steel by washing thoroughly with clean water and soap and

rinsing with clean water.

Touchup Painting: Cleaning and touchup painting of field welds, bolted connections, and

abraded areas of shop paint are specified in Division 9 Section "Painting,"

Galvanized Surfaces: Clean field welds, bolted connections, and abraded areas and repair

galvanizing to comply with ASTM A 780.

PROTECTION

Protect finishes of handrails and railings from damage during construction period with

temporary protective coverings approved by railing manufacturer. Remove protective

coverings atthe time of Substantial Completion.

Restore finishes damaged during installation and construction period so that no evidence

remains of correction work. Retum items that cannot be refinished in the field to the shop;

make required alterations and refinish entire unit, or provide new units.

END OF SECTION 05521

PIPE AND TUBE RAILINGS

nope: Br]

‘OSSD - Page 12

ISSUED FOR TENDER

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GratingsDocument9 pagesGratingsAkber HassanNo ratings yet

- Project: Rayadah Investment Company Subjet Rayadah Housing Complex, Jeddah Div. 8: Wooden DoorsDocument3 pagesProject: Rayadah Investment Company Subjet Rayadah Housing Complex, Jeddah Div. 8: Wooden DoorsAkber HassanNo ratings yet

- 14mm Diameter: Project: Rayadah Investment Company Subjet Rayadah Housing Complex, Jeddah Estimated Qty: 56,109 TonDocument1 page14mm Diameter: Project: Rayadah Investment Company Subjet Rayadah Housing Complex, Jeddah Estimated Qty: 56,109 TonAkber HassanNo ratings yet

- Div. 12 - BOQ - (Floor Grating)Document1 pageDiv. 12 - BOQ - (Floor Grating)Akber HassanNo ratings yet

- Project: Rayadah Investment Company Subjet Rayadah Housing Complex, JeddahDocument2 pagesProject: Rayadah Investment Company Subjet Rayadah Housing Complex, JeddahAkber HassanNo ratings yet

- வீரகேசரி 26072020 PDFDocument48 pagesவீரகேசரி 26072020 PDFAkber HassanNo ratings yet

- Div. 05 - BOQ - (Metal Works)Document2 pagesDiv. 05 - BOQ - (Metal Works)Akber HassanNo ratings yet

- 2019 Course List 1Document2 pages2019 Course List 1Akber HassanNo ratings yet

- Plain Concrete Grade 200kg/cm As Described in SpecificationDocument1 pagePlain Concrete Grade 200kg/cm As Described in SpecificationAkber HassanNo ratings yet

- Ucem PDFDocument7 pagesUcem PDFAkber HassanNo ratings yet

- Types of Information SystemsDocument8 pagesTypes of Information SystemsAkber HassanNo ratings yet

- Information Technology Features: Centralized SystemsDocument8 pagesInformation Technology Features: Centralized SystemsAkber HassanNo ratings yet

- IT2403 Systems Analysis and Design: (Compulsory)Document6 pagesIT2403 Systems Analysis and Design: (Compulsory)Akber HassanNo ratings yet

- CS-1 Year: Systems Analysis and DesignDocument22 pagesCS-1 Year: Systems Analysis and DesignAkber HassanNo ratings yet

- Price List NawalaDocument1 pagePrice List NawalaAkber HassanNo ratings yet

- ஏறாவூர் வரலாறு புத்தகம்Document8 pagesஏறாவூர் வரலாறு புத்தகம்Akber HassanNo ratings yet

- ஏறாவூர் வரலாறு புத்தகம்Document13 pagesஏறாவூர் வரலாறு புத்தகம்Akber Hassan100% (1)

- Lotus Notes BeginnerDocument28 pagesLotus Notes BeginnerAkber HassanNo ratings yet