Professional Documents

Culture Documents

Chapter 06 8 X 11 Part 1 Mark 8 2009 Rev06

Uploaded by

Alexander LopezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 06 8 X 11 Part 1 Mark 8 2009 Rev06

Uploaded by

Alexander LopezCopyright:

Available Formats

KOBELCO

Mark 8

Hydraulic Schematics

Kobelco Construction

Machinery America LLC

Mark 8 03/09 Rev. 06

Page 6-1

SYMBOLS AND COMPONENTS

24

2 19 18

MAIN CONTROL VALVE P2 P1 T T2

CMR1

PL1 MR1 CMR2

PTb PBL

TRAVEL LEFT

PAL

AL

Unit Assembly Lines

STRAIGHT TRAVEL CT2 CP2 BL

Drb LCs ¯ 1.4

PBs

TRAVEL RIGHT PBs2

SWING Pss

CT1 P

PAr ¯ 1.4 PAs SE5

Br

Ar

As

Bs a3

CP1 (T3)

Dra

BUCKET LCc BOOM CONFLUENCE

Test Port identification

PBc ¯ 0.8

PB1

PAc

Bc

Ac

LCb

CCb PLc2

Drd

numbers

PBb

Drc LCa PBa

PLc1 BOOM ARM

PAb

PAa

Bb

Pisc

CRb Aa

CRa

CAr

Ab Ba

X1 ¯ 3.5

ARM

¯ 0.4 CONFLUENCE ¯ 0.4

PCb ¯ 0.4 ¯ 0.4 Pis

PA1

P1 NEUTRAL CUT

CCa

P2 NEUTRAL CUT

ARM VARIABLE

RECIRCULATION PCa indication of variable or

(P4) TB PBo2 proportional component

PAo2

Ao2

Bo2

(P3)

Na m e Sym bols Re m a rks

The main line is the suction

Main line line, pressure line and return

line.

Pilot line Used for all pilot circuits.

SE1

Pressure Transducer Can be low or high pressure.

Connection of line Dot represents connection

Hydraulic oil Returning to the

Tank (Drain) Symbol

Hydraulic Tank

Line intersecting W ithout connection point.

Mark 8 03/09 Rev. 06

Page 6-2

SYMBOLS AND COMPONENTS

Name Symbol Remarks

One way check valve

Example: swivel for

excavators

Swivel Joint

Example: hydraulic gear

Fixed displacement pump for pilot system

hydraulic pump

Variable displacement Example: main hydraulic

hydraulic pump pump

Mark 8 03/09 Rev. 06

Page 6-3

SYMBOLS AND COMPONENTS

Name Symbol Remarks

Cushion cylinders helps

Single cushioned cylinder prevent damage to circuits

and cylinder.

Double cushioned cylinder Cushion cylinders helps

prevent damage to circuits

and cylinder.

Bi-directional motor

(Variable speed) Typical of the travel

motors used on the

excavators

Electromagnetic Solenoids

Normally Open: Swing P/B

Normally closed: Lever Lock, Att boost, 1/2 speed travel

Proportional: P2 neutral cut, Travel priority, P1 neutral cut,

Mark 8 03/09 Rev. 06

Page 6-4

SYMBOLS AND COMPONENTS

Name Symbol Remarks

Compound main relief

Two stage main relief Potential two stage relief

with check valves when pilot oil is added to

spring to increase pressure.

Used on excavators with

4974 psi at 39.6 gpm power boost heavy lift.

5400 psi at 39.6 gpm

The number of the

continuous squares

(rectangle) will indicate the

numbers of the valve

selecting position.

Pilot operated,

open center work spool As a general rule, the

SPOOL will be shown in the

neutral position. Neutral is

described as the following

the hydraulic pump is

producing flow and the

operator has not activated

a function.

Springs drawn on each end of the spool

assembly will return the spool to the

drawn position in the circuit, when not The arrow entered in each

activated by pilot oil. of the squares (rectangle)

will indicate flow direction at

Triangles drawn on the end of the spool one of the selecting position.

and filled (colored) indicate pilot oil will

shift the spool.

Mark 8 03/09 Rev. 06

Page 6-5

Hydraulic Control System Logic

MARK 8 SERIAL NUMBER RANGE

SK170LC YM04U1601 ~ Positive Control

ED195LC YL04U0301 ~ Positive Control

SK210LC YQ08U3301 ~ Positive Control

SK260LC LL10U1501 ~ Positive Control

SK295LC LB05U0801 ~ Positive Control

SK350LC YC08U1601 ~ Positive Control

SK480LC YS07U0701 ~ Positive Control

Positive control system: Proportional solenoid

valves (PSV) use pilot pump oil (P3) thru the PSV

to control the servo piston of the pump by placing

force on the compensating spool in the pump

regulator it forces the compensating spool to allow

pressure only to the small diameter end of the

servo piston to push the pump on stroke. This

pressure is at a minium range(80~100psi) at

neutral. PSV pressure is increased to allow the

stroke angle of the pump’s rotating group to

change from a low flow state to a high flow state

based on system working pressure and electronic

control of the PSV-1 and PSV-2 by the main C-1

computer. Thus sense the pressure is added (

addition) or increased this is where the term

positive control derives from.

Mark 8 03/09 Rev. 06

Page 6-6

Insert 11x17 pages of main hydraulic schematic here

Mark 8 03/09 Rev. 06

Page 6-7

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Kitchen Ventilation Design GuideDocument15 pagesKitchen Ventilation Design GuideCuong Vu100% (2)

- Workshop Manual W3024EN2.pdf Workshop Manual W3024EN2 PDFDocument64 pagesWorkshop Manual W3024EN2.pdf Workshop Manual W3024EN2 PDFAlexander LopezNo ratings yet

- Birth Time RectificationDocument5 pagesBirth Time RectificationSandeep SinghNo ratings yet

- SWADE - Summoner's CircleDocument38 pagesSWADE - Summoner's CircleJoao Pedro Omena Dos Santos0% (2)

- DML Electric Test Manual 2657868267 - 007Document77 pagesDML Electric Test Manual 2657868267 - 007Alexander Lopez100% (2)

- Manual de Operacion - Xas 185 JD7 IngDocument27 pagesManual de Operacion - Xas 185 JD7 IngAlexander Lopez100% (2)

- Calibration Techniques and Process: Abdul Latif, Pe H (NI)Document69 pagesCalibration Techniques and Process: Abdul Latif, Pe H (NI)Engr Umair AzizNo ratings yet

- Workshop Manual W3015EN2.pdf Workshop Manual W3015EN2 PDFDocument20 pagesWorkshop Manual W3015EN2.pdf Workshop Manual W3015EN2 PDFAlexander LopezNo ratings yet

- QSB4.5 Curve and Datasheet-FR91611Document3 pagesQSB4.5 Curve and Datasheet-FR91611Alexander Lopez100% (2)

- A Reader's Guide To The Anthropology of Ethics and Morality - Part II - SomatosphereDocument8 pagesA Reader's Guide To The Anthropology of Ethics and Morality - Part II - SomatosphereECi b2bNo ratings yet

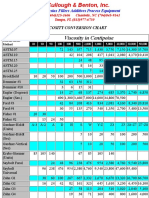

- Viscosity Conversion ChartDocument2 pagesViscosity Conversion ChartCorvetteNo ratings yet

- The Pastor's WifeDocument61 pagesThe Pastor's WifeandrewNo ratings yet

- 2002 Engine Manual J08E-TA, TB - S5UJ08E02BDocument351 pages2002 Engine Manual J08E-TA, TB - S5UJ08E02BAlexander LopezNo ratings yet

- S1 134e 19 1Document386 pagesS1 134e 19 1Alexander LopezNo ratings yet

- Drillcare: Atlas Copco Drilling SolutionsDocument2 pagesDrillcare: Atlas Copco Drilling SolutionsAlexander LopezNo ratings yet

- Operation and Maintenance - CP2100 - 2015 - 4812316022Document109 pagesOperation and Maintenance - CP2100 - 2015 - 4812316022Alexander LopezNo ratings yet

- Drillcare: Atlas Copco Drilling SolutionsDocument2 pagesDrillcare: Atlas Copco Drilling SolutionsAlexander LopezNo ratings yet

- 2011 Tracked PaverDocument24 pages2011 Tracked PaverAlexander LopezNo ratings yet

- Drillcare: Atlas Copco Drilling SolutionsDocument2 pagesDrillcare: Atlas Copco Drilling SolutionsAlexander Lopez100% (1)

- DRILLCare Hydraulic First Aid KitDocument2 pagesDRILLCare Hydraulic First Aid KitAlexander LopezNo ratings yet

- Plant Type Model LanguageDocument3 pagesPlant Type Model LanguageAlexander LopezNo ratings yet

- Chapter 03 REV 06 2009Document48 pagesChapter 03 REV 06 2009Alexander LopezNo ratings yet

- Chapter 04 Mark 8 Rev-06Document20 pagesChapter 04 Mark 8 Rev-06Alexander LopezNo ratings yet

- Item Cds Repair Oper. Parts TrainDocument2 pagesItem Cds Repair Oper. Parts TrainAlexander LopezNo ratings yet

- kOBELCO-POLICY MANUAL ONLYDocument37 pageskOBELCO-POLICY MANUAL ONLYAlexander LopezNo ratings yet

- Manual de Instrucciones ICA250-5EN2Document111 pagesManual de Instrucciones ICA250-5EN2Alexander LopezNo ratings yet

- He 388Document27 pagesHe 388Alexander LopezNo ratings yet

- 4BTA3.9-C110 Curve and Datasheet-FR90024Document6 pages4BTA3.9-C110 Curve and Datasheet-FR90024Alexander LopezNo ratings yet

- Market Information - InternalDocument2 pagesMarket Information - InternalAlexander LopezNo ratings yet

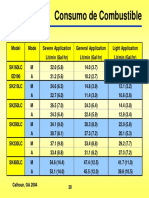

- Consumo de Combustible EXC, KOBELCO)Document1 pageConsumo de Combustible EXC, KOBELCO)Alexander LopezNo ratings yet

- Service Bulletin (ECB) Priority - Ii - Iii - : Rebuilding Kit - Parking Brake SwitchDocument2 pagesService Bulletin (ECB) Priority - Ii - Iii - : Rebuilding Kit - Parking Brake SwitchAlexander LopezNo ratings yet

- Workshop Manual W3030EN1.pdf Workshop Manual W3030EN1 PDFDocument43 pagesWorkshop Manual W3030EN1.pdf Workshop Manual W3030EN1 PDFAlexander LopezNo ratings yet

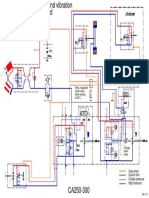

- CA250-300 Steering Vibration Driving Barkes Disengaged PDFDocument1 pageCA250-300 Steering Vibration Driving Barkes Disengaged PDFAlexander LopezNo ratings yet

- TOEFL Ibt WritingDocument9 pagesTOEFL Ibt WritingEdward Enriquez RicaurteNo ratings yet

- HY15 3500l001Document7 pagesHY15 3500l001AdrianaNo ratings yet

- Pune Metagraph CoDocument49 pagesPune Metagraph CoAmol JadhavNo ratings yet

- Disaster Preparedness of Hotel Industry Abroad: A Comparative AnalysisDocument8 pagesDisaster Preparedness of Hotel Industry Abroad: A Comparative AnalysisJoannabelNo ratings yet

- Dual Functional Roof VentilatorDocument7 pagesDual Functional Roof VentilatorIJRASETPublicationsNo ratings yet

- Grade 10 Mathematics - Review of The BasicsDocument42 pagesGrade 10 Mathematics - Review of The BasicsDouglas WeberNo ratings yet

- HemophiliaDocument3 pagesHemophiliasanghamitra jana0% (1)

- Soal Label 2Document13 pagesSoal Label 2TATI HARIATINo ratings yet

- New Applications December 2021Document135 pagesNew Applications December 2021sachinmaster434No ratings yet

- Formal Task Risk Assessment / Jsa FormDocument4 pagesFormal Task Risk Assessment / Jsa FormMuhammad Umar GondalNo ratings yet

- DatasheetDocument49 pagesDatasheetdaniel oscar gonzalezNo ratings yet

- Science Q4 Worksheet Week3Document4 pagesScience Q4 Worksheet Week3JEMIMA BERNARDONo ratings yet

- Brosur Tomy MDX-310 - Refrigerated Centrifuge For Life ScienceDocument3 pagesBrosur Tomy MDX-310 - Refrigerated Centrifuge For Life ScienceMamik ShofiaNo ratings yet

- BPPV at A GLANCE 2022-Guide Book (Vestibuology) - 230330 - 083425Document56 pagesBPPV at A GLANCE 2022-Guide Book (Vestibuology) - 230330 - 083425EeraNo ratings yet

- Fuel System Non Cert Montacargas 30L-7 ListaDocument1 pageFuel System Non Cert Montacargas 30L-7 ListaJose A PerezNo ratings yet

- Performance MAPEHDocument4 pagesPerformance MAPEHNathaniel JuanNo ratings yet

- 1031 Exchange DST: Property MenuDocument32 pages1031 Exchange DST: Property MenuwaynesailNo ratings yet

- Name: Class / Term: VII/ I Subject: Math DateDocument4 pagesName: Class / Term: VII/ I Subject: Math DateLuciana Yuniari MurwantiNo ratings yet

- Fortigate 400f SeriesDocument10 pagesFortigate 400f SeriesDaniel MontanoNo ratings yet

- Classic Reinterpreted StyleDocument26 pagesClassic Reinterpreted StyleShabnamNo ratings yet

- Autodesk Revit 2015 What Is NewDocument31 pagesAutodesk Revit 2015 What Is NewNicolas CardonaNo ratings yet

- Traffic Demand Management in DhakaDocument16 pagesTraffic Demand Management in DhakaSarwar_hossain24No ratings yet