Professional Documents

Culture Documents

Battery - Technical - Data Sheet - 00569 - 18 - 02 PDF

Uploaded by

Moez AlouiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Battery - Technical - Data Sheet - 00569 - 18 - 02 PDF

Uploaded by

Moez AlouiCopyright:

Available Formats

TECHNOLOGICAL SHEET MODEL

TECHNOLOGICAL SHEET CHANGE LETTER: DATE: No.1

LEAD ACID STORAGE BATTERIES - 12 VOLTS

SUPPLIER: INTERNAL DESIGNATION:

Supplier Part No. TBD Part No.

{

CASING Colour

Material

Average part of recycled material contained

Type (L-LB) : .... Cover

{ Colour

Material

Average part of recycled material contained

Closing devices

Caps

{ Colour

Material

CELLS Number of plates

{ Positives per cell

Negatives per cell

Plate dimensions Height x width mm

Positive plate thickness mm

Negative plate thickness mm

Chemical composition of grids and active material

+

{ Calcium content %

{

Tin content %

-

Calcium content %

Tin content %

Type of grid production process

Separator Type

Thickness in cell mm

Overlap of separator vs. plate height mm

Wedging Type N/A

ELECTROLYTE Volume Per cell ml

In and between plates ml

Volume above plates ml

Height above plates min mm

max mm

Density on delivery (with tolerance interval) at 25 °C: g/cm3

Na2SO4 concentration : %

WEIGHT Grids

{ Positives

Negatives

g

Plates

{ Positives

Negatives

g

Battery Total g

rings, strips, connections, terminals and welds g

electrolyte ml

lead used g

RATIO Mpure acid / Mactive material =

Mpure acid = V × d ×C M: Mass (Weight)

V: acid volume per cell (cm3)

Mactive material= Sum (Mpositive material and Mnegative material) non-formed, per cell (g). d: nominal density in charged state, without additives

C: nominal density function coefficient at 25 °C (C1,28= 0,3738)

PERFORMANCE Capacity 20 h. / 5h. / 2h.

Peukerts constants n,C (20°C,9V)

Self discharge rate (20°C)

SAE HRD

Reserve Capacity

Other

Rinternal - 20 °C : 0 °C : 30 °C :

Name Department Date Signature

Design Engineer R&D Department

Supplier

signature Head of R&D Department

Technical Manager

Page 1/1

You might also like

- MSS - Definitions - Coating MaterialsDocument4 pagesMSS - Definitions - Coating MaterialsIsmailEmreCanbolatNo ratings yet

- 02 - Mold MatrixDocument4 pages02 - Mold MatrixBruno SingleNo ratings yet

- SPSX LinecardDocument6 pagesSPSX LinecardJoe.StrongNo ratings yet

- "Shaviv" Deburring ToolsDocument1 page"Shaviv" Deburring ToolsRino SutrisnoNo ratings yet

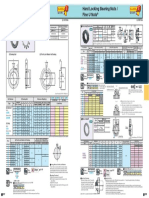

- HLB Flier MisumiDocument1 pageHLB Flier MisumiJayden BarnesNo ratings yet

- General Description: % Ir Min (S) Max (S)Document1 pageGeneral Description: % Ir Min (S) Max (S)muhammetNo ratings yet

- LMS00644 - Fastpack - 71812 - Sistema de Extincion - Liberacion 04.12Document6 pagesLMS00644 - Fastpack - 71812 - Sistema de Extincion - Liberacion 04.12Anthony Kcana AliagaNo ratings yet

- Mold SpecificationDocument1 pageMold SpecificationVictor Villouta LunaNo ratings yet

- Replacement Wheels For Casters Wheel Shafts / Grooved Wheels / Caster HoldersDocument1 pageReplacement Wheels For Casters Wheel Shafts / Grooved Wheels / Caster HoldersPugynNo ratings yet

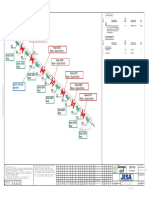

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- Caracteristici Otel BetonDocument2 pagesCaracteristici Otel Betonridzim4638No ratings yet

- Oåel Beton: Proprietãåi MecaniceDocument2 pagesOåel Beton: Proprietãåi MecaniceAna-Maria VargaNo ratings yet

- Form and Position Tolerances: Tolerance Classes General Tolerances For Straightness and Flatness in MMDocument1 pageForm and Position Tolerances: Tolerance Classes General Tolerances For Straightness and Flatness in MMTrọng NgôNo ratings yet

- Water Chamber-Rs (016019A01000) :: WCHT WBHT + Wcepht - WBFWDocument11 pagesWater Chamber-Rs (016019A01000) :: WCHT WBHT + Wcepht - WBFWAyush ChoudharyNo ratings yet

- RENR1424Document2 pagesRENR1424ReymartinNo ratings yet

- Power Grid - MP: PROJECT - 132kV-D/C Monopole (Enquiry For PGICL TBCB MP PHASE-I/TL01) Summary SheetDocument1 pagePower Grid - MP: PROJECT - 132kV-D/C Monopole (Enquiry For PGICL TBCB MP PHASE-I/TL01) Summary SheetMOHAMMAD ZUEF - SKIPPER LIMITEDNo ratings yet

- Product Data Sheet: HVI®Conductor (819 020) : Part No. 819 020Document1 pageProduct Data Sheet: HVI®Conductor (819 020) : Part No. 819 020Mauricio VahosNo ratings yet

- Engineered Plastics GuideDocument1 pageEngineered Plastics GuideKmgsa BandaraNo ratings yet

- Challenger 65E, Challenger 75E, Agricultural Tractors Electrical System Challenger 85E, and Challenger 95EDocument2 pagesChallenger 65E, Challenger 75E, Agricultural Tractors Electrical System Challenger 85E, and Challenger 95EСергей Таргонь100% (1)

- Heat Trace Tubing enDocument5 pagesHeat Trace Tubing eninglegs75No ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

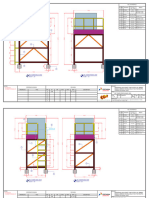

- 2023 Tote Tower For IBC Cap. 1000 LTR Ver.2.0Document4 pages2023 Tote Tower For IBC Cap. 1000 LTR Ver.2.0wahyudi.generaliNo ratings yet

- Shafts Shafts: Precision Standards Precision Standards, ContinuedDocument1 pageShafts Shafts: Precision Standards Precision Standards, ContinuedJean AlexNo ratings yet

- M BeddroomDocument6 pagesM BeddroomParth HindiaNo ratings yet

- 924f Pala CargadoraDocument2 pages924f Pala CargadoraRemberto75% (4)

- 924F Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument2 pages924F Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsguayanecitroNo ratings yet

- LED Battens: Version: 1018.C.1 Price Validation: December, 2018Document1 pageLED Battens: Version: 1018.C.1 Price Validation: December, 2018Khuzaim KhanNo ratings yet

- Secondary Education Option - 02Document1 pageSecondary Education Option - 02cartdj0307No ratings yet

- Datasheet For Battery Stand and Battery BoxDocument1 pageDatasheet For Battery Stand and Battery Boxkechaouahmed81No ratings yet

- Installation Instructions Cable Routing Diagram Version With One Access PointDocument6 pagesInstallation Instructions Cable Routing Diagram Version With One Access PointNguyễn Văn HùngNo ratings yet

- D10T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesD10T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsEdison PondaNo ratings yet

- 135hea PDFDocument2 pages135hea PDFMohamed Harb100% (1)

- Product Data Sheet: Extended Rotary Handle - Black - For NSX400..630Document1 pageProduct Data Sheet: Extended Rotary Handle - Black - For NSX400..630srivatsan boffinsNo ratings yet

- Configurable Plates - Aluminum, High Precision: A5052P (A - MG Aluminum Alloy, Precision Rolled Products)Document1 pageConfigurable Plates - Aluminum, High Precision: A5052P (A - MG Aluminum Alloy, Precision Rolled Products)HERDI SUTANTONo ratings yet

- Multi - 1 Drills: YE-ML20Document2 pagesMulti - 1 Drills: YE-ML20Michel DominguesNo ratings yet

- ExpressDocument2 pagesExpressabhi.c01487No ratings yet

- D7R Track Type Tractor Electrical System (Differential Steer)Document2 pagesD7R Track Type Tractor Electrical System (Differential Steer)Mauricio BellidoNo ratings yet

- Leveling ScrewsDocument1 pageLeveling ScrewsdbaNo ratings yet

- CV Flexible Body Filler, Light Grey: Technical InformationDocument2 pagesCV Flexible Body Filler, Light Grey: Technical InformationGoodBoi EsberNo ratings yet

- 777D AGC1301 ElectricalDocument2 pages777D AGC1301 ElectricalFaidh Allanz FairhiaNo ratings yet

- 50 W To 750 W: Table of Part Numbers and OptionsDocument4 pages50 W To 750 W: Table of Part Numbers and OptionsAung Naing OoNo ratings yet

- Swimming Pool-Layout1.pdf SectionDocument1 pageSwimming Pool-Layout1.pdf Sectionamruta potdarNo ratings yet

- Panchshil Realty (Msetcl) : PROJECT - 132kV-D/C Monopoles Option-1 Summary SheetDocument2 pagesPanchshil Realty (Msetcl) : PROJECT - 132kV-D/C Monopoles Option-1 Summary SheetMOHAMMAD ZUEF - SKIPPER LIMITEDNo ratings yet

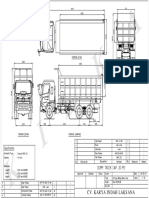

- GA FinalDocument1 pageGA Finalseil iexNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- Snap-On Hinge 105°: Base Plates For HingeDocument1 pageSnap-On Hinge 105°: Base Plates For HingeToan LuongkimNo ratings yet

- LMS00644 - Fastpack - 71812 - Sistema de Extincion - 2024 ExtincionDocument4 pagesLMS00644 - Fastpack - 71812 - Sistema de Extincion - 2024 ExtincionAnthony Kcana AliagaNo ratings yet

- Wellsite Database D - 06Document22 pagesWellsite Database D - 06boimcukNo ratings yet

- Snowdon Towers: AutodeskDocument55 pagesSnowdon Towers: Autodesksofia.pi.bbNo ratings yet

- Format: Pdd-He - 01 Supply List For Heat Exchangers As Per Tema Supplier NameDocument11 pagesFormat: Pdd-He - 01 Supply List For Heat Exchangers As Per Tema Supplier NameJitendra BhatewaraNo ratings yet

- SENR1862Document2 pagesSENR1862Cecilia Gomez.contrerasNo ratings yet

- SikaAnchorFix-Selection Chart-ENDocument1 pageSikaAnchorFix-Selection Chart-ENjcunha4740No ratings yet

- Punch Industry attaches great importance to the environment, and only 「Eco-friendly Products」are deliveredDocument1 pagePunch Industry attaches great importance to the environment, and only 「Eco-friendly Products」are deliveredlian silalahiNo ratings yet

- Dimensions: (MM) PropertiesDocument4 pagesDimensions: (MM) PropertiesMOHSENNo ratings yet

- DT 20 M3 602315-uTYPEDocument1 pageDT 20 M3 602315-uTYPEMild-yh GarnadiNo ratings yet

- Sheet Metal Mounting Plate / Brackets (For Sensors) Sheet Metal Mounting Plate / Brackets (For Sensors)Document1 pageSheet Metal Mounting Plate / Brackets (For Sensors) Sheet Metal Mounting Plate / Brackets (For Sensors)Karim SamhyNo ratings yet

- PinPointPDF - Charges - ElectricityDocument12 pagesPinPointPDF - Charges - ElectricityP. V. GAMINGNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Introduction To Operations ManagementDocument15 pagesIntroduction To Operations ManagementMoez AlouiNo ratings yet

- Motrio Battery Identity 00587 16 02 PDFDocument3 pagesMotrio Battery Identity 00587 16 02 PDFMoez AlouiNo ratings yet

- Perations Anagement: O P L 1 (C 1)Document26 pagesPerations Anagement: O P L 1 (C 1)Moez AlouiNo ratings yet

- Front Sticker: CFITG Supplier Code Voltage CapacityDocument3 pagesFront Sticker: CFITG Supplier Code Voltage CapacityMoez AlouiNo ratings yet

- Annex III REACH CERTIFICATE TABLE - 20190906Document36 pagesAnnex III REACH CERTIFICATE TABLE - 20190906Moez AlouiNo ratings yet

- Industrial Process Gamma Tomography: IAEA-TECDOC-1589Document153 pagesIndustrial Process Gamma Tomography: IAEA-TECDOC-1589Moez AlouiNo ratings yet

- Risk LogisticDocument47 pagesRisk LogisticMoez AlouiNo ratings yet

- Reverse Fmea: AMDEC InverséeDocument12 pagesReverse Fmea: AMDEC InverséeMoez Aloui100% (2)

- Assignment ProblemsDocument22 pagesAssignment ProblemsPooja Yadav100% (1)

- BUCA IMSEF 2021 Jury Evaluation ScheduleDocument7 pagesBUCA IMSEF 2021 Jury Evaluation SchedulePaulina Arti WilujengNo ratings yet

- D4530Document5 pagesD4530rimi7al100% (1)

- BP KWN RPM W KGW KGW KGW KG SFC GM KWHR Caloricfivalue MJ KGDocument3 pagesBP KWN RPM W KGW KGW KGW KG SFC GM KWHR Caloricfivalue MJ KGHoàng Khôi100% (1)

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 pagesFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNo ratings yet

- (Dust of Snow) & 2 (Fire and Ice) - NotesDocument3 pages(Dust of Snow) & 2 (Fire and Ice) - NotesdakshNo ratings yet

- Maximus MHX DatasheetDocument5 pagesMaximus MHX Datasheetjulya julyaNo ratings yet

- Theoretical Grammar of EnglishDocument132 pagesTheoretical Grammar of EnglishMisarabbit NguyenNo ratings yet

- Pre Post and Infix NotationsDocument12 pagesPre Post and Infix NotationsGolla GirijaNo ratings yet

- Adsa Ka SyllabusDocument3 pagesAdsa Ka SyllabusHacker RanjanNo ratings yet

- 01 AirCircuitBreakers LV10 102021 EN 202111301146249676Document136 pages01 AirCircuitBreakers LV10 102021 EN 202111301146249676bkNo ratings yet

- Brochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Document2 pagesBrochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Fernanda RizaldoNo ratings yet

- Mbeya University of Science and TecnologyDocument8 pagesMbeya University of Science and TecnologyVuluwa GeorgeNo ratings yet

- Symptoms and DiseasesDocument8 pagesSymptoms and Diseaseschristy maeNo ratings yet

- Command Center Processing and Display System ReplacementDocument2 pagesCommand Center Processing and Display System ReplacementImranNo ratings yet

- Guidelines and Standards For External Evaluation Organisations 5th Edition v1.1Document74 pagesGuidelines and Standards For External Evaluation Organisations 5th Edition v1.1Entrepre NurseNo ratings yet

- Amanuel MekonnenDocument125 pagesAmanuel Mekonnenabata yohannesNo ratings yet

- CV LeTranNguyen enDocument4 pagesCV LeTranNguyen enLe Tran NguyenNo ratings yet

- Understanding ISO 9001 Calibration RequirementsDocument6 pagesUnderstanding ISO 9001 Calibration RequirementsAldrin HernandezNo ratings yet

- Oracle Pac 2nd KeyDocument48 pagesOracle Pac 2nd KeyKrishna Kumar GuptaNo ratings yet

- Quotation Request Form: Customer DetailsDocument1 pageQuotation Request Form: Customer DetailsAmanda RezendeNo ratings yet

- Absolute Containers Brochure 2019 2 27 PDFDocument19 pagesAbsolute Containers Brochure 2019 2 27 PDFEduardo SolanoNo ratings yet

- Heat ExchangerDocument5 pagesHeat Exchangersara smithNo ratings yet

- Science 8: Learning Activity SheetDocument9 pagesScience 8: Learning Activity SheetVan Amiel CovitaNo ratings yet

- Listening Lesson PlanDocument3 pagesListening Lesson PlanPınar AkgünNo ratings yet

- NAAC 10.12.1888888 NewDocument48 pagesNAAC 10.12.1888888 Newచిమ్ముల సందీప్ రెడ్డిNo ratings yet

- Getting Started in Steady StateDocument24 pagesGetting Started in Steady StateamitNo ratings yet

- PSY502 OLd PapersDocument6 pagesPSY502 OLd Paperscs619finalproject.com100% (4)

- ECON 304 Course ContentDocument2 pagesECON 304 Course ContentAanand JhaNo ratings yet

- International Trade SyllabusDocument3 pagesInternational Trade SyllabusDialee Flor Dael BaladjayNo ratings yet