Professional Documents

Culture Documents

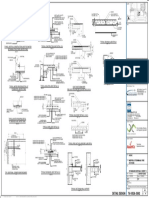

Water Chamber-RS (016019A01000) Design and Tolerances

Uploaded by

Ayush ChoudharyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Chamber-RS (016019A01000) Design and Tolerances

Uploaded by

Ayush ChoudharyCopyright:

Available Formats

Water Chamber-RS (160-19)

Water Chamber-RS (016019A01000):

WbHt 2WbFw

WcEpHt WbCL HwEl HwTk HwIr HwFP BpTk

2

WcHt = WbHt + WcEpHt – WbFw

WcW = (CsW / 2) + WbFw

* Optional user input ** Input taken by program other than expression 1

Water Chamber-RS (160-19)

T.R.:

1. Visual inspection of weld seams as per HW0620099.

Classification group as follows:

a) BS/BK for lifting ribs.

b) CS/BK for other items.

2. Non-destructive examination of weld seams as per HW0850199 part-10.

3. Weld edge preparation as per AA0620502.

4. The general tolerances of straightness, flatness and parallelism shall be maintained

as per AA0621105 Grade-F.

5. Painting is to be done as per HE77001.

6. Threads should confirm to AA0231800.

7. Technical supports item nos. ------- are to be removed prior to final dispatch.

8. Dimension given in bracket are before machining.

9. a) Holes shall be transferred on Front Water Chamber (RS) from Front Water Box

(RS).

b) Holes shall be transferred on Rear Water Chamber (RS) from Front Water Box

(RS).

* Optional user input ** Input taken by program other than expression 2

Water Chamber-RS (160-19)

Reference dimensions for Selection of water box /water chamber

wall thickness, flange and bolting (Bolt Size – M30)

Maximum Allowable Tightening Torque = 1361 NM (For Class 8.8 Bolts)

1913 NM (For Class 10.9 Bolts)

2297 NM (For Class 12.9 Bolts)

Thick mmMin. Cover Plate

Machining mmWeld Size Before

Kg/cm2(g)Design Press.(P)

Thick(d) * mmMachined Flange

Machining Allowance mm

(f) $ mmMin.Weld Size

Kg/cm2(g)Test Press.(1.5P)

mmBolt Pitch

(FW/FW1) $ mmFlange Width

Bolt Class

Thick mmRaw Material

MWSet Rating

Size(f) mmMachinedWeld

(d) $ * mmMin. FlangeThick

2.0 3.0 16 115 40 10 50 20 10 36.5 5 100/50 8.8

3.0 4.5 20 115 53 15 63 25 10 46.5 5 100/50 8.8

210 4.0 6.0 25 105 60 20 70 30 10 57 8 100/50 10.9

5.0 7.5 28 95 70 20 80 30 10 67 10 110/55 10.9

2.0 3.0 16 115 40 10 50 20 10 36.5 5 100/50 8.8

3.0 4.5 20 115 53 15 63 25 10 46.5 5 100/50 8.8

250 4.0 6.0 25 105 60 20 70 30 10 57 8 100/50 10.9

5.0 7.5 28 95 70 20 80 30 10 67 10 110/55 10.9

2.0 3.0 20 115 50 20 63 33 13 43 5 100/50 8.8

3.0 4.5 25 115 60 20 80 40 20 55 8 100/50 10.9

500 4.0 6.0 32 95 70 20 90 40 20 69 12 110/55 10.9

5.0 7.5 36 90 80 25 100 45 20 80 17 110/55 12.9

Reference dimensions for Selection of water box /water chamber wall

thickness, flange and bolting (Bolt Size – M36)

Maximum Allowable Tightening Torque = 1361 NM (For Class 8.8 Bolts)

1913 NM (For Class 10.9 Bolts)

Kg/cm2(g)Test Press.(1.5P)

(f) $ mmMin.Weld Size

MWSet Rating

mmBolt Pitch

(FW/FW1) $ mmFlange Width

Bolt Class

Machining Allowance mm

Kg/cm2(g)Design ress.(P)

Thick mmMin. Cover Plate

Thick(d) * mmMachined Flange

Machining mmWeld Size Before

Size(f) mmMachinedWeld

(d) $ * mmMin. FlangeThick

Thick mmRaw Material

2.0 3.0 16 140 46 10 56 20 10 39 5 120/60 8.8

3.0 4.5 20 140 53 15 63 25 10 50 5 120/60 8.8

210 4.0 6.0 25 140 70 20 80 30 10 59 8 120/60 10.9

5.0 7.5 28 120 80 20 90 30 10 71 10 120/60 10.9

2.0 3.0 16 140 46 10 56 20 10 39 5 120/60 8.8

* Optional user input ** Input taken by program other than expression 3

Water Chamber-RS (160-19)

3.0 4.5 20 140 53 15 63 25 10 50 5 120/60 8.8

250 4.0 6.0 25 140 70 20 80 30 10 59 8 120/60 10.9

5.0 7.5 28 120 80 20 90 30 10 71 10 120/60 10.9

2.0 3.0 20 140 50 20 63 33 13 46 5 120/60 8.8

3.0 4.5 25 140 65 20 80 35 15 58 8 120/60 10.9

500 4.0 6.0 32 110 80 20 100 40 20 75.5 12 120/60 10.9

5.0 7.5 36 105 90 25 110 45 20 89 17 120/60 10.9

Reference dimensions for Selection of water box /water chamber wall

thickness, flange and bolting (Bolt Size – M42)

Maximum Allowable Tightening Torque = 3871 NM (For Class 8.8 Bolts) Thick mmMin. Cover Plate

Machining mmWeld Size Before

Kg/cm2(g)Design Press.(P)

Thick(d) * mmMachined Flange

Machining Allowance mm

(f) $ mmMin.Weld Size

Kg/cm2(g)Test Press.(1.5P)

mmBolt Pitch

(FW/FW1) $ mmFlange Width

Bolt Class

Thick mmRaw Material

MWSet Rating

Size(f) mmMachinedWeld

(d) $ * mmMin. FlangeThick

2.0 3.0 16 160 46 10 56 20 10 41 5 130/65 8.8

3.0 4.5 20 160 60 15 70 25 10 51 5 130/65 8.8

210 4.0 6.0 25 160 70 20 80 30 10 60 8 130/65 8.8

5.0 7.5 28 125 80 20 90 30 10 73 10 130/65 8.8

2.0 3.0 16 160 46 10 56 20 10 41 5 130/65 8.8

3.0 4.5 20 160 60 15 70 25 10 51 5 130/65 8.8

250 4.0 6.0 25 160 70 20 80 30 10 60 8 130/65 8.8

5.0 7.5 28 125 80 20 90 30 10 73 10 130/65 8.8

2.0 3.0 20 160 60 20 80 40 20 48 5 130/65 8.8

3.0 4.5 25 160 70 20 90 40 20 60 8 130/65 8.8

500 4.0 6.0 32 125 80 20 100 40 20 76 12 130/65 8.8

5.0 7.5 36 125 90 25 110 45 20 85 17 130/65 8.8

$ For deviation from these values, separate calculation may be required.

* Wherever threads are there, full thread depth to be used.

Flange material s0.2 >230N/mm2.

* Optional user input ** Input taken by program other than expression 4

Water Chamber-RS (160-19)

1. Bottom Horizontal Flange (316018A01P01):

WcHFL = (CSW / 2) – CclFd + WbFw

WbFtkb = WbFtk + WbFma

WbFwdb = WbFwd + WbFma

2. Top Horizontal Flange (316018A01P02):

WcHFL = (CSW / 2) – CclFd + WbFw

WbFtkb = WbFtk + WbFma

WBFwdb = WbFwd + WbFma

3. Middle Vertical Flange (316018A01P03):

* Optional user input ** Input taken by program other than expression 5

Water Chamber-RS (160-19)

WcMvfL = WbHt – 2 (WbFw + WbPtk)

WbFtkb = WbFtk + WbFma

WBFwdb= WbFwd + WbFma

WbVfWd = 2 WbFwD

4. Vertical Flange (316018A01P04):

WcVFL = WbHt – 2 WbFw

WbFtkb = WbFtk + WbFma

WBFwdb = WbFwd + WbFma

* Optional user input ** Input taken by program other than expression 6

Water Chamber-RS (160-19)

5. Bottom Plate -RS (316019A01P05):

WcBpL = CsW / 2

WcPFC = WbFw + CclFd

WbFtkb = WbFtk + WbFma

WBFwdb = WbFwd + WbFma

6. Top Plate -RS (216019A01P06):

WcBpL = CsW / 2

WcpWw = WbFw + CclFd

WBFwdb = WbFwd + WbFma

WbFtkb = WbFtk + WbFma

* Optional user input ** Input taken by program other than expression 7

Water Chamber-RS (160-19)

7. Middle Plate (316018A01P07):

WcMpL = WbHt – 2(WbFw + WbPtk)

WBFwdb = WbFwd + WbFma

8. Side Plate (316018A01P08):

WcSpL = WbHt – 2 (WbFw + WbPtk)

WBFwdb = WbFwd + WbFma

WcWtd = 2.5 SwTk

9. End Plate (316018A01P09):

1

WcEpL CsW WbPtk

2

WbHt 2WbFw

WcEpHt WbCL ( HwEL HwTk HwIr HwFP BpTk )

2

* Optional user input ** Input taken by program other than expression 8

Water Chamber-RS (160-19)

10. Bottom Rib (316018A01P10):

WcBrW = WcBpW – WbFtk – WcEpd –WcEpTk

11. Bottom Lifting Rib (316018A01P11):

WcBrW = WcBpW – WbFtk – WcEpd –WcEpTk

WcLHCL = WbFw + 2WcLhD

* Optional user input ** Input taken by program other than expression 9

Water Chamber-RS (160-19)

12. Top Rib (316018A01P12):

WcTrL1= WcStpD + MtpTk + DwTpD – WbFtk

WcTrL2= WcTrL1 + (WbFw * Tan (LdwFang)

Where:

LdwTeWL CNeckL

LdwFang tan 1

2.LdwFHt

LdwTeWL = LBTP – 2 DwTpD

WBHt 2.WbFW LdwInc

LdwFHt TgCL LdwUEL WbCL

2 2

LdwInc = LdwTeWL * tan(IcAng)

13. Top Lifting Rib (316018A01P13):

14. Main Tube Plate (216018A01P14):

* Optional user input ** Input taken by program other than expression 10

Water Chamber-RS (160-19)

CsW

MtpW CcLFd WbFw 2WbPTk

2

MtpHt= WbHt – 2 WbFw- 2 WbPTk

T.R.:

1. Out the flatness of the tube plate should be with in 1 mm per meter.

2. Preservation of the tube plate is to be done as per HE77001.

3. Total ------ holes to be drilled as per tube layout drg no. 1-160-00-70----.

4. Weight of the blank (undrilled) tube plate is --------.

* Optional user input ** Input taken by program other than expression 11

You might also like

- Mechanical Tee Grooved Outlet Reducing Cross With Female ThreadDocument2 pagesMechanical Tee Grooved Outlet Reducing Cross With Female ThreadRonald Junes GarciaNo ratings yet

- Hill Cutting Work Progress ReportDocument5 pagesHill Cutting Work Progress Reportabhishek negiNo ratings yet

- SPSX LinecardDocument6 pagesSPSX LinecardJoe.StrongNo ratings yet

- 01ti15-98 TDMDocument1 page01ti15-98 TDMChelsito CH MNo ratings yet

- WPS MatrixDocument4 pagesWPS MatrixHarshaVeeragandham50% (2)

- Idler TestingDocument1 pageIdler Testingpmf engineering limitedNo ratings yet

- FT-RAN Fig 130 - Tee Recta MECH ULFMDocument1 pageFT-RAN Fig 130 - Tee Recta MECH ULFMJean SegoviaNo ratings yet

- Bore Pump Lookup Data (MC Rev B)Document12 pagesBore Pump Lookup Data (MC Rev B)chrisNo ratings yet

- Timing Belts (MXL, XL, L, H) : TBN TUNDocument1 pageTiming Belts (MXL, XL, L, H) : TBN TUNPraveenNo ratings yet

- 02 - Mold MatrixDocument4 pages02 - Mold MatrixBruno SingleNo ratings yet

- 90° Elbow Light-Duty Rigid Coupling: Vds VdsDocument1 page90° Elbow Light-Duty Rigid Coupling: Vds VdsMirko Gutierrez QuirozNo ratings yet

- T BEAM Rectangular Beam 3sections FinalDocument24 pagesT BEAM Rectangular Beam 3sections FinalDipanjan MitraNo ratings yet

- Drill Rigs, HydraulicDocument3 pagesDrill Rigs, Hydraulicفاقد السيطرهNo ratings yet

- Building Plans4Document1 pageBuilding Plans4Evanrey EnriquezNo ratings yet

- American-Marsh Pumps Series 460 OSD Flex-Coupled ANSI End Suction Pumps SpecsDocument24 pagesAmerican-Marsh Pumps Series 460 OSD Flex-Coupled ANSI End Suction Pumps Specsjuan davidNo ratings yet

- Basic ReportDocument2 pagesBasic ReportMilenko RakovicNo ratings yet

- Suction Head Calculation: Local Factors of FittingsDocument1 pageSuction Head Calculation: Local Factors of Fittingsmohamad azipNo ratings yet

- Fpi 2021 011152 Vetm Tec DC R4Document4 pagesFpi 2021 011152 Vetm Tec DC R4Mohamed AklNo ratings yet

- TGS Sukhoi Su-35sDocument1 pageTGS Sukhoi Su-35sairsoft doença100% (1)

- API-600-Valve-TrimDocument2 pagesAPI-600-Valve-TrimVictor NairNo ratings yet

- Trider Scheda Tecnica ENDocument2 pagesTrider Scheda Tecnica ENHFNo ratings yet

- Retaining Wall Crack Width Calc 4-12-19Document1 pageRetaining Wall Crack Width Calc 4-12-19nikhil nikhilNo ratings yet

- MisumiDocument1 pageMisumiMoonzaRNo ratings yet

- LC-326 SM Cylinder CAN Production HALT No. (T1) Process Q-Inspection Check SheetDocument36 pagesLC-326 SM Cylinder CAN Production HALT No. (T1) Process Q-Inspection Check Sheetsegar PalanisamyNo ratings yet

- Timing Belts (MXL, XL, L, H) : TBN TUNDocument1 pageTiming Belts (MXL, XL, L, H) : TBN TUNdownloadable776No ratings yet

- TEE Mecanica Tipo UboltDocument1 pageTEE Mecanica Tipo UboltTeo Pozo JNo ratings yet

- Beam TableDocument4 pagesBeam TableShiba MagarNo ratings yet

- Compact Installation Instructions: Sinamics G120XDocument2 pagesCompact Installation Instructions: Sinamics G120XSharath Teja ReddyNo ratings yet

- Adex Lighting Price ListDocument4 pagesAdex Lighting Price ListShibleNo ratings yet

- Slab Design SheetDocument8 pagesSlab Design SheetMano CivilengineerNo ratings yet

- Rates of Pakur variety stone aggregates at different railway yardsDocument5 pagesRates of Pakur variety stone aggregates at different railway yardsSwapan Kumar DharaNo ratings yet

- Db-0000-13300-0002!00!00001 Structural Det Elev Layout PLN Steel Member ListDocument1 pageDb-0000-13300-0002!00!00001 Structural Det Elev Layout PLN Steel Member ListByron TorioNo ratings yet

- NTPC-FGD-TAL-LCH-CH-MRB11 - Rev 2Document1 pageNTPC-FGD-TAL-LCH-CH-MRB11 - Rev 2TAMILarasuNo ratings yet

- Steel SectionsDocument33 pagesSteel Sectionssam_antony2005No ratings yet

- Dilatoflex KP High PressureDocument1 pageDilatoflex KP High PressureJo KingsNo ratings yet

- NHA SPECIFICATION (1998) FOR CONSTRUCTION MATERIALSDocument2 pagesNHA SPECIFICATION (1998) FOR CONSTRUCTION MATERIALSAbdul SaboorNo ratings yet

- Key Reinforcement PlanDocument1 pageKey Reinforcement PlanMazen IsmailNo ratings yet

- BAR Mark Type and Size No. of Bars in Each No. of Mbrs Total NO. Length of Each BAR MM Shape Code A MMDocument1 pageBAR Mark Type and Size No. of Bars in Each No. of Mbrs Total NO. Length of Each BAR MM Shape Code A MMAmila SampathNo ratings yet

- 832-LT1-119-H1-R4 Plano Micropilotes ST42 GB 119Document1 page832-LT1-119-H1-R4 Plano Micropilotes ST42 GB 119Francisco RoseroNo ratings yet

- Welding Notes: Bill of Materials For Assembly MK'D: Ama3-1: Assy Qty: 1Document1 pageWelding Notes: Bill of Materials For Assembly MK'D: Ama3-1: Assy Qty: 1Seena NaikNo ratings yet

- BC-LP-001 2021-22Document2 pagesBC-LP-001 2021-22Ravikant YadavNo ratings yet

- Technical Threading Chart 2015Document1 pageTechnical Threading Chart 2015D_D_76No ratings yet

- WEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHDocument12 pagesWEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHRicardo LeiteNo ratings yet

- PC110R-1 Wess001201 0902Document2 pagesPC110R-1 Wess001201 0902prajjwal patidarNo ratings yet

- Acero planilla detalle 8mmDocument1 pageAcero planilla detalle 8mmCriss GomezNo ratings yet

- Cong Ty Co Phan Au T Phat Trien Phuc Ien Phuc Dien Development Investment Joint Stock CompanyDocument1 pageCong Ty Co Phan Au T Phat Trien Phuc Ien Phuc Dien Development Investment Joint Stock CompanyHoan TrươngNo ratings yet

- VBSLP-RAJVDE-JC-L0-DR-S-0682 Test Pile DataDocument1 pageVBSLP-RAJVDE-JC-L0-DR-S-0682 Test Pile DataPravin AwalkondeNo ratings yet

- 201992-PZI-6-700-01-01 Dispozicija-General Layout PDFDocument1 page201992-PZI-6-700-01-01 Dispozicija-General Layout PDFDejan Deki MaticNo ratings yet

- Mv-22 Details 02Document1 pageMv-22 Details 02riyazNo ratings yet

- Durafit 500 DURALAY TSDocument2 pagesDurafit 500 DURALAY TSNaim ZeghriniNo ratings yet

- Precast T-Wall Alt 1Document2 pagesPrecast T-Wall Alt 1Kinantoko FauzanNo ratings yet

- USGS Wentworth Grain Size ChartDocument1 pageUSGS Wentworth Grain Size Chartetchplain100% (1)

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxNo ratings yet

- ACO Surface Selector 204Document2 pagesACO Surface Selector 204Miltiades SiopisNo ratings yet

- 3bhk Plan Devichapada Sachin M-Model - Pdf... 9876Document1 page3bhk Plan Devichapada Sachin M-Model - Pdf... 9876viveksawant242No ratings yet

- Comau Medium Payload Eng NJDocument2 pagesComau Medium Payload Eng NJHakan BayrakNo ratings yet

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxNo ratings yet

- Trek MTB 2011 Geometry MediaBookDocument1 pageTrek MTB 2011 Geometry MediaBookMarco TonioloNo ratings yet

- Borelog CP.101Document1 pageBorelog CP.101radixkusumaNo ratings yet

- Intro1 M02 FeaDocument14 pagesIntro1 M02 FeaAyush ChoudharyNo ratings yet

- New Doc 2021-04-09 09.14.36-14Document2 pagesNew Doc 2021-04-09 09.14.36-14Ayush ChoudharyNo ratings yet

- New Doc 2021-04-09 09.14.36-8Document2 pagesNew Doc 2021-04-09 09.14.36-8Ayush ChoudharyNo ratings yet

- Pressure ReliefDocument5 pagesPressure ReliefAyush ChoudharyNo ratings yet

- Intro1 M03 Getting StartedDocument54 pagesIntro1 M03 Getting StartedAyush ChoudharyNo ratings yet

- ANSYS Native Geometry Creation Best PracticesDocument42 pagesANSYS Native Geometry Creation Best PracticesAyush ChoudharyNo ratings yet

- Intro1 M04 BasicsDocument32 pagesIntro1 M04 BasicsAyush ChoudharyNo ratings yet

- General Analysis ProcedureDocument20 pagesGeneral Analysis ProcedureAyush ChoudharyNo ratings yet

- Intro1 M06 Create Solid ModelDocument36 pagesIntro1 M06 Create Solid ModelAyush ChoudharyNo ratings yet

- Viscoplasticity: Chapter FiveDocument36 pagesViscoplasticity: Chapter FiveAyush ChoudharyNo ratings yet

- Chapter 13 - Postprocessing OverviewDocument52 pagesChapter 13 - Postprocessing OverviewAyush ChoudharyNo ratings yet

- Intro1 M11 StructuralDocument26 pagesIntro1 M11 StructuralAyush ChoudharyNo ratings yet

- Intro1 M12 ThermalDocument22 pagesIntro1 M12 ThermalAyush ChoudharyNo ratings yet

- Intro1 M14 Short-TopicsDocument30 pagesIntro1 M14 Short-TopicsAyush ChoudharyNo ratings yet

- Viscoelasticity: Chapter SevenDocument40 pagesViscoelasticity: Chapter SevenAyush ChoudharyNo ratings yet

- Modeling Rubber with HyperelasticityDocument92 pagesModeling Rubber with HyperelasticityAyush ChoudharyNo ratings yet

- 08 GeotechnicalDocument30 pages08 GeotechnicalJorge LuisNo ratings yet

- 2 09-ContactDocument16 pages2 09-ContactmohanjatinderNo ratings yet

- 04 CreepDocument58 pages04 CreepYousef Adel HassanenNo ratings yet

- 2 02-ArrayparDocument20 pages2 02-ArrayparSudhir KumarNo ratings yet

- ANSYS Advanced Structural Nonlinearities Training ManualDocument18 pagesANSYS Advanced Structural Nonlinearities Training ManualAyush ChoudharyNo ratings yet

- Plasticity: Chapter ThreeDocument98 pagesPlasticity: Chapter ThreeAyush ChoudharyNo ratings yet

- Coupling in AnsysDocument19 pagesCoupling in AnsysBalaji ModepalliNo ratings yet

- ANSYS Submodeling TechniqueDocument16 pagesANSYS Submodeling TechniqueEagle SpiritNo ratings yet

- 2 05-BeamDocument20 pages2 05-BeamMARUFNo ratings yet

- Introduction To ANSYS 6.0: Training ManualDocument4 pagesIntroduction To ANSYS 6.0: Training ManualAyush ChoudharyNo ratings yet

- Working with Element OrientationDocument42 pagesWorking with Element OrientationZu RZNo ratings yet

- 2 07-ModalDocument12 pages2 07-ModalMicky MouseNo ratings yet

- 2 10-MacroDocument16 pages2 10-MacrotonysawanNo ratings yet

- Introduction to Nonlinear Analysis in ANSYSDocument11 pagesIntroduction to Nonlinear Analysis in ANSYSkiran129No ratings yet

- Plastomer and ElastomerDocument6 pagesPlastomer and Elastomerحسين الشهريNo ratings yet

- Zenith CH601 Zodiac Aircraft Flight Manual PDFDocument41 pagesZenith CH601 Zodiac Aircraft Flight Manual PDF6976297902No ratings yet

- 2016 Pratik PDCAreviewDocument6 pages2016 Pratik PDCAreviewRheza Nugraha PrabareswaraNo ratings yet

- Electric Arc Furnace SteelmakingDocument55 pagesElectric Arc Furnace SteelmakingIIT SRININo ratings yet

- Weld Carbon Steel Plates in Horizontal and VerticalDocument21 pagesWeld Carbon Steel Plates in Horizontal and VerticalJohnvincent paroneNo ratings yet

- Development Length - Part 1Document39 pagesDevelopment Length - Part 1Tawfeeq AbusaifNo ratings yet

- Catloge (PEACOCK) PDFDocument6 pagesCatloge (PEACOCK) PDFSundarNo ratings yet

- Caustic Recovery PlantsDocument37 pagesCaustic Recovery PlantsCaustic Recovery PlantsNo ratings yet

- JIS G 4805 Seamless Pipe Steel StandardsDocument12 pagesJIS G 4805 Seamless Pipe Steel StandardsGerardo Emmanuel Romana BrianoNo ratings yet

- PDPP - Presentation.2.Four Plane Concept of Manufacturing - January.2021Document12 pagesPDPP - Presentation.2.Four Plane Concept of Manufacturing - January.2021Ashish Kumar100% (1)

- PDS Stopaq Subsea Intermediate Wrap V3 enDocument1 pagePDS Stopaq Subsea Intermediate Wrap V3 enAndyNo ratings yet

- Plastic As A Packaging Material: Mrs. Kirteebala PawarDocument53 pagesPlastic As A Packaging Material: Mrs. Kirteebala PawarJillianne JillNo ratings yet

- Tool Engineering (Elective) - Sample-Question-Paper (Msbte-Study-Resources)Document4 pagesTool Engineering (Elective) - Sample-Question-Paper (Msbte-Study-Resources)Shivraj KolambekarNo ratings yet

- Rdso DRG 11754 SeriesDocument11 pagesRdso DRG 11754 SeriesRVNL GoaNo ratings yet

- Bardken-Crawler-Systems-BrochureDocument9 pagesBardken-Crawler-Systems-BrochureAlex LeeNo ratings yet

- QUIZ TQM Part - 3 QUES ANS SHEETDocument38 pagesQUIZ TQM Part - 3 QUES ANS SHEETAjay MishraNo ratings yet

- 20 Microns Coated Calcium Carbonate 1t VDocument1 page20 Microns Coated Calcium Carbonate 1t VChandrakantNo ratings yet

- PGS Data SheetDocument9 pagesPGS Data Sheetkiran panditNo ratings yet

- RCD6 Tbeams PartialDocument34 pagesRCD6 Tbeams PartialNelle SarmientoNo ratings yet

- Final Report IETS G8Document25 pagesFinal Report IETS G8tsaqifNo ratings yet

- Mechanical Caliper GuideDocument13 pagesMechanical Caliper GuideArchana RachelNo ratings yet

- Analysis of Epoxy Coated & Glass Fiber Bamboo & Steel ReinforcedConcrete BeamsDocument7 pagesAnalysis of Epoxy Coated & Glass Fiber Bamboo & Steel ReinforcedConcrete BeamsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Strongcoat Primer RangeDocument2 pagesStrongcoat Primer Rangeosama mohNo ratings yet

- Oc 6 Metal Joining (Recovered)Document29 pagesOc 6 Metal Joining (Recovered)Janaki RamanNo ratings yet

- Scale Model Replicas: CAT 395 Next Generation Hydraulic ExcavatorDocument57 pagesScale Model Replicas: CAT 395 Next Generation Hydraulic ExcavatorANGELA ARACELLY PAREDES PEREZNo ratings yet

- Hempaline Defend 630: Product DescriptionDocument3 pagesHempaline Defend 630: Product DescriptionSalas VinicioNo ratings yet

- Kilian: Bearings & AssembliesDocument4 pagesKilian: Bearings & AssembliesLuis Angel Rivera MacielNo ratings yet

- Research-2 DollhouseDocument6 pagesResearch-2 DollhouseManmayee RoutNo ratings yet

- BMC 100 Important Questions 71Document24 pagesBMC 100 Important Questions 71Its WorldNo ratings yet

- HFY-PIP-SP-00004 X Specification For Sour Service - A-CommentedDocument9 pagesHFY-PIP-SP-00004 X Specification For Sour Service - A-CommentedVignesh PanchabakesanNo ratings yet