Professional Documents

Culture Documents

832-LT1-119-H1-R4 Plano Micropilotes ST42 GB 119

Uploaded by

Francisco RoseroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

832-LT1-119-H1-R4 Plano Micropilotes ST42 GB 119

Uploaded by

Francisco RoseroCopyright:

Available Formats

4 NOTES

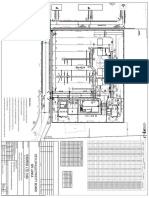

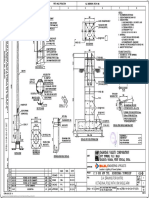

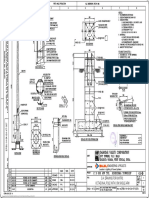

BASE SLAB MICROPILE

0.075

TOWER TYPE ST42 B B

1. MICROPILES SYSTEM CONSISTS OF DSI (DYWDAG SYSTEMS INTERNATIONAL) CONTINUOUS THREAD SELF-DRILLING

Sumergido HIGHER TOWER NUMBER

SOIL TYPE CLASS Base slab Base slab

HOLLOW BARS, WHICH ALLOW THE BAR TO BE CUT TO ANY LENGTH (STANDARD LENGTH = 3M) AND ARE CONNECTED

B1 View detail D-1 View detail D-1 B1

OUTCROP HEIGHT FROM G.L., OC (mm) 500 BY DSI COUPLERS. THE BARS WILL BE MANUFACTURED WITH SEAMLESS STEEL TUBE COMPOSED OF FINE-GRAINED

B1 B1

B

EMBEDDED HEIGHT OF SHAFT, H (mm) 1800 B STEEL AND HIGH ALLOY.

THICKNESS, T (mm) 700 Chimney Chimney 2. DURING DRILLING, IT IS INJECTED A MIXTURE OF GROUT COMPOSED OF TYPE I PORTLAND CEMENT AND WATER, MIXED

WIDTH OF CHIMMEY AT HORIZONTAL PLANE B1(mm) 800 View detail C-1 View detail C-1 INTO A WATER/CEMENT RATIO (W/C) = 0.8. DOSING IN THE INITIAL GROUT WORK WILL BE 2.5 SACKS OF CEMENT PER

WIDTH OF SLAB, B (mm) 2500 25 GALLONS OF WATER. WHEN THE SIDEWALLS OF THE PERFORATED CAVITIES NOT PRESENT COLLAPSE DURING

B C

EMBEDDED LENGHT OF STUB ANGLE IN SUBSOIL, H1 (mm) 2200 4 DRILLING INJECTION (INITIAL INJECTION) CAN BE CARRIED OUT EXCLUSIVELY WITH WATER.

DIAM (mm) 25 3. THERE WILL BE A FINAL INJECTION, ONCE WE HAVE REACHED THE LENGTH OF DRILLING WITH A MIXTURE OF GROUT

Ls (mm) 2198 COMPOSED OF TYPE I PORTLAND CEMENT AND WATER, MIXED INTO A WATER/CEMENT RATIO (W/C) = 0.45. DOSING

Ls b (mm) 310 WILL BE 4.5 SACKS OF CEMENT PER 25 GALLONS OF WATER. THE FINAL MICROPILES GROUT MUST HAVE A MINIMUM

1 Total length (mm) 2508 COMPRESSION RESISTANCE (F' C) OF 5,000 PSI (34 MPa) AT 28 DAYS. NO ADDITIVES ARE NEEDED IN THE MIXTURE.

W.U. (kg) 9.66 4. FOR CONTROL AND FIELD VERIFICATION OF STEEL BARS AND THEIR ACCESSORIES,QUALITY CERTIFICATE MUST

QUANT. 16 BE DELIVERED TO INSPECTOR WHEN ASKED. FOR THE FINAL GROUT OF MICROPILES, MUST BE DETERMINED AT

b

W TOTAL (kg) 154.6 0.075 FIELD BY WORKING DAY, THE FINAL GROUT SPECIFIC GRAVITY BY MUD BALANCE TEST. MINIMUM FINAL GROUT

DIAM (mm) 10 SPECIFIC GRAVITY SHOULD BE AT LEAST 1.7 gr/cm³ IN ORDER TO ENSURE THE PROPER GROUT DOSING (WATER /

0.075 0.075

a (mm) CEMENT RATIO OF 0.45) AND THEREFORE RESISTANCE TO 5000 PSI (34 MPA) AT 28 DAYS.

E-1 PLAN BASE SLAB OF FOUNDATION

650

b

b (mm) 100 SCALE: 1:25 5. THE STEEL MUST SATISFY OR EXCEED THE REQUIREMENTS ESTABLISHED IN ASTM A 615 STANDARD, GRADE 75 STEEL

Total length (mm) 2800 5 BARS.

2 a W.U. (mm) 1.73

6. IT MUST USE A SUITABLE HYDRAULIC DRILL (ROTATION AND PERCUSSION) FOR THE SIZE OF DRILL AND ROD USED. THE

0.075

ROTATION SHOULD BE MAINTAINED BETWEEN 80 AND 120 RPM WITH A TORQUE OF 300 NM AND A MAXIMUM

QUANT. 16

ENERGY OF 84 JOULES PERCUSSION IF IT IS REQUIRED.

Space (mm) 150

W TOTAL 7. TO PREPARE THE GROUT, IT MUST HAVE A HIGH TURBULENCE COLLOIDAL MIXER WITH SEPARATE WATER TANK AND

(kg) 27.6

DIAM DOSAGE OF CEMENT. OPTIONALLY, THE GROUT PREPARATION CAN BE MADE BY STIRRING OR MANUAL MIXING.

(mm) 10

MANUAL MIXING SHOULD BE VERIFIED BY TESTING THE MUD BALANCE.

a (mm)

C-2

230

8. IT MUST USE A PUMP WITH A CAPACITY OF MINIMUM INJECTION OF 25 LITERS PER MINUTE AND/OR A MINIMUM OF

b (mm) 325 250 PSI.

a c (mm)

c 100 A D 9. BASE SLAB MATERIALS COMPRESSION STRENGTH f'c= 21MPa, REINFORCEMENT STEEL YIELD STRENGTH Fy= 420MPa

5

3 b Total length (mm) 2420

B1

Base slab

View detail D-1

Base slab

View detail D-1 B1

ASTM STANDARD GRADE 60

W.U. (kg) 1.49 GENERALS

B1 B1 B

QUANT. 16 B 10. ALL DIMENSIONS ARE IN METERS EXCEPT OTHERWISE STATED

Space (mm) 150 Chimney 11. ALL SCALES ARE INDICATED ON THE DRAWING

W TOTAL (kg) Chimney View detail C-1

23.9 12. THE PROPOSED FOUNDATION SYSTEM MUST BE LOCATED IN THE FIELD, FROM TOPOGRAPHIC REFERENCING PROJECT

View detail C-1 LOWER TOWER NUMBER

DIAM (mm) 16 B B 13. WATER SHALL BE CLEAN AND FREE FROM OIL, ALKALI ORGANIC WATER AND OTHER CHEMICAL MATERIALS.

a (mm) 2350 14. CONCRETE USED FOR CAP ON GRADE CONSTRUCTION SHALL HAVE A W/C RATIO NOT TO EXCEED 0.40m

0.075

C-2

a b (mm) 400 15. CONCRETE SHALL BE MIXED AND PLACED IN ACORDANCE WITH ACI 318M.USE MIXES WITH MAXIMUN AGGREGATE SIZE

b Total length (mm) 3150 PLAN AT BOTTOM FUNDATION 0.075 0.075

APROPIATE FOR FORM SPACES AND REINFORCEMENT PLACEMENT REQUIRED IN THIS PROYECT.

b P-1 ESCALE: 1:50 PLAN BASE

E-2 SCALE: 1:25 SLAB OF FOUNDATION

4 W.U. (kg) 4.97 16. STUB ANGLE AND SETTING OUT A1 AND B1 ARE SHOWN IN DWG N° 40-SA05661S-T0205-56.

QUANT. 20+20 17. THE DIMENSIONS Lj REFER TO PANEL ERECTION DRAWINGS OF ST42 TOWER TYPE DWG. NO. HEI-ECEHV-I-TLW-DW-240

A1

Space (mm) 124 18. MINIMUN COVER FOR THE REBAR IS 75 mm

W TOTAL (kg) 198.8 B1 STUB

STUB

DIAM (mm)

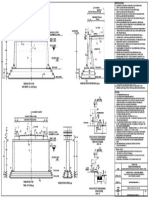

TOWER CENTER LINE

16 GRADIENT Lj

a (mm) 2350 Bearing plate

a b (mm) Anchor nut R 38 (0.20 x 0.20 x 0.025)

400

b b Total length (mm) 3150 Anchor nut R 38

5 W.U. (kg) 4.97

QUANT. 24+24 B1

Space (mm) 102

W TOTAL (kg) 238.6 Base slab C-3 C-3

OC 1

EXCAVATION VOLUME (m3) 11.56

CENTER LINE OF CHIMNEY

1 Ground line

BACK FILL VOLUME (m3) 6.17

CONCRETE VOLUME (m3) 5.40 Chimney

TOTAL REINFORCEMENT (kg) 644

LEAN CONCRETE VOLUMEN 3

(m ) 0.31 2 Rugged construction board

B1

MICROPILES CONCRETE VOLUME 3

(m ) 3.37 2 3

* THE QUANTITIES SHOWN ARE PER ONE LEG 3

H

4 Base slab

B1 0.075

E-1 E-1

Spacer C-3 SECTION

NO SCALE

T

0.35

Grout f'c=5,000 PSI - E-2 E-2

0.075

34 MPa (at 28 days)

0.05 B

Lean Concrete

Coupler 5

Spacer 15.75

View Detail D-2 16.1 Corporación Eléctrica del Ecuador

Micropile

View Detail D-2

A

B

B C-2 C-2

1.60

0.80 0.80

3

C-1 GENERAL

SCALE: 1:25

SECTION OF FOUNDATION

0.80

Base slab

DSI R38-550 Drill hollow bar

2

B

DSI R38-550 Drill hollow bar View manufacturer's specifications

View manufacturer's specifications

0.80

Micropile

View detail D-2 DSI R38 115 mm drill bit Grout f'c=5,000 PSI -

34 MPa (at 28 days)

1 Bearing plate DRILL HOLLOW BAR

(0.20 x 0.20) ø 165mm (6.5 in) BAR TOTAL

View detail D-2 MICROPILES LENGTH

DRILL BIT

DSI R38-550 CROSSWISE 115MM 24 16.10 M

D-1

MICROPILES DISTRIBUTION MICROPILE DETAIL C-2 MICROPILE SECTION

SCALE: 1:25 D-2 SCALE: 1:10

SCALE: 1:10

You might also like

- Design CWR - R0Document38 pagesDesign CWR - R0abhishek5810No ratings yet

- Analysis and Design of 5-Storey RC School Building Using Midas GenDocument140 pagesAnalysis and Design of 5-Storey RC School Building Using Midas GenBenjamin Flores100% (1)

- Repairing ConcreteDocument19 pagesRepairing ConcreteMKOZERDEMNo ratings yet

- Type-1 - Structural Plan - 2013-02-16 PDFDocument3 pagesType-1 - Structural Plan - 2013-02-16 PDFjremptymak0% (1)

- Curing Concrete - Concrete Technology - Portland Cement Association (PCA)Document6 pagesCuring Concrete - Concrete Technology - Portland Cement Association (PCA)civhari100% (1)

- Erection of Steel Structures PDFDocument76 pagesErection of Steel Structures PDFUmar MohammadNo ratings yet

- FP-07 - All Home Cdo - 070317 PDFDocument1 pageFP-07 - All Home Cdo - 070317 PDFLowentan LaxamanaNo ratings yet

- List of Codes - IRC - Pavement & MaterialsDocument4 pagesList of Codes - IRC - Pavement & MaterialsMadhava Reddy N80% (5)

- Design of Concrete Lined Flood Control ChannelsDocument26 pagesDesign of Concrete Lined Flood Control Channelswikoboy100% (1)

- SOP FOR Bored Cast in Situ Pile WorkDocument13 pagesSOP FOR Bored Cast in Situ Pile Workom prakashNo ratings yet

- Tunnel Support - Use of Lattice Girders in Sedimentary RockDocument94 pagesTunnel Support - Use of Lattice Girders in Sedimentary RockJunaida Wally100% (3)

- CB3 Me-13Document1 pageCB3 Me-13J-R MERLIN CabatoNo ratings yet

- R0404-MT - Rev - 0 DF Da Bateria de CicloneDocument2 pagesR0404-MT - Rev - 0 DF Da Bateria de CiclonecaapasaNo ratings yet

- 2016 0928 BGHMC PSY COMPLEX Foundation 4 ModelS4Document1 page2016 0928 BGHMC PSY COMPLEX Foundation 4 ModelS4Justine Pearl SibugNo ratings yet

- Foundation and Slab (A3)Document1 pageFoundation and Slab (A3)Princess BarredoNo ratings yet

- AD SHENDE SLAB BEAM RC 01 CEAD R0 25-02-2022-Model1Document1 pageAD SHENDE SLAB BEAM RC 01 CEAD R0 25-02-2022-Model1swapnil bokadeNo ratings yet

- PURLIN ROOF SYSTEMelDocument1 pagePURLIN ROOF SYSTEMelAbid AyubNo ratings yet

- Connection Details: Adrian M. Reyes Adrian M. ReyesDocument1 pageConnection Details: Adrian M. Reyes Adrian M. ReyesAdrian Marasigan ReyesNo ratings yet

- Erection Drawing SST 36MDocument14 pagesErection Drawing SST 36MyuwonoNo ratings yet

- 0403bon N WM Qp02 Ci DRD 0001 b01 Battery LimitsDocument6 pages0403bon N WM Qp02 Ci DRD 0001 b01 Battery LimitsNaji RaheemNo ratings yet

- Design Guidelines: Getting It Right From The StartDocument1 pageDesign Guidelines: Getting It Right From The StartBk HumansNo ratings yet

- A1 Side A2 Side: Longitudinal Sectional Elevational On 'Xyz'Document1 pageA1 Side A2 Side: Longitudinal Sectional Elevational On 'Xyz'sheikNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- Cross Section Cross Section: Bureau of DesignDocument1 pageCross Section Cross Section: Bureau of DesignMNo ratings yet

- Stub Setting Tower CC+3 - DPTDocument1 pageStub Setting Tower CC+3 - DPTKenari UtamiNo ratings yet

- Released ForDocument1 pageReleased ForchannajayamangalaNo ratings yet

- 03.DET 2 Layout1Document1 page03.DET 2 Layout1division4 designsNo ratings yet

- Structural - 3Document3 pagesStructural - 3Angela MaeNo ratings yet

- Schedule of Beam: Foundation Plan Second Floor Framing Plan Roof Framing PlanDocument1 pageSchedule of Beam: Foundation Plan Second Floor Framing Plan Roof Framing PlanLeonard Delos ReyesNo ratings yet

- Construction Notes: D. Notes On Foundation Design CriteriaDocument9 pagesConstruction Notes: D. Notes On Foundation Design CriteriaIrene Ionie Rarangol - TengcoNo ratings yet

- K221-BFW-06-006702 01 1 2Document1 pageK221-BFW-06-006702 01 1 2goushbashaNo ratings yet

- Beam DetailsDocument1 pageBeam DetailsXaira Alexa Mari CastroNo ratings yet

- Three Pile Cap (Beam Action) : Plan Showing Piles Reinforcement Plan Showing Pile Cap Reinforcement PlanDocument1 pageThree Pile Cap (Beam Action) : Plan Showing Piles Reinforcement Plan Showing Pile Cap Reinforcement PlanVinayakNo ratings yet

- A B C D A B C D A B C D: Legend SpecificationDocument1 pageA B C D A B C D A B C D: Legend SpecificationFreyaNo ratings yet

- Alta Prima Conv S-2Document1 pageAlta Prima Conv S-2Ronnel John CruzNo ratings yet

- Design of Beam - Model Reaction (Staad-ETABS)Document6 pagesDesign of Beam - Model Reaction (Staad-ETABS)Nitesh SinghNo ratings yet

- Sa-0224311 0001 0000Document1 pageSa-0224311 0001 0000Bilal ChohanNo ratings yet

- Notes:: 1F at SSL + 4.00mDocument1 pageNotes:: 1F at SSL + 4.00massis alihNo ratings yet

- AA-036878-001 - SPREADER BEAMS - H BeamDocument1 pageAA-036878-001 - SPREADER BEAMS - H BeamGaurav BedseNo ratings yet

- Aashto M182Document1 pageAashto M182azeem sarwar0% (1)

- Ysc Ms 769 DW 0001sht1of2rev BDocument1 pageYsc Ms 769 DW 0001sht1of2rev BbalamuralinakshatraNo ratings yet

- S3 Sample Working DrawingDocument1 pageS3 Sample Working DrawingjasonNo ratings yet

- S 1 PDFDocument1 pageS 1 PDFfrancis sebastian lagamayoNo ratings yet

- Plumbing p1 2Document1 pagePlumbing p1 2Pol DoggoNo ratings yet

- Project: Bearing of Hole (Degree) Collar Elevation (M) Started: Ground Elevation (M) Completed Feature Total Depth (M) Type (S) of Core Barrel Drilling Agency: Chainage:-Co-OrdinatesDocument1 pageProject: Bearing of Hole (Degree) Collar Elevation (M) Started: Ground Elevation (M) Completed Feature Total Depth (M) Type (S) of Core Barrel Drilling Agency: Chainage:-Co-OrdinatesumerNo ratings yet

- Bureau of Design: LegendDocument1 pageBureau of Design: LegendKristine ChavezNo ratings yet

- 225KL - 18M-Blank-1Document1 page225KL - 18M-Blank-1Tarun SinghalNo ratings yet

- Notes: Epc Contract For Tyra Redevelopment Project - WHRPDocument1 pageNotes: Epc Contract For Tyra Redevelopment Project - WHRPaung aungNo ratings yet

- Bureau of Design: LegendDocument1 pageBureau of Design: LegendMNo ratings yet

- FT Mini Sportster v1.0 Full-SizeDocument4 pagesFT Mini Sportster v1.0 Full-SizeUdhasu NayakNo ratings yet

- Bill of MaterialsDocument1 pageBill of MaterialsgoushbashaNo ratings yet

- Plan at Canopy Top Level: Detail - ZDocument1 pagePlan at Canopy Top Level: Detail - ZEr navneet jassiNo ratings yet

- RB A225 Approval Rev 1 - 11 11Document1 pageRB A225 Approval Rev 1 - 11 11TariqMahmoodNo ratings yet

- Pages From 4355-AI-DX-00000017 - DSDocument2 pagesPages From 4355-AI-DX-00000017 - DSamitNo ratings yet

- Truss Detail Gutter Detail: Ft1 Detail Rr1 DetailDocument1 pageTruss Detail Gutter Detail: Ft1 Detail Rr1 DetailMaxine GarcesNo ratings yet

- Cross Axis: Section PlanDocument1 pageCross Axis: Section PlanMarvin BermidoNo ratings yet

- E SH35 MJB DD 001 Sheet 1Document1 pageE SH35 MJB DD 001 Sheet 1MATHANNo ratings yet

- K221-LPS-06-051065 01 1 1Document1 pageK221-LPS-06-051065 01 1 1goushbashaNo ratings yet

- Typical Elevation of Intermediate Frame Beams Showing Bar Cut-OffDocument1 pageTypical Elevation of Intermediate Frame Beams Showing Bar Cut-Offricca.bojo15No ratings yet

- Epbu 14 04 Ga KT 057a (6m Octagonal Pole) r4 ApprovalDocument1 pageEpbu 14 04 Ga KT 057a (6m Octagonal Pole) r4 ApprovalP.MannaNo ratings yet

- Epbu-14-04-Ga-Kt-057a (6M Octagonal Pole) R4-Approval PDFDocument1 pageEpbu-14-04-Ga-Kt-057a (6M Octagonal Pole) R4-Approval PDFP.MannaNo ratings yet

- Details "B" BD 110: - Cadd Designer'SDocument1 pageDetails "B" BD 110: - Cadd Designer'SDileep K MahadevaiahNo ratings yet

- Rafter & Rod Details - RL S5Document1 pageRafter & Rod Details - RL S5Abid AyubNo ratings yet

- Multi - 1 Drills: YE-ML20Document2 pagesMulti - 1 Drills: YE-ML20Michel DominguesNo ratings yet

- Da 950092 001Document1 pageDa 950092 001munnaNo ratings yet

- JP305821Document7 pagesJP305821alexanderNo ratings yet

- S 1 PDFDocument1 pageS 1 PDFSketch UpNo ratings yet

- LT-CCS - San Rafel-1Document1 pageLT-CCS - San Rafel-1Francisco RoseroNo ratings yet

- Plano 2Document1 pagePlano 2Francisco RoseroNo ratings yet

- Plano 1Document1 pagePlano 1Francisco RoseroNo ratings yet

- LEVANTAMIENTO PLANIMÉTRICO SANTA TERESITA BELISARIO QUEVEDO-ModelDocument1 pageLEVANTAMIENTO PLANIMÉTRICO SANTA TERESITA BELISARIO QUEVEDO-ModelFrancisco RoseroNo ratings yet

- Design of Concrete-Filled Steel Tubular Members According To The Australian Standard As 5100 Model and CalibrationDocument18 pagesDesign of Concrete-Filled Steel Tubular Members According To The Australian Standard As 5100 Model and Calibrationoui6592No ratings yet

- Thomann Hanry Facade Cleaning Guide PDFDocument30 pagesThomann Hanry Facade Cleaning Guide PDFkaduwdNo ratings yet

- Structural Design of A Reinforced Concrete Balcony Slab To BS 8110Document4 pagesStructural Design of A Reinforced Concrete Balcony Slab To BS 8110OscarKonzultNo ratings yet

- Voided SlabsDocument8 pagesVoided SlabsAnonymous dxsNnL6S8hNo ratings yet

- The History of Developments Toward Open Building in JapanDocument8 pagesThe History of Developments Toward Open Building in JapanAfonso PortelaNo ratings yet

- VOL 2b-Particular Design and Performance SpecificationsDocument126 pagesVOL 2b-Particular Design and Performance SpecificationsAngel Lisette LaoNo ratings yet

- Course Title: Structural Design - I Course Code: 5015 Course Category: A Periods/Week: 5 Periods/Semester: 65 Credits: 5Document4 pagesCourse Title: Structural Design - I Course Code: 5015 Course Category: A Periods/Week: 5 Periods/Semester: 65 Credits: 5Shamnas P MNo ratings yet

- RETAINING WALL 2.5m HeightDocument53 pagesRETAINING WALL 2.5m HeightHemam PrasantaNo ratings yet

- A Study On Properties of Reactive Powder Concrete: Sarika SDocument4 pagesA Study On Properties of Reactive Powder Concrete: Sarika SAkshay MehtaNo ratings yet

- DUDBC Design CatalogueDocument172 pagesDUDBC Design Cataloguedhakal.binaya0750% (2)

- Visit Report: Visit Date: 4 JULY 2018 TIME BETWEEN 10:00 Am To 12:30 PMDocument8 pagesVisit Report: Visit Date: 4 JULY 2018 TIME BETWEEN 10:00 Am To 12:30 PMAnep AmeerNo ratings yet

- RC 1 Course OutlineDocument1 pageRC 1 Course Outlinehanose100% (1)

- Block of 4 Flats Calculation Report 2Document152 pagesBlock of 4 Flats Calculation Report 2Isaac JosephNo ratings yet

- Friable Base: Extra Material For CrossDocument6 pagesFriable Base: Extra Material For CrossPravin MasalgeNo ratings yet

- 1 Brushbond (M)Document3 pages1 Brushbond (M)marzuki0202No ratings yet

- Orion Flat Slab Design TrainingDocument134 pagesOrion Flat Slab Design TrainingAdigwe George Chima100% (4)

- Parliament Building Report PDFDocument36 pagesParliament Building Report PDFYin YeeNo ratings yet

- Conbextra EP: T T T T T TDocument4 pagesConbextra EP: T T T T T TFeri Oktara IrawanNo ratings yet

- PolycreteDocument2 pagesPolycreteStressDyn ConsultantsNo ratings yet

- ECRD - Relato OKDocument104 pagesECRD - Relato OKelvisNo ratings yet

- Latex Agents For Bonding Fresh To Hardened ConcreteDocument2 pagesLatex Agents For Bonding Fresh To Hardened ConcreteEvert RiveraNo ratings yet