Professional Documents

Culture Documents

BX Mid-Size Breaker Series Brochure PDF

Uploaded by

abbas0 ratings0% found this document useful (0 votes)

25 views1 pageOriginal Title

BX Mid-Size Breaker Series Brochure.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views1 pageBX Mid-Size Breaker Series Brochure PDF

Uploaded by

abbasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

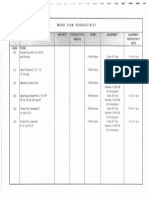

SIZE YOUR BREAKER DETERMINE YOUR OUTPUT

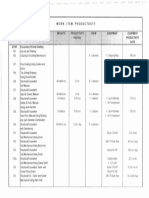

PRODUCTION RATE MATTERS

ONE SIZE DOES NOT FIT ALL

The hardness of the materials you’re breaking will identify the right breaker for your job. The material size and hardness

BTI’s BX Series RockBreakers break-up concrete, aggregate, limestone, hard rock, and granite. To get the best

plus rockbreaker size will determine your production flow rate. Use this chart to ensure you’re maximizing your

performance from your BTI RockBreaker, you need to account for three things: your carrier size, the material you’re

production rate and getting the most from your BTI RockBreaker.

breaking, and your production goals. Your carrier’s operating weight and hydraulic system capabilities determine your

breaker size. Use this chart to match the correct BTI RockBreaker to your carrier. Production Rate Chart

Model:

Carrier Sizing Chart BX40

Carrier Weight in Tonnes (metric) BX30

BREAKER

MODEL 0 5 10 15 20 25 30

BX20

BX10 5–8 Non-reinforced Concrete / Shale

1000 ft • lb (1 350 joule) Reinforced Concrete

BX15 Medium Rock

Hard Rock

BX15 6–9 BX10

1500 ft • lb (2 000 joule)

50 100 150 200 250 300 350 400

BX20 10–15

2000 ft • lb (2 700 joule)

Based on production rates in cubic yard per eight hour shift.

Note: Values are non-binding industry guidelines by foot-pound class and will vary depending on rock formation, machine, operator and job conditions. BX15 and smaller are not recommended for hard rock.

BX30 16–22

3000 ft • lb (4 100 joule)

BX40 18–25

4000 ft • lb (5 400 joule)

10380

Skidsteer Backhoe Mini-excavator Excavator

www.rockbreaker.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Work Item ProductivityDocument1 pageWork Item ProductivityabbasNo ratings yet

- Work Item ProductivityDocument1 pageWork Item ProductivityabbasNo ratings yet

- Work Item Productivity: " (1/'CQDEDocument1 pageWork Item Productivity: " (1/'CQDEabbasNo ratings yet

- Equipment Productivity RateDocument1 pageEquipment Productivity RateabbasNo ratings yet

- Work Item ProductivityDocument1 pageWork Item ProductivityabbasNo ratings yet

- Work Item Productivity: 0 LM '19 LMDocument1 pageWork Item Productivity: 0 LM '19 LMabbasNo ratings yet

- Work Item ProductivityDocument1 pageWork Item ProductivityabbasNo ratings yet

- Diameter 5000.0 MM: Excluding TravelDocument2 pagesDiameter 5000.0 MM: Excluding TravelabbasNo ratings yet

- Work Item Productivity: I I 10 MHLCMDocument1 pageWork Item Productivity: I I 10 MHLCMabbasNo ratings yet

- Fresh Ready-Mixed Concrete Waste in Construction Projects: A Planning ApproachDocument9 pagesFresh Ready-Mixed Concrete Waste in Construction Projects: A Planning ApproachabbasNo ratings yet

- Enduring Structure, Easy Access To Maintenance Areas: Symmetrical, Reversible Housing On-Machine RechargingDocument1 pageEnduring Structure, Easy Access To Maintenance Areas: Symmetrical, Reversible Housing On-Machine RechargingabbasNo ratings yet

- Work Item Phoductivity: Excavatiofl, Fili andDocument1 pageWork Item Phoductivity: Excavatiofl, Fili andabbasNo ratings yet

- Work Item ProductivityDocument1 pageWork Item ProductivityabbasNo ratings yet

- Sound Suspension, Long-Lasting ComponentsDocument1 pageSound Suspension, Long-Lasting ComponentsabbasNo ratings yet

- Specifications: H110Es H115Es H120Es H130Es H140Es H160Es H180EsDocument1 pageSpecifications: H110Es H115Es H120Es H130Es H140Es H160Es H180EsabbasNo ratings yet

- Dimensions: Front/Back SideDocument1 pageDimensions: Front/Back SideabbasNo ratings yet

- Productivity: H110Es H115Es H120Es H130Es H140Es H160Es H180EsDocument1 pageProductivity: H110Es H115Es H120Es H130Es H140Es H160Es H180EsabbasNo ratings yet

- Pages From C10501115-1-3Document1 pagePages From C10501115-1-3abbasNo ratings yet

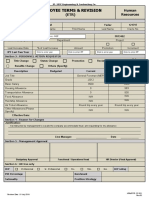

- Employee Term and Revision (ETR) Form - HR - PPR-SF-001Document1 pageEmployee Term and Revision (ETR) Form - HR - PPR-SF-001abbasNo ratings yet

- For Certification: S, No Badge NameDocument15 pagesFor Certification: S, No Badge NameabbasNo ratings yet

- Book1 PDFDocument3 pagesBook1 PDFabbasNo ratings yet

- Time & Quantity Report (TQR) - Civil: Time Performance Location PlanningDocument1 pageTime & Quantity Report (TQR) - Civil: Time Performance Location PlanningabbasNo ratings yet

- DPSD ProjectDocument30 pagesDPSD ProjectSri NidhiNo ratings yet

- IKEA SHANGHAI Case StudyDocument5 pagesIKEA SHANGHAI Case StudyXimo NetteNo ratings yet

- School of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1Document2 pagesSchool of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1STEM Education Vung TauNo ratings yet

- Companyprofil E: Erfanconstructionsolut IonDocument14 pagesCompanyprofil E: Erfanconstructionsolut IonNurin AleesyaNo ratings yet

- Modulo EminicDocument13 pagesModulo EminicAndreaNo ratings yet

- Arnold Ventures Letter To Congressional Social Determinants of Health CaucusDocument7 pagesArnold Ventures Letter To Congressional Social Determinants of Health CaucusArnold VenturesNo ratings yet

- Bana LingaDocument9 pagesBana LingaNimai Pandita Raja DasaNo ratings yet

- Fss Presentation Slide GoDocument13 pagesFss Presentation Slide GoReinoso GreiskaNo ratings yet

- Roleplayer: The Accused Enchanted ItemsDocument68 pagesRoleplayer: The Accused Enchanted ItemsBarbie Turic100% (1)

- Space Hulk - WDDocument262 pagesSpace Hulk - WDIgor Baranenko100% (1)

- Lec 33 - Householder MethodDocument11 pagesLec 33 - Householder MethodMudit SinhaNo ratings yet

- Hole CapacityDocument2 pagesHole CapacityAbdul Hameed OmarNo ratings yet

- The Person Environment Occupation (PEO) Model of Occupational TherapyDocument15 pagesThe Person Environment Occupation (PEO) Model of Occupational TherapyAlice GiffordNo ratings yet

- Golf Croquet Refereeing Manual - Croquet AustraliaDocument78 pagesGolf Croquet Refereeing Manual - Croquet AustraliaSenorSushi100% (1)

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 pagesUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcNo ratings yet

- ISBN Safe Work Method Statements 2022 03Document8 pagesISBN Safe Work Method Statements 2022 03Tamo Kim ChowNo ratings yet

- Linguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowDocument2 pagesLinguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowMonette Rivera Villanueva100% (1)

- Aleksandrov I Dis 1-50.ru - enDocument50 pagesAleksandrov I Dis 1-50.ru - enNabeel AdilNo ratings yet

- Hamstring - WikipediaDocument21 pagesHamstring - WikipediaOmar MarwanNo ratings yet

- Lecture 4 ENGR 243 DynamicsDocument45 pagesLecture 4 ENGR 243 DynamicsRobby RebolledoNo ratings yet

- Carriage RequirementsDocument63 pagesCarriage RequirementsFred GrosfilerNo ratings yet

- Module 1: Overview of Applied Behaviour Analysis (ABA)Document37 pagesModule 1: Overview of Applied Behaviour Analysis (ABA)PriyaNo ratings yet

- Equivalent Fractions Activity PlanDocument6 pagesEquivalent Fractions Activity Planapi-439333272No ratings yet

- Online Extra: "Economists Suffer From Physics Envy"Document2 pagesOnline Extra: "Economists Suffer From Physics Envy"Bisto MasiloNo ratings yet

- Partes de La Fascia Opteva Y MODULOSDocument182 pagesPartes de La Fascia Opteva Y MODULOSJuan De la RivaNo ratings yet

- Computing of Test Statistic On Population MeanDocument36 pagesComputing of Test Statistic On Population MeanKristoffer RañolaNo ratings yet

- Project Scheduling and TrackingDocument47 pagesProject Scheduling and TrackingArun VinodhNo ratings yet

- 3 ALCE Insulators 12R03.1Document12 pages3 ALCE Insulators 12R03.1Amílcar Duarte100% (1)

- Nutrition and CKDDocument20 pagesNutrition and CKDElisa SalakayNo ratings yet

- PED003Document1 pagePED003ely mae dag-umanNo ratings yet