Professional Documents

Culture Documents

MS Compressed

MS Compressed

Uploaded by

Yousaf Richu0 ratings0% found this document useful (0 votes)

10 views8 pagesOriginal Title

MS_compressed

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views8 pagesMS Compressed

MS Compressed

Uploaded by

Yousaf RichuCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

[es

BARO Group

was cab

METHOD STATEMENT

FOR

FIBER OPTIC CABLE

WORK

Doc No: BG/MS/CM/07/08/20

Date:24/08/2020 ; Rev:00

MAIN CONTRACTOR: - OOREDOO.

LOCATION: - LOSAIL CIRCUIT SPORTS CLUB

‘WORK ORDER NO: - 65598-3 (PROV OF 12 FO CABLE FOR OD53 DP-3498

FROM KTM)

Name Date Signature

Prepared ——

JQ THOMAS KOSHY 07/09/2020 = _

Reviewed a >

SAIFUDHEEN K MUSTHAFA 07/09/2020 |

‘Approved T

METHOD STATEMENT FOR Doc No: BG/MS/CM/01/08/20

i BARG Group FIBER OPTIC CABLE | Date:24/08/2020 ; Rev:00

one OA work

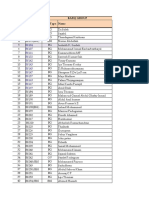

TABLE OF CONTENTS

ACRONYMS ...

OBJECTIVE

SCOPE

REFERENCE DOCUMENTS ..

GENERAL

RESPONSIBILITY ..

LAYING OF FOC.

SPLICING

INSPECTION & TESTING

© e2N ane wn

NOOR Aww ww

10 HEALTH & SAFETY...

METHOD STATEMENT FOR Doc No: BG/MS/CIW/01/08/20

by BAR Group, FIBER OPTIC CABLE —_Date:24/08/2020 ; Rev:00

one work

3. ACRONYMS

PM PROJECT MANAGER

Pam PROJECT QUALITY MANAGER

acm | QUALITY CONTROL MANAGER

OTDR | OPTICAL TIME DOMAIN REFLECTOMETER

FOP FIBER DISTRIBUTION PANEL

FOC FIBER OPTIC CABLE

am NANOMETER

4. OBJECTIVE

This method of statement covers the Installation of Fiber Optic Cable Laying, Optical Fiber Splicing & Testing

for Ooredoo Customers.

SCOPE

To ensure that the telecommunications, conduits and cable works Including inspections and testing

activities are carried out in accordance with the project specifications and manufacturer's instruction as

well as meet acceptable workmanship and installation standard

5. REFERENCE DOCUMENTS

* Contract Documents

© Available Layout Drawings

* Project Specification

6. GENERAL

This document details the test plans and acceptance criteria for procedures to be carried out before and

after installation of the cable to verify that:

Hf

METHOD STATEMENT FOR] Doc No: BG/MS/CM/01/08/20

BARD Group FIBER OPTIC CABLE | Date:24/08/2020 ; Rev:00

vers Cop WORK

The Fiber Optic Cable exhibits no abnormal light blocking, scattering or reflective event (cracks,

fiber separations or excessive micro-bending) that might have occurred during transporting or

installation

Total Line Loss measurement meets project design specifications

All Cable splicing and testing shall be performed after necessary notification from Ooredoo

7. RESPONSIBILITY

The primary responsibility of carrying out all the activities mentioned in this method statement

rests with the Project Engineer unless mentioned otherwise.

Project Engineer directly supervises Site Supervisors. He is responsible to ensure that all correct

procedures have been followed and all necessary permits for the works are obtained in advance.

A full time Supervisor shall be available at site when the work is in progress and is accountable

for the work progress including safety aspects.

Project Manager ~- shall be responsible for the overall implementation of this procedure,

coordination with vendor / sub-Contractor, supply the drawing and materials necessary to ensure

efficient execution of works in accordance with the project specification,

8. LAYING OF Foc.

+ Manufacturer's instructions for installation have to be followed up.

+ Loading of cable drum has to be done by using suitable crane. There after itis transported by

means of cable trailer/jack. The access up to the trench should be checked before

transportation

‘+ Location of cable drum should be planned before transportation of cable drum. (Practically

could differ at one or two places for easy installation of cable).

‘+ The cable drums shall be inspected for mechanical or physical damages and check the

cables to be used at site prior to the start of the installation process. Any sort of damage shall

be noted in the damage report.

+ Nylon ropes shall be pulled inside the HDPE pipes using duct cy

‘+ The pipes shalll be checked for straightness before filling the dur

4

b

METHOD STATEMENT FOR] Doc No: BG/MS/CM/01/08/20

BARQ Group FIBER OPTIC CABLE _| Date:24/08/2020 ; Rev:00

ww Sra WORK

Fiber Optic cable drum shall be kept at the middle of the span (ie. equidistant from both the

terminals) and cables shall be pulled towards one end manually inside the HDPE pipes using

the Nylon ropes.

The backfilled trenches are excavated at intervals of every 300m and also at each bend to

act as Fiber Optic cable pulling draw pits.

Once the cable reaches the terminal end, the remaining cable in the drum shall be looped

‘and coiled in the form of “8° 11. After looping the remaining cables in the drum, pulling of the

Fiber optic cable inside the HDPE ducts, as before shall be carried out towards the other

terminal end.

After pulling of all the Fiber Optic cables, the draw pits are backfilled according to the

backfiling procedure

The final survey shall be conducted for the additional details and information needed to

prepare the as built drawings.

Cable pulling shall be done under strict supervision during the entire period of operation.

Safety noms shall be observed and shall stick to the standard requirements of Ooredoo.

9. FIBER OPTIC CABLE SPLICING PROCEDURE.

* Care must be taken to see that there is no dust, coating material or cable fill compound in

the cable.

+ The cable to be cut to the required length and outside insulation removed.

+ Strip the cable using the stripper. It should be ensured that multiple passes with stripping

tool is not done, which may cause damage to the cable.

* After stripping, debris should be cleaned off the fiber using an alcohol wipe. This wipe

should be replaced with fresh wiper after each use.

‘+ Cleave the cable to get perpendicular ends. The cleaver should be cleaned and there

should be no stray pieces of fiber left in the cable.

+ After cleaving, the fiber end should not be wiped again. This coul

end face of the fiber, which can cause problem with splicing,

| METHOD STATEMENT FOR Doc No: BG/MS/CM/01/08/20

kl A BARD Group FIBER OPTIC CABLE —_ Date:24/08/2020 ; Rev:00

oars CHL WORK

* Put the sleeve before placing the cable in the splicing machine. - Place the ends of the

cable in the splicing machine and splice it. Note down the Theoretical splice loss for each

fiber.

+ Ifany metallic member is used as strength member, it must be grounded to main

Grounding Grid as per manufacture's recommendations.

* Secure the cable in an optical fiber splicer organizer + Bond and ground all metallic.

members of the cable. The measured ground resistance shall be 25 ohms or less.

* To prevent fiber damage handle buffer tubes and fibers carefully, when bending and

placing in the organizer.

+ While Working at Junction Box barricade shall be Installed using Tarpaulin an a table to

accommodate OTDR to ensure safety of bare Fiber Optic Cable during splicing as

practicable.

10. INSPECTION & TESTING

This test will be conducted prior to receipt of the cable from the lay-down yard. This includes

visual inspection of the cable and test using an Optical Time Domain Reflectometer(OTDR) to

check that the fiber optic cable exhibits no abnormal light blocking, scattering or reflective events

that have been induced during transportation.

Before commencing the work, whole site shall be inspected according to the pre-installation

procedure mentioned below to ensure that there are no obstructions to the work.

In accordance with the Project Specifications and Quality requirements applicable, inspection

and testing shall be conducted on installations. On satisfactory completion of the inspection by

the Client, clearance shall be obtained for the next activity,

Visual Inspection is to verify that the cable sustained no damage during shipment and to verify

that the number of fibers and their color coding complies with the contractual specifications. An

evaluation of the quality of cable spooiing onto the delivery drums and their visual appearance

shall be conducted. Cable Specifications shall be verified against the Map ers’ Cable Test

ie

Sor

Report supplied with each reel of cable.

All cables shall be inspected to verify fiber counts, fiber coding, spg

Cable marking shall be checked against the Manufacturers’ Cable|

| METHOD STATEMENT FOR) Doc No: BG/MS/CM/01/08/20 —

aT BARO Group, FIBER OPTIC CABLE —_Date:24/08/2020 ; Rev:00 |

wos CHL WORK

* Fiber count and coding shall be as specified on the Manufacturer supplied Cable Test Report.

The cables shall be coiled onto the delivery drum in even layers, allowing final packaging to

prevent the cables from uncoiling and the layers on the drum tangling during transport. Visual

inspection shall confirm that there is no physical damage to the cable drum and cable

+ OTDR testis to verify that the cable sustained no damage during shipment. This test will be

conducted prior to transport of the cable to the work site. Before conducting this test, a visual

inspection will be performed to ensure that there is no physical damage to the cable reel.

10.4 Testing Procedure

+ All fibers on the cable reel are to be tested by means of an OTDR & Light Source Power

Meter

+ Remove a sufficient portion of the cable sheath and clean it for testing,

‘+ Strip and cleave the fiber.

* Connect the pigtail to the OTDR.

* Connect the bare fiber to the pigtail

an Elastomeric Splice or bare fiber adapter.

+ Run the OTDR test to check for abnormalities and to measure the cable length, total loss

and average loss per kilometer. No peak discontinuities above 0.1 dB at 1560 nm and

1310 nm)

+ OTDR data will be recorded on a CD for evaluation and printout using @ PC with the

OTDR manufacturer's software.

+ Repeat the above steps for each fiber.

‘+ The cable will be kept ready for installation if there is no discrepancy during the reel test.

+The cable will be re-sealed after the completion of the test

+ Coredoo Approved and certified technician and splicer will do and conduct cable splicing

and testing

11, SAFETY AND RISK MANAGEMENT

The contractor will be responsible for all necessary safety measures at orks will be

executed in accordance with the project health and safety plan

| METHOD STATEMENT FOR) Doc No: BG/MS/CM/01/08/20

by BARO Group. FIBER OPTIC CABLE Date:24/08/2020 ;

ens Cy WORK

gev:00

Safety induction will be conducted at site before the start of the job activities to make all the personnel

associated be aware about the necessary safety precautions.

Following risk management is performed in general:

‘+ The tools used are suitable and safe to use.

+ Supervisor shall be present at work site throughout the execution of the work.

* Safety hamesses are being used by personnel working on high-elevated platform.

+ Precautionary warning signs for this type of work place are visibly kept in place.

+ Supervisor or Foreman in charge shall ensure the proper equipment for lifting are available with

valid test certificates.

+ Equipment such as the overhead crane and forklift shall be used with a rate capacity suitable to

‘weight of the load to be lifted.

* Supervisor or Foreman in charge shall ensure the proper equipment for lifting is available with

valid test certificates.

* All personne! handling the heavy equipment's and associated accessories shall be provided with

proper type of gloves.

‘+ The safety officer shall report any untoward incident and stop any unsafe activity

‘+The safety officer shall inform the site engineer and the project manager of any violation against

HSE and report to the HSE manager.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Competency Awareness & Training ProcedureDocument3 pagesCompetency Awareness & Training ProcedureYousaf Richu100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDocument8 pagesInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu75% (4)

- BG-TM-FRM-04-13 IrarDocument9 pagesBG-TM-FRM-04-13 IrarYousaf RichuNo ratings yet

- BCG-TM-PRO-16-13 Transport SafetyDocument4 pagesBCG-TM-PRO-16-13 Transport SafetyYousaf RichuNo ratings yet

- BG-TM-FRM-05 Significant Risk RegisterDocument3 pagesBG-TM-FRM-05 Significant Risk RegisterYousaf RichuNo ratings yet

- BCG-TM-PRO-12-13 CAPA ProcedureDocument2 pagesBCG-TM-PRO-12-13 CAPA ProcedureYousaf RichuNo ratings yet

- BCG-TM-PRO-13-13 HSE Performance & Calibration ProcedureDocument2 pagesBCG-TM-PRO-13-13 HSE Performance & Calibration ProcedureYousaf RichuNo ratings yet

- Identification of Legal and Compliance ProcedureDocument2 pagesIdentification of Legal and Compliance ProcedureYousaf RichuNo ratings yet

- BCG-TM-PRO-08-13 Waste Management ProcedureDocument1 pageBCG-TM-PRO-08-13 Waste Management ProcedureYousaf RichuNo ratings yet

- BG-QA-CL-308-14 Check List.R3.Final - Modern.090214Document3 pagesBG-QA-CL-308-14 Check List.R3.Final - Modern.090214Yousaf RichuNo ratings yet

- Name: Transport Safety: Traffic RoutesDocument4 pagesName: Transport Safety: Traffic RoutesYousaf RichuNo ratings yet

- 3 BG-QA-FRM-03-13 Maintenance Machine HistroryDocument4 pages3 BG-QA-FRM-03-13 Maintenance Machine HistroryYousaf RichuNo ratings yet

- 15 5.6 4.6 MGMT Review ProcDocument2 pages15 5.6 4.6 MGMT Review ProcYousaf RichuNo ratings yet

- 3 W.O/Issue No.: CWC No.: Designation Signature Date Send Date RecDocument1 page3 W.O/Issue No.: CWC No.: Designation Signature Date Send Date RecYousaf RichuNo ratings yet

- Inspection Report BG/QA/FRM-04/13 Rev:00: (Clients/Consultants) Project ManagerDocument1 pageInspection Report BG/QA/FRM-04/13 Rev:00: (Clients/Consultants) Project ManagerYousaf RichuNo ratings yet

- Hse Monthly Performance Report 14-15Document132 pagesHse Monthly Performance Report 14-15Yousaf Richu100% (4)

- Cleaning ServiceDocument94 pagesCleaning ServiceYousaf RichuNo ratings yet

- BG-HR-FRM-12-14 Leave Request Form NEW-R-03Document3 pagesBG-HR-FRM-12-14 Leave Request Form NEW-R-03Yousaf RichuNo ratings yet

- Permit To Work v3.3: Method Statement - Compressed - PDF Risk Assessment - PDF WO-65598-3 PDFDocument1 pagePermit To Work v3.3: Method Statement - Compressed - PDF Risk Assessment - PDF WO-65598-3 PDFYousaf RichuNo ratings yet

- BS104 BS107 BS111 BS132 BS142 BS143 BS145 BS147 BS157 BS163 BS167 BS169Document18 pagesBS104 BS107 BS111 BS132 BS142 BS143 BS145 BS147 BS157 BS163 BS167 BS169Yousaf RichuNo ratings yet

- BCG-TM-FRM-43-17-A Barq Induction Attendence & Recard SheetDocument2 pagesBCG-TM-FRM-43-17-A Barq Induction Attendence & Recard SheetYousaf RichuNo ratings yet