Professional Documents

Culture Documents

ASTM A 513-00 Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

ASTM A 513-00 Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

Uploaded by

cancery07070 ratings0% found this document useful (0 votes)

67 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

67 views8 pagesASTM A 513-00 Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

ASTM A 513-00 Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

Uploaded by

cancery0707Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

My Designation: A 518-00

Standard Specification for

Electric-Resistance-Welded Carbon and Alloy Steel

Mechanical Tubing’

1. Soope

Lis spelen

on cov tb rata ee ae

bot ays bg oe mec ng

2 Tis pcan oes ch hing ofan

|hot- oF cokl-tolled steel wee

1 "hsp cor ed sar, cng a

special shape tubing, a

imisen

1 Option agent ice ied and

ten lcs os re

13 The au sted nich rnd ats oo be ep

as the standard. ws

2: Referenced Documents

21 ASTM Sdn

1570s Moca Dsitons or Mehl Testing

ct Sel

#18 Pat fo Sampling Stl an on for Deter

and Tubing* one a

2773 Pres Uso Examination of Longa

‘Welded Pipe and Tubing* “Tessin

1309 Prete fo bly Caren amin of Se Te

‘elr Prot Une Nap Saran

B90 Pct fr Px eugene of eon

nei Stel Tubular Prehcst

22 ANS Stans

B46. Surace Tenure!

23. Miliary Sandan

IMIL-STD-129 Masking for Shipment and Storage!

MIL-STD.163 Stal Mill Products Pepin for Ship.

en and Storage

24 Federal Standard

Fad. S.No. 123 Making for Shipments (Civil Agencies)?

Ordering

5.1 Orde: for miteal under thie spesifcton shoud

inal he following tel aden ee the

312 Rome ot ee eS ans

EI pe dn de eters, (ston 1 and

3.14 Thermal condi, (12,

313 Ps condon, (123,

3:9 Rap ch a Soe a,

seque (Seton ad),

(een eens rene reid

sag CO oo eer a

tine (wel) sued etn

Siena wal ns coca ree es

911 and 9.2) aamname

31111 Swrce tai (11.2

235112 Length, ond, mil ents or define cat eng (ose

53), squce and rectangular, sped length (ee 9)

2.1.18 Squuenes of it ound tubing, freed (ce

a vd tubing, frog,

nformation

By nst0-00

3.1.14 Burs removed if quired ee 11),

SULAS Protective cong (se 14.0,

31.16 Spvil packaging (se 17-1,

3.117 specication designation,

3.418 End ae,

3.1.19 Special rauitemens,

3.120 Special marking (Seton 16) snd

SILK Staighines Test Method (so 8 apd 96),

4, Matera aad Manaticture

41 The soe may be made by any process.

142 Ifa spect tye of malig is required by the purchases,

isha be a sited on the porcase ore

13 The primary mcking may incorporate separa deg

sing or telning, ad tay be flowed by secondary meling,

fick as clei or taenunrate semiing. If seeoodary

tockng is employed the eat sll be defied as all of the

egos remele fon single primary RE

“LA Stes my be cat nme may be stand east. When

scl of diferent grades i sequentially trad ens, enti

tio of the rant anson maeral is required The

procera emove de taston atrial hy an estbshed

[roc ta positvely sears the rales

“fT shall be made by the elec esistance-welded

process aed hal be sade tom hot o coldvoled ste as

‘pected

‘5.1 The see shall conform 10 the requirements 35 10

chemical conpostion presario in Tables 1 apd 2 fo grade

i speetied, Grades MT 1010 to MT 1020 maybe furl

‘Auagses of steels other tun those Usted are avalible. To

decomine ti aval, the puchasor should! comact the

produce

5.2 When a eso sel grade i ordered ner tis pe

fection, spoing an alloy grade ht specially requires the

iin of any element her tha hoe listed fe he ordered

trade a Tables Tae 2 not peril

sora eee

Coen sent mes Pt mals ect

eae Gem wimp MNS BUM

Tempo nyasismx rage cepepste es macnn

6, Heat Analysis

61. An nays ofeach buat of sel shall be made bythe

sect emnafacturer to detrmine the percatges ef the le

Toons specied: if secondary sting grosses ne employed

{Be ea anayss sul be cae from one ered ingot ce

{Be pret of one remeled got of cach primary mel The

teat analysis sal comform to the requirement specified,

Cheep hat whee the eat deity aso been mained oF

Sher the analysis not stfenty complete to pent

Trevoomance to be determine, the chemical composition

‘Soermined fom’ prodct analysis made by the ‘ubylat

Imumfacatr sll cforms othe requiemes spect for

at alg When request the ondr or const a ep.

1 soch ins shal be frist Tote purchase.

7. Product Analysis

“7.1 When request om the purchase rds product analy

sis shal be mae By the sopler. The numer and source of

anples for sch Bot tals shall be fase on the

{evil heat o tent f ne ofthe following forms of

‘mae

“LL Heat Identity Manained—One procs analysis po

heat sl be made o iter the asad tock o be,

4.12 Heat hdenty Not Maintined—A prod fom ons

tube pe 2000 (610m) lee for sas over 3. (6.2m

fn one tube per 500 (150) 9 eas fr ies 3 in

7 Snes fox pis i xe pecs

mpeniton has deerme sal caespond to te reei=

‘nent of Tables 1

73 If he engin te for prot analysis alls rete of

‘vo abtiool lengths of laos tock or tabs shall be

Inte Both tests forth lemtnts in questo shall moe the

Feaiements ofthe speciation; otherwise, all emining

Tria inte eat or Yor al Beret, ate option af

the proce, each length of atoll stock or tbe may be

{nsdually tested for acceptance, Leni of Datroled stock

‘tues hich not mest the roiement of the specifica

thon sa be eect

Permissible Variations io Dimensions for Round

thing

81 Diameter and Woll Thickness (Hor Rolled, Stel) —

Viton rom weed oui dhanee for"as- welded” and

s-welded and sonalod” bing made fom hotrod set

‘fal not exced the mount pressed in Table 4, Permisble

‘asians i oobi diameter for tubing that has bee snk

Urswn for closer tolerance on cate ameter re shown in

Table 5, Pennisi vations i wal cikes or bing ha

{hs bea sink-drawe fr closer trance on otside aneters

tne. 210% of the nomial wall of “0010 in. (0.25 nim)

Wthichever is greater, Permisible varatons in wal tikes

{or bing made fos hotles sta are shown in Tale 6

‘Pernisibievarnon in outside and inside ameter fr bing

fade rom hovrolled sel tht bas ban me dawn fee

ose tlraecy are shown in Table with wall tokraces

Shown in Tle 7.

: Qy asis-00 |

TABLE? Chemica! Roques fr Oto Carbon ani oy Stale

Qy Asis-00

TABLE Olamote Tolerances for Type (AMR) Roun Tabi

a—evrevreoverr aaa i

: sae as oe Fea BOE SS RAS jst Sas ee

: TADLES Tomes te Pout ar Bu Sows havnt en fn Tale Wl thoes ane tw | Bees eS Ss sm ie

$m i ______aswelded” tubing made from coldcotled steel are shovn i Ove 5108, et 200800 ‘0204 0800 0 oe ame 288

TERS Theo Aimche wtm in mal unas ie mead | geeces a ma oS ee

— purr ‘be. made ds fr clo ees a sen | SESS spy gibt S 33 so

eaten The. Pemistievatatesinwalteknes erage | Sores ce 1. ERS 2 = & i

weg ts en aid esr tne ote de

can eee S= SiO of th minal wall’ 20000 225 oa eg agente sm ge pas aa

ser aiel 40 ne ‘whichever i greater. hed iaasaa Pod soe = eae

E gee Bae 83 Lenguh (ot ad Cold Rolled Stet)—Mechicl wh- 8h, kates a. So ea =

. wie tient ing conmony thelial 1S manor

foene mT Definite cut lens ae finshed when sposited ty. the ww ed we tas oo awe

si Durchasr Termes for dette catlngts eon wbiagabal | S86 ie eee ae nae ae to

: a ec eve os 1 and Seite osc S is Gs is

sen Sia 84 Squarenes of Cu Hot and Cold Rolled Stel)—Whea | See BETLEL inane __ sata =

: me ggieemee SS sete le agatha 250 cana un temas vena

sein TEES SE eetmmnbe lt Meammnccsaemuswineccea | aceumacarestat

cisiboans ih _i8_ “Tue mvletreee Ss ipafspar teat, | “Cacti mamaria mare ans ama nonna ne haertnnes

_—- SEERSERN Lr marnancian sas twedameer cep mmm gh of fim C54 mm ant | “Eaemeticts meee teatime saesracemngason =) oor Seen newt hares

‘toe anc bain pale ange “reece maximum length of, (1016 man), Outside dameter bur to sesjme unes es i ram aint enc ah hn eat vera,

: Theta Ceca nen am eemtmmnaenn Bommel tn 1. ect eda ane er a gata Sina ea ea TS

. 85 Sache The seganen wns tor rans | See ooo

32 Diameter and ll Tin (Codd Sed ings 600 NTS Me aw heOD In AD. | A ewan eon tt me ena n sensu eo

: Yatton in gusde Sane an ie er af" th eid ats er 8000 de hes

(RoR SL iewele ed ate” bie ode tom above, aighines leans OD a (52 mam) | to fr stags mene ti mnaio's 46 Ova (a and Cll See} Th oy sa

alii tel amin Tile. Outer legs For og de | the sihes tence sal | tponmeracpeictmenool peeked tees bese end Coll ee) Te ory sal

: tle ool cel wig ink de so aie) Wrage up vere Reta ea eee ce | thar3 oft san dane

TABLES ameter Torneo or Type 3,45, and (SHR,

‘SOC, WO and 9310) Round Teng

costorane] Nabe | Rind ae

er eat ee Snes em nas

"Sine par Tipps bi ace rt end

861 such cates for Types I and 2 AWALR. and

AMR) the ovlty may be 30 5 grr tha the tice

‘olerances bot the man outs diameter stall be within the

Specie eras

862 For Types 3, 6 5, and 6 (SDA, SCR, MD,

tnd SSD, the anal ovlityshll be follows ths

mean oot dlameer shall be within the spied alerance

yA 513-00

ti ati soe nnn

9. Permbsible Variations fn Dimensions of Square and

[Rectangular Tung

9 Diameter and Will Thickners—Pensieble vations

in outside dimensions for square aad ectangula ating sll

teas given in Table 13, The wall hiknes eran 10%

ft nmin wall hicks

9.2 Comer Radi Untes otherwise specifi, the cers

of square and rectangular tubing shal be shih romded

Inside aod outside, consent with wll thickness The otic

comers may be sighs teed The radi of cornet sl bs

28 sven in Tole 14

83 Squareness- Permissible vations for squares shall

be dacrmine by the flowing equation

2b oetance for oat of squats and

= linet extemal dimension actoss ts

‘The squareess of here commun dleined by cn of

he ftlowing meth,

3.1 A.square wil wo adjustable contact pins on ech

su is placed on wo ies, A aed feces gage then

ease the makimum dstnce between the ce conta! poi

fd the sare ofthe bing

1932 Asie equiped with dec dng vetnet,may

reused o determine he angola devistion which a acy

be vlad to ditance in ince

944 Legth—Variaions fom the specified length sal wot

‘exced the amount prescribed in Tae 15

‘9.5 Twst—TWsttolernes ie shown in Table 16. The

twist io square and rectangle tubiny may be mest by

Inkling oo ene the ing rface plate a oti the

[sight of ether comer of te opposite ed of sn side ove

the vue plate. Twist may alo be mesure by te se Of

beveled pracioc equipped wih a level sed noting the

angular deviation on oposite ads, ort any pt thoughout

the length

‘96 Siraighineso— The salghines tolerance Is An in

(1.7 mmm. The te meth for signe ase nets

(ANWAR) Rou Ting

Ay A 513-00

TABLE Wall Tctnes Totrances of Types 6 an 8. and

Elo) noua ing

the mamsfictrer'seption, unless a speific fest ato is

‘pesitod ia the purchase once,

10. Tubing Sections Osher Than Square and Rectangular

10. Th addin to square ad rectangular tubing, tay

produce supply vst af special soto, riche ova

Scaled hexagonal ocapo rtd inside texan

for oetagoal cus, ribbed side oa, ang, roa

rectnglar and D stages. Manafscturing practices iat the

‘Sze range and section avlable from the various praducers

‘These special ctons may te made throgh asc aloe

Groups die with oe wathot ve of « mandel Since the

section ar speci, des and wer tools ae not eld valle

‘Therefore, wea inguin for shapes oer than sguare nd

reclngla, Is esential opie fal Stil 8 f denon,

nd ih

1, Workmansi

Fn, and Appearance

11 The tubing sal be fee of injrous defects and shall

ave work i fish,

112 Unless otherwise spied inthe purchase ond, the

tubing shal te re of scl In te ate thermal tated

ning slight amount of cola will me considered ae for

113 When burs must be removed frm ae or bt nds, it

shal be speed inthe purchase ale

12. Condon

1.1 The types and conditions of tobing covered by this

specication are

12.2 Thermal conons uber which tubing may be

ished ste: 0 fn thenmal tetent ses relieved, sa

{neal or aonmatied

123 Mash conditions under which ang inay e rise

‘ae a follows. Th Hath sll he removed fcr the olsioe

lamer of thing covered by thie spacieaton Taking

famishod to is speciation may have the following end

‘is of welding Mash onthe inside date

123.1 Flas-in—Tobing ia which the inside diameter Wek

ing Mlash doc ot exceed he wall icknes or s(t),

Ihichovr i less. This contion i avaable in Types 2. 3

tod 4

12.32 Flash Contoled to 2010 (0.25 mony maximum —

TUbing in which he hei of he remsiing welding Ash ie

tole 50 as nt to ekcoot 0.010 in, This conto is

fallble in Types 1 and 9 over tin, (285mm) ouside

‘tamer aod yes 3 a 3

12.33 Flask Contd 0005 in, (0.13 mon. meine

“Tubing eoduced to outside diameter td wal thickness side

ameter ad wall thickness or outside damster an! ide

‘ances tolerices which ae so contol thatthe height of

the emining inside diameter a dos ot exes 085

‘Any remaining inside diameter leh i par of the ape

Inside dismeter tolerance. This condition i valle n Types

12,3,and4

1234 No lash tubing free prcesed for coset tle

tsances with mandrel sbing produced io ous dare a

‘all thickness, inside ameter and wall ihnes,o ote

Siamese and inside date fo tolerances with no dimensional

indian of inside dees. This condition is avaiable

in-Types 5 and 6

124 Tes shal be frmishe inthe following shapes as

secitied by the purchaser: rend, square, sean, oF

special shapes (as gota)

13, Surface Finish

12.1 Tubes shall hve surface finish compatible wih the

‘onions (Seeton 1) fo which they ae ert (see Ape

ax Xt}.

14, Coating

4.1 When specie, tubing shal be costed with 2 Am of

‘il before shipping to ean ase Shou the ode pity tat

Tubing be shipped without mst raring oi he fin of ele

@y asis—o0

TABLES ameter Tleraoee for Type 2(AW.CR) Round Ting

Ve

""Efan Comets 230m mans ting cn ef ng ne ees dm a commen ped se et enn

"Sh eaaiog tosh musmentson ret woe tines utc os roe Seen nd oe

"hoc wasn eso

fonder species o il te presse asumes responsiblity for

142 Special sce preparations as may be gute for

specie applications are twin te scope oft scion,

Sich regent stall be considered ender the spleen.

tary or fof pchate provision of thir epetenton nd

‘denis sh be povied inthe prcase det,

15, Reietion

1S Tubes tht full to mest the requirements of this

spccleton stall be set sede and the produce shu be

ed

16, Product and Package Marking

shall eed by «tan of Senet with mance tame

:

i

ABLE 9_Wall Thine Tlwanon for Type 2 (AWE) Round Ting

TABLE Lang Tolan Pn Sr or De at

“ABLE 12 Tolerance ine for Squares ot Ct (er Ed)

‘hen Species for Rouna ubng™

or brn, specif sz, type, purchaser's order number, and

this qeitenton number Bar coding i accepale 8 1

fopplementay isifetion method. Barcoding should be

Coistn! withthe Aone Industry Acton Group [AIAG]

Stanare prepa by the Primary Meas Subcom of he

AIAG Bar Coe Projet Tea,

2. Goverament Procurrment Wen specie ia te con

seek oroner nd fo et procurerent by o dic sbprnent

to the Government making for tigers, aldston to

Featiements speed in the conrct or ore, sll be in

cordance wth RIL-STD-129 for Miry agencies and in

fcordanee wt Fd Su No, 123 foe cv gence.

Ti Bar Coding addon tothe rogirerents in 16.1

and 162, tar ealing i seseptale asa soppemental ent

Cation method. The purchaser may spenty i the oer =

‘Speci bar coding sytem to be wed

17 Pacagig

174 Chin Procrsmont Oo wing 16 gage (.29 ma)

aod lighter, the proder sil delemaie whther of not the

febing wil be boxed, ered, cstoned, packaged in secured

Tits or bundled to ensue safe dliery unless otherwise

imtacted, Tubing heater han 16 gago will oxmally be

‘Sippel lose, bundled, orn secured its, Spec packaging

@y nsis—o0

"TABLES Tees Ouse Dinas Sar ad

rearing ex perstions other than those normally wed by 8

Proce sur be apsied om the xd

Square ana Rectangle Tubing”

ama eaege tae varteeesn fae

enon “Giada tamara wot ponorsos tae a

112. Government Procurement—When species in the

contct or ore, fr dst prosumer by dict

Shipmeat to the Governmest when Level A ie specifiod,

ppeseaton,pockaping. an packing sal o i accordance

tit he Level A reqitement of MIL-STD16%

|

AQy Asta~00

[ABLE 18 Length Tohanees—Souere and Racing Ting

18. Keywords

alloy set tbe: carbon sel tute; mechanical big

resistance welded steel be: scl he; welded tel he

‘Square and Rectangulaechenial Tubing

SUPPLEMENTARY REQUIREMENTS

Definitions A370,

SL. Tubes for Cylinders

1. Round ubig, nae drawn freind poiations

wid inside diameter camp allowances te considered 10 be

lines tubing Taba i-1 shows the mim ine dm

ter allowance for removal of ede sures imperfestios by

honing operation.

2. Cleanup hy Centerles Grinding

2.1 Round thing, mandel dean for applications with

side dameterallowances considered ote special sh

atid sac aig Table $2.1 shows the minima side

Sianeter stock allowance for removal of oui sven

impetecons by comers ging

‘8. Cleanup by Machining

3.1 Cleanup is permite om ound ting andl down

forapplcaoas where machining x ese emo sae

Imperfections. Tale 93.1 shows the msi sock silowance

for removal of surface imperfecta fm either or boa the

tse and inside surfaces by nokia

Sport fanaa Seeineretons by Honing

‘Darter or Rove af Ouse Srace imparts oy

‘enarnoe Gansing One Orewn haa

(@) asis—o0

Sune (pes Smoot nace ameter Rag)

ohning iene Deven Tso

4. Special Smooth Inside Surface

SA. Round wbing, special smoot inside diameter for

cinder applietons with coin fish apd ise lamer

‘eanup allowances considered tobe special sco inside

Serle tobig Table S61 shows the maximam averege

‘crinch readings om ho inside sic. Table S82 shows the

‘imum wall depth allowance fori sage impertoo

'. Hardness and Tensile Requirements

5.1 When hadness properties are apitied on the order

round tubing al coform nthe hardness specie sn

‘ible SSL anes “Tensile Properties Regie” especie in

the purcase onke. When "Tense Properties Reywie” it

TABLE S42 Abowance sures ingeteone on iniso

‘haters of Spec! Snooth Fen

‘Rotem requitement and ot ocean the hardness

show in Table $5.1 Tor grades of ound tubing ao shown in

tres tsa be ups apresmen betwen the nce

fore am the parchaser

5.7 Number of tee snd retest sal be a follows: ne

terion tet perfor sal be made (Note S1) and 1 ofa abs

per lt tat into case fess than 5 bes thal be teed for

Frednes I the eu ofthe mechanical texts doa conf

fothereiements sown in th bl, tse sale ade or

ditional tubes doube the original narber selected, each of

Sich sal conform othe pei eiemens,

‘tee nat weg jee wih me ang eos

853 The yield strength comesponding oa permanent set

of 0.2% ofthe gage length of the specimen or 1 8 teal

txenson of 05 0 the gage length ander load. shal be

‘diernined

$6. Round tubing and bing © be formed into ote

shapes when in the souad fort shall met th following

‘$62 Platting Text tes to in (101.610 1524)

in ength sll be facenedtwoen parallel leet wih the

.

Mp as13-00

‘wel 90° from the detion of applied force at he pint of

‘maximum bending) ant opposite walle the thing mc.

Eept as allowed in $621, no opening in the wel ball ake

place util de distge hetwecn the ples lest than Ivo

‘hi ofthe eign ease dame F te ting. No cracks

for breaks inthe base mill shall occ onl the distance

bese the pnt ls than one hid of he vigil tise

dame f the toing, Bain no cas Tes thn five times the

Iheknes of the ting wal. Evidence of amnion or burst

mate stl to develop daring the Ratening pres, the

S63 Flaring Test section of tube sponte 4 in

(401.mm) inlet shal stad eng Hart wth a ol ving

160" included ange uni he be at he mouth he ae as

been expanded 15 ofthe Inside dante, witha encking

or showing flaws

‘S64 Inder prope eval weld quiy the penser

this pon may noemalize thes spsimen pie tng

865 Nomber of tests and ets: two Atening ed e80

Aang tents shal be mai from cach fot (Note 1,

(Gy As13-00

‘eld shall not show injrour dees,

‘S621 When low Dito ao foing is tested, becuse the

sxaia imped dae to geometry is unreseonaly igh onthe

inside src tthe si an ele o'clock oct, cack st

these locate sal note cae for ejston the Do ais

TABLE SE Moanats Lint nd Teo Proper or Rnd Ting

Never ngs eye wth tpg ton sale a, 24) a adn of ecg pot om ee

song aces 08 a esate

Som (4a) m

He a fi

one one een H I

ia 3a3 ints : iH

& 23 aco :

i aio aa z

= ae St &

ise oon men ©

‘8. Hydrostatic Test Round Tubing

S71 All ahing willbe givens bysotti ts clcalated as

follows

pares

where

Pe hydronic tes rss pst oe MPa

5 = allowable ber rest of {8.000 pe or 965 MPa,

2 spec wal thickness, nm, an

> = specie cutie dames ot min

‘St, Nondestructive Electric Test

‘ELE Each ube shale ested with unondesrctive elec

tertin scondane wth Practice £213, Practice £773, Petco

500, or Pracice F570. Ts the itent ofthis test eject

‘uhos contin injsous defects

‘SE2 For eily-citet txting, the cairn the shall

oma atthe opdan a he produce, anyone of he Following

‘Gsconinaes to estash a nimum sensitivity eel or

‘ejection, Fr welded tubing they sll be placed inthe weld

it vibe

S821 Dad Hole—A ole not lager han 0031 in, (0:73

sm} ia damcter shall be dled radilly and completely

Through tho tube wall cre being thon to vad distrtion ct

the tbe while diling

'S8.22 Transverse Tangent! NotchUsing around oo

file wih «Vein (Scum) diameter, «noth sll be filed ot

riled angel tote surface ad anverse tthe Logi

final ani of he tubs. Said noch shal have 4 dep Dot

encoding 1214 f the spect wal hckness ofthe rbe oe

(0.06 in (0102 mam), whichever ares

‘88.2.3 Longin Nock A ote (1031 (0.79)

‘es in width shal be machined ins radial plane paral othe

tube ani onthsoutdesrface of the te to be depth not

crceeding 1235 ofthe spot wal hicknse of tht ot

(0.004 n (0102 ma, whichver ie grester. The length of the

etch shall be compatibie with the ting metho,

‘8.3 For wlsni testing, the logit ealiation ee

erence noche sal be at the open ofthe race any one

of he the common notch shapes shown in Practice E213 or

Practice E273 Te depth of meh shall a exceed 1216 af

the specified wall thickness of the tobe or OM in (0.102

mmm, whichever is pester Foe welded ubing the ath ball

be placed in the wed if visible

‘St For ux leakage testing, each of the longitainal

cabation niches shal ea aight sided noth nt oer 125

ofthe wall tikes in depth and not over LO 25 cm)

in length. Both ouside diameter and inside ameter nts

thal be plaod inthe tbe lossed suc spat fo enable

Seperation and deteton ofthe gal

S85 Tohingprosacng signal equal to o greater dan the

calbation defect shall be sbjet 1 rejection. The aes

prodcing the signal maybe esting

‘S851 Tet signals produced by imperfections which cant

‘eden, or produce by craks o eraktike dees cal

rest in rjecton of thee subject rework at test.

|

@y a sis—o0

$835.2 Test signe proce by impertetons sch those

Hise fetow eaky te judged 3% injurious oF moniqioe,

spending on vital cession oftheir see or he typeof

sig they pede om the esting equips! use bs

S652 1 Dinges

‘$8522 Suaighiener mans,

86523 Loos inside diameter bead and cating chips,

StS24 Soruces,

88525 Stet de amps,

885.206 Chater fash im,

‘8852.7 Sup marks, or

4528 Tue rect ripple

835.3 Any imperfection othe above type excreting 1.008

in, (0.102 em) or 1244 of the spected wall theres

(whichever spent) in dee sl be conde injure

‘65.3.1 Ith impeseson i judged as injuroay, the ex

Shall be reese but may te recondoned ond este

Providing the dimensional reements ae met

85.3.2 I he imperfection is explored ote extol hat it

an be identified as ninjas, the toe ay be aoe

‘witht further test providing the inperecn doesnot

each onthe sium wall ike afer due sllowance for

‘leanup in andre dri tubes.

89, Certieation for Goveroment Orders

S91 A producer's ce syppir'sceticaton shal be fr

shed othe Govemment th the mati was auld

Sampled, tte, and inspect in accontnce within

eatin and has bees found to moe the retements This

‘acte shall include a report of hea anys (grout

analysis when requested inthe purchase avd) and wht

spected inthe purchase order o contac, ep of tet

els sal be arise

S10, Refetion Provisions for Government Orders

10,1 Each loth of bing recived er he manutictrer

may he ispcted bythe parca ad ft does meet ie

‘egiements ofthe spacteation bed the isp and

fest method as outlined in the specication, the tbe my bs

rejected andthe manuticer sl beniod.Dispxiogs of

‘ejected bing abl be a mater of apremeat hetwoen the

‘marafurr ind the prctase

$10.2 Material ht sin ny of he fring operations or

inthe process of insaliton ani fxad to be defetve ll

test aside andthe manacter sal enoiied for mil

ahutioa of the material's sutabiliy, Disposition ot tach

ae shal fea mater for grees

APPENDIX,

(Nemmundsar Intrmaton)

Xi. MEASURING MICROINCHT FINISH

X11 The procedre for making micoinck readings on

ieror surfaces of cold worked bing (aoe polsed or

round) Yin (127mm) inside ameter nd age ite

fale:

XU Measurements on tehing with tongitainsl 0 20

Predominant lay should ‘be ‘ircunferenial on the mie

Sarfee othe tp tbe rio to ay fabrication, om plane

spproxinely perpendicular othe tse axis, Measurements

‘om bing with ciumseental ly should he longi

X12 Measurements should be made nt less than 1 a

(254mm) tom th ed

X13 Measurements shoold he te at four postions

spproximatly 80° spat or over «complete ctamfrene

the trove shoud otis over

XIL4 The length of wae sould be in acordance with the

latest eevision of Section $f ANSI Th 46.1 (ot les than

(0.600 in (1524) Ton)

XL15 A minimum of thee sich msremeats should be

made spaced no les tan 4 fm (6 an) pat long the

Tengen ans

X1.16 The numerics rang shall ie the avthnetie! ave

{886 microneh of ll readings taken. Hach teaing to be

verge told be the mean position ofthe nso ding

‘he se any momentary mete excisions ecupying et hae

105% of the toa ace shouldbe ignored

X17 A deviation n names! agin Vato pans of

tube may Be expected. Expedence to dale nieaen ht 4

Varian of abou £39 % i rma

X12 struments should mect the spelfatins given in

the lex revision of ANSI 461

X13 Mechanical using is prefered. If hand tiling is

sed, the sped of race should no vary by mote th 10 ©

from the reid to give the appropriate exo The 0.050

roughness wiih cio suid fe wea

Xie Miecoinch determinations cay tee o roughness of

teas that dono oon defect nurs oars Sock

etx as seas, slivers pits psc are subject ony

sual inspection in accordance with apcalespetctons

or trade ctor, ad have no ations to foushness

i a

(Qy as13-00

sgh sana tne Sana ely st nak cay noes woe

‘inert rea ea ney

ast nat natn fy mga emma a

sntanaa be aed Aer naa Pangaea iat a ‘sacra

sin rf NOS rey, BIOMED fin, or meer a We ay a A ee

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ER-5861 SSDA Slotted Web Beam-To-Column Steel Moment Frame ConnectionDocument6 pagesER-5861 SSDA Slotted Web Beam-To-Column Steel Moment Frame Connectioncancery0707No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- APA E315 Research Report 138 - Plywood DiaphragmsDocument59 pagesAPA E315 Research Report 138 - Plywood Diaphragmscancery0707No ratings yet

- Woodworks - 2017 Wood ConnectionsDocument59 pagesWoodworks - 2017 Wood Connectionscancery0707No ratings yet

- Long-Hand Design of A Two-Way Post-Tensioned Floor SystemDocument73 pagesLong-Hand Design of A Two-Way Post-Tensioned Floor Systemcancery070783% (6)

- A35 Testing LetterDocument1 pageA35 Testing Lettercancery0707No ratings yet

- 10-17-13 SK GOSH Webinar PT - TwoWay - Floor - SystemDocument73 pages10-17-13 SK GOSH Webinar PT - TwoWay - Floor - Systemcancery0707No ratings yet

- Cast Iron - A Historical Background (SE December 2011)Document3 pagesCast Iron - A Historical Background (SE December 2011)cancery0707No ratings yet

- Roll-Up Door Approximate WeightsDocument2 pagesRoll-Up Door Approximate Weightscancery0707No ratings yet

- Steelwise - Does This Beam Make My Building Look Too HeavyDocument5 pagesSteelwise - Does This Beam Make My Building Look Too Heavycancery0707No ratings yet

- CE541a Lecture Notes Set 03Document43 pagesCE541a Lecture Notes Set 03cancery0707No ratings yet

- Opm 0203 13Document211 pagesOpm 0203 13cancery07070% (1)

- 2006-12-04 ICC Limitations On Capacities of Concrete AnchorsDocument13 pages2006-12-04 ICC Limitations On Capacities of Concrete Anchorscancery0707No ratings yet

- Glass Rail Base TestingDocument21 pagesGlass Rail Base Testingcancery0707No ratings yet

- Flagpole Design Sample Calculations PDFDocument4 pagesFlagpole Design Sample Calculations PDFcancery0707No ratings yet

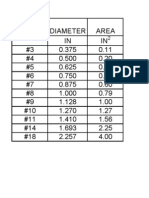

- Rebar TableDocument1 pageRebar Tablecancery0707No ratings yet

- Cooper B-Line Seismic Restraints OPA-0114Document160 pagesCooper B-Line Seismic Restraints OPA-0114cancery0707No ratings yet