Professional Documents

Culture Documents

Quality Control Daily Analysis Report: Mabuhay Vinyl Corporation

Uploaded by

nimrovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Control Daily Analysis Report: Mabuhay Vinyl Corporation

Uploaded by

nimrovCopyright:

Available Formats

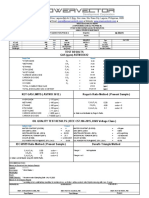

MVC-QF-TECH-008(19) QUALITY CONTROL DAILY ANALYSIS REPORT

Effectivity Date: February 15, 2011 MABUHAY VINYL CORPORATION

Date : 01/20/12 Time : 1130 AM [ ] IEM 1 [ ] IEM 2 [ ] MSG [ ] QC file

IEM 1 IEM 2

50 % CAUSTIC SODA 50 % CAUSTIC SODA Specs

Online Tk – B Online Tk - 9

% NaOH 49.62 49.12 49.16 48.94 48-50

32 % CAUSTIC SODA 32 % CAUSTIC SODA

Online Tk- Online Tk - 8

% NaOH 30.93 31.56 30-32

HYDROCHLORIC ACID HYDROCHLORIC ACID

Online Tk- Tk- Online CTA 1 CTA 3

% HCl NA 31.96 31.50 32.55 32-33.5

Color 1 1 1 # 3, max

POLISHED BRINE(After Precoat) POLISHED BRINE(After Precoat)

Ca+Mg, ppm + NA = + NA = 5 ppm, max.

SPB (After Headtank) SPB (After Headtank)

Ca+Mg, ppb nil + 2 = 2 8 + nil = 8 20 ppb, max.

NaCl, gpl 292 316 290 gpl,min.

Na2SO4,gpl 4.29 6.81 7 gpl, max.

NaClO3,gpl 8.03 14.54 20 gpl,max.

DEPLETED BRINE DEPLETED BRINE

NaCl, gpl 209 201 200 gpl, min.

Free Cl2 negative positive Negative

NaClO3,gpl 11.75 22.32 27 gpl, max.

SODIUM HYPOCHLORITE PLANT

Tank No. 2 3 4

% NaOCl 8.91 8.51 8.34 7.40, min

% NaOH 0.72 0.83 0.85 0.40-1.0

Sp. Gr. 1.132 1.134 1.132 1.108, min

LIQUID CHLORINE PLANT UTILITIES

LIQUID CHLORINE SULFURIC ACID INSTRUMENT AIR @ 1030AM

Source % Cl2 Specs Source % H2SO4 Specs Dew Point, °C -0.5 ≤3.8 °C

LCP Tk.# NA 99.5 %,min BOILER WATER

LCP Comp NA 97 %, min.

Cl2 Feed 91.0 %,min. SiO2, ppm NA 150 ppm, max

GAS ANALYSIS

IEM 1 IEM 2 FLUE GAS

% Cl2 % H2 O2 + CO2 % Cl2 % H2 O2 + CO2 % CO % CO2 % O2

Line A NA NA nil 8.6 7.2

Line B

POLLUTION C O N T R O L - EFFLUENTS

pH OIL Hg TDS TSS Color COD

Source 6AM 7PM (+ or -) ppb ppm mg/L Pt-Co Units mg/L

S-2 7.93 8.01 -

S-5 7.91 NA -

Lagoon NA

Sludge Pond NA

Source pH gpl NaOH Source pH SPECIFICATIONS

JBC NA S-3 NA pH = 6-9 COD = 150 mg/li, max Hg = 2, ppb, max.

Evap Canal S-4 Oil = Negative TDS = 1000 ppm, max TSS = 150 mg/li, max

Total Canal S-7 Color = 200 Pt-Co units, max.

Remarks: IEM 1 : None Analyzed by Certified Correct

OFF-SPECS IEM 2 : HCL - online, CTA 1; Depleted brine - Free Cl2

Others : Instrument air - dewpoint NEY/ANB/RGD OVA

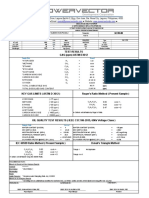

MVC-QF-TECH-004 (12)

Effectivity Date: May 20, 2010

MABUHAY VINYL CORPORATION PRODUCT TRANSFER CLEARANCE

Assumption Heights, Iligan City

Date : 01/20/12 [ ] IEM 1 [ ] IEM 2 [ ] Mktg [ ] QC file

IEM 1

HYDROCHLORIC ACID LIQUID CAUSTIC SODA SODIUM HYPOCHLORITE

Tk # % HCl SG @ 30”C Color Tk # 50% 32%. Tk # % NaOCl % NaOH SG @ 30”C

1 NA A NA NA 1 NA

2 NA B 49.12 NA 2 8.91 0.72 1.132

3 NA 3 8.51 0.83 1.134

4 NA 4 8.34 0.85 1.132

5 NA 5 NA

IEM 2 SPECIFICATIONS

HYDROCHLORIC ACID LIQUID CAUSTIC SODA HYDROCHLORIC ACID

Tk # % HCl SG @ 30”C Color Tk # 50% 32%. % HCl 32.0 - 33.5

CTA 1 NA 9 48.94 - SG @ 30”C, min 1.152

CTA 2 NA 8 - NA Color, max #3

CTA 3 32.55 1.158 1 LIQUID CAUSTIC SODA

CTB 1 NA 50% 32%

CTB 2 NA % NaOH 48 - 50 30 - 32

Remarks: % NaCl 0.10 0.10

WITHIN SPECS, OK for transfer ppm Fe, max 10 10

SODIUM HYPOCHLORITE

Analyzed by Certified Correct % NaOCl, min 7.40

% excess NaOH 0.40 - 1.00

RGD OVA SG @ 30”C, min 1.109

You might also like

- Alchemy IlluminatedDocument100 pagesAlchemy Illuminatedtravellerfellow100% (11)

- Evaluating Salt and Water as an Alternative Electricity SourceDocument38 pagesEvaluating Salt and Water as an Alternative Electricity SourceSchievvie AbanillaNo ratings yet

- Antidotes For Various ChemicalsDocument8 pagesAntidotes For Various ChemicalsDr. KaushaL PateL100% (9)

- SOBM Calculation SheetDocument15 pagesSOBM Calculation SheetChintan GohelNo ratings yet

- Carbopol Ultrez 21 Hoja Tecnica PDFDocument4 pagesCarbopol Ultrez 21 Hoja Tecnica PDFAdrian Copa JNo ratings yet

- CO2 and Lime Dosage Sea WaterDocument11 pagesCO2 and Lime Dosage Sea WaterNoureddine Merah100% (2)

- Water Chemistry & DM Plant Rev00Document27 pagesWater Chemistry & DM Plant Rev00AbhiNo ratings yet

- Multi-stage desalination process data and calculationsDocument17 pagesMulti-stage desalination process data and calculationsThomy Vollmer0% (1)

- Din 50942-96Document13 pagesDin 50942-96RONALD100% (2)

- Chlor Alkali TechnologyDocument14 pagesChlor Alkali TechnologyTinTin100% (1)

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- MVC daily analysis and product transfer reportDocument2 pagesMVC daily analysis and product transfer reportnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- QC 011712Document2 pagesQC 011712nimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- QC DAILY REPORTDocument2 pagesQC DAILY REPORTnimrovNo ratings yet

- MVC daily analysis and product transfer reportDocument2 pagesMVC daily analysis and product transfer reportnimrovNo ratings yet

- QC DAILY REPORTDocument2 pagesQC DAILY REPORTOliver V. ArominNo ratings yet

- April 2017 Daily Analysis ReportDocument253 pagesApril 2017 Daily Analysis ReportnimrovNo ratings yet

- October 1 Daily Analysis ReportDocument253 pagesOctober 1 Daily Analysis ReportnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationOliver V. ArominNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationOliver V. ArominNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationOliver V. ArominNo ratings yet

- Solids Evaluation in Mud TSDocument3 pagesSolids Evaluation in Mud TSNovri IsrarNo ratings yet

- 20HDP Template SuCyProcess v0Document18 pages20HDP Template SuCyProcess v0Mario Cancino SerranoNo ratings yet

- The SuCy Process SulfatosDocument18 pagesThe SuCy Process SulfatoslauramanjarresNo ratings yet

- Chlor Alkali Process: Membrane ElectrolysisDocument18 pagesChlor Alkali Process: Membrane ElectrolysisLuqmanNo ratings yet

- Calculation For Lime ConsumptionDocument4 pagesCalculation For Lime Consumptionhemendra499No ratings yet

- Es1c02165 Si 001Document18 pagesEs1c02165 Si 001Ronei de AlmeidaNo ratings yet

- Template Design BasisDocument5 pagesTemplate Design BasisMuhammad UthmanNo ratings yet

- 32 TR 13Document1 page32 TR 13John Aaron ComiaNo ratings yet

- Recovery Boiler Chemical PrinciplesDocument18 pagesRecovery Boiler Chemical PrinciplesAA MAXNo ratings yet

- Example Report - Batam Line Gas MonitoringDocument1 pageExample Report - Batam Line Gas MonitoringSindu WidodoNo ratings yet

- Dissolve Gas Analysis ReportDocument1 pageDissolve Gas Analysis ReportJohn Aaron ComiaNo ratings yet

- 32 TR 12Document1 page32 TR 12John Aaron ComiaNo ratings yet

- Calculation For Lime ConsumptionDocument7 pagesCalculation For Lime Consumptionhemendra499No ratings yet

- Ammonia Plant Description by Sohail Raza-2Document30 pagesAmmonia Plant Description by Sohail Raza-2Kade Kevin100% (1)

- SOBM Calculation SheetDocument18 pagesSOBM Calculation Sheetongcchemist gd chitraNo ratings yet

- New ZQCCS1Document22 pagesNew ZQCCS1Faizan FarrukhNo ratings yet

- Gras 4G0409Document32 pagesGras 4G0409ctopher63No ratings yet

- Dissolve Gas Analysis Report SummaryDocument1 pageDissolve Gas Analysis Report SummaryJohn Aaron ComiaNo ratings yet

- c06s02 PDFDocument6 pagesc06s02 PDFDewiRSNo ratings yet

- ADVANCE CONSULT ProcessDocument6 pagesADVANCE CONSULT Processsaramartori.2002No ratings yet

- Water ContentDocument21 pagesWater Contentrivai munthe100% (1)

- Gas Condensate Specification and Test ResultsDocument1 pageGas Condensate Specification and Test Resultsriza alfrizaNo ratings yet

- 32 TR 09Document1 page32 TR 09John Aaron ComiaNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- QC DAILY REPORTDocument2 pagesQC DAILY REPORTnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- QC 011712Document2 pagesQC 011712nimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- MVC daily analysis and product transfer reportDocument2 pagesMVC daily analysis and product transfer reportnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- BS 812-118 1988 Sulphate Content硫酸盐含量Document15 pagesBS 812-118 1988 Sulphate Content硫酸盐含量yangNo ratings yet

- Chemistry All Paper 41,42,43 Final 2014-2020-591-1102Document512 pagesChemistry All Paper 41,42,43 Final 2014-2020-591-1102Ashtav ArunNo ratings yet

- Cri 311L Unit 2 Big Picture BDocument7 pagesCri 311L Unit 2 Big Picture Bvworldpeace yanibNo ratings yet

- Brand Product # Description Unit of MeasureDocument13 pagesBrand Product # Description Unit of MeasureGia DinhNo ratings yet

- Dry Ashing Procedure For Plant MaterialsDocument21 pagesDry Ashing Procedure For Plant MaterialsWaseem Hayat HaiderNo ratings yet

- CLS Aipmt 16 17 XI Che Study Package 3 SET 2 Chapter 10Document18 pagesCLS Aipmt 16 17 XI Che Study Package 3 SET 2 Chapter 10kalloli67% (3)

- Kroger Free From 101 RequirementsDocument1 pageKroger Free From 101 RequirementsSarahbeth RennieNo ratings yet

- Cambridge IGCSE: Chemistry 0620/22Document16 pagesCambridge IGCSE: Chemistry 0620/22Mohammed khaled GhazalNo ratings yet

- Class Xi (Nurture) Sample Test PaperDocument21 pagesClass Xi (Nurture) Sample Test PaperAllen NashikNo ratings yet

- 8 - Potassium Sorbate USPDocument2 pages8 - Potassium Sorbate USPasmae.labindusNo ratings yet

- Marine AgarDocument1 pageMarine AgarChandni JaniNo ratings yet

- Iraqi Kaolin yields high purity aluminaDocument9 pagesIraqi Kaolin yields high purity aluminaPuturrú De FuáNo ratings yet

- Light Anhydrous Silicic Acid 1402Document2 pagesLight Anhydrous Silicic Acid 1402TrinhphuongNo ratings yet

- Series Toolkit Unit 5 Ionic Charges Chart Cations and AnionsDocument1 pageSeries Toolkit Unit 5 Ionic Charges Chart Cations and AnionsokNo ratings yet

- ESM GR MG GranulesDocument3 pagesESM GR MG GranulesjucyapleNo ratings yet

- Heat and ReactionsDocument8 pagesHeat and ReactionsEldin EnggNo ratings yet

- MetalsDocument10 pagesMetalsPeterNo ratings yet

- Science 20 - Unit 1 Chemistry Lesson 1 - The Structure of MatterDocument5 pagesScience 20 - Unit 1 Chemistry Lesson 1 - The Structure of MatterTahsim AhmedNo ratings yet

- Ash Insoluble in HCIDocument24 pagesAsh Insoluble in HCIChristoferson Haradji BalanayNo ratings yet

- Saint Louis University School of Engineering and Archiecture Department of Chemical EngineeringDocument24 pagesSaint Louis University School of Engineering and Archiecture Department of Chemical EngineeringUploader101No ratings yet

- Concise guide to key concepts in Physics, Chemistry, Maths, Biology and other subjectsDocument40 pagesConcise guide to key concepts in Physics, Chemistry, Maths, Biology and other subjectsAbhishek VashistNo ratings yet

- Barbital EUROPEAN PHARMACOPOEIA 5.0Document2 pagesBarbital EUROPEAN PHARMACOPOEIA 5.0Orlando David Medinueta De AvilaNo ratings yet

- Aieese Secondary Pcme 3Document18 pagesAieese Secondary Pcme 3test1234No ratings yet

- METALLIC BONDING AND STRUCTURE (39Document6 pagesMETALLIC BONDING AND STRUCTURE (39Juan Francisco Olivares GonzalesNo ratings yet