Professional Documents

Culture Documents

BCR8KM-14LA RenesasTechnology

Uploaded by

osvaldoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BCR8KM-14LA RenesasTechnology

Uploaded by

osvaldoCopyright:

Available Formats

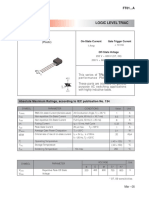

BCR8KM-14LA

Triac

Medium Power Use

REJ03G0333-0100

Rev.1.00

Aug.20.2004

Features

• IT (RMS) : 8 A • Insulated Type

• VDRM : 700 V • Planar Passivation Type

• IFGTI , IRGTI, IRGTⅢ : 30 mA (20 mA)Note5

www.DataSheet4U.com • UL Recognized : Yellow Card No. E223904

• Viso : 2000 V File No. E80271

Outline

TO-220FN

2

1. T1 Terminal

2. T2 Terminal

3. Gate Terminal

3

1

1

2 3

Applications

Switching mode power supply, washing machine, motor control, heater control, and other general purpose control

applications

Maximum Ratings

Voltage class

Parameter Symbol Unit

14

Note1

Repetitive peak off-state voltage VDRM 700 V

Non-repetitive peak off-state voltageNote1 VDSM 840 V

Rev.1.00, Aug.20.2004, page 1 of 7

BCR8KM-14LA

Parameter Symbol Ratings Unit Conditions

RMS on-state current IT (RMS) 8 A Commercial frequency, sine full wave

360° conduction, Tc = 89°C

Surge on-state current ITSM 80 A 60Hz sinewave 1 full cycle, peak value,

non-repetitive

I2t for fusing I2 t 26 A2s Value corresponding to 1 cycle of half

wave 60Hz, surge on-state current

Peak gate power dissipation PGM 5 W

Average gate power dissipation PG (AV) 0.5 W

Peak gate voltage VGM 10 V

Peak gate current IGM 2 A

Junction temperature Tj – 40 to +125 °C

Storage temperature Tstg – 40 to +125 °C

Mass

www.DataSheet4U.com — 2.0 g Typical value

Isolation voltage Viso 2000 V Ta = 25°C, AC 1 minute,

T1·T2·G terminal to case

Notes: 1. Gate open.

Electrical Characteristics

Rated value

Parameter Symbol Unit Test conditions

Min. Typ. Max.

Repetitive peak off-state current IDRM — — 2.0 mA Tj = 125°C, VDRM applied

On-state voltage VTM — — 1.6 V Tc = 25°C, ITM = 12 A,

Instantaneous measurement

Gate trigger voltageNote2 Ι VFGTΙ — — 1.5 V Tj = 25°C, VD = 6 V, RL = 6 Ω,

ΙΙ VRGTΙ — — 1.5 V RG = 330 Ω

ΙΙΙ VRGTΙΙΙ — — 1.5 V

Gate trigger currentNote2 Ι IFGTΙ — — 30Note5 mA Tj = 25°C, VD = 6 V, RL = 6 Ω,

ΙΙ IRGTΙ — — 30Note5 mA RG = 330 Ω

ΙΙΙ IRGTΙΙΙ — — 30Note5 mA

Gate non-trigger voltage VGD 0.2 — — V Tj = 125°C, VD = 1/2 VDRM

Thermal resistance Rth (j-c) — — 3.6 °C/W Junction to caseNote3

Critical-rate of rise of off-state (dv/dt)c 10 — — V/µs Tj = 125°C

commutating voltageNote4

Notes: 2. Measurement using the gate trigger characteristics measurement circuit.

3. The contact thermal resistance Rth (c-f) in case of greasing is 0.5°C/W.

4. Test conditions of the critical-rate of rise of off-state commutating voltage is shown in the table below.

5. High sensitivity (IGT ≤ 20 mA) is also available. (IGT item: 1)

Commutating voltage and current waveforms

Test conditions

(inductive load)

1. Junction temperature Supply Voltage Time

Tj = 125°C

2. Rate of decay of on-state commutating current (di/dt)c

Main Current Time

(di/dt)c = – 4 A/ms

3. Peak off-state voltage Main Voltage Time

VD = 400 V (dv/dt)c VD

Rev.1.00, Aug.20.2004, page 2 of 7

BCR8KM-14LA

Performance Curves

Maximum On-State Characteristics Rated Surge On-State Current

102 100

7

5 90

Surge On-State Current (A)

3 80

On-State Current (A)

2

Tj = 125°C

70

101

7 60

5

3 50

2 Tj = 25°C 40

100

7 30

5

20

3

www.DataSheet4U.com 2 10

10–1 0

0.6 1.0 1.4 1.8 2.2 2.6 3.0 3.4 3.8 100 2 3 4 5 7 101 2 3 4 5 7 102

On-State Voltage (V) Conduction Time (Cycles at 60Hz)

Gate Trigger Current vs.

Gate Characteristics (I, II and III) Junction Temperature

× 100 (%) 103

3 Typical Example

2 VGM = 10V PG(AV) = 0.5W 7

PGM = 5W 5

Gate Trigger Current (Tj = 25°C)

101 4

Gate Trigger Current (Tj = t°C)

7 3

Gate Voltage (V)

5 IGM = 2A IRGT III

3 2

VGT = 1.5V

2

102

100 IRGT I, IFGT I

7 7

5 5

3 4

2 3

IFGT I IRGT I, IRGT III VGD = 0.2V 2

10–1

7

5

101

101 2 3 5 7 102 2 3 5 7 103 2 3 5 7 104 –60 –40 –20 0 20 40 60 80 100 120 140

Gate Current (mA) Junction Temperature (°C)

Gate Trigger Voltage vs. Maximum Transient Thermal Impedance

Junction Temperature Characteristics (Junction to case)

× 100 (%)

102 2 3 5 7 103 2 3 5

Transient Thermal Impedance (°C/W)

103 4.0

7 Typical Example

5 3.5

Gate Trigger Voltage (Tj = 25°C)

4

Gate Trigger Voltage (Tj = t°C)

3 3.0

2 2.5

102 2.0

7

5 1.5

4

3 1.0

2 0.5

101 0

–60 –40 –20 0 20 40 60 80 100 120 140 10–1 2 3 5 7 100 2 3 5 7 101 2 3 5 7 102

Junction Temperature (°C) Conduction Time (Cycles at 60Hz)

Rev.1.00, Aug.20.2004, page 3 of 7

BCR8KM-14LA

Maximum Transient Thermal Impedance

Characteristics (Junction to ambient) Maximum On-State Power Dissipation

3

Transient Thermal Impedance (°C/W) 10 16

7 No Fins

On-State Power Dissipation (W)

5

3 14

2

2

10 12 360° Conduction

7

5 Resistive,

3 10 inductive loads

2

1

10 8

7

5

3 6

2

0

10 4

7

5

3 2

2

www.DataSheet4U.com –1

10 1 0

2 3 4 5 0 2 4 6 8 10 12 14 16

10 2 3 5 710 2 3 5 710 2 3 5 710 2 3 5 710

Conduction Time (Cycles at 60Hz) RMS On-State Current (A)

Allowable Case Temperature vs. Allowable Ambient Temperature vs.

RMS On-State Current RMS On-State Current

160 160

Curves apply regardless All fins are black painted

140 of conduction angle 140 aluminum and greased

Ambient Temperature (°C)

Case Temperature (°C)

120 120 120 × 120 × t2.3

100 100 100 × 100 × t2.3

80 80 60 × 60 × t2.3

60 60 Curves apply

regardless of

40 40 conduction angle

360° Conduction Resistive,

20 Resistive, 20 inductive loads

inductive loads Natural convection

0 0

0 2 4 6 8 10 12 14 16 0 2 4 6 8 10 12 14 16

RMS On-State Current (A) RMS On-State Current (A)

Allowable Ambient Temperature vs. Repetitive Peak Off-State Current vs.

× 100 (%)

RMS On-State Current Junction Temperature

160 105

Natural convection 7 Typical Example

Repetitive Peak Off-State Current (Tj = 25°C)

140 No Fins 5

Ambient Temperature (°C)

Repetitive Peak Off-State Current (Tj = t°C)

Curves apply regardless 3

120 of conduction angle 2

Resistive, inductive loads 104

100 7

5

80 3

2

60

103

7

40 5

3

20 2

0 102

0 0.5 1.0 1.5 2.0 2.5 3.0 –60 –40 –20 0 20 40 60 80 100 120 140

RMS On-State Current (A) Junction Temperature (°C)

Rev.1.00, Aug.20.2004, page 4 of 7

BCR8KM-14LA

Holding Current vs. Latching Current vs.

Junction Temperature Junction Temperature

× 100 (%) 103 103

7 Typical Example 7

5

5

3

Latching Current (mA)

4 Distribution

2 T2+, G–

3

Holding Current (Tj = 25°C)

Holding Current (Tj = t°C)

2 102 Typical Example

7

5

102 3

7 2

5 101

4 7

3 5

2 3 + +

2 T2–, G– Typical Example

T2 , G

www.DataSheet4U.com 101 100

–60 –40 –20 0 20 40 60 80 100 120 140 –40 0 40 80 120 160

Junction Temperature (°C) Junction Temperature (°C)

Breakover Voltage vs. Breakover Voltage vs.

× 100 (%)

Junction Temperature Rate of Rise of Off-State Voltage

× 100 (%)

160 160

Typical Example Typical Example

140 Breakover Voltage (dv/dt = 1V/µs) 140 Tj = 125°C

Breakover Voltage (dv/dt = xV/µs)

Breakover Voltage (Tj = 25°C)

120 120

Breakover Voltage (Tj = t°C)

100 100

80 80

60 60 III Quadrant

40 40

20 20 I Quadrant

0 0

–60 –40 –20 0 20 40 60 80 100120 140 101 2 3 5 7 102 2 3 5 7 103 2 3 5 7 104

Junction Temperature (°C) Rate of Rise of Off-State Voltage (V/µs)

Gate Trigger Current vs.

Commutation Characteristics Gate Current Pulse Width

× 100 (%)

103

3 Typical Example Main Voltage Time Typical Example

Critical Rate of Rise of Off-State

2 Tj = 125°C (dv/dt)c VD

7

Commutating Voltage (V/µs)

Main Current 5 IFGT I

102 IT = 4A IT (di/dt)c 4

7 τ = 500µs τ 3 IRGT I

Gate Trigger Current (DC)

5 VD = 200V Time

Gate Trigger Current (tw)

3 f = 3Hz 2 IRGT III

2

102

101

7 I Quadrant 7

5 5

3 Minimum 4

2 Characteristics 3

Value

III Quadrant 2

100

7

5

101 0

100 2 3 5 7 101 2 3 5 7 102 2 3 5 7 103 10 2 3 4 5 7 101 2 3 4 5 7 102

Rate of Decay of On-State Gate Current Pulse Width (µs)

Commutating Current (A/ms)

Rev.1.00, Aug.20.2004, page 5 of 7

BCR8KM-14LA

Gate Trigger Characteristics Test Circuits

6Ω 6Ω

6V A 6V A

330Ω 330Ω

V V

Test Procedure I Test Procedure II

6Ω

A

6V

330Ω

V

www.DataSheet4U.com

Test Procedure III

Rev.1.00, Aug.20.2004, page 6 of 7

BCR8KM-14LA

Package Dimensions

TO-220FN

EIAJ Package Code JEDEC Code Mass (g) (reference value) Lead Material

2.0 Cu alloy

10 ± 0.3 2.8 ± 0.2

6.5 ± 0.3

3 ± 0.3

15 ± 0.3

φ 3.2 ± 0.2

3.6 ± 0.3

14 ± 0.5

1.1 ± 0.2

1.1 ± 0.2

www.DataSheet4U.com

0.75 ± 0.15

0.75 ± 0.15

2.54 ± 0.25 2.54 ± 0.25

4.5 ± 0.2

Dimension in Millimeters

Symbol

Min Typ Max

2.6 ± 0.2

A

A1

A2

b

D

E

e

Note 1) The dimensional figures indicate representative values unless x

otherwise the tolerance is specified. y

y1

ZD

ZE

Order Code

Standard order

Lead form Standard packing Quantity Standard order code

code example

Straight type Plastic Magazine (Tube) 50 Type name BCR8KM-14LA

Lead form Plastic Magazine (Tube) 50 Type name – Lead forming code BCR8KM-14LA-A8

Note : Please confirm the specification about the shipping in detail.

Rev.1.00, Aug.20.2004, page 7 of 7

Sales Strategic Planning Div. Nippon Bldg., 2-6-2, Ohte-machi, Chiyoda-ku, Tokyo 100-0004, Japan

www.DataSheet4U.com

Keep safety first in your circuit designs!

1. Renesas Technology Corp. puts the maximum effort into making semiconductor products better and more reliable, but there is always the possibility that trouble

may occur with them. Trouble with semiconductors may lead to personal injury, fire or property damage.

Remember to give due consideration to safety when making your circuit designs, with appropriate measures such as (i) placement of substitutive, auxiliary

circuits, (ii) use of nonflammable material or (iii) prevention against any malfunction or mishap.

Notes regarding these materials

1. These materials are intended as a reference to assist our customers in the selection of the Renesas Technology Corp. product best suited to the customer's

application; they do not convey any license under any intellectual property rights, or any other rights, belonging to Renesas Technology Corp. or a third party.

2. Renesas Technology Corp. assumes no responsibility for any damage, or infringement of any third-party's rights, originating in the use of any product data,

diagrams, charts, programs, algorithms, or circuit application examples contained in these materials.

3. All information contained in these materials, including product data, diagrams, charts, programs and algorithms represents information on products at the time of

publication of these materials, and are subject to change by Renesas Technology Corp. without notice due to product improvements or other reasons. It is

therefore recommended that customers contact Renesas Technology Corp. or an authorized Renesas Technology Corp. product distributor for the latest product

information before purchasing a product listed herein.

The information described here may contain technical inaccuracies or typographical errors.

Renesas Technology Corp. assumes no responsibility for any damage, liability, or other loss rising from these inaccuracies or errors.

Please also pay attention to information published by Renesas Technology Corp. by various means, including the Renesas Technology Corp. Semiconductor

home page (http://www.renesas.com).

4. When using any or all of the information contained in these materials, including product data, diagrams, charts, programs, and algorithms, please be sure to

evaluate all information as a total system before making a final decision on the applicability of the information and products. Renesas Technology Corp. assumes

no responsibility for any damage, liability or other loss resulting from the information contained herein.

5. Renesas Technology Corp. semiconductors are not designed or manufactured for use in a device or system that is used under circumstances in which human life

is potentially at stake. Please contact Renesas Technology Corp. or an authorized Renesas Technology Corp. product distributor when considering the use of a

product contained herein for any specific purposes, such as apparatus or systems for transportation, vehicular, medical, aerospace, nuclear, or undersea repeater

use.

6. The prior written approval of Renesas Technology Corp. is necessary to reprint or reproduce in whole or in part these materials.

7. If these products or technologies are subject to the Japanese export control restrictions, they must be exported under a license from the Japanese government and

cannot be imported into a country other than the approved destination.

Any diversion or reexport contrary to the export control laws and regulations of Japan and/or the country of destination is prohibited.

8. Please contact Renesas Technology Corp. for further details on these materials or the products contained therein.

RENESAS SALES OFFICES http://www.renesas.com

Renesas Technology America, Inc.

450 Holger Way, San Jose, CA 95134-1368, U.S.A

Tel: <1> (408) 382-7500 Fax: <1> (408) 382-7501

Renesas Technology Europe Limited.

Dukes Meadow, Millboard Road, Bourne End, Buckinghamshire, SL8 5FH, United Kingdom

Tel: <44> (1628) 585 100, Fax: <44> (1628) 585 900

Renesas Technology Europe GmbH

Dornacher Str. 3, D-85622 Feldkirchen, Germany

Tel: <49> (89) 380 70 0, Fax: <49> (89) 929 30 11

Renesas Technology Hong Kong Ltd.

7/F., North Tower, World Finance Centre, Harbour City, Canton Road, Hong Kong

Tel: <852> 2265-6688, Fax: <852> 2375-6836

Renesas Technology Taiwan Co., Ltd.

FL 10, #99, Fu-Hsing N. Rd., Taipei, Taiwan

Tel: <886> (2) 2715-2888, Fax: <886> (2) 2713-2999

Renesas Technology (Shanghai) Co., Ltd.

26/F., Ruijin Building, No.205 Maoming Road (S), Shanghai 200020, China

Tel: <86> (21) 6472-1001, Fax: <86> (21) 6415-2952

Renesas Technology Singapore Pte. Ltd.

1, Harbour Front Avenue, #06-10, Keppel Bay Tower, Singapore 098632

Tel: <65> 6213-0200, Fax: <65> 6278-8001

© 2004. Renesas Technology Corp., All rights reserved. Printed in Japan.

Colophon .1.0

You might also like

- BCR20KM 12LDocument7 pagesBCR20KM 12LLeonardoNo ratings yet

- D bcr8lm-14lj TDocument8 pagesD bcr8lm-14lj TJonn Sim-OneNo ratings yet

- BCR8PM-12L RenesasTechnologyDocument8 pagesBCR8PM-12L RenesasTechnologyAriel GarciaNo ratings yet

- bcr12pm 12laDocument8 pagesbcr12pm 12laSutirtha MaitiNo ratings yet

- R07ds0959ej0400 bcr16fm14ljDocument9 pagesR07ds0959ej0400 bcr16fm14ljJacky NplNo ratings yet

- BCR1AM 12 TB DatasheetzDocument7 pagesBCR1AM 12 TB DatasheetzAjie CahyadiNo ratings yet

- BCR3KM 12la PDFDocument7 pagesBCR3KM 12la PDFCartuNalguesNo ratings yet

- REN R07ds1031ej0300 bcr16cm12lc DST 20190201Document9 pagesREN R07ds1031ej0300 bcr16cm12lc DST 20190201Purwanto B012No ratings yet

- Datasheet - HK bcr12fm-14lbbb0 7074219Document8 pagesDatasheet - HK bcr12fm-14lbbb0 7074219phetronyo ferreira de oliveiraNo ratings yet

- BCR08 TriacDocument8 pagesBCR08 TriacMr TechNo ratings yet

- Cr02am-8 (To-92)Document8 pagesCr02am-8 (To-92)Manuel De Jesus Andrade PalacioNo ratings yet

- BT169Document5 pagesBT169zaveriprernaNo ratings yet

- Bta06 600BDocument7 pagesBta06 600BMikhaelA.RodriguezNo ratings yet

- BT169 01Document7 pagesBT169 01Rizky SyahNo ratings yet

- MCR100W 10M 0-2902672Document12 pagesMCR100W 10M 0-2902672chawkigenieNo ratings yet

- BT139Document6 pagesBT139BryanTipánNo ratings yet

- Thyristors BT168W Series Logic Level For RCD/ GFI/ LCCB ApplicationsDocument7 pagesThyristors BT168W Series Logic Level For RCD/ GFI/ LCCB ApplicationshassamNo ratings yet

- BT152 PhilipsSemiconductorsDocument8 pagesBT152 PhilipsSemiconductorsDiego RicardoNo ratings yet

- PAT308Document4 pagesPAT308Muhommetmyrat KakajanowNo ratings yet

- 2P4M: Pb Free Plating Product 2.0 Ampere Passivated Process Thyristor---Sensitive Gate SCRDocument3 pages2P4M: Pb Free Plating Product 2.0 Ampere Passivated Process Thyristor---Sensitive Gate SCRbasheer almetwakelNo ratings yet

- BT151Document8 pagesBT151Javier ParedesNo ratings yet

- Standard TriacDocument4 pagesStandard TriacHector Alberto SanchezNo ratings yet

- Bta 12 6008 Impressora SansungDocument6 pagesBta 12 6008 Impressora SansungLuciano Francisco Dos SantosNo ratings yet

- TRIACS CatálogoDocument8 pagesTRIACS CatálogoJacy FigueNo ratings yet

- Low Power 600V 0.8A TRIAC DatasheetDocument4 pagesLow Power 600V 0.8A TRIAC DatasheetsergioNo ratings yet

- Data SheetDocument5 pagesData SheetLucas QuarchioniNo ratings yet

- scp25c60Document5 pagesscp25c60ly7123No ratings yet

- Triacs BT137-600D Logic Level: General Description Quick Reference DataDocument7 pagesTriacs BT137-600D Logic Level: General Description Quick Reference DataGabriel Alexander R. MNo ratings yet

- TRIAC Series: 1 DescriptionDocument4 pagesTRIAC Series: 1 Descriptionjamal232No ratings yet

- Datasheet TV JEFA PDFDocument4 pagesDatasheet TV JEFA PDFluis rivasNo ratings yet

- Datasheet BT150 500RDocument6 pagesDatasheet BT150 500RJosemar M. FerreiraNo ratings yet

- Datasheet PDFDocument4 pagesDatasheet PDFmargarita_ceron_1No ratings yet

- Logic Level Triac: TO92 (Plastic)Document4 pagesLogic Level Triac: TO92 (Plastic)abel gaunaNo ratings yet

- BT137Document7 pagesBT137Gabriel RacovskyNo ratings yet

- Thyristors BT169 Series Logic Level: General Description Quick Reference DataDocument6 pagesThyristors BT169 Series Logic Level: General Description Quick Reference Datawasantha bandaraNo ratings yet

- BT138 SeriesDocument8 pagesBT138 SeriesYogi RuliemNo ratings yet

- BT151 Series 2Document7 pagesBT151 Series 2Louie Derek OrtizNo ratings yet

- BT 151Document6 pagesBT 151Oscar FernandezNo ratings yet

- General Description: T (RMS)Document6 pagesGeneral Description: T (RMS)Szabolcs ZavagyilNo ratings yet

- BT169DDocument1 pageBT169DBuho FielNo ratings yet

- PHT2508CFDocument5 pagesPHT2508CFArnulfo Muñoz FraustoNo ratings yet

- datasheet4Document6 pagesdatasheet4echkomNo ratings yet

- Thyristor Module: 60A / 1200 To 1600VDocument5 pagesThyristor Module: 60A / 1200 To 1600VIhtisham uddinNo ratings yet

- D Data Sheet: BT131W SeriesDocument9 pagesD Data Sheet: BT131W Seriesuser_scribd54635No ratings yet

- LOGIC LEVEL TRIAC TECHNICAL SPECIFICATIONSDocument4 pagesLOGIC LEVEL TRIAC TECHNICAL SPECIFICATIONSAnatoly WolkoffNo ratings yet

- 12 A 800 V Snubberless Triac in TO-220AB Package: FeaturesDocument11 pages12 A 800 V Snubberless Triac in TO-220AB Package: FeaturesDelos Santos JojoNo ratings yet

- Act108w 600eDocument15 pagesAct108w 600eRogerioNo ratings yet

- Three Quadrant Triacs BTA212 Series B High Commutation: General Description Quick Reference DataDocument6 pagesThree Quadrant Triacs BTA212 Series B High Commutation: General Description Quick Reference DataВасилий ЛитвинNo ratings yet

- Tiger Electronic Co.,Ltd: Thyristors Logic LevelDocument1 pageTiger Electronic Co.,Ltd: Thyristors Logic Leveljontan019No ratings yet

- Features: 12 A SCRDocument8 pagesFeatures: 12 A SCRSem NomeNo ratings yet

- FT0107MN FagorDocument4 pagesFT0107MN FagorAnatoly WolkoffNo ratings yet

- FT12 WSTDocument4 pagesFT12 WSTJavier BelizanNo ratings yet

- BT139 PhilipsDocument6 pagesBT139 PhilipsDelcu MarinicaNo ratings yet

- Surface Mount Triac: SOT223 (Plastic)Document4 pagesSurface Mount Triac: SOT223 (Plastic)Mike BrdnNo ratings yet

- Thyristors BTA151 Series Sensitive Gate: General Description Quick Reference DataDocument6 pagesThyristors BTA151 Series Sensitive Gate: General Description Quick Reference DatarogeriocorreaNo ratings yet

- BT131 Series: General Description Quick Reference DataDocument5 pagesBT131 Series: General Description Quick Reference DataDabro FabioNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- HP Parts Compatible 24082021 (Fusers)Document1 pageHP Parts Compatible 24082021 (Fusers)osvaldoNo ratings yet

- Operation Manual: Smart-UPSDocument18 pagesOperation Manual: Smart-UPSosvaldoNo ratings yet

- Installation Guide Smart-UPS 1200/1500 VA 100/120/230 Vac Rack-Mount 1UDocument6 pagesInstallation Guide Smart-UPS 1200/1500 VA 100/120/230 Vac Rack-Mount 1UosvaldoNo ratings yet

- Imagerunner Advanceseries PDFDocument64 pagesImagerunner Advanceseries PDFPinku BhattaNo ratings yet

- Canon ImageCLASS D1600 Brochure FinalDocument4 pagesCanon ImageCLASS D1600 Brochure FinalosvaldoNo ratings yet

- Imagerunner 1643 Series: Black-And-White - Compact - User-FriendlyDocument4 pagesImagerunner 1643 Series: Black-And-White - Compact - User-FriendlyosvaldoNo ratings yet

- imageCLASS LBP6030 - 6030w PDFDocument2 pagesimageCLASS LBP6030 - 6030w PDFikigayo ikuyoNo ratings yet

- Imagerunner Advance c5051 SeriesDocument23 pagesImagerunner Advance c5051 SeriesKaimook CopierNo ratings yet

- Aficiompw3601 PDFDocument4 pagesAficiompw3601 PDFosvaldoNo ratings yet

- BL Embassy Mexico PDFDocument1 pageBL Embassy Mexico PDFosvaldoNo ratings yet

- (PREP SƯU TẦM) Destination B1-22-25Document4 pages(PREP SƯU TẦM) Destination B1-22-25hanhuNo ratings yet

- GSAA HET 2005-15, Tranche M2 - JPMorgan Investment Funds / Income Oppt'y FundDocument192 pagesGSAA HET 2005-15, Tranche M2 - JPMorgan Investment Funds / Income Oppt'y FundTim BryantNo ratings yet

- International Journal of Pressure Vessels and PipingDocument3 pagesInternational Journal of Pressure Vessels and PipingVikas SharmaNo ratings yet

- Student Report Card ManagementDocument38 pagesStudent Report Card ManagementKannan Thangaraju41% (17)

- Seaskills Maritime Academy: Purchase OrderDocument8 pagesSeaskills Maritime Academy: Purchase OrderSELVA GANESHNo ratings yet

- Inorganic Polymers: Classification and PropertiesDocument46 pagesInorganic Polymers: Classification and PropertiesGokul KannanNo ratings yet

- 775 Further MATH - 2 PDFDocument13 pages775 Further MATH - 2 PDFEkema SundiNo ratings yet

- Proceedings of 2006 WSEAS Conference on Heat and Mass TransferDocument7 pagesProceedings of 2006 WSEAS Conference on Heat and Mass TransferAnonymous knICaxNo ratings yet

- Mercruiser 4.3L Mpi SpecsDocument2 pagesMercruiser 4.3L Mpi Specssalvatore dalessandro100% (1)

- Botulinum Toxin in Aesthetic Medicine Myths and RealitiesDocument12 pagesBotulinum Toxin in Aesthetic Medicine Myths and RealitiesЩербакова ЛенаNo ratings yet

- HW3 Solutions 2017 SpringDocument4 pagesHW3 Solutions 2017 SpringAtaush Sabuj100% (1)

- Translation Task 1Document5 pagesTranslation Task 1Beatrice FontanaNo ratings yet

- Isoefficiency Function A Scalability Metric For PaDocument20 pagesIsoefficiency Function A Scalability Metric For PaDasha PoluninaNo ratings yet

- Flexi Edge Bts SystemDocument25 pagesFlexi Edge Bts SystemMuty Koma67% (3)

- Balco. Vicky. Project Optimation of Product MixDocument67 pagesBalco. Vicky. Project Optimation of Product Mixvicky_rock00007No ratings yet

- CH 6 SandwichesDocument10 pagesCH 6 SandwichesKrishna ChaudharyNo ratings yet

- Donor Selections..Document17 pagesDonor Selections..OmamaNo ratings yet

- Letters of CreditDocument33 pagesLetters of CreditConnie SulangNo ratings yet

- PBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Document45 pagesPBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Ramdas KambleNo ratings yet

- L05 - Selection of Indicators (ENG)Document9 pagesL05 - Selection of Indicators (ENG)killerkissNo ratings yet

- Criminal Law 2 - TreasonDocument408 pagesCriminal Law 2 - TreasonInna SalongaNo ratings yet

- ConnercasememoDocument12 pagesConnercasememoapi-339018690No ratings yet

- ExxonMobil History, Strategies, and Financial PerformanceDocument50 pagesExxonMobil History, Strategies, and Financial PerformanceJose FrancisNo ratings yet

- Y-16-30 WOF Maintenance ManualDocument158 pagesY-16-30 WOF Maintenance ManualSeth Barbour100% (1)

- Partial Molar PropertiesDocument6 pagesPartial Molar PropertiesNISHTHA PANDEYNo ratings yet

- Research Paper On Tourism in NepalDocument7 pagesResearch Paper On Tourism in Nepalgw0he255100% (1)

- Review Movie: Title:the Conjuring 2: The Enfield PoltergeistDocument2 pagesReview Movie: Title:the Conjuring 2: The Enfield PoltergeistBunga IllinaNo ratings yet

- 9A01709 Advanced Structural Analysis PDFDocument8 pages9A01709 Advanced Structural Analysis PDFReddy Kiran KDNo ratings yet

- Blue Ocean Strategy: A SummaryDocument21 pagesBlue Ocean Strategy: A SummaryDeshandra Afga NagaraNo ratings yet

- Understanding and Applying The ANSI/ ISA 18.2 Alarm Management StandardDocument260 pagesUnderstanding and Applying The ANSI/ ISA 18.2 Alarm Management StandardHeri Fadli SinagaNo ratings yet