Professional Documents

Culture Documents

Model E & Pe Series: Two-Stage Regulator Repair Kit Instructions

Uploaded by

bernardo angeles rojasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model E & Pe Series: Two-Stage Regulator Repair Kit Instructions

Uploaded by

bernardo angeles rojasCopyright:

Available Formats

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

MODEL E & PE SERIES

TWO-STAGE REGULATOR REPAIR KIT INSTRUCTIONS

Important: Any maintenance, service or repair

should be performed by trained and

experienced service technicians. Proper tools

and equipment should be used to prevent

injury to the servicing technician, property or

system components. Service repairs should

always be performed in a safe environment

and the technician should always wear

protective clothing to prevent injury.

The IMPCO PPI-2 repair kit instructions will

provide the technician information to

successfully repair the model E and PE

regulators. Always inspect the major casting

pieces for damage, corrosion or cracks before

attempting a service repair. Be sure the repair

kit part number you are using is correct for the

regulator being serviced. Diaphragms are

color coded and have different performance

characteristics:

BLACK: Hydrin diaphragm material is the

standard material and is well suited for the

most common applications.

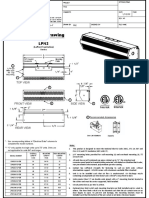

Model E Two Stage Regulator

YELLOW: Silicone diaphragm material is the

optional upgrade material that provides

excellent flexibility in cold weather climates

and is more resistant to chemical

contamination.

BLUE: Fluorosilicone diaphragm material Do not use Teflon tape to seal any fuel fittings.

provides excellent high and low temperature Failure to follow this warning may cause the

durability with increased chemical resistance. regulator to leak internally, that may cause

This material is recommended for turbo serious injury and/or property damage.

applications.

REPAIR KIT PART NUMBERS

Part # Description

RK-E Repair Kit Model E, Hydrin Diaphragm

RK-E-2 Repair Kit Model E, w/Silicone Diaphragm

RK-E-3 Repair Kit Model E, Fluorosilicone Diaphragm

RK-PE Repair Kit Model PE, Hydrin Diaphragm

RK-TE Repair Kit Model E, Turbo w/Silicone Diaphragm

November, 2014 IMPCO Technologies Inc. PPI-2 REV. J

3030 South Susan St. Page 1 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

MODEL E & PE SERIES REGULATORS

MODEL E SHOWN

ITEM # PART # DESCRIPTION

1 S7-1 (NSS) Screen, Atmospheric Vent

2 S1-3* Screw, 10-24 x 5/8" SEMS (8)

3 AC1-22-10298-001 (NSS) Cover, Secondary

AD1-14-1* (1) (NSS) Diaphragm, Secondary, Hydrin Model E

AD1-23* (2) (NSS) Diaphragm, Secondary, Silicone Model E

4 AD1-23-4* (3) (NSS) Diaphragm, Secondary, Flourosilicone E

AD1-14-2* (4) (NSS) Diaphragm, Secondary, Hydrin PE

AD1-23-2* (5) (NSS) Diaphragm, Secondary, Silicone PE

5 L1-86* (NSS) Lever, Secondary w/ or w/o Hole

6 S4-37* (NSS) Seat, Secondary

S2-22 Spring, Secondary Regulator (Blue), Standard

7†

S2-23 Spring, Secondary Regulator (Orange), Option

P1-7 (NSS) Pin, Secondary Lever Fulcrum (Early Model)

8

P1-8 (NSS) Pin, Secondary Lever Fulcrum (Later Model)

9 S1-40* (NSS) Screw, 10-24 x 3/8" SEMS

10 S1-1555-002* (1)(2)(3)(NSS) Screw, 12-24 x 1 1/8" SEMS Model E Only

C1-20 (NSS) Cover, Primary Diaphragm (Early Model)

11

C1-50815-001 (NSS) Cover, Primary Diaphragm (Later Model)

12 S2-13 (NSS) Spring, Primary Regulator EB (2)

13 AD1-15* (NSS) Diaphragm Assy, Primary

14 P1-11* (NSS) Pin, Primary Valve

15 AB1-20A-10307-001 (NSS) Body, Regulator E Series

16 G1-37* (NSS) Gasket, Regulator Body

17 F3-1* (NSS) Sponge

18 S4-7* (NSS) Seat, Primary

19 AB1-19-10309-001 (NSS) Body, Assy, Heat Exchanger

20 P3-13 (NSS) Plug, Hex Head, 1/8 NPT (3)

21 G1-30079-1* Gasket, Heat Exchanger Cover

22 C1-21PM (NSS) Cover, Heat Exchanger

23 W1-27* (NSS) Washer, hand primer

24 S1-1560-004 (NSS) Screw 8-32 x .25" (Later Model)

25 W1-14187-016 (NSS) Flat Washer (Later Model)

26 P1-8* (NSS) Pin, Lever Diaphragm Link

NSS = Not Serviced Separately

* Repair kit components. (1) = RK-E; (2) = RK-E-2;

(3) = RK-E-3; (4) RK-PE; (5) = RK-TE

† Two vapor outlet pressures are available. The Orange secondary

spring gives Neg. 0.50” w.c. (Neg 0.12 kPa) pressure. Blue secondary

spring gives a Neg. 1.50” w.c. (Neg. 0.37 kPa) pressure.

PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 2 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

COMPONENT MODEL PE

MODEL PE COMPONENTS SHOWN

ITEM # PART# DESCRIPTION

1 S7-1 (NSS) Screen, Atmospheric Vent

2 S1-3* Screw, 10-24 x 5/8" SEMS (8)

3 C1-22-2 (NSS) Cover Assembly

AD1-14-2* Diaphragm, Secondary, Hydrin

4

AD1-23-2* Diaphragm, Secondary, Silicone

S2-37 Spring, Secondary Standard PE

7

S2-42 Spring, Secondary, PE (Optional)

27 S1-101* Screw, 6-32 x 1/4" SEMS (4)

28 H3-3 (NSS) Housing, Spring

29 G1-84* Gasket, Spring Housing

NSS-Not Serviced Separately

*Repair Kit Components

REBUILD INSTRUCTIONS

1.Under normal conditions, installation of a complete

repair kit should be necessary only at the time of a major

engine overhaul or when the regulator has been out of

service for an extended period of time. Each kit includes

the necessary gaskets, diaphragms, seals and some

replacement screws.

2. Model PE Only (Skip for E): Remove the spring

retainer housing cover screws (27) and cover (28).

Remove the housing gasket (29) and secondary spring

(7).

November, 2014 IMPCO Technologies Inc. PPI-2 REV. J

3030 South Susan St. Page 3 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

3.Remove the diaphragm cover (3) by taking out the eight

screws (2) around the circumference of the top cover.

4.Remove the secondary diaphragm (4). This requires

the assembly be moved about one inch away from

the gas outlet to disengage the two prongs of the

diaphragm link from the lever (5).

5.Diaphragm (4) and cover (3) removed showing

secondary lever (5).

Early Models Only (Skip to Step 9 for later models):

6.Loosen the screw (10) retaining the fulcrum pin (8).

PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 4 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

7. Extract the screw (10) in preparation for removal of

the fulcrum pin (8).

8. Slide out the fulcrum pin (8) and remove the pin.

Later Models Only (Skip to Step 10 for Early Models)

9. Using a T-20 Torx tool, remove the screw (24) and

washer (25) holding the fulcrum pin (8). Remove

fulcrum pin (8).

10. Remove the lever and seat assembly (5 & 6). E

Only: Remove Spring (7).

November, 2014 IMPCO Technologies Inc. PPI-2 REV. J

3030 South Susan St. Page 5 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

11. Remove the primary diaphragm cover (11). This

requires removal of four fillister head screws (10)

and two pan head screws (9).

12. Remove springs (12) and the primary diaphragm

assembly (13).

13. Remove the primary valve pin (14) as shown by

the tip of the pen.

14. Remove the last two fillister screws (10).

PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 6 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

15. Loosen and separate the body (15) from the heat

exchanger (19).

16. Remove the old primary valve seat (18) and

sponge (17). Discard both.

17. Remove the back cover screws (2).

18. Tap the side of the cover (22) firmly with the

handle of the screw driver to break the cover

loose from the gasket (21).

November, 2014 IMPCO Technologies Inc. PPI-2 REV. J

3030 South Susan St. Page 7 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

19. Deposits may accumulate from the use of hard

water. This condition can be alleviated through

the use of radiator additives or permanent

antifreeze solutions. Remove any accumulation

with a wire brush before assembly. Steel water

inlet and outlet fittings may cause erosion from

electrolysis. Use brass or plastic water fittings

only.

REASSEMBLY OF REGULATOR

• Carefully clean and inspect all metal parts; springs, levers, pivot pins and screws. Replace all parts

that are included in the repair kits.

• Carefully clean the body casting and inspect all sealing surfaces . Wipe with a clean rag. Inspect

the primary section for foreign materials that might loosen and damage the soft face valves.

• Clear out the inlet and outlet passages with compressed air. Be sure no foreign material remains in

these passages.

• Inspect the primary orifice and the secondary orifice for nicks, scratches or uneven wear.

IMPORTANT!

If the primary or secondary seats show any of the above mentioned conditions, the regulator is not

rebuildable and must be replaced.

20. Reassemble the back cover (22) and gasket (21)

to the heat exchanger body (19). Replace six

screws (2). Match the mounting bosses in the

cover with those on the heat exchanger. Tighten

the two screws shown in the photo first, then

upper and lower screws diagonally opposite to

draw the cover down evenly. Torque to 25-35 in-

lbs (2.8-4.0 Nm).

21. The pen indicates the recess cast in the body

(19) to retain the sponge (17). Be sure to

accurately install the sponge in the recess.

PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 8 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

22. After the sponge (17) is in place, the primary seat

(18) can be installed. Place the seat so the

rubber side is down towards the jet.

23. Reinstall the body (15) and body gasket (16).

Mount the body gasket on the primary pin boss

and two locating pins on the underside of the

body. Use two screws (10) to locate the body on

the heat exchanger body (19). Finger tighten the

screws to hold the two parts in place.

24. Replace the primary valve pin (14).

25. The new primary diaphragm assembly (13) is

ready to be put into place.

November, 2014 IMPCO Technologies Inc. PPI-2 REV. J

3030 South Susan St. Page 9 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

26. Install the primary diaphragm (13) over the

locating pins and screw bosses, providing

alignment for the assembly of the springs (12)

and cover (11).

27. Place the two primary valve springs (12) on their

locating perches extruded from the backup plate

on the primary diaphragm (13).

28. Press the primary cover (11) in place over the

primary valve springs (12) and diaphragm

assembly (13). Insert two screws (9) and finger

tighten.

Note that two screws (9) securing the top of

primary cover (11) and in the center are different

from the other four screws (10).

29. Early Models: Replace four of the five screws

(10). DO NOT replace the one shown by the

arrow. Torque to 35-45 in-lbs. (4.0-5.1 Nm).

Torque the two inner screws (9) to 22-28 in-lbs.

(2.5-3.2 Nm).

Later Models: Replace all five screws (10) and

torque to 35-45 in-lbs. (4.0-5.1 Nm). Torque the

two inner screws (9) to 22-28 in-lbs. (2.5-3.2 Nm).

Skip to Step 35.

PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 10 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

30. Slide the pin through the larger of the two hole

openings of the lever (5) and place over a socket

that will support the area of the lever around the

hole. Using a hammer, knock in the pin (26)

through the smaller hole until it is even on both

sides.

31. Inspect the tabs on the lever (5) to verify they are

not bent and the pin (26) is centered.

32. Insert the seat (6) by pressing the nub through

the hole in the lever (5).

Early Models Only (Skip to Step 35 for Later

Models)

33. Replace the secondary lever (5) and insert the

fulcrum pin (8).

November, 2014 IMPCO Technologies Inc. PPI-2 REV. J

3030 South Susan St. Page 11 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

34. Replace the final screw (10) and finger tighten.

Skip to Step 36.

Later Models Only (Skip to Step 36 for Early Models)

35. Insert fulcrum pin (8) through lever (5) and place

in slot on top of primary diaphragm cover (11).

Place washer (25) on screw (24), insert and

tighten until snug.

36. Lightly pull the lever (5) up against the secondary

seat for measuring. Use a straight edge or the

IMPCO G2-2 gauge to check the lever height. The

secondary lever link pin should be approximately

1/32” (0.8mm) below the level of the body casting.

If the lever height is incorrect, continue to Step 37.

Once the lever height is correct, skip to Step 38.

37. If necessary, remove the fulcrum pin (8) and lever

(5) and bend slightly if required. Do not attempt to

bend the lever when installed--unnecessary force

on the lever may damage the secondary seat (6).

PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 12 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

Early Models Only (Skip to Step 39 for Later

models):

38. Tighten the screw to the left of the lever pin and

torque to 35-45 in-lbs. (4.0-5.1 Nm). Skip to Step

40.

Later Models Only (Continue to Step 40 for Early

Models)

39. Apply Loctite® 242 or equivalent to screw threads.

Thread screw (24) into the diaphragm cover and

torque to 17-23 in-lbs. (1.9-2.6 Nm).

40. Model E Only (Skip for PE): Slip the spring (7)

under the secondary lever (5) making sure it is

retained by the two tabs at the sides and the

single tab punched through the top of the lever.

41. Replace the secondary diaphragm (4) engaging

the slotted link to lever pin shown.

November, 2014 IMPCO Technologies Inc. PPI-2 REV. J

3030 South Susan St. Page 13 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

42. Photo shows the link and the link pin properly

connected.

43. Replace hand primer seal washer (6) indicated

by pencil.

44. Replace the cover (3). Turn the eight screws (2)

until all contact the cover. Then tighten in a criss-

cross pattern until are firmly seated. Torque to

25-35 in-lbs. (2.8-4.0 Nm).

45. PE Only (Skip for E): Place the secondary

spring (7) on the secondary diaphragm (4)

perch.

PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 14 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

46. PE Only (Skip for E): Install the gasket (28) and

spring housing (27). Align the spring retainer

housing screw holes to the cover (26) and insert

cover screws (23). Torque to 7-11 in-lbs.(0.8-1.2

Nm).

47. E Only: Apply 100 psi (6.9 Bar) of air pressure

to the inlet side of the regulator and test for

leaks. Draw a soap bubble across the regulator

outlet to verify that no air is flowing through the

outlet. If air escapes, the rebuild has failed and

the regulator must be replaced. Actuate the

primer button and the soap bubble should burst

and air flow should be noted at the regulator

outlet. Use soap and/or a commercial leak

detector solution to inspect the gasket seals

around the perimeter of the regulator for leaks.

If no leaks are found, the repair is now complete.

PE Only: Pressurize the PE with 100 psi (6.9

Bar) compressed air (the regulator should free

flow). Slowly reduce the flow at the outlet port (a

one inch NPT PVC pipe plug with a 1/8” or a 3

mm hole drilled in the center is ideal for this

test). Check for leaks around the PE body

gasket and test port plugs using a liquid leak

detector solution. Verify or reset final outlet

pressure for adjustable PE units. If no leaks are

found, the repair is now complete.

November, 2014 IMPCO Technologies Inc. PPI-2 REV. J

3030 South Susan St. Page 15 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

WARNING:

IMPROPER INSTALLATION OR USE OF THIS PRODUCT MAY CAUSE

SERIOUS INJURY, DEATH AND/OR PROPERTY DAMAGE

SERVICE TECHNICIANS AND USERS SHOULD CAREFULLY READ AND ABIDE BY THE PROVISIONS SET FORTH IN

NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37 FOR STATIONARY ENGINES, #52 FOR CNG VEHICULAR

FUEL SYSTEMS OR #58 FOR LPG SYSTEMS.

INSTALLERS LPG INSTALLATIONS IN THE UNITED STATES MUST BE DONE IN ACCORDANCE WITH FEDERAL, STATE

AND LOCAL LAWS AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #58, STANDARD FOR STORAGE

AND HANDLING OF LIQUEFIED PETROLEUM GASES, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION

OF FEDERAL, STATE OR LOCAL LAW.

COUNTRIES OUTSIDE OF USA REFER TO THE GOVERNING AGENCIES OVERSEEING CNG AND PROPANE

APPLICATIONS.

CNG INSTALLATIONS IN THE UNITED STATES MUST BE DONE IN ACCORDANCE WITH FEDERAL, STATE AND LOCAL

LAW AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #52, COMPRESSED NATURAL GAS (CNG)

VEHICULAR FUEL SYSTEMS, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION OF FEDERAL, STATE OR

LOCAL LAW.

LPG AND/OR NATURAL GAS INSTALLATIONS ON STATIONARY ENGINES MUST BE DONE IN ACCORDANCE WITH

FEDERAL, STATE AND LOCAL LAW AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37, STATIONARY

COMBUSTION ENGINES AND GAS TURBINE ENGINES, TO THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION

WITH FEDERAL, STATE OR LOCAL LAW. FAILURE TO ABIDE BY THE ABOVE WILL VOID ANY IMPCO WARRANTY ON

THE PRODUCTS AND MAY CAUSE SERIOUS INJURY OR PROPERTY DAMAGE.

SERVICE TECHNICIANS DUE TO THE INHERENT DANGER OF GASEOUS FUELS, IMPCO PRODUCTS SHOULD NOT BE

INSTALLED OR USED BY PERSONS NOT KNOWLEDGEABLE OF THE HAZARDS ASSOCIATED WITH THE USE OF

GASEOUS FUELS. ANY MAINTENANCE, SERVICE OR REPAIR SHOULD BE PERFORMED BY TRAINED AND

EXPERIENCED SERVICE TECHNICIANS.

PROPER TOOLS AND EQUIPMENT PROPER TOOLS AND EQUIPMENT SHOULD BE USED TO PREVENT INJURY TO

THE SERVICING TECHNICIAN, PROPERTY OR SYSTEM COMPONENTS. SERVICE REPAIRS SHOULD ALWAYS BE

PERFORMED IN A SAFE ENVIRONMENT AND THE TECHNICIAN SHOULD ALWAYS WEAR PROTECTIVE CLOTHING TO

PREVENT INJURY.

INSPECT BEFORE USE ALWAYS INSPECT THE MAJOR CASTING PIECES FOR DAMAGE, CORROSION OR CRACKS

BEFORE ATTEMPTING A SERVICE REPAIR. BE SURE THE REPAIR KIT PART NUMBER YOU ARE USING IS CORRECT

FOR THE COMPONENT(S) BEING SERVICED.

NO TEFLON TAPE DO NOT USE TEFLON TAPE TO SEAL ANY FUEL FITTINGS. FAILURE TO FOLLOW THIS WARNING

MAY CAUSE THE REGULATOR TO LEAK INTERNALLY, POSSIBLY RESULTING IN SERIOUS INJURY, DEATH AND/OR

PROPERTY DAMAGE AND MAY VOID ANY WARRANTY COVERAGE.

PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 16 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

You might also like

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Electronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesFrom EverandElectronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesNo ratings yet

- Model Ev & Pev Series: Two-Stage Regulator Repair Kit InstructionsDocument15 pagesModel Ev & Pev Series: Two-Stage Regulator Repair Kit Instructionsluis tocoraNo ratings yet

- Model L: Two-Stage Regulator Repair Kit InstructionsDocument14 pagesModel L: Two-Stage Regulator Repair Kit Instructionsbernardo angeles rojasNo ratings yet

- VerdampersDocument30 pagesVerdampersFolkwin LapNo ratings yet

- Model J Series Converter: Repair Kit InstructionsDocument12 pagesModel J Series Converter: Repair Kit InstructionsJorge MorenoNo ratings yet

- C03059CGDocument2 pagesC03059CGVoja ElektronikNo ratings yet

- Model E & Pe RegulatorsDocument5 pagesModel E & Pe RegulatorsMiguel Angel NajeraNo ratings yet

- LPN2 Unheated Sanitation SubmittalsDocument2 pagesLPN2 Unheated Sanitation SubmittalsGabriel Ortiz MNo ratings yet

- Emerson CoughAssist - Service ManualDocument16 pagesEmerson CoughAssist - Service Manualmr_phenriqueNo ratings yet

- T60 Regulator: Repair Kit InstructionsDocument15 pagesT60 Regulator: Repair Kit InstructionsPK Carlos CristanchoNo ratings yet

- Freezer: Exploded ViewDocument17 pagesFreezer: Exploded ViewErnesto HiltonNo ratings yet

- SB 7-1-101Document5 pagesSB 7-1-101jussmeeeNo ratings yet

- Vol 4 - Bill of Material - Swallows LILO132 R1Document15 pagesVol 4 - Bill of Material - Swallows LILO132 R1Hossam AlzubairyNo ratings yet

- 19-0699 SPDocument2 pages19-0699 SPOmar turco curiNo ratings yet

- 0903 A Propeller Shaft and Stern Tube Inspection Rev. IDocument46 pages0903 A Propeller Shaft and Stern Tube Inspection Rev. IHoss SaidNo ratings yet

- Ckag02 Windshield Washer and Wiper InstallationDocument8 pagesCkag02 Windshield Washer and Wiper Installationrandy pascuaNo ratings yet

- Sony xr-3740 c340 SMDocument40 pagesSony xr-3740 c340 SMAvalos Vaca FernandoNo ratings yet

- Service Manual: SE-G1/PCR-T273/SM-T274Document39 pagesService Manual: SE-G1/PCR-T273/SM-T274Enyah RodriguezNo ratings yet

- Drawing 80AQ15-60 Non CodedDocument2 pagesDrawing 80AQ15-60 Non Codeddaus nasNo ratings yet

- 3265542-J M12 Pe BomDocument3 pages3265542-J M12 Pe BomYair CorredorNo ratings yet

- Ef 50 1.4 UsmDocument6 pagesEf 50 1.4 UsmNguyen DuyNo ratings yet

- 1Document1 page1Galih WicaksonoNo ratings yet

- MX45VAE Diag Elect 7000M P-K601-017-E-R1 AD0002Document75 pagesMX45VAE Diag Elect 7000M P-K601-017-E-R1 AD0002Andres Conejo VargasNo ratings yet

- 3259262Document4 pages3259262M Iqbal AdmanNo ratings yet

- getPDFAttachment PDFDocument3 pagesgetPDFAttachment PDFRichardReveloNo ratings yet

- BateriaDocument17 pagesBateriaGabriel MarzolaNo ratings yet

- Service Manual: Audio System Power AmplifierDocument14 pagesService Manual: Audio System Power AmplifierMantasPuskoriusNo ratings yet

- Shooting Star: Assembly InstructionsDocument8 pagesShooting Star: Assembly InstructionsbellscbNo ratings yet

- Electrical Part ListDocument76 pagesElectrical Part ListIsaac Ramirez GarciaNo ratings yet

- Driveline Components Catalog Center Yokes, Tube Yokes and Ball Stud Tube YokesDocument16 pagesDriveline Components Catalog Center Yokes, Tube Yokes and Ball Stud Tube YokesPrasadNo ratings yet

- Service Information: See To Following PageDocument2 pagesService Information: See To Following PageanthonypardoNo ratings yet

- Flatsider 6: Assembly InstructionsDocument8 pagesFlatsider 6: Assembly InstructionsbellscbNo ratings yet

- Mj10-12 Ipl FF OnlyDocument16 pagesMj10-12 Ipl FF OnlyJandric Nebojsa-JimmyNo ratings yet

- Model J Series Converter: Repair Kit InstructionsDocument12 pagesModel J Series Converter: Repair Kit InstructionsAcaJoksimovicNo ratings yet

- Samsung MAX-936 Service ManualDocument59 pagesSamsung MAX-936 Service Manualmarro55No ratings yet

- PDP S21 LR - RRV3010Document5 pagesPDP S21 LR - RRV3010zanildoNo ratings yet

- 7 5 PDFDocument20 pages7 5 PDFSaid GedeonNo ratings yet

- IMPCO Model JDocument4 pagesIMPCO Model JGerson Rodriguez TorresNo ratings yet

- JB ScheduleDocument42 pagesJB ScheduleJagadeesan ShanmugamNo ratings yet

- Boss AB 2 2 Way Selector Service Manual PDFDocument7 pagesBoss AB 2 2 Way Selector Service Manual PDFJesus Galan ArribasNo ratings yet

- Ef 85 1.8 UsmDocument5 pagesEf 85 1.8 UsmblarkarkNo ratings yet

- Electrical Part ListDocument76 pagesElectrical Part ListIsaac Ramirez GarciaNo ratings yet

- GetDocument2 pagesGetluigacanNo ratings yet

- T-10, T20 Service Manual (EN) 201710 Rev.D (VR)Document35 pagesT-10, T20 Service Manual (EN) 201710 Rev.D (VR)Leandro PifferNo ratings yet

- Bill of Material SBTDocument25 pagesBill of Material SBTcesar coronadoNo ratings yet

- Rotorcorp Air Conditioning KitDocument2 pagesRotorcorp Air Conditioning KitHolman OrjuelaNo ratings yet

- Boiler AccesoriesDocument127 pagesBoiler Accesoriesramnath008100% (1)

- M18 018 eDocument3 pagesM18 018 eFalgon IslamNo ratings yet

- Data Sheet For Valves (Ball Valve) VF.013421X.02Document2 pagesData Sheet For Valves (Ball Valve) VF.013421X.02Jitendra PrasadNo ratings yet

- Group 5 Connectors Group 5 Connectors: 1. Connector Destination 1. Connector DestinationDocument20 pagesGroup 5 Connectors Group 5 Connectors: 1. Connector Destination 1. Connector Destinationmohamed omerNo ratings yet

- G3512e 315-2630 Cylinder Head AsDocument3 pagesG3512e 315-2630 Cylinder Head Asေအာင္ ပိုင္ ေဇာ္No ratings yet

- Piping Isometrics CPF Area Cpf2 Process Area - Drawing IndexDocument12 pagesPiping Isometrics CPF Area Cpf2 Process Area - Drawing IndexWnava CrisNo ratings yet

- DL650K9Document187 pagesDL650K9Juan Abraham AjpopNo ratings yet

- Opel Corsa Aircon InstallationDocument18 pagesOpel Corsa Aircon InstallationMOLL1234100% (1)

- Medeli dd306 Casio ld80Document28 pagesMedeli dd306 Casio ld80diego-tNo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument10 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Ambition Sep 2002Document111 pagesAmbition Sep 2002La Castle Automobile ChannelNo ratings yet

- BUELL X1 Teile CatalogDocument79 pagesBUELL X1 Teile CatalogMoander SmithNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- TriPac EVOLUTION Diagnostic Manual 55739-19-OD Rev 0 (08-13)Document341 pagesTriPac EVOLUTION Diagnostic Manual 55739-19-OD Rev 0 (08-13)Joe Ortiz83% (18)

- Internal Gear Pump: 1 GeneralDocument12 pagesInternal Gear Pump: 1 GeneralManny CalNo ratings yet

- Shaper MachineDocument36 pagesShaper MachineAdnan ParkerNo ratings yet

- Fiat Allis M65 Motor Grader ManualDocument236 pagesFiat Allis M65 Motor Grader ManualLeland Oeser92% (12)

- F90900476S219Document5 pagesF90900476S219syafiqNo ratings yet

- Catalogue 1700 Chieftain Powerscreen TerexDocument20 pagesCatalogue 1700 Chieftain Powerscreen TerexMahmoud Abd El MonemNo ratings yet

- Despiece JU6H-UF54 - PE6068E010701Document31 pagesDespiece JU6H-UF54 - PE6068E010701Daniel Bartholomes100% (1)

- SDLG L968F SpecificationDocument1 pageSDLG L968F SpecificationjamesNo ratings yet

- Espar Airtronic M d4s ManualDocument70 pagesEspar Airtronic M d4s ManualMiu MiuNo ratings yet

- Cce - WL - C Series - 821C - Specs - 07-21-2010 - 2 PDFDocument6 pagesCce - WL - C Series - 821C - Specs - 07-21-2010 - 2 PDFHelverNo ratings yet

- New Research Roberto M Cayapan JRDocument16 pagesNew Research Roberto M Cayapan JRTrebor NapayacNo ratings yet

- Category Title NFR: EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019Document81 pagesCategory Title NFR: EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019GMNo ratings yet

- Ael Zc441 Course HandoutDocument5 pagesAel Zc441 Course HandoutJoel George AlexNo ratings yet

- Interface - Signal Locations: Interface Viewed From BelowDocument2 pagesInterface - Signal Locations: Interface Viewed From Belowmdelvallev100% (3)

- Modular Architecture ChassisDocument4 pagesModular Architecture ChassisFelipe MayNo ratings yet

- .ArchivetempA034T572 I5 ManualServico PCC3201Document60 pages.ArchivetempA034T572 I5 ManualServico PCC3201Marneth RendonNo ratings yet

- BitBox CarList 2022 10 28Document97 pagesBitBox CarList 2022 10 28marcos hernandezNo ratings yet

- ClusterDocument16 pagesClusterSARAMQRNo ratings yet

- Engine Performance Curve: Rating: Application:MarineDocument4 pagesEngine Performance Curve: Rating: Application:Marinekman548No ratings yet

- 793D SERV1817-01 - SLIDE - Aug2006Document233 pages793D SERV1817-01 - SLIDE - Aug2006Ishan IqbalNo ratings yet

- Viswa Lab - Meeting The 2015 Eca Regulations PDFDocument18 pagesViswa Lab - Meeting The 2015 Eca Regulations PDFnauta007No ratings yet

- Volkswagen Service Training Vwcom 20l Tsi Turbo24803Document5 pagesVolkswagen Service Training Vwcom 20l Tsi Turbo24803james100% (42)

- Iveco Daily Shop ManualDocument20 pagesIveco Daily Shop Manualpaul100% (53)

- 4 Electricity Production: MAN B&W Diesel A/S S60MC-C Project GuideDocument27 pages4 Electricity Production: MAN B&W Diesel A/S S60MC-C Project GuideАлександр КозыревNo ratings yet

- TATA Trucks Tractor Trailers SpecificationsDocument61 pagesTATA Trucks Tractor Trailers SpecificationsLandsky IndiaNo ratings yet

- Catalogo ParkerDocument524 pagesCatalogo ParkerViníciusE.FláviaNo ratings yet

- 400R Self Propelled Dry SpreaderDocument2 pages400R Self Propelled Dry Spreaderlaurentiu ruseNo ratings yet

- Truck 5 0.0.0: IDC5 Softwar e UpdateDocument64 pagesTruck 5 0.0.0: IDC5 Softwar e UpdatescaniaNo ratings yet

- General Aviation Airworthiness Alerts 43-16 Alert 55 02-01-1983Document14 pagesGeneral Aviation Airworthiness Alerts 43-16 Alert 55 02-01-1983JacksonNo ratings yet

- Anand Sardar - NWP MRP LIST DT 01.01.2021Document11 pagesAnand Sardar - NWP MRP LIST DT 01.01.2021sssakol1981No ratings yet