Professional Documents

Culture Documents

Jig para Montar Paineis Colados - Técnica Simples

Uploaded by

jpl.guedes6842Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jig para Montar Paineis Colados - Técnica Simples

Uploaded by

jpl.guedes6842Copyright:

Available Formats

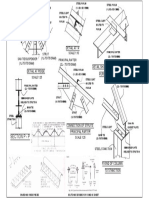

Shop-Made Panel Clamps

I can always use more clamps.

So, when I needed a few extra

clamps for a recent project, I

decided to get creative and build

my own as shown here.

SIMPLE PARTS. The clamps I came

up with are built using a length

of threaded rod. A pair of large

dowels on each end of the

threaded rod serve as knobs.

In the center of each dowel, I

drilled a hole and added a T-nut.

The last bit of the puzzle is to

add a set of plywood clamping

jaws. These help apply even

clamping pressure.

JAWS With the clamp assembled as

(2"x 2"- !/4"Ply.)

shown, I can slide the jaws to

the workpiece and tighten the

%/16" T-nut knobs. The jaws keep the pres-

sure even, and allow me to apply

just the right amount of clamping

%/16" pressure. The best thing of all is

threaded rod they’re much cheaper than com-

mercial clamps.

KNOB NOTE: T-nuts are hammered Dan Hendricks

(1!/2"x 4" dowel) into ends of the knobs

Omaha, Nebraska

QUICK TIPS

Disposable Epoxy Mixer. When Crayola Resaw Push Stick. Scott Kirk of Solon, IA often

England of Des Moines, IA had some epoxy to uses his band saw to resaw stock. When resawing

mix up, she decided to get a little creative. thin stock, James likes to use a thin push stick. By

She used a section from an old set of mini attaching a magnet to the end, James can hang

blinds. The plastic strip is sturdy enough to the push stick from his band saw cover so it’s

mix the epoxy and is the perfect spreader. readily available when he needs it.

8 • Woodsmith / No. 245

You might also like

- DIY Cornhole Board Plans - Printable PDFDocument7 pagesDIY Cornhole Board Plans - Printable PDFuga100% (1)

- The Joiner and Cabinet Maker (2009)Document373 pagesThe Joiner and Cabinet Maker (2009)fernangd100% (4)

- Diy Ferestrau Vertical at HomeDocument104 pagesDiy Ferestrau Vertical at HomeFlorinNo ratings yet

- Building Tips and Tricks PDFDocument16 pagesBuilding Tips and Tricks PDFcodeethylNo ratings yet

- Arts and Crafts Display CabinetDocument17 pagesArts and Crafts Display Cabinetzoie2009No ratings yet

- Woodsmith No. 252 - Vol. 42 - Diciembre-Enero 2021Document70 pagesWoodsmith No. 252 - Vol. 42 - Diciembre-Enero 2021rpreciadoruizNo ratings yet

- ColourfulDreams LittelDragonENDocument16 pagesColourfulDreams LittelDragonENperobelli handmade100% (5)

- 18th Century Six-Board ChestDocument6 pages18th Century Six-Board ChestSteven HeinsNo ratings yet

- Hemp Fishbone & Bead Choker: Skill Level Time Required Materials CommentsDocument8 pagesHemp Fishbone & Bead Choker: Skill Level Time Required Materials CommentsAleksandraNo ratings yet

- English Layout SquareDocument2 pagesEnglish Layout Squarev00d00bluesNo ratings yet

- FendersDocument3 pagesFendersAbdul MuttalibNo ratings yet

- Making A Prallel Jaw Bar ClampDocument34 pagesMaking A Prallel Jaw Bar ClampHomayoon GeramifarNo ratings yet

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsFrom EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsRating: 5 out of 5 stars5/5 (1)

- Loose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsDocument6 pagesLoose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsFausto Martin Vicente MoralesNo ratings yet

- Season: © 2016 Cruz Bay Publishing, IncDocument8 pagesSeason: © 2016 Cruz Bay Publishing, IncGeoNo ratings yet

- 5 Shop Made Clamps - SSCDocument1 page5 Shop Made Clamps - SSCjuan olivaNo ratings yet

- December 2015 PWM Pages 39 42Document4 pagesDecember 2015 PWM Pages 39 42JuanRodriguez100% (2)

- Making A New Violin BridgeDocument9 pagesMaking A New Violin BridgefuyberNo ratings yet

- Structural DwgsDocument11 pagesStructural DwgsELaAruNo ratings yet

- A Benchtop BenchDocument2 pagesA Benchtop Benchcorneliu.modilca67% (3)

- Penny Plane by John BarkerDocument11 pagesPenny Plane by John Barkerdcloin100% (4)

- A32VII Class Manual-Rev 02242009Document158 pagesA32VII Class Manual-Rev 0224200988No1Fan100% (2)

- DP Series Build SheetDocument49 pagesDP Series Build SheetJoe Creole100% (1)

- Miniature Machining Tools - American EdelstaalDocument40 pagesMiniature Machining Tools - American EdelstaalPica MoixonencNo ratings yet

- Build A Bowsaw: This Classic Tool Still Has A Place in The ShopDocument4 pagesBuild A Bowsaw: This Classic Tool Still Has A Place in The ShopBenjamin BeckerNo ratings yet

- Fender Knot CraftDocument17 pagesFender Knot Craftekindedeoglu4913No ratings yet

- Harga Satuan BahanDocument5 pagesHarga Satuan Bahanlinus heriantoNo ratings yet

- Motor Canoe Boat PlansDocument4 pagesMotor Canoe Boat PlansJim100% (6)

- PicnicTable PDFDocument2 pagesPicnicTable PDFAvi KarmonNo ratings yet

- Plywood EdgeDocument2 pagesPlywood EdgeE100% (1)

- Contemporary Cables: Classic Aran Reimagined in Current StylesFrom EverandContemporary Cables: Classic Aran Reimagined in Current StylesRating: 4 out of 5 stars4/5 (6)

- Tom's Carcassonne Tuckboxes v2 6 The TunnelDocument1 pageTom's Carcassonne Tuckboxes v2 6 The TunnelCanal do TucanoNo ratings yet

- Guide To Inkle Weaving:: Free Inkle Loom Patterns, Plans, and ProjectsDocument16 pagesGuide To Inkle Weaving:: Free Inkle Loom Patterns, Plans, and Projectssusan uptonNo ratings yet

- ShopNotes #17 (Vol. 03) - Easy To Build Sawhorse - Text-28Document1 pageShopNotes #17 (Vol. 03) - Easy To Build Sawhorse - Text-28adanNo ratings yet

- Suspension Bridge: Tension and CompressionDocument8 pagesSuspension Bridge: Tension and CompressionKachen MachomNo ratings yet

- Wooden Bar Clamps PlansDocument14 pagesWooden Bar Clamps PlansWalter RamirezNo ratings yet

- Totem Truck 4.1 Instructions v.1.4 v3Document59 pagesTotem Truck 4.1 Instructions v.1.4 v3Adomas P.No ratings yet

- Cheerful ChapterchapOneDocument8 pagesCheerful ChapterchapOnekq9yzcgkdtNo ratings yet

- Bench Hooks For WorkbenchDocument2 pagesBench Hooks For WorkbenchZahid AsifNo ratings yet

- Bed Base ProjectDocument5 pagesBed Base ProjectPron GoesNo ratings yet

- Review FinishnailersDocument8 pagesReview FinishnailersJon DavisNo ratings yet

- Building Stripper CanoesDocument7 pagesBuilding Stripper Canoesontherig100% (1)

- 105 Krenov-Saw-Horse RevisedDocument6 pages105 Krenov-Saw-Horse RevisedPeter BriggsNo ratings yet

- 8x8 Shelter 2.0 Assembly InstructionsDocument23 pages8x8 Shelter 2.0 Assembly InstructionsKevin BlanerNo ratings yet

- Improvebargainlute PDFDocument9 pagesImprovebargainlute PDFGrillo ParlerinoNo ratings yet

- DR Seussesque Wrist Warmers Knitting PatternDocument3 pagesDR Seussesque Wrist Warmers Knitting PatternSusan Flockhart100% (15)

- Perfect Finish Viking KnitDocument6 pagesPerfect Finish Viking KnitMisa BijouxNo ratings yet

- Easy To Build WorkbenchDocument4 pagesEasy To Build WorkbenchJelaiNo ratings yet

- 39-Clamping - Got ProofDocument6 pages39-Clamping - Got ProofSam MartzNo ratings yet

- Asian-Inspired Vase: Super-SimpleDocument4 pagesAsian-Inspired Vase: Super-SimpleInform7105No ratings yet

- Project Title: Design of An Improvised SeismographDocument3 pagesProject Title: Design of An Improvised SeismographBSCE 5BNo ratings yet

- Drill Chargingand Storage Station PlanDocument25 pagesDrill Chargingand Storage Station PlanNerminNo ratings yet

- Tom's Carcassonne Tuckboxes v4 1-Sheep OnlyDocument1 pageTom's Carcassonne Tuckboxes v4 1-Sheep Onlyjoviy50654No ratings yet

- Madera25 100 2Document89 pagesMadera25 100 2martin789No ratings yet

- Assembly Instructions: ElephantDocument3 pagesAssembly Instructions: ElephantJohn MarinNo ratings yet

- How To Make A Fire Devil StickDocument9 pagesHow To Make A Fire Devil StickPrimaria AvrigNo ratings yet

- Wooden KazooDocument16 pagesWooden KazooAlberto CorralesNo ratings yet

- 04 - Build Storage CabinetDocument8 pages04 - Build Storage CabinetMartin GyurikaNo ratings yet

- RHN0101 024896MDocument3 pagesRHN0101 024896MItzbibiiz 0No ratings yet

- 101 - Stub Tenon and Groove JoineryDocument3 pages101 - Stub Tenon and Groove JoineryRob Pierce100% (1)

- Plastidip Shield TutorialDocument49 pagesPlastidip Shield TutorialjpackaNo ratings yet

- Layout SquareDocument4 pagesLayout SquareInsane HiNo ratings yet

- Modeling SubmarinesDocument30 pagesModeling SubmarinesGuilherme SantosNo ratings yet

- GuidesDocument7 pagesGuidesALCHY IGNNo ratings yet

- "Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLDocument2 pages"Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLTamara MarreroNo ratings yet

- Technical Instruction Sheets: Marking Out and Cutting: Dovetail JointsDocument5 pagesTechnical Instruction Sheets: Marking Out and Cutting: Dovetail JointstesterNo ratings yet

- Disquietude Jan10Document3 pagesDisquietude Jan10chenamberNo ratings yet

- Quick Tomato, White Bean and Kale Soup Recipe - NYT CookingDocument1 pageQuick Tomato, White Bean and Kale Soup Recipe - NYT Cookingjpl.guedes6842No ratings yet

- Quick Tomato Soup With Grilled Cheese Recipe - NYT CookingDocument1 pageQuick Tomato Soup With Grilled Cheese Recipe - NYT Cookingjpl.guedes6842No ratings yet

- Easiest Chicken Noodle Soup Recipe - NYT CookingDocument1 pageEasiest Chicken Noodle Soup Recipe - NYT Cookingjpl.guedes6842No ratings yet

- Potato and White Bean Puttanesca Soup Recipe - NYT CookingDocument1 pagePotato and White Bean Puttanesca Soup Recipe - NYT Cookingjpl.guedes6842No ratings yet

- Make-It-Your-Own Udon Noodle Soup Recipe - NYT CookingDocument1 pageMake-It-Your-Own Udon Noodle Soup Recipe - NYT Cookingjpl.guedes6842No ratings yet

- Savory Mixed-Nut Shortbread Recipe - NYT CookingDocument1 pageSavory Mixed-Nut Shortbread Recipe - NYT Cookingjpl.guedes6842No ratings yet

- Gingerbread Biscotti Recipe - NYT CookingDocument1 pageGingerbread Biscotti Recipe - NYT Cookingjpl.guedes6842100% (1)

- Royal Institute of PhilosophyDocument21 pagesRoyal Institute of Philosophyjpl.guedes6842No ratings yet

- Peppermint Brownie Cookies Recipe - NYT CookingDocument1 pagePeppermint Brownie Cookies Recipe - NYT Cookingjpl.guedes6842No ratings yet

- Savory Mixed-Nut Shortbread Recipe - NYT CookingDocument1 pageSavory Mixed-Nut Shortbread Recipe - NYT Cookingjpl.guedes6842No ratings yet

- Royal Institute of Philosophy, Cambridge University Press PhilosophyDocument6 pagesRoyal Institute of Philosophy, Cambridge University Press Philosophyjpl.guedes6842No ratings yet

- Royal Institute of PhilosophyDocument16 pagesRoyal Institute of Philosophyjpl.guedes6842No ratings yet

- The Aristotelian Society, Wiley Proceedings of The Aristotelian Society, Supplementary VolumesDocument37 pagesThe Aristotelian Society, Wiley Proceedings of The Aristotelian Society, Supplementary Volumesjpl.guedes6842No ratings yet

- Pleasure Vs Happiness - Sir Roger ScrutonDocument4 pagesPleasure Vs Happiness - Sir Roger Scrutonjpl.guedes6842No ratings yet

- The London School of Economics and Political Science, London School of Economics, Wiley The British Journal of SociologyDocument6 pagesThe London School of Economics and Political Science, London School of Economics, Wiley The British Journal of Sociologyjpl.guedes6842No ratings yet

- Papers On Logic and Language. Edited B y DAVID HOLDCBOFT. (University of WarwickDocument3 pagesPapers On Logic and Language. Edited B y DAVID HOLDCBOFT. (University of Warwickjpl.guedes6842No ratings yet

- Scruton 2009Document17 pagesScruton 2009jpl.guedes6842No ratings yet

- Hildebrand On ArchitectureDocument107 pagesHildebrand On Architecturejpl.guedes6842No ratings yet

- Scruton 1987Document16 pagesScruton 1987jpl.guedes6842No ratings yet

- A Cult of Fakery Has Taken Over What's Left of High Culture - Aeon EssaysDocument10 pagesA Cult of Fakery Has Taken Over What's Left of High Culture - Aeon Essaysjpl.guedes6842No ratings yet

- PDF DatastreamDocument185 pagesPDF Datastreamjpl.guedes6842No ratings yet

- Discussion: 1. Sound, Tone and Musical ExperienceDocument15 pagesDiscussion: 1. Sound, Tone and Musical Experiencejpl.guedes6842No ratings yet

- Content - Architectural Theory. An Anthology I e IIDocument17 pagesContent - Architectural Theory. An Anthology I e IIjpl.guedes6842No ratings yet

- Shelves, Closets and Cabinets by Peter JonesDocument305 pagesShelves, Closets and Cabinets by Peter Jonesjpl.guedes6842No ratings yet

- Manufacturing of Spur Gear: Aim of The ExperimentDocument5 pagesManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNo ratings yet

- Trusses 05 ModelDocument1 pageTrusses 05 ModelKirat WaliaNo ratings yet

- Ultimate Miter StandDocument10 pagesUltimate Miter StandLuciano Engel 99No ratings yet

- ES - 11152 Carpentry SHOP (W3)Document31 pagesES - 11152 Carpentry SHOP (W3)coolinkenanatamNo ratings yet

- IS 1538 1993 Table 6 Standard Flange Drilling of Flanged Pipes and Fittings (Chuse 9.1) All SpacedDocument1 pageIS 1538 1993 Table 6 Standard Flange Drilling of Flanged Pipes and Fittings (Chuse 9.1) All SpacedAkshat Jain0% (1)

- MANUAL BrusilicaDocument56 pagesMANUAL BrusilicaAjdinNo ratings yet

- Drill Bit Size ChartDocument8 pagesDrill Bit Size ChartMohamed ElsayedNo ratings yet

- Carolus Catalog GeneralDocument196 pagesCarolus Catalog GeneralNebun de LegatNo ratings yet

- Dimensional Tolerance of ASME B16.5 FlangesDocument1 pageDimensional Tolerance of ASME B16.5 FlangesAlwinNo ratings yet

- Delta 33-055 ManualDocument18 pagesDelta 33-055 Manualspayt0% (1)

- Silverware Chest Plan DrawingsDocument1 pageSilverware Chest Plan DrawingsPenis Launcher100% (1)

- FSC STD 40 004b V1 0 EN FSC Species Terminology PDFDocument25 pagesFSC STD 40 004b V1 0 EN FSC Species Terminology PDFEMINANo ratings yet

- OB Afety Nalysis: Perating A Rill RessDocument3 pagesOB Afety Nalysis: Perating A Rill RessKarl Makoy100% (1)

- Timber Home Living 2016-09-10Document84 pagesTimber Home Living 2016-09-10SilviuOlariuNo ratings yet

- Urea-Formaldehyde ResinDocument9 pagesUrea-Formaldehyde ResinAna Marcia LadeiraNo ratings yet

- International Management Institute, BhubaneshwarDocument9 pagesInternational Management Institute, BhubaneshwarDiksha LathNo ratings yet

- Concept PaperDocument1 pageConcept Paperzettevasquez8No ratings yet

- 003 MillingDocument59 pages003 MillingKalikene MwambeloNo ratings yet

- Kriss VectorDocument9 pagesKriss Vectorhuella37No ratings yet

- Corridor Plumbing Wall Assembly Per UL W304 (AO)Document6 pagesCorridor Plumbing Wall Assembly Per UL W304 (AO)TobinNo ratings yet

- Loop Loc Install GuideDocument12 pagesLoop Loc Install GuideJustin CaseNo ratings yet

- MCT SEM 4 Engineer WoodDocument16 pagesMCT SEM 4 Engineer WoodKhushi ChauhanNo ratings yet