Professional Documents

Culture Documents

Adjacent Box Girders Without Internal Diaphragms or Post-Tensioned Joints PDF

Uploaded by

Santi CheewabantherngOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adjacent Box Girders Without Internal Diaphragms or Post-Tensioned Joints PDF

Uploaded by

Santi CheewabantherngCopyright:

Available Formats

Adjacent

box girders

without

internal

diaphragms

or post-

tensioned

joints

Kromel Hanna,

George Morcous,

and Maher K. Tadros

Precast, prestressed concrete box-girder bridges represent

approximately one-third of all prestressed concrete bridges

built in the United States. The adjacent box-girder system

is the most prevalent box-girder system for short- and

medium-span bridges, especially on secondary roadways.

These bridges consist of multiple precast, prestressed con-

crete box girders that are butted against each other to form

the bridge superstructure and deck. The boxes are laterally

connected at their interface using grouted shear keys, tie

rods, transverse post-tensioning, or variations thereof. The

topping is typically a 2-in.-thick (50 mm) nonstructural

wearing surface or a 5 in. to 6 in. (130 mm to 150 mm)

structural composite slab. The main advantages of this

bridge system include the following:

• ease and speed of construction because of elimination

of concrete forming and placement

■ This paper advocates the elimination of internal box-girder

diaphragms and presents the development of two non-post- • shallow superstructure depth that is necessary to main-

tensioned transverse continuous connections designed to tain the required vertical clearance

transfer transverse shear and moment between adjacent boxes

in precast, prestressed concrete box-girder bridges. • low construction cost compared with I-girder bridges

and other competing systems

■ Fatigue- and monotonic load testing were performed on the

two proposed connections and one commonly used connection • improved bridge aesthetics due to the flatness of the

to evaluate their fatigue capacity, ultimate capacity, and joint soffit and the slenderness of the superstructure

leakage.

The American Association of State Highway and Transpor-

■ Test results indicate that both proposed connections outperform tation Officials’ (AASHTO’s) Standard Specifications for

the current connection in addition to being more economical. Highway Bridges1 does not provide adequate guidance for

PCI Journal | Fa l l 2011 51

designing and detailing the transverse connection in adja- intermediate diaphragms, grouting, and post-tensioning

cent box-girder bridges. Although the specifications stipu- was used between the box girders. The connection consists

late that continuous longitudinal shear key and transverse of a wide and continuous half-depth shear key that was

tie reinforcement be provided for using live load distribu- poured monolithically with the reinforced concrete deck.

tion factors of multibeam decks, there are no requirements For this connection, a minimum 6-in.-thick (150 mm)

for prestressing the transverse reinforcement. The AASHTO composite concrete deck was used to provide adequate

LRFD Bridge Design Specifications2 does not consider the stiffness in the transverse direction.

use of transverse mild steel reinforcing rods secured by

nuts sufficient to achieve full transverse flexural continuity. Another common non-post-tensioned transverse connection

The specifications recommend a minimum average effec- is the one adopted by the Illinois Department of Transporta-

tive post-tensioning stress of 250 psi (1700 kPa) between tion (IDOT). This connection consists of a half-depth con-

adjacent boxes. However, the specifications do not indicate tinuous shear key and transverse ties at the intermediate dia-

the contact area over which the required pressure is ap- phragm locations. Transverse ties for the system are placed

plied, such as intermediate diaphragms, shear keys, or the at the skew angle rather than at a right angle. They connect

entire box side surface. the adjacent box girders in pairs in the transverse direc-

tion. Each tie consists of two 1-in.-diameter × 46-in.-long

The Precast Prestressed Concrete Bridge Design Manual3 (25 mm × 1200 mm) rods threaded 4 in. (100 mm) at each

presents charts for determining the required post-tension- end and connected with a 5-in.-long (130 mm) coupling

ing force to achieve adequate stiffness in the transverse nut. A 5 in. (130 mm) noncomposite reinforced concrete

direction for adjacent box girders. El-Remaily et al.4 devel- topping distributes the loads uniformly across all girders

oped these charts assuming that post-tensioned transverse and protects the shear keys from cracking and leakage.

diaphragms are the primary mechanism for the distribution

of wheel loads across the bridge and the differential deflec- Objective

tion limit between adjacent boxes is 0.02 in. (0.5 mm).

Hanna et al.5–7 developed updated design charts to account The objective of this research was to develop non-post-

for the latest AASHTO LRFD specifications’ loads and tensioned transverse connections between adjacent box

governing parameters, such as bridge width, span-to-depth girders that have performance characteristics superior to

ratio, and skew angle. and more economical than connections currently used.

This paper proposes two non-post-tensioned connections

Although the use of transverse post-tensioning to connect that emulate monolithic construction and eliminate the

adjacent box girders is an effective and practical solution need for diaphragms, post-tensioning, and cast-in-place

in many cases, it has some disadvantages. Post-tensioned concrete topping. These connections are termed the wide-

transverse connections require the use of end and interme- joint system and the narrow-joint system. The elimination

diate diaphragms to achieve continuity in the transverse of end and intermediate diaphragms results in simplified

direction. Diaphragms in skewed bridges are difficult to production. It also gives the producer the option of using

construct and may have to be staggered or built in stages. reusable void forms. Furthermore, elimination of a cast-in-

This leads to a significant increase in the construction cost place composite concrete topping would result in greater

and schedule due to the variation in diaphragm location, speed of construction, as well as other savings.

large number of post-tensioning operations, and excessive

traffic control required in replacement projects. Moreover, Wide-joint system

post-tensioned diaphragms provide transverse continuity

only at discrete locations, which makes the system more The wide-joint system connects adjacent boxes with top

susceptible to cracking and leakage. and bottom transverse reinforcement located in a wide

shear key filled with concrete, instead of the typical

There are several types of non-post-tensioned transverse concrete composite topping. The wide-joint system differs

connections used in adjacent box girders in the United from the aforementioned NASA Road 1 Bridge connec-

States. The NASA Road 1 Bridge over Interstate 45 (I-45) tion by eliminating topping and diaphragms. The mono-

between Houston, Tex., and Galveston, Tex., used one of lithic joint with top and bottom reinforcement provides a

these connections in its construction.8 This bridge was built continuous connection that transfers shear and moment

in 2002 as one of a pair of parallel bridges carrying four between boxes, eliminating the need for intermediate and

lanes of traffic; the other structure is a traditional steel- end diaphragms. The elimination of topping and dia-

girder bridge. The 300-ft-long (90 m) bridge consists of phragms significantly increases the speed of production

four equal 75 ft (23 m) spans with skew angles ranging and construction operations while reducing material, labor,

from 0˚ to 30˚. Each span has nine adjacent type 4B28 box and erection costs.

girders that were formed using the side forms of a standard

Texas I-girder spaced approximately 4 ft (1.2 m) apart. A The shear keys in the wide-joint system are full length and

unique transverse connection that eliminated the need for full depth, requiring minimal modifications to the forms of

52 Fall 2 0 1 1 | PCI Journal

3 ft 7 in.

51/2 in. 2 ft 8 in. 51/2 in.

6 in.

4 in.

2 ft 3 in. to 3 ft 6 in. 15 in.

4 in.

5 /2 in.

1

3 in. 6 in.

8 in.

4 ft

Figure 1. Wide-joint-system box dimensions. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m.

the standard box cross section. Figure 1 shows a modified flange every 4 ft (1.2 m), and two 8-in.-long (200 mm) ×

AASHTO PCI box section that is 33 in. (850 mm) deep 5.5-in.-wide × 4.5-in.-deep blockouts in the bottom flange

and 48 in. (1200 mm) wide. The modifications include every 4 ft. Figure 2 shows the reinforcement for the top-

a 2.5 in. (65 mm) recess on each box side to create the and bottom-flange blockouts. The reinforcing bars protrude

5-in.-wide (130 mm) shear key, two 5.5-in.-long (14 mm) × from the top and bottom flanges of each box and are lap

5.5-in.-wide × 4.5-in.-deep (113 mm) blockouts in the top spliced with short reinforcing bars confined by 1/4 -in.-

Coil rod high tensile strength

Top connection every 48 in.

Block out 51/2 in.× 41/2 in. × 51/2 in. each side

1 ft 4 in.

Spiral, 3 in. outer diameter, 1/4 in. wire, 1 in. pitch, 14 in. long

51/2 in. 41/2 in.

5 in.

Block out 8 in. × 41/2 in. × 51/2 in. each side

23/4 in.

8 in.

Bottom connection every 48 in.

Coil rod high tensile strength

Elevation

Every 48 in.

51/2 in.

Plan view

Figure 2. Wide-joint connection detail. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m.

PCI Journal | Fa l l 2011 53

6 in. 2 ft 111/2 in. 6 in. 5

/8 in.

5

/8 in.

6 in.

3 in.

2 in. 2 in. 15 in.

2 ft 3 in. to 3 ft 6 in.

11/4 in. 11/4 in.

6 in.

11/2 in.

4 ft

Figure 3. Narrow-joint-system box dimensions. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m.

thick (6 mm) wire coiled to 3-in.-diameter (75 mm) spirals Analytical investigation

pitched at 1 in. (25 mm). This confinement reinforcement

is necessary to provide adequate development length for Boxes without internal diaphragms behave fundamentally

the short lap splices. differently from those with significant reinforced concrete

diaphragms. The mathematical model essentially involves

It is recommended to provide an additional 0.5 in. (13 mm) a deforming top transverse slab and a similar bottom slab

thickness to the top surface of the box and the shear keys with webs connecting them. This is similar to an I-girder

when grinding is required to provide a roughened surface bridge superstructure. Thus, the massive torsional stiffness

for skid resistance. The use of self-consolidating concrete that has caused reflective cracking in the current applica-

to fill the wide shear key is also recommended to eliminate tions is substantially reduced. Three-dimensional (3-D)

the need for grouting, which is a costly and time-consum- computer models were developed to calculate the load

ing operation. effects on the proposed connections. Each box girder was

modeled using shell elements for the flanges and webs of

Narrow-joint system the boxes and frame elements for the connections between

the boxes. The assumptions made for developing the com-

The narrow-joint system differs from the IDOT connec- puter models include the following:

tion by eliminating diaphragms and replacing the single

mid-depth transverse tie with top and bottom transverse • Shell and frame elements represent the centerlines of

ties. The narrow-joint system uses Grade 75 (520 MPa) the modeled components.

threaded rods at every 8 ft (2.4 m) to connect each pair of

adjacent boxes at the top and bottom flanges. These rods • The length of shell elements in the direction of traffic

provide a continuous connection that transfers shear and is 12 in. (300 mm).

moment between adjacent boxes more efficiently than the

mid-depth transverse ties at discrete diaphragm locations. • The thickness of shell elements equals the total con-

crete thickness of the corresponding component (that

Figure 3 shows the slight modification made to the stan- is, top flange, bottom flange, web).

dard box cross section to incorporate full-length horizontal

and full-depth vertical shear keys. Figure 4 shows the • Frame elements are repeated every 4 ft (1.2 m) in the

boxes fabricated with plastic ducts in the top and bottom wide-joint model and every 8 ft (2.4 m) in the narrow-

flanges to create openings for the threaded rods. The bot- joint model along the bridge length.

tom duct is inserted between the two layers of prestressing

strands, while the top duct is located 3 in. (75 mm) from • The cross section of the connecting frame elements

the top surface to provide adequate concrete cover. Vertical is rectangular. The width of this rectangle equals

vents are provided at one side of each box to allow the air the spacing between frame elements, while its depth

to escape during the grouting operation. equals the thickness of the corresponding flange.

54 Fall 2 0 1 1 | PCI Journal

4 in. × 4 in. × 1/2 in. washer Coupling nut 5 in. long

6 in.

2 /4 in.

3

1

/2 in. vent 1

/2 in. vent

Plastic duct

Nut for 3/4-in.-diameter rod /4-in.-diameter × 3 ft 10 in.

3

Threaded rods

Elevation

Every 96 in.

Plan view

Figure 4. Narrow-joint connection detail. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m.

The loads applied for the analysis include the concrete curb required tension force is greater in narrow bridges (52 ft

and rail dead load and the HL 93 live load with a dynamic [15 m] width or less) than in wide bridges (wider than

load allowance of 0.33. Single- and multiple-lane loadings 52 ft). Calculating and plotting the force per unit length,

were applied to determine the most critical loading case for Fig. 7 compares the required tension force for the two

the design of the transverse connections. The dead load due proposed connections. It indicates that the force required

to the self-weight of box girders and wearing surface was for the wide-joint system is greater than that for the

not considered because it is uniformly distributed over the narrow-joint system for any given bridge width and box

bridge and consequently does not generate load effects in depth. These required forces are a result of the factored

the transverse direction. The weight of the concrete curb dead load DL and live load LL (1.25DL + 1.75LL) and can

and railing was assumed to be 0.48 kip/ft (7.0 kN/m) and be divided by the yield strength of the reinforcing steel to

was applied to the outside box girders. determine the required area of reinforcement.

The 3-D computer models helped develop the design Figures 8 and 9 show the effect of the span-to-depth ratio

charts to evaluate the effects of the box-girder depth, and box depth on the transverse tension force in the wide-

span width, and span-to-depth ratio on the two proposed joint and narrow-joint connections, respectively. These

transverse connections. Figures 5 and 6 show the effect of charts were developed for a bridge width of 52 ft (15 m) at

the box depth and bridge width on the tension force in the a 0˚ skew angle. Both charts show that the required trans-

transverse connection for the wide-joint and narrow-joint verse tension force increases as the span-to-depth ratio

systems. These charts were developed for a 0˚ skew angle increases. This effect is more pronounced in the narrow-

and span-to-depth ratio of 30. The tension force increases joint system than in the wide-joint system and in shallower

as the bridge width increases and decreases as the box boxes than in deep boxes.

depth increases. Also, the effect of the bridge width on the

PCI Journal | Fa l l 2011 55

80.0

Wide-joint connection every 4 ft

70.0

Span-to-depth ratio = 30

60.0

Tension force, kip

50.0

40.0

Box depth, in.

27

30.0

33

20.0

39

10.0 42

0.0

24 34 44 54 64 74 84

Bridge width, ft

Figure 5. Effect of box depth and bridge width on the required transverse tension force for the wide-joint system. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m; 1 kip = 4.448 kN.

Experimental investigation systems were the connection currently used by IDOT, the

wide-joint connection, and the narrow-joint connection.

Three transverse connections were experimentally inves- Three specimens were fabricated. Each specimen consisted

tigated to determine and compare their structural perfor- of two boxes that were 8 ft × 4 ft × 27 in. (2.4 m × 1.2 m ×

mance under static and cyclic loading conditions. The three 690 mm).

120.0

Narrow-joint connection every 8 ft

Span-to-depth ratio = 30

100.0

80.0

Tension force, kip

Box depth, in.

60.0

27

40.0 33

39

20.0

42

0.0

24 34 44 54 64 74 84

Bridge width, ft

Figure 6. Effect of box depth and bridge width on the required transverse tension force for the narrow-joint system. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m; 1 kip = 4.448 kN.

56 Fall 2 0 1 1 | PCI Journal

20.0

HL 93 live load

Joint spacing = 1.0 ft

18.0

Span-to-depth ratio = 30

16.0

14.0

Tension force, kip

12.0

10.0

Box depth, in.

8.0

27 (Wide joint)

6.0

27 (Narrow joint)

4.0

42 (Wide joint)

2.0 42 (Narrow joint)

0.0

28 32 36 40 44 48 52 56 60 64 68 72 76 80 84

Bridge width, ft

Figure 7. Tension force required for wide-joint and narrow-joint systems. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m; 1 kip = 4.448 kN.

80.0

70.0

60.0

Tension force, kip

50.0

40.0

30.0 Box depth, in.

27

20.0

Wide-joint connection every 4 ft 42

Bridge width = 52 ft

10.0

0.0

25 30 35 40

Span-to-depth ratio

Figure 8. Effect of span-to-depth ratio on required transverse tension force for wide-joint system. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m; 1 kip = 4.448 kN.

PCI Journal | Fa l l 2011 57

120.0

Narrow-joint connection every 8 ft

Bridge width = 52 ft

100.0

80.0

Tension force, kip

60.0

Box depth, in.

40.0

27

42

20.0

0.0

25 30 35 40

Span-to-depth ratio

Figure 9. Effect of span-to-depth ratio on required factored transverse tension force for narrow-joint system. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m; 1 kip = 4.448 kN.

The developed finite element models and design charts (360 mm × 360 mm) loading plate located 5 in. (130 mm)

presented in the previous section were used to calculate the from the centerline of the connection.

required transverse reinforcement for both wide-joint and

narrow-joint connections. The example bridge was 48 ft Testing of current IDOT connection

× 28 ft × 27 in. (15 m × 8.5 m × 700 mm). The required

transverse reinforcement was 3/4-in.-diameter (20 mm), To prepare the specimen for testing, two threaded rods and

Grade 75 (520 MPa) coil rods for the narrow-joint system a coupling nut connected the two boxes, and the horizontal

and no. 6 (19M), Grade 60 (410 MPa) bars for the wide- and vertical shear keys between the boxes were filled with

joint system. The IDOT connection requires two 1-in.- non-shrink, multipurpose grout. This grout had an average

diameter (25 mm) threaded rods connected with a coupling compressive strength of 3200 psi (22 MPa) after 24 hours,

nut regardless of the bridge width, depth, or span. which exceeds the 3000 psi (21 MPa) minimum strength

specified by IDOT. A water dam was also built in the top

Number 4 (13M), Grade 60 (410 MPa) reinforcing bars of the box girder and filled with water to measure the water

were used to replace the longitudinal prestressing strands leakage through the joint during testing.

due to the short length of the specimens and the fact that

specimens are tested only in the transverse direction. The calculated applied load was a 16 kip (71 kN) wheel

load of HL93 multiplied by the 1.15 dynamic load factor

Static loading was performed to determine the ultimate for fatigue, according to AASHTO LRFD specifications.

flexural capacity of each connection. The cyclic loading This resulted in a total of 18.4 kip (81.8 kN) applied

simulated the effects of live load and impact by generat- vertically to the specimen in both the downward and

ing positive and negative bending moments and shear at upward directions for 10,000 cycles. The joint was care-

the transverse connection. Each pair of boxes was con- fully monitored for cracks and water leakage during the

nected and supported using 12-in.-wide (300 mm) steel test. After 10,000 cycles, the test was stopped because of

beams parallel to the transverse connection to restrain the excessive cracking and water leakage at the joint. The poor

vertical movement of the boxes. The distance between performance of the joint (Fig. 10) was primarily due to the

the centerline of supports was 7 ft (2.1 m), which was the inadequate negative moment capacity of the current IDOT

loading span. The loading frame was attached to the floor connection, which caused cracks to extend from the top

using threaded rods to provide adequate stability under surface of the specimen through the depth of the shear key.

cyclic loading. The load was applied using a 14 in. × 14 in.

58 Fall 2 0 1 1 | PCI Journal

of the test specimen. The actual failure load was 138.7 kip

(616.9 kN), 23% higher than the theoretical load. The tie

assembly of this system is repeated every 24 ft (7.3 m), so

the flexural capacity for a 24-ft-long segment is equivalent

to a uniform load of 5.8 kip/ft (85 kN/m) along the bridge

length. Figure 11 shows the failure under ultimate load,

which was primarily delamination at the interface between

the box and the noncomposite concrete topping due to

inadequate horizontal shear resistance.

Testing of wide-joint connection

To prepare the wide-joint connection specimen for testing,

the surface of the shear key was roughened. The first box

girder was placed on top of the support from one side,

Figure 10. Failure of the current connection without topping.

while a temporary support was provided at the other side.

Splicing bars with the spiral reinforcement were attached

Another fatigue test was performed after adding a 5 in. to the first box at the two connecting locations. The second

(130 mm) noncomposite concrete topping to the specimen, box was placed against the first box, and the splicing bar

which is a common IDOT practice. The concrete topping and spiral were attached. The shear key was then cleaned

was reinforced with one layer of no. 5 (16M) bars at 12 in. and filled with self-consolidating concrete.

(300 mm) in both directions. The reinforcement was placed

at the mid-depth of the topping. After the topping achieved After the joint concrete cured and reached a compressive

the specified concrete strength of 5000 psi (34 MPa), a strength of 6000 psi (41 MPa), a static load was applied.

static load was applied to the specimen. The static load in- The static load increased from 0 kip to 6.14 kip (0 kN to

creased from 0 kip to 18.4 kip (0 kN to 81.8 kN), decreased 27.3 kN), reversed from 6.14 kip to -6.14 kip, and returned

from 18.4 kip to -18.4 kip, and then returned to 0 kip. This to 0 kip. The calculated applied load was 1/3 of the IDOT

test was performed to evaluate the stiffness of the connec- connection applied load of 18.4 kip (81.8 kN), represent-

tion before applying fatigue loads. The cyclic load was ing the equivalent load per two connections spaced at 4 ft

applied for 2 million cycles, and the total movement of the (1.2 m). The cyclic load was then applied, ranging from

specimen was recorded for each cycle. The movement of 6.14 kip to -6.14 kip for 2 million cycles at a rate of 2

0.09 in. (2.3 mm) remained relatively constant, which in- cycles/sec. The total movement recorded over 2 million cy-

dicated that the connection maintained its stiffness through cles remained constant at approximately 0.02 in. (0.5 mm).

the 2 million cycles. The dam on the top surface of the specimen was filled with

water and monitored for cracks and water leakage during

The calculated moment capacity of the IDOT system with the fatigue test. Another static load was applied after 2 mil-

a 5-in.-thick (130 mm) noncomposite concrete topping lion cycles to determine whether there was any change to

was 145.4 kip-ft (197.1 kN-m) using strain compatibility. the connection stiffness as a result of connection fatigue.

Using simple beam analysis, this moment is equivalent to a

point load of 112.5 kip (500.4 kN) applied at the midspan Before increasing the magnitude of the cyclic load, a

higher static load was applied to the specimen. The static

load increased from 0 kip to 18.4 kip (0 kN to 81.8 kN),

reversed to -18.4 kip, and returned to 0 kip. Then the cyclic

load range of ±18.4 kip was applied for 3 million cycles

at a rate of 2 cycles/sec. The joint performed well under

the cyclic loads, and there were no visible cracks or water

leakage. The total movement recorded over the 3 mil-

lion cycles remained constant at approximately 0.07 in.

(1.8 mm).

The calculated moment capacity of the wide-joint system

using strain compatibility was 125 kip-ft (169 kN-m),

which corresponds to an ultimate point load of 161 kip

(716 kN) applied at the midspan of the specimen. The ac-

tual failure load was 162 kip (721 kN), which is equivalent

to a distributed load of 20.3 kip/ft (296 kN/m) along the

8-ft-long (2.4 m) bridge segment.

Figure 11. Failure of the current system.

PCI Journal | Fa l l 2011 59

Figure 12. Failure of the wide-joint connection.

Figure 12 shows the failure conditions of the wide-joint a concrete drill to allow for the threaded rod placement. To

specimen. The top cracks were located between the web avoid this complication in the future, a smooth reinforcing

and the top flange of the box girder. This indicated that the bar can be placed inside the plastic duct before concrete

elimination of intermediate diaphragms allowed the top placement and removed after release of the prestressing

flange to work as a slab and transfer the load continuously. force. The horizontal and vertical shear keys were cleaned

The failure at the bottom of the box occurred at the end of and filled with a non-shrink, nonmetallic grout.

the splicing bar.

After the joint cured and the grout compressive strength

Testing of narrow-joint connection reached 6000 psi (41 MPa), the loading was applied to the

specimen. The static- and cyclic load applications followed

The narrow-joint connection specimen was built by placing the same sequence as described in the testing of the wide-

the two box girders against each other and inserting threaded joint connection.

rods at the top and bottom openings. Couplers were used

to connect the threaded rods at the joint, and a 1/2-in.-thick The joint performed well under the cyclic loads, and there

(13 mm) steel plate and nuts were used at the outside face were no visible cracks or water leakage. The total movement

of the box girder. The plastic ducts of the threaded rods recorded in the first 2 million cycles was constant at 0.02 in.

were damaged during concrete placement at both top and (0.5 mm). The movement increased to approximately

bottom locations. As a result, the opening was not sufficient 0.07 in. (1.8 mm) when the load increased from 6.14 kip

for placement of the 3/4-in.-diameter (20 mm) threaded rods. (27.3 kN) to 18.4 kip (81.8 kN). The movement of 0.07 in.

The opening was increased to 1 in. (25 mm) diameter using remained constant in the following 3 million cycles.

Figure 13. Failure of the narrow-joint connection.

60 Fall 2 0 1 1 | PCI Journal

25

Theoretical capacity

Actual capacity

20

Capacity, kip/ft

15

10

0

Current Wide joint Narrow joint

Figure 14. Theoretical capacity and testing capacity of the three systems. Note: 1 ft = 0.305 m; 1 kip = 4.448 kN.

The calculated moment capacity of the narrow-joint system IDOT detail with the 5-in.-thick (130 mm) noncomposite

was 83 kip-ft (113 kN-m) using strain compatibility. This concrete topping has.

corresponds to a point load of 107 kip (476 kN) applied at

the midspan of the specimen. The actual failure load was Conclusion

156 kip (694 kN), significantly higher than the theoreti-

cal load. Distributing the failure load uniformly along the This paper presents a new proposal consisting of two main

8-ft-long (4.2 m) segment results in an equivalent uniform elements: the elimination of all intermediate diaphragms

load of 19.5 kip/ft (285 kN/m). The failure of the narrow- in adjacent box girder decks and the use of non-post-

joint specimen in Fig. 13 shows the grout split around the tensioned concrete to resist interface shear, torsion, and

coupling nut due to stress concentration at the bottom of flexure. Two new non-post-tensioned transverse connec-

the box connection. tions in adjacent box girders were presented.

Comparison between The proposed narrow-joint and wide-joint connections

connection systems were developed to be structurally superior to existing

connections while being more practical and economical.

Figure 14 and Table 1 compare the theoretical flexure ca- Both connections were designed to eliminate the need for

pacities and actual testing capacities of the three systems. post-tensioning, cross and end diaphragms, and concrete

The wide-joint and narrow-joint systems have significantly topping. This will significantly simplify box production,

higher theoretical capacities and testing capacities than the increase the speed of bridge construction, and reduce the to-

Table 1. Comparing the flexure and shear capacities of the three systems

Theoretical capacity Actual capacity

Connection type Difference, %

Moment, kip-ft Load, kip Moment, kip-ft Load, kip

Current connection 145 112.5 179 139 19.0

Wide-joint connection 125 161 126 162 0.8

Narrow-joint connection 83 107 119 156 30.3

Note: 1 ft = 0.305 m; 1 kip = 4.448 kN.

PCI Journal | Fa l l 2011 61

tal cost. The elimination of diaphragms facilitates inspection References

of voids, provides better drainage of moisture, results in a

lighter section weight for handling and shipping, and allows 1. American Association of State Highway and Transpor-

for continuous rather than discrete (quarter-point) connec- tation Officials (AASHTO). 1996. Standard Specifica-

tions. The proposed narrow-joint and wide-joint connections tions for Highway Bridges. 16th ed. Washington, DC:

have horizontal and vertical shear keys for shear transfer AASTHO.

with top- and bottom-flange reinforcement to provide an

adequate moment transfer mechanism between the boxes. 2. AASHTO. 2007. AASHTO LRFD Bridge Design

Specifications, Fourth Edition—2008 Interim Revi-

Finite element models were developed to determine the sions. Washington, DC: AASHTO.

effect of design parameters on the design of the proposed

connections, such as span length, bridge width, and girder 3. PCI Bridge Design Manual Steering Committee. 2003.

depth. The latest AASHTO LRFD specifications’ live load Precast Prestressed Concrete Bridge Design Manual.

and dynamic load factors were applied to determine the re- MNL-133. 2nd ed. Chicago, IL: PCI.

quired reinforcement in the two connections. Design charts

were developed for each system to facilitate connection 4. El-Remaily, A., M. K. Tadros, T. Yamane, and G.

design in various bridge widths ranging from 28 ft to 84 ft Krause. 1996. Transverse Design of Adjacent Precast

(8.5 m to 26 m); span-to-depth ratios of 25, 30, and 35; Prestressed Concrete Box Girder Bridges. PCI Jour-

and four standard depths of 27 in., 33 in., 39 in., and 42 in. nal, V. 41, No. 4 (July–August): pp. 96–113.

(690 mm, 840 mm, 990 mm, and 1070 mm). Based on the

analysis results, the following conclusions can be made for 5. Hanna, K. E., G. Morcous, and M. K. Tadros. 2007.

the wide-joint and narrow-joint connections: Transverse Design and Detailing of Adjacent Box

Beam Bridges. In The PCI National Bridge Confer-

• The required connection reinforcement increases as ence: Proceedings, October 22–24, 2007, Phoenix,

the bridge width increases. Arizona. CD-ROM.

• The required connection reinforcement decreases as 6. Hanna, K. E. 2008. Behavior of Adjacent Precast

the bridge depth increases. Prestressed Concrete Box Girder Bridges. PhD diss.

University of Nebraska, Lincoln, NE.

• The required connection reinforcement increases as

the span-to-depth ratio increases. 7. Hanna, K. E., G. Morcous, and M. K. Tadros. 2009.

Transverse Post-tensioning Design and Detailing of

Based on test results, it can be concluded that non-post-ten- Precast Prestressed Concrete Adjacent Box Girder

sioned transverse connections can be designed and detailed Bridges. PCI Journal, V. 54, No. 4 (Fall): pp. 160–

to have comparable performance to post-tensioned connec- 174.

tions and be more economical and practical. A significant

improvement in production economy is caused by the 8. PCI Bridges Committee. Forthcoming. The State of

ability to remove all diaphragms and to use a reusable steel the Art of Practice of Precast/Prestressed Adjacent

void-forming system. The proposed non-post-tensioned Box Beam Bridges. Chicago, IL: PCI.

wide-joint and narrow-joint connections performed well

under static and cyclic loads; therefore, both connections

are recommended for practical applications in bridge con-

struction.

Acknowledgments

The authors wish to acknowledge the invaluable support of

Kevin Eisenbeis of Harrington and Cortelyou Inc., who was

chairman of the PCI Subcommittee on Adjacent Member

Bridges. Acknowledgement also goes to PCI’s financial sup-

port of Kromel Hanna through a Danel P. Jenny Fellowship.

In addition, the authors would like to thank Andy Keenan,

Michael Johnson, and Emil Tadros at Prestress Engineering

Corp. for specimen fabrication, as well as Taylor Slate and

Rick Thomson of Hamilton Form Co. and Helser Industries,

respectively, for technical advice on internal void forming.

62 Fall 2 0 1 1 | PCI Journal

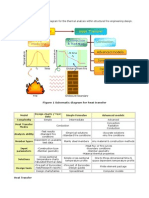

Production of box girders U-shaped upper form

Box girders are more challenging to produce than open- Sliding side plate

Sliding side plate

section girders, such as I-girders and U-girders. Traditional

production methods include the use of expanded polysty- U-shaped lower form

Jack

rene (EPS) for void forming and the two-stage box produc-

Mold expanded

tion using the U-girder and a top slab. Although the use of

EPS for void forming is practical and economical for many

applications, steel forms can be significantly more cost-

effective with their standardized shapes and repeated usage.

More important, EPS forms do not provide precise dimen-

sions and do not allow void inspection. The two-stage pro-

Mold collapsed

duction of box girders results in slower production, higher

cost, and lower quality than single-cast box girders.

Figure A3. Proposed void forming system.

The main advantages of the proposed concepts are as fol-

lows: • The use of continuous forms eliminates intermediate

and end diaphragms and allows for void inspection.

• The use of easily removable steel forms provides

precise dimensions and forms can have multiple reuses • The adoption of single-cast forms permits placing the

while maintaining high production quality. concrete for the entire box in one stage and eliminates

construction joints. This can be easily achieved using

self-consolidating concrete that can be placed through

Moving the wedges outward

one stem until it rises up the other stem without the

Wedge

need for vibration.

L-shaped steel form Several steel void form systems already exist in the U.S.

market and abroad. For example, precast concrete manu-

facturers use voided box-girder systems for the railroad

Mold expanded industry. However, the main impediments of these systems

for use in the production of highway box girders are the

Moving the wedges inward longer spans (over 120 ft [37 m]) and greater camber values

Wedge (up to 3 in. [75 mm]) of highway bridge girders. Therefore,

the concepts proposed in this paper include two systems

L-shaped steel form adopted by two private companies with slight modifications

in addition to one new system proposed by the authors.

Mold collapsed Figure A1 shows the system adopted by a private company,

which consists of two L-shaped steel forms and two corner

Figure A1. Form system adapted from current industry system. wedges. By moving the wedges outward, the form expands

Part 3

Part 1

1 ft 9 in. Open gap, to be covered with sheet metal and duct tape

Part 4

Part 2 Elevation - mold expanded

Part 3

Part 1 3 ft

78 ft 31/2 in.

Plan view - mold expanded

1 ft 6 in.

Elevation - mold collapsed

Plan view - mold collapsed

Figure A2. Form system adapted from current industry system. Note: 1 in. = 25.4 mm; 1 ft = 0.305 m.

PCI Journal | Fa l l 2011 63

to the required dimension. By moving the wedges inward, Figure A3 shows the system proposed by the authors,

the form collapses to the position that allows the initial which consists of one U-shaped lower form and one in-

camber to take place at release before form removal. verted U-shaped upper form. The forms can expand and col-

lapse using multiple vertical jacks. Two additional sliding

Figure A2 shows the system adopted by a different private side plates are needed to cover the longitudinal joint when

company, which consists of four tapered parts with wave- the two forms are expanded. This form can accommodate

shaped webs. The top and bottom halves of the form can be various box depths, span lengths, and initial cambers.

drawn toward each other using external jacks and released

from the inside face of the form before the release of pre-

stressing to allow for initial camber.

About the authors This paper presents the development of two non-post-

tensioned transverse connections for possible simplifica-

Kromel E. Hanna, PhD, is a tion of this already efficient bridge system. The proposed

post-doctoral fellow in the Depart- continuous connections transfer shear and moment

ment of Civil Engineering at the between adjacent boxes without the need for diaphragms.

University of Nebraska–Lincoln. The connections are based on monolithic emulation of a

multicell cast-in-place box-girder superstructure, similar

to a system commonly used in California. The wide-joint

connection consists of a wide full-depth shear key filled

George Morcous, PhD, P.Eng., with flowable concrete and top and bottom reinforcement.

P.E., is an associate professor at The narrow-joint connection consists of top and bottom

the Charles W. Durham School of couplers and full-depth grouted shear keys. Finite element

Architectural Engineering and models were used to develop design charts for different

Construction at the University of bridge configurations. Fatigue and static load testing were

Nebraska–Lincoln. performed on the proposed connections and one com-

monly used connection to evaluate their fatigue capacity,

Maher K. Tadros, PhD, P.E., is an ultimate capacity, and joint leakage. Test results indicate

emeritus professor of civil that the proposed connections outperform the current

engineering at the University of connection in addition to being more economical. Innova-

Nebraska–Lincoln and principal tive concepts for the production of precast concrete box

of e.construct.USA. girders for highway bridges are also presented.

Keywords

Abstract

Box girders, shear key, post-tensioning, transverse

Precast, prestressed concrete adjacent box-girder bridges connections, bridge superstructure.

are widely used in short- and medium-span bridges.

Rapid construction and low cost are the main advantages Review policy

of this system. Although the use of transverse post-ten-

sioning to connect adjacent box girders can be effec- This paper was reviewed in accordance with the Precast/

tive and practical, end and intermediate diaphragms are Prestressed Concrete Institute’s peer-review process.

necessary for continuity. Construction of diaphragms in

skewed bridges is difficult and may significantly increase Reader comments

in the construction cost and schedule. Moreover, post-

tensioned transverse diaphragms result in continuity at Please address any reader comments to journal@pci.org

discrete locations, making the system more susceptible to or Precast/Prestressed Concrete Institute, c/o PCI Jour-

cracking and leakage. nal, 200 W. Adams St., Suite 2100, Chicago, IL 60606. J

64 Fall 2 0 1 1 | PCI Journal

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Fisher Whisper TrimDocument8 pagesFisher Whisper TrimCecep AtmegaNo ratings yet

- Evapco O&M InstructionDocument52 pagesEvapco O&M InstructionYutt WattNo ratings yet

- Design by First PrincipleDocument47 pagesDesign by First Principlesaam456100% (2)

- ETAG005 1revDocument58 pagesETAG005 1revSerban RaduNo ratings yet

- ACI 201.1R-08 Guide For Conducting A Visual Inspection of Concrete in ServiceDocument19 pagesACI 201.1R-08 Guide For Conducting A Visual Inspection of Concrete in ServicehoustonhimselfNo ratings yet

- Bs Steel CodeDocument14 pagesBs Steel CodeA.K.A. HajiNo ratings yet

- Precast Cement Concrete Block Construction GuideDocument12 pagesPrecast Cement Concrete Block Construction GuideDjajithNo ratings yet

- Transverse Post-Tensioning Design and Detailing of Precast Prestressed Concrete Adjacent-Box-Girder Bridges PDFDocument15 pagesTransverse Post-Tensioning Design and Detailing of Precast Prestressed Concrete Adjacent-Box-Girder Bridges PDFSanti CheewabantherngNo ratings yet

- Hi Force CatalogDocument124 pagesHi Force CatalogMasterrNo ratings yet

- GBT 20065-2006 - English VersionDocument12 pagesGBT 20065-2006 - English VersionSanti Cheewabantherng100% (1)

- Thermal Analysis: Figure 1 Schematic Diagram For Heat TransferDocument8 pagesThermal Analysis: Figure 1 Schematic Diagram For Heat TransferBogdan BotofanNo ratings yet

- Comparing HDPE Pipes for UV ResistanceDocument8 pagesComparing HDPE Pipes for UV ResistanceSanti CheewabantherngNo ratings yet

- EAD-160027-00-0301-Special Filling Products For Post-Tensioning KitsDocument25 pagesEAD-160027-00-0301-Special Filling Products For Post-Tensioning KitsSanti CheewabantherngNo ratings yet

- Etag 002 PT 3 PDFDocument26 pagesEtag 002 PT 3 PDFRui RibeiroNo ratings yet

- ETAG006 2finDocument66 pagesETAG006 2finSerban RaduNo ratings yet

- 6DA1 - FailureDocument4 pages6DA1 - FailureSanti CheewabantherngNo ratings yet

- BE Mono Coupler-BULGAR EDEN ENTERPRISE CO., LTDDocument2 pagesBE Mono Coupler-BULGAR EDEN ENTERPRISE CO., LTDSanti CheewabantherngNo ratings yet

- Administration: Name of JurisdictionDocument10 pagesAdministration: Name of JurisdictionSanti CheewabantherngNo ratings yet

- Vb2010 - 3 - Bull Page94Document1 pageVb2010 - 3 - Bull Page94Santi CheewabantherngNo ratings yet

- New books on bridge design, earthquake engineeringDocument14 pagesNew books on bridge design, earthquake engineeringSanti CheewabantherngNo ratings yet

- Bulletin 38: Fire Design of Concrete Structures - : Materials, Structures and ModellingDocument2 pagesBulletin 38: Fire Design of Concrete Structures - : Materials, Structures and ModellingSanti CheewabantherngNo ratings yet

- PDF EnglishDocument36 pagesPDF EnglishSanti CheewabantherngNo ratings yet

- HiForce Catalog Torque-EngDocument8 pagesHiForce Catalog Torque-EngKannika ChaipanthiNo ratings yet

- LLG Low Locknut Load Return: Innovative Hydraulic SolutionsDocument1 pageLLG Low Locknut Load Return: Innovative Hydraulic SolutionsSanti CheewabantherngNo ratings yet

- State of The Art in External PresstressingDocument63 pagesState of The Art in External PresstressingJames ClaytonNo ratings yet

- State of The Art in External PresstressingDocument63 pagesState of The Art in External PresstressingJames ClaytonNo ratings yet

- Connection Details for Adjacent Precast Box Beam BridgesDocument76 pagesConnection Details for Adjacent Precast Box Beam BridgesSanti CheewabantherngNo ratings yet

- Overview and Applications of Precast Prestressed Concrete Adjacent Box-Beam Bridges in South KoreaDocument25 pagesOverview and Applications of Precast Prestressed Concrete Adjacent Box-Beam Bridges in South KoreaSanti CheewabantherngNo ratings yet

- 0092-14-01-Final-Report - Reflective Cracking Between Precast Prestressed Box GirdersDocument128 pages0092-14-01-Final-Report - Reflective Cracking Between Precast Prestressed Box GirdersJulio PinedaNo ratings yet

- PCI - Ext PT of Adj-Box-Bms - Spring-2012 PDFDocument16 pagesPCI - Ext PT of Adj-Box-Bms - Spring-2012 PDFScott CanfieldNo ratings yet

- SuperelevationDiscussion9 03Document16 pagesSuperelevationDiscussion9 03Onik PlabonNo ratings yet

- Aci 117 R90Document11 pagesAci 117 R90Rafael Elgueta Aravena100% (1)

- Screw-thread Steel Bars for the Prestressing of Concrete - GB T 20065-2016 - Chinese - 预应力混凝土用螺纹杆钢筋Document12 pagesScrew-thread Steel Bars for the Prestressing of Concrete - GB T 20065-2016 - Chinese - 预应力混凝土用螺纹杆钢筋Santi CheewabantherngNo ratings yet

- Connection Details for Adjacent Precast Box Beam BridgesDocument76 pagesConnection Details for Adjacent Precast Box Beam BridgesSanti CheewabantherngNo ratings yet

- Document ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018Document1 pageDocument ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018dhanishlNo ratings yet

- Lecture 21Document24 pagesLecture 21jnmanivannanNo ratings yet

- VAUTID ASW 143 Engl 041016Document1 pageVAUTID ASW 143 Engl 041016rusf123No ratings yet

- Course Information and Lesson Plan Design of Machine Elements-1 PDFDocument2 pagesCourse Information and Lesson Plan Design of Machine Elements-1 PDFAyushSaraswatNo ratings yet

- Comm Off - Repairs and Painting To Pump House and Back Side ToiletsDocument32 pagesComm Off - Repairs and Painting To Pump House and Back Side ToiletsthesmileynoobNo ratings yet

- Theories of Failure: Machine Design StructuralDocument3 pagesTheories of Failure: Machine Design Structuralamarkiran vinayakNo ratings yet

- Ib Tutorial 4 (12 13) Sem 2Document5 pagesIb Tutorial 4 (12 13) Sem 2omarnasriNo ratings yet

- 01-Dinamika Fluida Lanjut-Basic of Viscous Flow AnalysisDocument17 pages01-Dinamika Fluida Lanjut-Basic of Viscous Flow AnalysisZulham SasmitaNo ratings yet

- Theory of Elasticity 1 PDFDocument53 pagesTheory of Elasticity 1 PDFwasim raza jamaniNo ratings yet

- Appendix C Steam TablesDocument8 pagesAppendix C Steam TablesWin Alfalah Nasution100% (1)

- Dowel Laminated Timber: The All Wood Mass Timber PanelDocument32 pagesDowel Laminated Timber: The All Wood Mass Timber PanelStephanyNo ratings yet

- Buderus Logalux PL750/2S Combi Solar Tank SpecificationsDocument2 pagesBuderus Logalux PL750/2S Combi Solar Tank Specificationse-ComfortUSANo ratings yet

- High Strength SteelDocument19 pagesHigh Strength SteelBHARANINo ratings yet

- Ice-O-Matic - ICE0320W & ICEO520W - Coke Freestyle HeadDocument2 pagesIce-O-Matic - ICE0320W & ICEO520W - Coke Freestyle HeadSneha AshokNo ratings yet

- SpeedHeat EzeeStat II Instructions Rev 04Document4 pagesSpeedHeat EzeeStat II Instructions Rev 04Lefa Doctormann RalethohlaneNo ratings yet

- 120G Wired Remote ManualDocument42 pages120G Wired Remote ManualHaytahNo ratings yet

- 3RD Term S2 Technical DrawingDocument30 pages3RD Term S2 Technical DrawingDada RasheedNo ratings yet

- Astm D 510Document3 pagesAstm D 510Indira BanerjeeNo ratings yet

- ASME Sec VIII - Temper Bead TechniqueDocument1 pageASME Sec VIII - Temper Bead TechniquezanlogNo ratings yet

- Junction Box Product ListDocument1 pageJunction Box Product ListtxagusNo ratings yet

- Fi SV DaDocument16 pagesFi SV Dam mNo ratings yet

- Brochure - Luffa Cylindrica Fiber As An Additive in Concrete MIxtureDocument2 pagesBrochure - Luffa Cylindrica Fiber As An Additive in Concrete MIxtureRhizyl Jhane EstrellaNo ratings yet

- Tabulation of Doors and Windows for Residential HouseDocument1 pageTabulation of Doors and Windows for Residential HouseAlbert Dela CruzNo ratings yet

- (Engin 1Document444 pages(Engin 1Esmael AdemNo ratings yet

- Maxwell Crushtech: Raw Material SizeDocument1 pageMaxwell Crushtech: Raw Material SizepatelchiragisNo ratings yet