Professional Documents

Culture Documents

3M 4279 Datasheet PDF

Uploaded by

Rehan SadiqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3M 4279 Datasheet PDF

Uploaded by

Rehan SadiqCopyright:

Available Formats

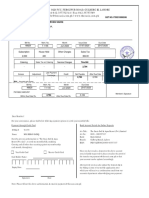

4000 Series Gas and

Vapour Respirators

Data Sheet

Main features Approvals

The 3M 4000 Series is a range of respirators which use innovative • The 3M 4000 series meet the performance requirements of the

technology to provide integral construction gas and vapour respirators. European Standard EN405:2002 for valved filtering half-mask respi-

The 3M 4000 Series uses twin inhalation valves to reduce breathing rators for gases, or gases and particulate combinations.

resistance, together with bonded carbon filters, which do not require • Are suitable for use under COSHH, CAW, CLAW and IRR.

granule containers. This is complemented with a parabolic valve which • The products are CE marked.

further reduces breathing resistance whilst preventing heat build-up.

Materials

The single piece integral construction also avoids operator assembly

errors and allows a respirator to be designated to a specific area, The following materials are used in the production of the product:

making a respirator programme easier to manage. An optional • Face piece - Thermoplastic elastomer

overspray guard is also available to prolong the life of the particulate • Head harness - Polypropylene/cotton braided elastic

filter when using the 3M 4251 or 3M 4255 respirators for paint • Plastic components - Polypropylene

spraying. • Gas/Vapour filter - Activated carbon

• Particulate filter - Polypropylene

• Exhale valve - Silicone rubber

Applications

• Inhale valve - Natural rubber

Product weight: 300g max.

MODEL HAZARD INDUSTRY Standards

4251/4255 Organic - Anywhere conventional paints are

(FFA1P2D/ Vapours used (subject to usage conditions). The products have been tested to European Standard EN405:2002

(FFA2P3D) and - Vehicle manufacture and have met the relevant requirements of the categories shown

Particulates - Plant equipment manufacture below.

- Shoe treatment and tanneries

The main performance tests in this standard are:

- Domestic appliance manufacture

- Aircraft manufacture and • Face Fit

refurbishment • Flammability

- Boat building

• Breathing Resistance

- Machinery manufacture

- Chemical manufacture and handling • Filter Performance

- Ink and dye manufacture and usage • Paraffin Oil Test

- Adhesive manufacture and

Within the criteria specified in the standard

laboratories

- Paint and varnish manufacture - The 3M 4251 (FFA1P2D) provides protection against organic

- Manufacture and use of resins vapours, (boiling above 65°C) up to 10 times the Occupational

Exposure Limit (OEL) or 1000 parts per million (ppm), whichever

4277 Organic As 4251 but also: is lower. 10 times OEL for particulates.* (Waterbased and non-

(FFABE1 Vapours, - Electrolytic processes volatile liquid aerosols).

P3D) Inorganic - Acid cleaning

- The 3M 4255 (FFA2P3D) provides protection against organic

Gases, - Metal pickling

Acid Gases - Metal etching vapours, (boiling above 65°C) up to 10 times OEL or 5000 ppm,

and whichever is lower. 20 times OEL for particulates.*(Waterbased

Particulates and non-volatile liquid aerosols).

- The 3M 4277 (FFABE1P3D) provides protection against

4279 Organic As 4277 but also: organic vapours, (boiling above 65°C), inorganic and acid gases, up

(FFABEK1 Vapours, - Manufacture and maintenance of to 10 times OEL or 1000 ppm, whichever is lower. 20 times OEL

P3D) Inorganic refrigeration equipment

and - Agrochemicals for particulates.*(Waterbased and non-volatile liquid aerosols).

Acid Gases - The 3M 4279 (FFABEK1P3D) provides protection against

plus

organic vapours (boiling above 65°), inorganic and acid gases and

Ammonia

and ammonia, up to 10 times OEL or 1000 ppm, whichever is lower.

Particulates 20 times OEL for particulates.*(Waterbased and non-volatile

liquid aerosols).

* Assigned Protection Factors according to (British Standard) BS4275: 1997.

3M 4000 Series Gas and Vapour Respirators

Fitting Instructions

Fitting instructions must be followed each time the respirator is worn.

2. Place the respirator over the

face, fitting it comfortably on

1. Assemble/adjust head cradle bridge of the nose, then pull the

by feeding the perforated strip head harness over the crown of

through the buckle and pressing the head. If necessary remove

down on the stud at the the respirator and readjust the

required length. Repeat for head cradle to a comfortable fit

second strip. and repeat step 2.

4. Tighten the top strap first by

pulling on the ends to achieve

a comfortable and secure fit.

3. Take a bottom strap in each Tighten bottom straps in a

hand, place them at the back of similar manner. (Strap tension

the neck and hook the straps may be decreased by pushing

together. out on back side of buckles.)

Use Limitations

5. Perform a positive pressure

fit check. Place palm of hand 1. This respirator does not supply oxygen. Do not use in atmospheres

over exhalation valve cover and containing less than 19.5 % oxygen.

exhale gently. If the facepiece

bulges slightly and no air leaks 2. Do not use when concentrations of contaminants are immediately

between the face and the hazardous to life and health, are unknown, or have poor warning prop-

facepiece are detected, a proper

fit has been achieved. erties (i.e. smell or taste).

If air leakage is detected, 3. Do not use when the organic vapour has a boiling point of less than

reposition the respirator on the

face and/or readjust the tension 65°C.

of the elastic strap and the head 4. Do not abuse or misuse this respirator.

harness to eliminate the

leakage. Repeat the above 5. Do not use with beards or other facial hair that prevents direct

facefit check. contact between the face and the edge of the respirator.

If you cannot achieve a proper

fit, do not enter the contamin- 6. Do not use for concentrations of contaminants which generate

ated area. See your supervisor. high heats of reaction.

7. Do not use for escape purposes.

Cleaning and Maintenance 8. Leave the contaminated area immediately if:

If the 3M 4000 Series is to be used for more than one shift, it should a) the respirator becomes damaged

be cleaned at the end of each shift and stored between shifts in its b) breathing becomes difficult

resealable packaging, away from the contaminated area. c) dizziness or distress occur

To clean the 3M 4000 Series the face seal area should be wiped with d) you taste or smell contaminants, or an irritation occurs

a cloth moistened with warm soapy water, (the water temperature

For help with selecting the most appropriate forms of PPE and relevant

should be below 40°C) and dried at room temperature.

Health & Safety legislation, or for more detailed product information,

The product MUST NOT be immersed in water during cleaning. please contact the 3M Health & Safety Helpline on: 0870 60 800 60.

Alternatively, the 3M 105 Face Seal Cleaner may be used. For callers within the Republic of Ireland: 1 800 320 500.

Occupational Health Group Occupational Health Group

CH4000A 11/2002

3M United Kingdom PLC 3M Ireland

3M House, PO Box 1, 3M House, Adelphi Centre, Upper Georges St.

Market Place, Bracknell, Dun Laoghaire

Berkshire RG12 IJU Co. Dublin, Ireland

You might also like

- Final Year ProjectDocument159 pagesFinal Year ProjectAhmad Riaz Khan100% (2)

- Corrosion Basics - An Introduction, 3rd EditionDocument35 pagesCorrosion Basics - An Introduction, 3rd EditioncarlosNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Caribbean Examinations: OI2I2O2O 2017005Document17 pagesCaribbean Examinations: OI2I2O2O 2017005keeonNo ratings yet

- Experiment 8 The Preparation of AcetanlideDocument12 pagesExperiment 8 The Preparation of AcetanlideRadhwanNo ratings yet

- Atoms and Molecules WorksheetDocument2 pagesAtoms and Molecules Worksheet23_11_1993No ratings yet

- 3M 4279 Datasheet PDFDocument1 page3M 4279 Datasheet PDFRehan SadiqNo ratings yet

- Parker Pneumatic Global Air Preparation System PDE2676TCUKDocument108 pagesParker Pneumatic Global Air Preparation System PDE2676TCUKeng_823664768No ratings yet

- 3M 9300 MFR Technical DataDocument2 pages3M 9300 MFR Technical DataMichael TadrosNo ratings yet

- Gas / Vapour Respirators: A. Horesch 96Document11 pagesGas / Vapour Respirators: A. Horesch 96Anonymous iI88LtNo ratings yet

- Enviroline 124: Protective Coatings Worldwide ProductDocument4 pagesEnviroline 124: Protective Coatings Worldwide ProductMohamed NouzerNo ratings yet

- Equipment for Corrosive Solutions and EnvironmentsDocument12 pagesEquipment for Corrosive Solutions and EnvironmentsRathawit SingpanjanateeNo ratings yet

- 02 en UsaDocument12 pages02 en UsaGonzalo de LuisNo ratings yet

- Fluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetDocument4 pagesFluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetFrancisco RodríguezNo ratings yet

- TDS OREVAC® 18341 v02.2015Document2 pagesTDS OREVAC® 18341 v02.2015Le MinhNo ratings yet

- PDS Perfecto XEP (2)Document3 pagesPDS Perfecto XEP (2)邢焕震No ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Protective & Marine Coatings: Zinc Clad Iv EuDocument2 pagesProtective & Marine Coatings: Zinc Clad Iv Eusrinath vNo ratings yet

- Technical Data Sheet IPA - Isopropyl Alcohol: ChemtronicsDocument3 pagesTechnical Data Sheet IPA - Isopropyl Alcohol: ChemtronicsIvan Rudolf De FretesNo ratings yet

- DS 058-Rev-02 Epilux 155 High Build MIO CoatingDocument2 pagesDS 058-Rev-02 Epilux 155 High Build MIO CoatingsojeckNo ratings yet

- F013Document2 pagesF013Sai PrasathNo ratings yet

- Thermaline 400: Selection & Specification DataDocument3 pagesThermaline 400: Selection & Specification DataJalaluddinNo ratings yet

- TDS 3440 Penguard Express MIO Eng USDocument5 pagesTDS 3440 Penguard Express MIO Eng USzattie89No ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interlac - 665 - Eng - Usa - LTR - 20090707Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interlac - 665 - Eng - Usa - LTR - 20090707Linnie McleodNo ratings yet

- Application Instructions Hempacore OneDocument9 pagesApplication Instructions Hempacore Onec-hiranNo ratings yet

- Intertherm 50: Silicone AluminiumDocument4 pagesIntertherm 50: Silicone Aluminiumnoto.sugiartoNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Thermaline 4000 Aluminum: Selection & Specification DataDocument3 pagesThermaline 4000 Aluminum: Selection & Specification DataKatherine Marimón JiménezNo ratings yet

- Arde Respira Ç ÃoDocument8 pagesArde Respira Ç ÃoSuprimentos IndaloNo ratings yet

- Lotader: Ethylene - Acrylic Ester - Maleic Anhydride TerpolymerDocument2 pagesLotader: Ethylene - Acrylic Ester - Maleic Anhydride TerpolymerLe MinhNo ratings yet

- Hempadur Multi-Strength 45540 Product Data SheetDocument3 pagesHempadur Multi-Strength 45540 Product Data SheetAhmad Syafiq B Che RahimNo ratings yet

- Material Product Data Sheet Iron Chromium Aluminum Yttrium (Fecraly) Thermal Spray PowderDocument3 pagesMaterial Product Data Sheet Iron Chromium Aluminum Yttrium (Fecraly) Thermal Spray PowderfrdnNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Hempadur 4774D EN - Ed March 2023Document4 pagesHempadur 4774D EN - Ed March 2023FreddyNo ratings yet

- ANFODocument2 pagesANFOYef PumacayoNo ratings yet

- Marfak 00, 0, 1Document2 pagesMarfak 00, 0, 1Hector IbarraNo ratings yet

- Mobil Pyrotec™ HFD 46Document2 pagesMobil Pyrotec™ HFD 46ABDUL REHMAN PIPRANINo ratings yet

- Aerospec 100 TdsDocument2 pagesAerospec 100 TdsHasnain ZaidiNo ratings yet

- Isophthalic Resin - AROPOL IN 5334Document3 pagesIsophthalic Resin - AROPOL IN 5334GautamNo ratings yet

- Carbothane 134 Series PDS Sept 2012Document2 pagesCarbothane 134 Series PDS Sept 2012salamrefighNo ratings yet

- MSDS Refined Oil Fuel Supply Waste CollectionDocument3 pagesMSDS Refined Oil Fuel Supply Waste CollectionPolaris Shipping LinesNo ratings yet

- Everlube 9002 TDSDocument2 pagesEverlube 9002 TDSValentinNo ratings yet

- Interline 850+br+eng PDFDocument2 pagesInterline 850+br+eng PDFMohamed NouzerNo ratings yet

- Hempadur 15130Document2 pagesHempadur 15130MuthuKumarNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- Intercure 99Document4 pagesIntercure 99Doby YuniardiNo ratings yet

- Thermaline 400 Primer PDSDocument3 pagesThermaline 400 Primer PDSQuy RomNo ratings yet

- Enviroline 405HT+ds+eng PDFDocument4 pagesEnviroline 405HT+ds+eng PDFMohamed NouzerNo ratings yet

- Carboxane 2000 PDSDocument4 pagesCarboxane 2000 PDSBERSE MAJU INDONESIANo ratings yet

- Derakane Resin Chemical ResistantDocument50 pagesDerakane Resin Chemical ResistantTim KuNo ratings yet

- AsmDocument13 pagesAsmVivekanandan JNo ratings yet

- Thermaline 400 Finish PDSDocument3 pagesThermaline 400 Finish PDSQuy RomNo ratings yet

- ยาง O-ringDocument78 pagesยาง O-ringJirakom LimmongkolkulNo ratings yet

- Enviroline 125u+ds+engDocument4 pagesEnviroline 125u+ds+engMohamed NouzerNo ratings yet

- Enviroline 376f-60+ds+eng PDFDocument4 pagesEnviroline 376f-60+ds+eng PDFMohamed NouzerNo ratings yet

- Shell Corena Oil AP Advanced Synthetic LubricantDocument2 pagesShell Corena Oil AP Advanced Synthetic LubricantGanesh AnandNo ratings yet

- High Build Epoxy Coating for PipelinesDocument3 pagesHigh Build Epoxy Coating for PipelinesAndrea Pamela León AlgarañazNo ratings yet

- Safe Handling of Compressed Gases: Kimi Zyky Lopez Reaño Lemuel Montril DivinaDocument47 pagesSafe Handling of Compressed Gases: Kimi Zyky Lopez Reaño Lemuel Montril DivinaKimi Zyky Lopez ReañoNo ratings yet

- Interlac 665 PDFDocument4 pagesInterlac 665 PDFEngTamerNo ratings yet

- TDS¤2063¤Tankguard 412¤Euk¤GBDocument6 pagesTDS¤2063¤Tankguard 412¤Euk¤GBAhmad SyawalNo ratings yet

- 410 UkDocument4 pages410 UkAhmed IbrahimNo ratings yet

- 312 UkDocument4 pages312 UkAhmed IbrahimNo ratings yet

- Ip9183 R1Document4 pagesIp9183 R1jeffinNo ratings yet

- Industrial Surfactants: An Industrial GuideFrom EverandIndustrial Surfactants: An Industrial GuideRating: 5 out of 5 stars5/5 (2)

- Notice AGM 2021Document3 pagesNotice AGM 2021Rehan SadiqNo ratings yet

- Solutions For Electrical Installation in Buildings - Catalogue - 2017Document8 pagesSolutions For Electrical Installation in Buildings - Catalogue - 2017BojanNo ratings yet

- London Metal Exchange - LME CopperDocument1 pageLondon Metal Exchange - LME CopperRehan SadiqNo ratings yet

- Standard Procedure and Formula for Price AdjustmentDocument13 pagesStandard Procedure and Formula for Price AdjustmentAbhinav Goel100% (3)

- Voestalpine Range of Supply Electrical Steel EN 030720Document11 pagesVoestalpine Range of Supply Electrical Steel EN 030720Rehan SadiqNo ratings yet

- Tianjin Grewin Technology Co.,Ltd. Electric Power Inductor/Bar Inductor /chokeDocument4 pagesTianjin Grewin Technology Co.,Ltd. Electric Power Inductor/Bar Inductor /chokeRehan SadiqNo ratings yet

- KE Electric Tenders Spare Parts for Flowserve Positioners, Load Break SwitchesDocument2 pagesKE Electric Tenders Spare Parts for Flowserve Positioners, Load Break SwitchesRehan SadiqNo ratings yet

- Tianjin Grewin Technology Co.,Ltd. Electric Power Inductor/Bar Inductor /chokeDocument4 pagesTianjin Grewin Technology Co.,Ltd. Electric Power Inductor/Bar Inductor /chokeRehan SadiqNo ratings yet

- General Terms of Sales & DeliveryDocument1 pageGeneral Terms of Sales & DeliveryRehan SadiqNo ratings yet

- T-1155 Mr. Rehan Sadiq: 17 Old FCC, Ferozpur Road, Gulberg Iii, LahoreDocument1 pageT-1155 Mr. Rehan Sadiq: 17 Old FCC, Ferozpur Road, Gulberg Iii, LahoreRehan SadiqNo ratings yet

- 7th National ISMO Class 6 Question PaperDocument10 pages7th National ISMO Class 6 Question PaperRehan SadiqNo ratings yet

- Soc Changes PDFDocument1 pageSoc Changes PDFAisha ShahabNo ratings yet

- Student Counselling ProfileDocument2 pagesStudent Counselling ProfileRehan SadiqNo ratings yet

- Export Price List for Wooden ProductsDocument8 pagesExport Price List for Wooden ProductsRehan SadiqNo ratings yet

- P263e BASFs Ultra-Light Polyurethane Utility Pole Helps Improve ResilienceDocument3 pagesP263e BASFs Ultra-Light Polyurethane Utility Pole Helps Improve ResilienceRehan SadiqNo ratings yet

- Field Studies Using the Cantilever Beam TestDocument5 pagesField Studies Using the Cantilever Beam TestRehan SadiqNo ratings yet

- Busbar SpecificationsDocument2 pagesBusbar SpecificationsFathi MusaNo ratings yet

- Dev Prof Test Gust PDFDocument8 pagesDev Prof Test Gust PDFjonalserNo ratings yet

- Computer Science 2210: The City SchoolDocument10 pagesComputer Science 2210: The City SchoolRehan SadiqNo ratings yet

- Dev Prof Test Gust PDFDocument8 pagesDev Prof Test Gust PDFjonalserNo ratings yet

- Bogo Lahore Brands - 2018-2019 - Sheet3Document24 pagesBogo Lahore Brands - 2018-2019 - Sheet3Rehan SadiqNo ratings yet

- Final English SBP Guidelines Edited24 MARCH2020 PDFDocument13 pagesFinal English SBP Guidelines Edited24 MARCH2020 PDFRehan SadiqNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Proficiency Testing RequirementsDocument22 pagesPerry Johnson Laboratory Accreditation, Inc.: Proficiency Testing Requirementscalibrator1No ratings yet

- Car Ij Appfrm PDFDocument4 pagesCar Ij Appfrm PDFNajeeb KhanNo ratings yet

- DDS 50-2007-MinDocument46 pagesDDS 50-2007-MinRehan SadiqNo ratings yet

- Car Ij Appfrm PDFDocument4 pagesCar Ij Appfrm PDFNajeeb KhanNo ratings yet

- DR Sania Nishtar Assets NewDocument4 pagesDR Sania Nishtar Assets NewRehan SadiqNo ratings yet

- Car Ij Appfrm PDFDocument4 pagesCar Ij Appfrm PDFNajeeb KhanNo ratings yet

- National TransmissionDocument236 pagesNational Transmissionhammadriaz1No ratings yet

- Evonik Home Care Product CatalogueDocument6 pagesEvonik Home Care Product Catalogue李雷No ratings yet

- CHE112P Lecture Recycle - BypassDocument22 pagesCHE112P Lecture Recycle - BypassYzeNo ratings yet

- Expt6 Sythesis of Phenacetin W15Document9 pagesExpt6 Sythesis of Phenacetin W15johnNo ratings yet

- Ansul: Inergen Material Safety Data SheetDocument5 pagesAnsul: Inergen Material Safety Data Sheet3138541950No ratings yet

- Kolb - Brochure Personal CareDocument9 pagesKolb - Brochure Personal CareRicardo CostaNo ratings yet

- AlcoholsDocument33 pagesAlcoholsSakib AhmedNo ratings yet

- Synthesis of Nanomaterials and Their Integration in Wastewater Treatment ProcessesDocument250 pagesSynthesis of Nanomaterials and Their Integration in Wastewater Treatment ProcessesnailaNo ratings yet

- Tablet Section Cost DR SabDocument6 pagesTablet Section Cost DR SabAbdul SamadNo ratings yet

- Eggert, G. y Schmutzler B. (Ed.) - Archaeological Iron Conservation. 2010Document98 pagesEggert, G. y Schmutzler B. (Ed.) - Archaeological Iron Conservation. 2010Trinidad Pasíes Arqueología-Conservación100% (2)

- Tds Solder Sn100cl enDocument2 pagesTds Solder Sn100cl enMarija JovanovicNo ratings yet

- LIQUID PROPELLANTS FOR USE IN GUNS A REVIEW Nathan KleinDocument40 pagesLIQUID PROPELLANTS FOR USE IN GUNS A REVIEW Nathan KleinkopcicleNo ratings yet

- Masterbrace 14146Document2 pagesMasterbrace 14146Mohammed Ashrey Shendi RatebNo ratings yet

- Tle-Cookery 7-Q1-M4Document15 pagesTle-Cookery 7-Q1-M4carla venturaNo ratings yet

- Question Bank of Chapter 1Document4 pagesQuestion Bank of Chapter 1lovika malhotraNo ratings yet

- Chemistry HSSC II Paper I AkuebDocument8 pagesChemistry HSSC II Paper I AkuebmehmoodaNo ratings yet

- Adhyayan Seminar PdfNewDocument34 pagesAdhyayan Seminar PdfNewFINAL YEAR PETROLEUM 2020 BATCHNo ratings yet

- Notes Chem NewDocument17 pagesNotes Chem Newilias1973No ratings yet

- Public Health Statement: Ethylene Glycol and Propylene GlycolDocument5 pagesPublic Health Statement: Ethylene Glycol and Propylene GlycolAnthony SimonaitisNo ratings yet

- CHEM10812: Introduction To Forensic & Analytical ChemistryDocument22 pagesCHEM10812: Introduction To Forensic & Analytical ChemistryAaron GrettonNo ratings yet

- Project Report On Washing Powder, Liquid Detergents, Lotion and ShampooDocument11 pagesProject Report On Washing Powder, Liquid Detergents, Lotion and ShampooEIRI Board of Consultants and PublishersNo ratings yet

- Isoniazid TabletDocument1 pageIsoniazid TabletVenkateshNo ratings yet

- Bell Helicopter Corrosion Control GuideDocument89 pagesBell Helicopter Corrosion Control GuideJosé Edwin Roldán67% (3)

- ELECTROCHEMISTRY REVIEWDocument8 pagesELECTROCHEMISTRY REVIEWAshwin Balaji100% (1)

- Tablet PuzzleDocument3 pagesTablet PuzzleRaya Ibarra LumogdangNo ratings yet

- Amberlite IRN 160 LDocument2 pagesAmberlite IRN 160 LJayanath Nuwan SameeraNo ratings yet