Professional Documents

Culture Documents

Victus Manifold

Uploaded by

Mahendran KuppusamyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Victus Manifold

Uploaded by

Mahendran KuppusamyCopyright:

Available Formats

MANAGED PRESSURE DRILLING TECH SPECS

Victus™ Manifold

Offers a customizable design, including between one and four legs,

to detect, control, and circulate out influxes

Applications

• Applying constant bottomhole

pressure as a method for

managed pressure drilling (MPD)

• Identifying and mitigating

common drilling problems

• Automatically detecting and

controlling kicks and losses

• Performing dynamic formation-

integrity tests (FIT) and leak-off

tests (LOT) without the need to

stop circulation or shut in the well

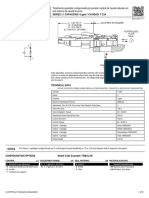

• Executing pressurized mud-cap The Weatherford Victus manifold is a fourth-generation design based on decades of performing and operating. The above manifold

drilling in wells with total losses. shows one possible customization that features three legs, each with its own respective choke and flowmeter. The manifold also

includes integrated junk catchers and a gut line.

Features and Benefits Manifold Description

• Manifold offers customization to A key component of Weatherford Victus intelligent MPD, the Victus

operational and customer needs. manifold enhances safety, minimizes nonproductive time, and increases

• Up to four choke legs increase drilling efficiency in land, shallow-water, or deepwater operations. Its

redundancy and enable small, modular design fits any rig-floor footprint and offers

continued drilling. customization to well, rig, and operator needs.

• Coriolis flowmeter installed

upstream of the choke facilitates The manifold offers the option of one to four legs to increase

measuring the flow of mud

redundancy. Each leg includes a choke and a Coriolis flowmeter. If

returns with high gas.

plugging or other issues occur, drilling can continue by swapping choke

• Flowmeter for each upstream

legs. The standard design includes a flowmeter placed upstream of the

choke leg enables continued

choke leg, which makes critical flow measurement possible. Placing the

operation.

flowmeter downstream of the choke leg is an option.

• Remote operation via an

intelligent control system enables

The manifold works in conjunction with an intelligent control system that

swapping chokes legs if plugging

occurs and functioning electric or

uses an advanced hydraulic model. In this way, the manifold maintains

hydraulic valves. the appropriate annular pressure profile in real time during drilling. If

• Design improvements reduce the

the system detects and indicates an influx, it is capable of closing the

loss of frictional pressure in the chokes to increase the surface backpressure. This rapid, automated

entire system. response can minimize the size of the influx circulated out. If the system

detects a loss, it is capable of opening the chokes to reduce surface

backpressure, which can help to minimize

formation damage and maintain

wellbore integrity.

weatherford.com © 2019 Weatherford. All rights reserved. 13029.00

MANAGED PRESSURE DRILLING TECH SPECS

Victus™ Manifold

Specifications

Size 4 in. 6 in.

System type MPD or mass balance MPD or mass balance

Pressure, manifold piping 5,000 psi (34.5 MPa) 5,000 psi (34.5 MPa)

Flanges size and rating API 6A 4-1/16 in. (103 mm) 5M API 6A 7-1/16 in. (103 mm) 5M

Temperature rating −20° 250°F (−29 to 121°C) −20° 250°F (−29 to 121°C)

Material class Class EE-NL NACE MR-0175 Class EE-NL NACE MR-0175

Design code API 6A, PSL-3, PR-2 API 6A, PSL-3, PR-1

Flowmeter (placed in front of the choke)

Pressure 2,855 psi (19.8 MPa) @ 250°F (121°C) 2,320 psi (16.0 MPa) @ 250°F (121°C)

Inlet/outlet connections ANSI/ASME B16.5, 4-in. Class 1500# ANSI/ASME B16.5, 6-in. Class 1500#

Maximum flow rate 2,400 gal/min (9,085 L/min) 6,000 gal/min (22,712 L/min)

Minimum flow rate 15 gal/min (56.8 L/min) 15 gal/min (56.8 L/min)

Chokes

Pressure 5,000 psi (34.5 MPa) 5,000 psi (34.5 MPa)

Inlet and outlet connections API 6A 4-1/16 in. (103 mm) 5M API 6A 7-1/16 in. (179 mm) 5M

Maximum flow rate* 800 gal/min (3,028 L/min) per unit 1,815 gal/min (6,871 L/min) per unit

Actuation Electric or hydraulic motor Electric or hydraulic motor

Material and NDE Class EE-NL, PSL 3, NACE MR-0175 Class EE-NL, PSL 3, NACE MR-0175

Gut Line Valve (optional)

Gate valve, manual API 6A, PR-2 API 6A, PR-1

Size 4-1/16 in. (103 mm) to 7-1/16 in. (179 mm) 7-1/16 in. (179 mm)

Pressure 5,000 psi (34.5 MPa) 5,000 psi (34.5 MPa)

Material and NDE Class EE-NL, PSL 3, NACE MR-0175 Class EE-NL, PSL 3, NACE MR-0175

Isolation Valves (optional)

Gate valve, manual API 6A, PR-2 API 6A, PR-1

Size 4-1/16 in. (103 mm) to 5-1/8 in. (179 mm) 7-1/16 in. (179 mm)

Pressure 5,000 psi (34.5 MPa) 5,000 psi (34.5 MPa)

Material and NDE Class EE-NL, PSL 3, NACE MR-0175 Class EE-NL, PSL 3, NACE MR-0175

* The maximum flow rate depends on mud weight and backpressure.

Options

• Manifold enables customization by choosing between various options:

− one, two, three, or four legs

− 4- or 6-in. choke sizes

− electric, hydraulic, or manual isolation valves

− integrated junk catchers

− gut line valves

• Flowmeter can be placed downstream of the choke as an option. The downstrean

flowmeter may be equipped to handle high pressures as an additional option.

• Integrated junk catcher option reduces the manifold footprint and manual handling.

weatherford.com © 2019 Weatherford. All rights reserved. 13029.00

Weatherford products and services are subject to the Company’s standard terms and conditions, available on request or at weatherford.com. For more information contact an authorized Weatherford representative. Unless noted otherwise, trademarks and service marks

herein are the property of Weatherford and may be registered in the United States and/or other countries. Weatherford products named herein may be protected by one or more U.S. and/or foreign patents. Specifications are subject to change without notice. Weatherford

sells its products and services in accordance with the terms and conditions set forth in the applicable contract between Weatherford and the client.

You might also like

- Sand Filters Datasheet PDFDocument2 pagesSand Filters Datasheet PDFJamesStenhouseNo ratings yet

- Hmk03 Duramax Spin-On Filters: Max Flow: 25 GPM (95 LPM)Document4 pagesHmk03 Duramax Spin-On Filters: Max Flow: 25 GPM (95 LPM)Wilson VelásquezNo ratings yet

- Catalogue Parker Ball ValveDocument28 pagesCatalogue Parker Ball ValvecazobertoNo ratings yet

- Cat Filling Station 2020 02 ENG LIGHT PDFDocument64 pagesCat Filling Station 2020 02 ENG LIGHT PDFAsesoría ContrataciónNo ratings yet

- HPK03Document4 pagesHPK03Tan CkNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- IPD AutoclaveEngineers Subsea Ball Valves CatalogDocument28 pagesIPD AutoclaveEngineers Subsea Ball Valves CatalogGabriel Jamariqueli BueresNo ratings yet

- IH RedukDocument14 pagesIH RedukPioneer PaperboyNo ratings yet

- EV58-34 Vented Directional ElementDocument2 pagesEV58-34 Vented Directional ElementcaiNo ratings yet

- Ge Dresser HPC Meter Spec SheetDocument4 pagesGe Dresser HPC Meter Spec SheetfharishputraNo ratings yet

- Datos Tecnicos FlujometroDocument4 pagesDatos Tecnicos FlujometroJuverCupeNo ratings yet

- Automated MPD Riser System: Expedites Installation On Offshore Rigs With An Integrated, Compact, and Smart DesignDocument5 pagesAutomated MPD Riser System: Expedites Installation On Offshore Rigs With An Integrated, Compact, and Smart DesignJavier Enrique Pozzo HuertaNo ratings yet

- Fdfa Valvula Reguladora de Caudal 200 LT - MinDocument3 pagesFdfa Valvula Reguladora de Caudal 200 LT - MinCarlosNo ratings yet

- 2-PX NPCU Manifold Data Sheet 20150318Document2 pages2-PX NPCU Manifold Data Sheet 20150318Joel FloresNo ratings yet

- Max Flow: 100 GPM (379 LPM) : SP80/90 Spin-On Filters Working Pressures To: Rated Static Burst To: Flow Range ToDocument4 pagesMax Flow: 100 GPM (379 LPM) : SP80/90 Spin-On Filters Working Pressures To: Rated Static Burst To: Flow Range Tofrancis_15inNo ratings yet

- Technical Proposal for Olympic Pool Filtration SystemDocument10 pagesTechnical Proposal for Olympic Pool Filtration SystemAlma DerajNo ratings yet

- FD2000 - GEN III Rev5 FMDocument5 pagesFD2000 - GEN III Rev5 FMJosé Alberto RodríguezNo ratings yet

- Global Filtration Technology 18/28/38P Series High Pressure FiltersDocument8 pagesGlobal Filtration Technology 18/28/38P Series High Pressure FiltersChris BanksNo ratings yet

- Webtec Products LimitedDocument20 pagesWebtec Products LimitedtecnicomanelNo ratings yet

- 99-0337-REV D CC ManifoldDocument3 pages99-0337-REV D CC Manifoldtdyhgt tdjhgyfytNo ratings yet

- Wascomat Crossover Dryer OPL Specifications DAWF0GNM Non Meteres Card Ready GasDocument2 pagesWascomat Crossover Dryer OPL Specifications DAWF0GNM Non Meteres Card Ready Gasmairimsp2003No ratings yet

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Document2 pagesModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNo ratings yet

- Serie D31 - Cetop 5Document35 pagesSerie D31 - Cetop 5Hugo MenendezNo ratings yet

- Ball Valves: 3-Way SeriesDocument8 pagesBall Valves: 3-Way SerieslorenzoNo ratings yet

- dynexPF2000 10 SpecsDocument5 pagesdynexPF2000 10 SpecsOILSERVICES COQUIMBONo ratings yet

- 11-5K Annular BOP Operation ManualDocument20 pages11-5K Annular BOP Operation ManualAlfonso Ibarra BenavidesNo ratings yet

- TECHNAFLODocument6 pagesTECHNAFLOValeria AlmazanNo ratings yet

- Chapter 1Document6 pagesChapter 1Edgar Allende ChavezNo ratings yet

- HPK04Document4 pagesHPK04Tan CkNo ratings yet

- PRDC Sun ValveDocument3 pagesPRDC Sun ValvekhairulanuarjunNo ratings yet

- Test Flowhead 3" X 10 K: Production ServicesDocument2 pagesTest Flowhead 3" X 10 K: Production Servicesshakouri1370_8902064No ratings yet

- Hammer Winch HMW 4.0 PHT STDocument1 pageHammer Winch HMW 4.0 PHT STArley RodriguezNo ratings yet

- Cat 320D SpecDocument1 pageCat 320D SpecadinugrohoNo ratings yet

- L170R... Mega DS 2021Document7 pagesL170R... Mega DS 2021ชัชวาล เมตตาNo ratings yet

- DeaeratorDocument6 pagesDeaeratorSyaeful SyariefNo ratings yet

- Rebrand 29 Hydril Pressue Control Compact 18 15Document2 pagesRebrand 29 Hydril Pressue Control Compact 18 15saidbajuri4No ratings yet

- Page 1271Document1 pagePage 1271EmilyTheDwarfNo ratings yet

- HF 760 - HF 761 Series: in Line High Pressure FiltersDocument28 pagesHF 760 - HF 761 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- Tools MaunalDocument86 pagesTools MaunalAbrar HussainNo ratings yet

- Pressuretrol l404 SeriesDocument12 pagesPressuretrol l404 SeriesFreddy TamayoNo ratings yet

- 2-Pes-043 Hel LTRDocument2 pages2-Pes-043 Hel LTRFouad ToumiNo ratings yet

- Model 25B Pump enDocument2 pagesModel 25B Pump enchahineNo ratings yet

- Tri-Tech Medical Inc.: For Healthcare High Pressure Cylinder ApplicationsDocument3 pagesTri-Tech Medical Inc.: For Healthcare High Pressure Cylinder ApplicationssabahiraqNo ratings yet

- Product Description: Screw Pump SeriesDocument12 pagesProduct Description: Screw Pump SeriesEugenio LombardiNo ratings yet

- Neptune 7100 Series Brochure PDFDocument4 pagesNeptune 7100 Series Brochure PDFKatherine MejíaNo ratings yet

- CHOKE MANIFOLD 3Document2 pagesCHOKE MANIFOLD 3fabianmed83No ratings yet

- 06 (1) Vol de Ran MedDocument7 pages06 (1) Vol de Ran MedLhau009No ratings yet

- Ap11t Ap101t Ap102t Ap141tDocument2 pagesAp11t Ap101t Ap102t Ap141tBalderas Rosas WilibaldoNo ratings yet

- Spraymec 8100 VC 100075525 USA & CanadaDocument11 pagesSpraymec 8100 VC 100075525 USA & CanadaEzequielNo ratings yet

- 6-Pes-150 Bap AltptDocument2 pages6-Pes-150 Bap AltptFouad ToumiNo ratings yet

- Mark 695 Series - Piloted Tank Blanketing Regulator (2 Inch)Document4 pagesMark 695 Series - Piloted Tank Blanketing Regulator (2 Inch)prihartono_diasNo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- D75KXDocument28 pagesD75KXDiego Duran MolinaNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- Limitadora de Presion Rvga-Lan Sun HydraulicsDocument1 pageLimitadora de Presion Rvga-Lan Sun HydraulicsCarlosNo ratings yet

- Solenoid Valve - BifoldDocument20 pagesSolenoid Valve - Bifoldkdalavadi3905No ratings yet

- Power Team Predator Air Pumps - CatalogDocument2 pagesPower Team Predator Air Pumps - CatalogTitanplyNo ratings yet

- Atlas Copco FlexiROC D60 D65 Surface Drill Rigs SpecsDocument5 pagesAtlas Copco FlexiROC D60 D65 Surface Drill Rigs SpecsJimmy Gonzalo Veliz Quispe0% (1)

- Pedrollo Submersible Drainage Pump - ToPDocument4 pagesPedrollo Submersible Drainage Pump - ToPGeorge CobraNo ratings yet

- LFM Netview ConfigurationDocument1 pageLFM Netview ConfigurationMahendran KuppusamyNo ratings yet

- Vaadivasal Novel PDFDocument191 pagesVaadivasal Novel PDFMahendran Kuppusamy33% (6)

- Tamil Telegram Channel for BooksDocument191 pagesTamil Telegram Channel for BooksMahendran Kuppusamy100% (2)

- Mss sp-75 2004 PDFDocument9 pagesMss sp-75 2004 PDFNesrine MhedhbiNo ratings yet

- Guide to Purchasing Wellhead & Tree EquipmentDocument24 pagesGuide to Purchasing Wellhead & Tree EquipmentMahendran KuppusamyNo ratings yet

- Minor Game PDFDocument134 pagesMinor Game PDFMahendran KuppusamyNo ratings yet

- API 6A Spec Flange Bolt+ Ring Chart PDFDocument1 pageAPI 6A Spec Flange Bolt+ Ring Chart PDFAlan JuanNo ratings yet

- Piping Thickness Calculation With An ExampleDocument10 pagesPiping Thickness Calculation With An ExampleMahendran KuppusamyNo ratings yet

- FP918ADocument28 pagesFP918AdosetiadiNo ratings yet

- SOFclass2.pdf - Google Drive PDFDocument1 pageSOFclass2.pdf - Google Drive PDFMahendran KuppusamyNo ratings yet

- Nominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe ChartDocument5 pagesNominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe CharthappywhewmiNo ratings yet

- Youthprograms Lessons at Home Around The WorldDocument9 pagesYouthprograms Lessons at Home Around The WorldMahendran KuppusamyNo ratings yet

- Smart 3d Interop White PaperDocument26 pagesSmart 3d Interop White PaperNico Van HoofNo ratings yet

- Autodesk Navisworks Simulate 2018 x64Document1 pageAutodesk Navisworks Simulate 2018 x64Mahendran KuppusamyNo ratings yet

- Youthprograms Lessons at Home Around The WorldDocument9 pagesYouthprograms Lessons at Home Around The WorldMahendran KuppusamyNo ratings yet

- Subt Counting Back PDFDocument1 pageSubt Counting Back PDFMahendran KuppusamyNo ratings yet

- Chetan Bhagat - Three Mistakes of My LifeDocument144 pagesChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyNo ratings yet

- Subtract On Number LineDocument1 pageSubtract On Number LineMahendran KuppusamyNo ratings yet

- Skip Counting PDFDocument1 pageSkip Counting PDFMahendran KuppusamyNo ratings yet

- MicroStation Basic Macros...Document4 pagesMicroStation Basic Macros...Anoop SV100% (1)

- Exam Past SimpleDocument10 pagesExam Past SimpleYvonne CarlileNo ratings yet

- Subtract On Number Line PDFDocument1 pageSubtract On Number Line PDFMahendran KuppusamyNo ratings yet

- Subt Counting Back PDFDocument1 pageSubt Counting Back PDFMahendran KuppusamyNo ratings yet

- ITPL Public School Summative Assessment KeyDocument6 pagesITPL Public School Summative Assessment KeyMahendran Kuppusamy100% (1)

- Skip Counting PDFDocument1 pageSkip Counting PDFMahendran KuppusamyNo ratings yet

- NCO - Class2 - Sample PaperDocument8 pagesNCO - Class2 - Sample PaperMahendran KuppusamyNo ratings yet

- Curves Sad FaceDocument1 pageCurves Sad FaceMahendran KuppusamyNo ratings yet

- Curves UDocument1 pageCurves UMahendran KuppusamyNo ratings yet

- 610 E11 Errata PDFDocument2 pages610 E11 Errata PDFMahendran KuppusamyNo ratings yet

- Comparison of ASME B31.1 and B31.3 piping codesDocument4 pagesComparison of ASME B31.1 and B31.3 piping codesPranpath Narupantawart100% (1)

- Manual de Servicio ES12-25WADocument38 pagesManual de Servicio ES12-25WARonald PiedrahitaNo ratings yet

- BullEx ITS User Manual XtremeDocument44 pagesBullEx ITS User Manual XtremeJonasDispersyn100% (1)

- OISD Standard for Inspection of PumpsDocument18 pagesOISD Standard for Inspection of PumpsNanu Patel100% (1)

- Chapter 11 Earth Pressure Theory 15Document27 pagesChapter 11 Earth Pressure Theory 15CharanNo ratings yet

- Heat TransferDocument87 pagesHeat TransferGülgün YenigünNo ratings yet

- API 650 Storage Tank SpecificationsDocument21 pagesAPI 650 Storage Tank SpecificationsElias EliasNo ratings yet

- Fabric Expansion Joint - 2021Document46 pagesFabric Expansion Joint - 2021cemalNo ratings yet

- YMA BrochureDocument9 pagesYMA Brochurenairam2003No ratings yet

- K.P Theory of Energy Bands, Wave Functions, and Optical Selection Rules in Strained Tetrahedral SemiconductorsDocument10 pagesK.P Theory of Energy Bands, Wave Functions, and Optical Selection Rules in Strained Tetrahedral SemiconductorsPeter EndersNo ratings yet

- NASA 1228 Fastener Design ManualDocument98 pagesNASA 1228 Fastener Design Manualjeddins_1No ratings yet

- Fluid Power Formulas GuideDocument4 pagesFluid Power Formulas GuidemahaveenNo ratings yet

- METAL ARTS - Career Studies Certificate: Program InfoDocument1 pageMETAL ARTS - Career Studies Certificate: Program InfoBobbyNo ratings yet

- High Ratio Axle-2025 & 20HP - NotesDocument2 pagesHigh Ratio Axle-2025 & 20HP - NotesHofmannsofHenleyNo ratings yet

- Rotational Inertia Lab ReportDocument8 pagesRotational Inertia Lab Reportbrian100% (1)

- Sample Problems For KinematicsDocument43 pagesSample Problems For Kinematicsdavid jenil nabuaNo ratings yet

- Simple Bending Stress AnalysisDocument14 pagesSimple Bending Stress AnalysisDaniel MukuhaNo ratings yet

- Component Maintenance Manual For External Design Wheels & BrakesDocument84 pagesComponent Maintenance Manual For External Design Wheels & BrakesAntonio OrtizNo ratings yet

- Relative Equilibrium of Liquids in MotionDocument13 pagesRelative Equilibrium of Liquids in MotionJay Dela CruzNo ratings yet

- Sample Quality Assurance Plan For Cs FlangesDocument2 pagesSample Quality Assurance Plan For Cs FlangesKaran BhanotNo ratings yet

- Eaton Vickers PVQ Piston Pumps GuideDocument6 pagesEaton Vickers PVQ Piston Pumps GuideRodolfo Rodriguez VargasNo ratings yet

- Suzuki Raider 150R Parts PDFDocument62 pagesSuzuki Raider 150R Parts PDFMohd Hafiez Hamid80% (20)

- Vestas 3.0MW V90-GeneralSpecificationDocument31 pagesVestas 3.0MW V90-GeneralSpecificationBrayden McLean100% (1)

- J Engstruct 2007 07 008Document12 pagesJ Engstruct 2007 07 008Jaouad OuaâzizNo ratings yet

- RSUDocument48 pagesRSUfrank1220uNo ratings yet

- Polsab Czesci Eksploatacyjne A2Document4 pagesPolsab Czesci Eksploatacyjne A2axisd47No ratings yet

- VOLVO SD45D SINGLE-DRUM ROLLER Service Repair Manual PDFDocument15 pagesVOLVO SD45D SINGLE-DRUM ROLLER Service Repair Manual PDFfjjsjekdmme100% (1)

- Mathieu Equation (Parametric Oscillator)Document6 pagesMathieu Equation (Parametric Oscillator)Rodrigo Mota AmaranteNo ratings yet

- Buy Karcher Parts OnlineDocument12 pagesBuy Karcher Parts Onlinedfirmo4925No ratings yet

- ASTM A333 Grade 6 Seamless Pipe SupplierDocument4 pagesASTM A333 Grade 6 Seamless Pipe SupplierRajendra FittingsNo ratings yet