Professional Documents

Culture Documents

3737 Ijecs Ijens PDF

Uploaded by

bepol88Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3737 Ijecs Ijens PDF

Uploaded by

bepol88Copyright:

Available Formats

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 8

Solar Dish Stirling System and its Economic

Prospect in Bangladesh

Khalid Yousuf Khan, Nahian Al Subri Ivan, Ansari Saeed Ahmed, Abdul Hasib Siddique, Dhrupad Debnath

Department of Electrical & Electronic Engineering, American International University – Bangladesh

Kamal Attaturk Avenue, Banani, Dhaka, Bangladesh

Khalid_aiub@yahoo.com

nahian.ivan@aiub.edu

Abstract— This paper presents the design aspect of solar dish

starling engine and the prospect of this type of power II. STIRLING CYCLE

generation unit in Bangladesh. .In addition, in this paper the The working principle of the Stirling engine and P-V

variable prospect of solar dish starling engine has been studied. diagram of Stirling cycle are shown in following Fig. 1. The

Bangladesh, being a developing country with perpetual Stirling cycle consists of 4 thermodynamic processes; Iso-

shortage of electricity and facing numerous hardships towards volumetric heating process described by stages 1-2 in P-V

generating it, is constantly in search of an alternative source of

Diagram, Isothermal expansion process by 2-3, Iso-

energy, in which case, Renewable Energy has gained quite a

reputation for. Harnessing electricity from solar energy looks volumetric cooling process by 3-4, and Isothermal

more viable among other types of renewable energy in compression process by 4-1 [3].

Bangladesh. The solar dish stirling engine technology is new

and specially designed to use the solar ray to convert it to

usable electricity. The economic aspect also gives this type of

engine a great advantage over the existing SHS (Solar Home

System). This paper explains working principle, grid

connectivity and economic viability of Stirling engine system

incorporated with effective design of solar tracking system to

enhance the efficiency.

Index Term— Stirling engine, Grid Connectivity, Modeling,

Fig. 1. Cycle of stirling engine

Over Voltage Protection, VAR compensators, NRE, Market

Potential

1-2 is Iso-volumetric heating process where the piston stays

I. INTRODUCTION on top. The pressure of working gas in cylinder is increased

This With rapid depletion of conventional fuel energy by heating. 2-3 is Isothermal expansion process where the

resource in the face of ever increasing energy demand, working gas expands keeping its temperature constant and

desperate efforts are being made to look for economic the engine does the work. 3-4 is Iso-volumetric cooling

alternative energy throughout the world. Technology for process where the piston stays at the bottom. The pressure

electricity generation from solar and wind power has already of working gas in cylinder is decreased by cooling. 4-1 is

been in wide application in many countries .In recent days Isothermal compression process where the working gas is

there has been a significant improvement in the efficiency compressed keeping its temperature constant. The heat

and cost effectiveness in the technology of harnessing wasted in the Iso-volumetric cooling process 3-4 is equal to

electric energy from wind and solar power. An Auto- the supplied heat in the Iso-volumetric heating process. Now,

Rotating Stirling engine system is a new and economically by adopting regenerator, the heat wasted in the Iso-

viable solution to extract electric energy from solar power volumetric cooling process is used in the Iso-volumetric

without producing any detrimental effect on environment. heating process and thus the cycle's thermal efficiency

The efficiency of the engine is improved when maximum follows:

solar power tracking device is incorporated in it. Stirling

engine is a closed cycle engine. It contains a fixed mass of ……….…………………………………..(1)

working fluid which is commonly air, hydrogen or helium. Where Th is higher temperature and Tc is lower temperature.

In normal operation the engine is sealed and no gas enters of This efficiency equals to the efficiency of Carnot cycle,

leaves the engine. No valves are required unlike other types therefore Stirling cycle has the highest efficiency.

of piston engines. However a small amount of lubrication is

needed as the working fluid is helium or hydrogen. The

solar power is used to heat the working fluid in this engine. III. CONSTRUCTION OF STIRLING ENGINE

25% overall efficiency as well as 98% thermal efficiency Stirling Engine outputs the work by repeating 4 thermal

has been achieved from this engine at present [1]. The processes which are isothermal heating, isovolumetric

Stirling engine has a smaller emission as the system is fully expansion, isothermal cooling and isovolumetric

based on green energy. The maintenance is low and it is a compression. But, only one piston cannot make this motion.

reliable system [2]. Practical Stirling engine has to displace volumes, one of

which is kept at high temperature and next is kept at low.

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 9

Above 4 processes are accomplished by the working gas of

engine that is reciprocated between these two volumes. And

practical engine adds three elements of heat exchangers

which are Heater, Cooler and Regenerator, for exchanging

heat more effectively [4].

Fig. 1. The schematic view of 1kW class low temperature difference

Stirling Engine

Fig. 2. The model of practical stirling engine

B. High Performance Plate Fin and Tube Type Heat

Exchanger

In E-H Expansion Space, the working gas is heated up by Suction’s high performance plate fin and tube type heat

the Heater and flows into this space. This space is displaced exchangers are used for the heater and the cooler of the

by the power piston in 2 piston type Stirling Engine or by engine, and conventional laminated wire net type is used in

the displacer piston in displacer type Stirling engine. The H- the regenerator. This wire net is made of Brass [5].

R Heater heats up the working gas. R-K Regenerator

receives the heat from the working gas while the gas is C. X Yoke Mechanism; The Unique Driver Mechanism

flowing from high temperature end to low temperature end, Both expansion and compression side power pistons are

or gives charged heat to the gas while the gas is flowing driven by unique mechanism, called X yoke Mechanism.

from low temperature end to high temperature end. Stirling This mechanism consists of two yokes. Each yoke has two

Engine's high thermal efficiency is obtained by this action, liner bearings, one of which is located for vertical direction

and then the performance of this element affects the engine and other one is located for a certain angle of inclination.

performance significantly. K-C Cooler cools down the These two yokes are combined with facing each other. With

working gas. In C Compression space, the working gas is rotation of crank, the sliders located on inclined linear

cooled by the Cooler and flows into this space. This space is bearings reciprocate along these bearings, and the yokes

displaced by the power piston in 2 piston type Stirling themselves work with linear motion for vertical direction

Engine, or by the displacer piston in displacer type Stirling that follows phase angle of this formula.

engine. To summarize, the Stirling engine uses the 1800-(the angle of inclination of slanting bearing)*2… (2)

temperature difference between its hot end and cold end to In this engine, slanting angle is set at 150. Therefore phase

establish a cycle of a fixed mass of gas, heated and angle of both pistons become 1500. By adopting this

expanded, and cooled and compressed, thus converting mechanism, engine's driving mechanism and engine itself

thermal energy into mechanical energy. The greater the becomes more compact, and helps to reduce mechanical

temperature differences between the hot and cold sources, friction losses which depend on side thrust of piston rings.

the higher the thermal efficiency. The maximum theoretical

efficiency is equivalent to the Carnot cycle; however the D. High Power Operation by Pressurized Buffer Space

efficiency of real engines is less than this value due to Engine's body is the applied structure of pressure vessels.

friction and other losses. Therefore the engine can operate under higher buffer

pressure than conventional low temperature difference

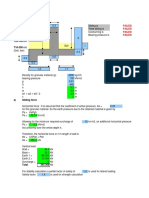

IV. DESCRIPTION OF 1KW DISH TYPE STIRLING ENGINE engines shown in Fig. 5 and Fig. 6. As a result, engine

This 1KW class low temperature difference Stirling performance increases significantly [5].

engine adopts unique Alpha Type construction originated by

suction, and succeeds in reducing friction losses and dead V. HELIOSTAT DEVICE

spaces. Generation of 740W of output power has been The designed solar tracker device has two identical parts:

accomplished by this engine. Control Unit and Operational unit. An embedded system has

been introduced to run the system successfully. Solid state

A. High Compression Ratio and Low Friction Losses relays have been used to bridge the electronic and

The In this engine, Fig. 3, Alpha type construction is mechanical part of the tracker device.

adopted, and expansion side and compression side power

pistons are located in a straight line. By this construction

design, the compression ratio of the engine is higher than A. Basic System Principle

conventional gamma type low temperature difference The circuit has been designed in such a way that it takes

engines and friction losses are also reduced significantly [5]. two inputs and controls the tracker. Basically the circuit

creates two instructions for the mechanical part. One is

given by the operator once and the other comes from the

light direction finding tube.

B. Control Unit

The heart of the electronic control unit is a PIC 16F84A

microcontroller. There are three types of PIC 16F84A, these

are PDIP, SOIP and SSOP. In Bangladesh PDIP is more

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 10

available than the other two types, thus in this circuit PDIP

has been used. It has three key features that satisfy the

objective:

8 bit multi channel analog to digital converter

13 input/output pins

64 bytes of data EEPROM memory

Fig. 4. PIC16F84A pin configuration

Fig. 6. Comparison with the previous image for showing the consistency

of the engine output

To control the motor, an additional circuit shown in Fig.

7 has been developed which consists of four 2N2222 model

transistors, four 1N4148 diodes and two 10 k ohms resistors.

A CN9103 NPN transistor has been used for tracker circuit

as it is capable of handling up to 500mA of current.

VCC

Q1

D1 D2

Q3

2N222 2N222

10K

MOTOR

Fig. 5. Output (wattage) and pressure volume curve of the used Stirling 2N222

Engine Q2 2N222

D3 Q4 D4

10K

Fig. 7. H-Bridge motor control

C. Operational Unit

It has several individual parts operating on the basis of

the instructions provided by the control unit.

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 11

Motor 1 is working for the elevation operation where supply

voltage is 24V DC and maximum elevation range is 900. 1N4007 1N4007

Motor 2 is working for the azimuth angle operation where

supply voltage is 24V DC and maximum Azimuth angle 1K

10K 10K

rang is 3600. Light detection or calibration tube allows the

1K

easy and comfortable finding of the direction or position CS9013

CS9013

with the maximum light. It consists of two light dependent

resistors (LDR). The PIC detects and obtains data from the

two LDR’s and then compares their resistance. The program 1N4004

is designed in such a way that the control unit places the 1N4004 12V

dish in a position where both the LDR’s resistance is equal.

Multipurpose mechanical connector has to be positioned in

between the items and the rotor head. The total system

needs 20 Watt of power.

3

D. Software For The Controlling The Heliostat Device And

2 1

Total Control Circuit\ 4

PIC16F84A

1:RA2 RA1:18 MOTOR

CW

2:RA3 RA0:17 22pF

3:RA4 C C1:16

4:MCLR C C2:15

5:Vss Vdd:14

22pF

6:RB0 RB7:13

7:RB1 RB6:12

8:RB2 RB5:11

7805

9:RB3 RB4:10 12V V V

in out

0.1 GND 0.1

2.2 uF 2.2 uF uF

`

` ` uF

` `

C C2 C C1 10K

10K

Fig. 9. Solar tracker control circuit

Analog inputs for the operation of the circuit (example): a.

Turn azimuth motor on 134.560: ―AZ = 134.56‖ b.

Elevation position change by 500: ―EL = 50‖ c. Using the

instruction word ―Focus‖ automatic starts on focusing run.

The flow chart of Fig. 8 is used in WinPIC 800 software

to run the solar tracker control circuit of Fig. 9 where the

azimuth angle and elevation position is given by the user.

VI. GRID CONNECTIVITY

As solar dish stirling system has inherently high overall

system efficiency in converting sunlight to electricity, so the

next target is to improve this system for supplying

electricity to the grid. To supply significant amount of

power to grid, it is necessary to design a system of

interconnected Stirling engines. To connect this system to

the power grid, the factors that need to be considered are

Fig. 8. Detailed software design flowchart power factor correction, over voltage protection, low

The detail circuit diagram of the whole solar tracking voltage ride-through and associated voltage recovery

system is as shown in Fig. 9. process [6].

A. Power Factor Correction

Solar dish stirling system needs to provide a power factor

correction capability and allow a range of 0.95 lagging to

0.95 leading for safety and reliability. The correction can

either be continuously variable or switched in discrete steps

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 12

that are not allowed to change voltage levels by more than power plant provides varying output power throughout the

one percent per step. The reactive power that is needed for day) has to be considered.

the solar power plant can be obtained by using generator or Sometimes MSC devices produce switching inrush

by using capacitors. current and associated over voltage on capacitors which

could shorten the life of capacitors. MSC has a slow

B. Generator response time which cannot give over voltage protection and

The Generator can normally produce reactive power but regulation during transient or system recovery periods.

it has high initial cost. Synchronous generator or DC To solve these problems Thyristor switched capacitors

generator can be used but it needs some redesigning. As a could be used. It can provide fast and smooth response

result, induction generator is used. If synchronous condenser without limits on number and frequency of switching.

with voltage regulator is used then it can absorb reactive

power (under excited) at low load and generate reactive C. Self Excitation Over Voltage Rating

power (over excited condition) at high load automatically When the induction machines are unexpectedly isolated

and thus improve power factor. from the grid with more capacitive current available than its

Based on the Power Factor Correction (PFC) requirement, no-load exciting current, the self excitation could occur. In

Table I shows the calculated reactive power data required this system capacitive current is generated from PFC

for a single 25KW induction generator with the variation of capacitors, capacitance from connecting transmission lines

load from 1 KW to 25 KW. and collection system cables. When the equivalent circuit

has enough capacitance in parallel with the generator

TABLE I

inductance creating undesired over voltages, the resonance

Reactive Power Calculation for a 25KW Induction Generator condition is met. Over voltage greater than 10 times the

rated voltage can occur as a result of self excitation

KW Rated PF Lagging KVAR KVAR conditions. If this fault is not cleared immediately then

KVAR required required

without for 0.95 for 0.95

saturation of the transformer could happen which will create

PFC leading lagging destructive ferroresonanse, insulator flashover or lightning

1.000 0.380 2.430 2.750 2.430 arrestor failure/ explosion.

By using high valued capacitance of induction generator,

2.900 0.429 6.090 7.040 5.140 self excitation is unavoidable in this system. To solve this

5.800 0.448 11.570 13.480 9.660 problem, fault has to be detected as early as possible and

generator has to be switched off from the grid. As a result of

10.600 0.646 12.530 16.010 9.050 isolating the generator from the grid, the rotor speed of the

15.900 0.739 14.500 19.730 9.270 generator could become very high. To solve this, a gas

management valve could be used to short circuit the high

22.400 0.804 16.570 23.930 9.210 and low pressure side of the stirling engine, which will

25.000 0.815 17.780 25.990 9.560 reduce the mechanical output and hence the generator power

to almost zero in a very short time.

Now as it is used for grid connection, a small unit of D. Low Voltage Ride Through (LVRT) Capability

Stirling engine system is considered that can generate at The FERC order states that a plant shall be able to remain

least 25 kW. From analysis it is seen that the output power online during voltage disturbances up to the time periods

ranging from 1 kW to 25 kW requires providing reactive and associated voltage levels set forth in the standard if the

power ranging from 2.43 kVAR to 25.99 kVAR per dish. So transmission provider’s system impact study shows that the

for providing 25.99 kVAR for a 100MW (4000 dishes) LVRT capability is required to ensure safety and reliability.

power plant requires a reactive power of 104 MVAR. The generator plant must have LVRT capability down to

Thus the capacitors have to provide a large amount of 15% of the rated line voltage for up to 0.625 seconds. To

reactive power. But before using capacitors, the capacitance meet this requirement, the over speed must be prevented at

of the line and the reactive power loss at the transformers of the low output voltage for the generators. The previously

two different voltage levels have to reach compensation discussed short circuit valve could be used to solve this

level of 0.70 lagging to 0.95 lagging. A 0.95 kVAR fixed problem. The procedures described above can be used to

capacitor can be connected in parallel with a 25 kW connect the solar dish stirling system with the grid.

induction generator which will provide adequate reactive

power at all power levels. So, adjustable part for a reactive VII. COMAPRISON BETWEEN STIRLING ENGINE AND

power of a 100 MW plant will be 66 MVAR. EXISTING SOLAR HOME SYSTEMS

The proposed design and the existing solar home system

RAV ) 1000( VV 5.9( – RAV 401

are compared on the basis of NRE (Non-Recurring

RAV ……………(2)

Engineering) cost, payback period, per unit cost and

For intermediate voltage levels, mechanically switched efficiency.

capacitors (MSC) can be used for power factor improvement Price of the solar home system components comprises its

as they are economically viable and can improve power NRE cost. Different distributors sell all these equipments in

factors in discrete steps. For using MSC, the lifespan of the a package along with the charge of installation. Field studies

mechanical switch and frequency of switching (as solar have revealed the price of the 1 KW solar home system in

Bangladesh as Tk 5 Lakhs [7].

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 13

Stirling engine system is much cost efficient. This system

becomes more efficient when the produced power is higher

[8]. The following table shows the NRE cost of the

proposed (1 KW) system [9].

TABLE II

Cost of Solar Dish Stirling Engine System

Components Price

(Tk)

Concentrators 35000

Receiver 6300

Hybrid 22750

Engine 7000

Generator 2800

Cooling System 2100

Fig. 10. Comparison between solar dish stirling engine system and

Electrical Balance of Plant 19250 existing pv/solar home system

General Facilities 8750

Fig. 10 shows the variation of output energy with the

Engineering Fee 10430 variation of input energy. It is clearly seen that a solar dish

Total System Cost 114380 stirling has superior performance compared to a solar home

system.

Solar home system sold in Bangladesh has an average life

expectancy of 30 years [7]. This system produces 1kw-h of The above discussion makes it clear that a Stirling engine

electrical energy for 8 hour (Average Sunshine Hour) a day system is much cost efficient. Per unit cost of the Stirling

[10]. Thus the average electrical energy produced through engine system is almost half of the solar home system. The

payback period of a solar home system stretches up to 2/3 of

its entire life time is 87600 KW-hr.

The maintenance cost is very low and normally carried by its total life time. On the other hand, a Stirling engine

the seller. So this cost can be excluded. Thus the per unit system has a payback period almost 1/3 of its entire life time.

cost of Solar Home System is approximately 5.70 Tk per Lastly, the efficiency curve shows the superiority of Stirling

KW-hr. engine system with a maximum efficiency of 25.75%. These

The expected life of a Stirling engine system is 60000 proofs are sufficient to show that for a country like

hour. With 8 hour of average sunshine this is equal to 20.5 Bangladesh with poor economical situation, Stirling engine

years. The average electrical energy produced through the system is much attractive compared to solar home system.

entire life time of a Stirling engine system is 59860 KW-hr VIII. MARKET POTENTIALITY IN BANGLADESH

All the maintenance that a Stirling engine system requires Bangladesh is facing acute electricity crisis for several

is the cleaning of the concentrators with water. This can be reasons. Some of them are due to lack of natural gas, old

done free from occasional rainfall, so the maintenance cost machinery at the power plant, distribution system with high

can be ignored. As the total system cost is Tk 114380, system loss. The total demand is 5200MW where the

therefore per unit cost for the Stirling engine system is Tk maximum generation is 4000MW [12]. This results in a

2.0 per KW-hr. development of interest towards the alternative energy.

DESCO charges its consumers Tk 3.5 for consumption of Average wind speed in Bangladesh is less than 4m/s [13]

1kh-hr of electricity. But the government pays a subsidy of (Minimum required for utility level generation is 6m/s) [14],

Tk 2. Thus the average production cost of 1kw-hr of so wind energy is out of the question. Natural head for

electricity is 5.5TK [7]. Considering 8 hour of sunshine in a hydroelectricity is also not sufficient. The only solution is

day throughout the year, a comparison is done finding the solar energy. But solar home system is beyond the reach of

payback period time for both the systems. The average cost commoners as showed in the previous section. Only a small

of production for DESCO for producing 1 KW power in a 8 portion of the population can afford this expensive solar

hour working day is Tk 16060 if per unit cost is TK 5.5. home system. In this situation the proposed system gives an

Therefore payback period for the existing solar home system economical solution. Through this system middle class

is 31.13 years and that of Stirling engine system is only 7 citizens of our country can be attracted. A whole village can

years. be covered by a single dish due to their low consumption

By considering efficiency of 10.53% for existing solar with respect to the urban citizens. If this system is

home system [7] and 25.75% for stirling engine system [2], manufactured in large scale, it costs 1/3 NRE compared to

a proportionate data have been generated for comparative solar home system.

performance analysis between the solar home system and

the solar dish stirling engine system. The generated data is

plotted as shown in Fig. 10.

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 14

IX. FUTURE IMPLEMENTATIONS [3] W. R. Martini (1983). ―Stirling Engine Design Pannel (2 nd edition)‖

URL:

Auto-rotating solar dish-stirling engine provides the ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/1930022057_19830220

developing country a hope for an uninterrupted energy 57.pdf. pp. 25-29

supply. [4] Mark L. Shelton (1994). ―The Next Great Thing: The Sun, the

Stirling Engine, and the Drive to Change the World‖ Published by

The concentrator used in the system under discussion is a W W Norton & Co., ISBN: 0393036197. pp. 179-185.

compound parabolic reflector. This can achieve 60-300°C [5] James Senft (1996). ―An Introduction to Low Temperature

which is very much convenient in this region. Moreover, if a Differential Stirling Engines‖; Moriya Press; ISBN: 0965245519. pp.

two-axis auto-rotating is installed, then about 1500°C can be 56-59.

[6] ixin Zhang; Osborn, B.‖ Solar Dish-Stirling Power Plants and

maintained [15]. Related Grid Interconnection Issues ‖ Power Engineering Society

Furthermore, this system can be used in combination with General Meeting, 2007. IEEE Publication Year: 2007 , pp. 1 – 5.

the existing natural gas, steam or fossil fuel power plant. [7] Information Collected from Rahim Afrooz Sales Center Uttara.

Parabolic solar collector can be used to focus sunlight [8] Bancha Kongtragool, Somchai Wongwises (2006). ―Performance of

low-temperature differential Stirling engines‖, Fluid Mechanics,

onto a receiver pipe through which synthetic oil can be Thermal Engineering and Multiphase Flow Research Lab.

preheated. The collector can also be used to generate steam. (FUTURE), Department of Mechanical Engineering, King

The stirling engine can also be used in areas where the Mongkut’s University of Technology Thonburi, Bangmod, Bangkok

wasted gases are given off as the engine requires heat to run. 10140, Thailand, pp-555-557, fig-4-7.

[9] http://www.solarpaces.org/CSP_Technology/docs/solar_dish.pdf

This system working in combination with the conventional [10] Mazharul Islam (2002). ―Assessment of Renewable Energy

system provides promising returns [15]. Resources Of Bangladesh‖ Electronic Book, ch-2,pp-13,table-

This solar system can be used in the day time as well as at 2.2.http://shakti.hypermart.net/publications/ebook1.pdf

night. This can be possible by storing heat in an insulated [11] MAIER Christoph, GIL Arnaud, AGUILERA Rafael, SHUANG Li,

YU Xue (2007). ―STIRLING ENGINE‖, UNIVERSITY OF

storage container which contains molten salt. So even at GÄVLE, pp-26,fig-26.

night-time, this system is not completely useless. [12] http://www.energybangla.com/index.php?mod=article&cat=Somethi

Utilization of the system seems complicated and ngtoSay&article=1729

expensive but the implementation cost is applied only once. [13] Mohammad Golam Kibria Khan, Talha Rahman and M.M. Alam

(2004).―WIND ENERGY IN BANGLADESH: PROSPECTS AND

As the system relies on renewable everlasting energy that is UTILIZATION INITIATIVES‖, 3rd International Conference on

the sun, it proves that it is cost effective [15]. Electrical & Computer Engineering, ICECE 2004, 28-30 December

2004, Dhaka, Bangladesh, pp-475, table-2.

IV. CONCLUSION [14] http://www.awea.org/faq/wwt_basics.html

The application of the auto-rotating solar dish-stirling [15] Soteris A. Kalogirou, ―Solar Energy Engineering – Processes and

Systems‖, Elsevier Inc, ch-3,10, pp-122,525,523.

system shows a promising future for the generation of

electricity. The system is very advantageous on the basis of Khalid Yousuf Khan received his B.Sc. degree in Electrical and

energy resources, excellent performance in the generation of Electronic Engineering in December 2010 from American International

electricity, life-cycle cost and almost negligible impact on University-Bangladesh (AIUB). He has been working as a lecturer in the

program of EEE under the department of computer science and technology

the environment. The only drawback of this system is the in Atish Dipakar Univeristy of Science & Technology since March 2011.

initial cost but potential investor is awaiting for a full His research interests are Renewable Energy, Fuzzy Logic Controllers,

demonstration of the system reliability. This system is Switchgear and Protective Relay etc.

proposed to promote our living standard and revolutionized

Ivan Md. Nahian-Al-Subri received his B.Sc. degree in Electrical and

the current system. This system is not a necessity, but a Electronic Engineering in August 2010 from American International

novelty. University-Bangladesh (AIUB). He has been working as a lecturer in the

faculty of Engineering, AIUB since September 2010. His research

ACKNOWLEDGMENT interests are Alternative Energy, Power Transmission & Distribution and

This research work is supported by Abdul Hasib Siddiqui, etc.

Drupad Debnath, Lecturer, Department of Electrical & Ansari Saeed Ahmed received his B.Sc. degree in Electrical and

Electronic Engineering, American International University – Electronic Engineering in August 2010 from American International

Bangladesh. University-Bangladesh (AIUB). His research interests are Renewable

This publication would not be possible without the Energy, Power Transmission & Distribution and etc.

guidance and undivided attention from Dr. Abdur Rahim

Mollah, Professor, Department of Electrical & Electronic

Engineering, American International University –

Bangladesh.

REFERENCES

[1] Gaun A. and Schmautzer E., ―Biomass-Fuelled Stirling Micro

Combined Heat and Power Plants‖, International Conference on

Clean Electrical Power, 2007, pp. 429-432.

[2] Technische Dokumentation SOLO STIRLING 161

Planungsunterlagen, Hydraulik; Version 1.9 für PlanerSOLO

STIRLING GmbH; http://www.stirling-engine.de July 2003

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 15

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 16

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 17

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 04 18

1N4007 1N4007

1K

10K 10K

1K

CS9013

CS9013

1N4004

1N4004 12V

2 1

4

PIC16F84A

1:RA2 RA1:18 MOTOR

CW

2:RA3 RA0:17 22pF

3:RA4 C C1:16

4:MCLR C C2:15

5:Vss Vdd:14

22pF

6:RB0 RB7:13

7:RB1 RB6:12

8:RB2 RB5:11

7805

9:RB3 RB4:10 12V V V

in out

0.1 GND 0.1

2.2 uF 2.2 uF uF

`

` ` uF

` `

C C2 C C1 10K

10K

114104-3737 IJECS-IJENS © August 2011 IJENS

IJENS

You might also like

- The Nature of Substance - Rudolf Hauschka PDFDocument250 pagesThe Nature of Substance - Rudolf Hauschka PDFBruno Morin100% (5)

- 14-Friedel Crafts Acylation FerroceneDocument10 pages14-Friedel Crafts Acylation FerroceneNguyen Minh Duc100% (1)

- EuroDish Stirling System Technical OverviewDocument9 pagesEuroDish Stirling System Technical OverviewfcompartNo ratings yet

- Preformed Expansion Joint Filler For Concrete (Bituminous Type)Document2 pagesPreformed Expansion Joint Filler For Concrete (Bituminous Type)Katerin HernandezNo ratings yet

- 11 - FORAGERS by Sam BoyerDocument106 pages11 - FORAGERS by Sam BoyerMurtaza HussainNo ratings yet

- A Typical Simulation of A 3 A Typical Simulation of A 3-KW Stirling Engine KW Stirling EngineDocument7 pagesA Typical Simulation of A 3 A Typical Simulation of A 3-KW Stirling Engine KW Stirling EngineIgor NehaNo ratings yet

- Renewable Energy Source with Stirling EngineDocument4 pagesRenewable Energy Source with Stirling EngineTzvetelina PetrovaNo ratings yet

- Solar Power Stirling EngineDocument23 pagesSolar Power Stirling EngineHariniReddy100% (1)

- An experimental study on the development of a β-type Stirling engine for low and moderate temperature heat sourcesDocument6 pagesAn experimental study on the development of a β-type Stirling engine for low and moderate temperature heat sourcesAbdul RehmanNo ratings yet

- In-Cylinder Heat Transfer in An Ericsson Engine Prototype: A. Fula, P. Stouffs and F.SIERRADocument6 pagesIn-Cylinder Heat Transfer in An Ericsson Engine Prototype: A. Fula, P. Stouffs and F.SIERRADriss ZiedNo ratings yet

- Design and Fabrication Stirling EngineDocument54 pagesDesign and Fabrication Stirling Engineermias100% (1)

- Mini Stirling Engine ProjectDocument6 pagesMini Stirling Engine ProjectGaurav Kumar50% (2)

- Power Generation With Solar Dish Stirling EngineDocument6 pagesPower Generation With Solar Dish Stirling EngineFaysal Abdul FattahNo ratings yet

- External Combustion Engines PDFDocument43 pagesExternal Combustion Engines PDFMariaEzzaSyUyNo ratings yet

- Literature Review On Development of Stirling Engine: Siddhant Jadhao, Prof .Y.V.MahantareDocument15 pagesLiterature Review On Development of Stirling Engine: Siddhant Jadhao, Prof .Y.V.MahantareJhun Rey N SagunNo ratings yet

- Stirling Engine Literature ReviewDocument4 pagesStirling Engine Literature Reviewtog0filih1h2100% (1)

- (Chapter) Free-Piston Stirling Engine GeneratorsDocument22 pages(Chapter) Free-Piston Stirling Engine GeneratorsĐạt VõNo ratings yet

- ME103 4.1 IdealStirlingCycleMachinesDocument10 pagesME103 4.1 IdealStirlingCycleMachinessandigricNo ratings yet

- A Stirling-Rankine Fuel-Fired Heat PumpDocument9 pagesA Stirling-Rankine Fuel-Fired Heat PumpDanny DurhamNo ratings yet

- Concentrated Solar Powered Water Pump Using Stirling EngineDocument27 pagesConcentrated Solar Powered Water Pump Using Stirling EngineBhanu PrakashNo ratings yet

- Electricity Generation Using Solar Powered Stirling Engine: Blessy Joy, Priya John, Anjuman Habeeb, Jeffy Marin JoseDocument5 pagesElectricity Generation Using Solar Powered Stirling Engine: Blessy Joy, Priya John, Anjuman Habeeb, Jeffy Marin JoseIntan Vara DibaNo ratings yet

- Solar Design Final ProjectDocument81 pagesSolar Design Final Projectayele mengistNo ratings yet

- The Most Efficient Waste Heat Recovery Device: A Gamma Type Stirling EngineDocument7 pagesThe Most Efficient Waste Heat Recovery Device: A Gamma Type Stirling EngineSutarmoNo ratings yet

- Stirling LaboratoryDocument4 pagesStirling LaboratorySilviu DnlNo ratings yet

- Pollution Less Engine: Name - Saif AnwarDocument15 pagesPollution Less Engine: Name - Saif AnwarSaif anwarNo ratings yet

- Stirling MotorDocument14 pagesStirling MotorlinerNo ratings yet

- Stirling Engine-Mini ProjectDocument9 pagesStirling Engine-Mini Projectyogesh sNo ratings yet

- Multiphase Stirling EnginesDocument11 pagesMultiphase Stirling EnginesPuzi UltraapandiNo ratings yet

- Stirling Engine & Applications Project SeminarDocument32 pagesStirling Engine & Applications Project SeminarLASINNo ratings yet

- Stirling EngineDocument22 pagesStirling EngineZeinab MahdiNo ratings yet

- In Memoriam Ivo KolinDocument5 pagesIn Memoriam Ivo KolinTimuçin KarabulutlarNo ratings yet

- Design and Fabrication of Solar Powered Stirling EngineDocument35 pagesDesign and Fabrication of Solar Powered Stirling EngineShubham shendeNo ratings yet

- Construction and Testing of A Dish Stirling EngineDocument5 pagesConstruction and Testing of A Dish Stirling EngineajejeyNo ratings yet

- (Chapter) Free-Piston Stirling Engine GeneratorsDocument22 pages(Chapter) Free-Piston Stirling Engine GeneratorsĐạt VõNo ratings yet

- Pollution Less Engine 5822 XPubAniDocument20 pagesPollution Less Engine 5822 XPubAnishivu bnNo ratings yet

- Design of Alpha Stirling Engine in Conjunction With Solar ConcentratorDocument6 pagesDesign of Alpha Stirling Engine in Conjunction With Solar ConcentratorimranakhtarNo ratings yet

- Stirling Engine Types and Components ExplainedDocument22 pagesStirling Engine Types and Components ExplainedAbhishek NaikNo ratings yet

- A Seminar On Stirling Engine: Vikash Kumar 07ESIAE050 4 Year, Automobile EnggDocument17 pagesA Seminar On Stirling Engine: Vikash Kumar 07ESIAE050 4 Year, Automobile EnggPrateek NangiaNo ratings yet

- Performance and Design Optimization of SDocument9 pagesPerformance and Design Optimization of Szaid AlkaissiNo ratings yet

- Stirling Engine: It Takes A Great Coder To Serve 400 Million Users. Sign Up For The October 2011 Coding Challenge NowDocument30 pagesStirling Engine: It Takes A Great Coder To Serve 400 Million Users. Sign Up For The October 2011 Coding Challenge NowShashi RaiNo ratings yet

- A Stirling Engine For Automotive ApplicationsDocument7 pagesA Stirling Engine For Automotive ApplicationsJoão SidônioNo ratings yet

- Operation and Maintenance of SUZUKI Generator SV1400LDocument30 pagesOperation and Maintenance of SUZUKI Generator SV1400LWeb FlowNo ratings yet

- Unit 4 Solar CoolingDocument12 pagesUnit 4 Solar CoolingSubhaNo ratings yet

- Stirling EngineDocument14 pagesStirling EngineShivakumar Ainapur100% (1)

- Stirling EngineDocument70 pagesStirling Engineamitsinghbvp100% (1)

- Stirling Engine: Presented By-Mechanical Engineers Rocks Visit-For More Mechanical StuffsDocument14 pagesStirling Engine: Presented By-Mechanical Engineers Rocks Visit-For More Mechanical StuffsSanjay ShreeshaNo ratings yet

- Stirling EngineDocument33 pagesStirling EnginepracheeNo ratings yet

- A Natural Gas Fired Duplex Stirling For Domestic RefrigeratiDocument11 pagesA Natural Gas Fired Duplex Stirling For Domestic RefrigeratiditoNo ratings yet

- Refrig Vehi ElectrDocument11 pagesRefrig Vehi ElectrDaniel martínNo ratings yet

- Dimensiones Stirling GammaDocument18 pagesDimensiones Stirling GammamikeNo ratings yet

- Stirling EngineDocument21 pagesStirling EngineNitish ManikeriNo ratings yet

- Thermodynamics Analysis of Reciprocating Machines and CyclesDocument13 pagesThermodynamics Analysis of Reciprocating Machines and CyclesVictoriaNo ratings yet

- Manufacturing and Testing of A Gamma Type Stirling EngineDocument10 pagesManufacturing and Testing of A Gamma Type Stirling EngineFlorin FloNo ratings yet

- Heat EngineDocument8 pagesHeat Enginekhaoula.ikhlefNo ratings yet

- Natural Gas EquipmentDocument26 pagesNatural Gas Equipmenthanisshi100% (1)

- A Case Study On Heat Rate of Boiler and Turbine in NSPCL DurgapurDocument10 pagesA Case Study On Heat Rate of Boiler and Turbine in NSPCL DurgapurRajneesh KaushalNo ratings yet

- Power Generation From Exhaust Gas & Engine Heat Using Teg.: ST - Vincent Pallotti College of Engineering and TechnologyDocument3 pagesPower Generation From Exhaust Gas & Engine Heat Using Teg.: ST - Vincent Pallotti College of Engineering and TechnologyMamta SarkarNo ratings yet

- 1 s2.0 S1359431117305458 MainDocument8 pages1 s2.0 S1359431117305458 Mainganfu2976No ratings yet

- Comparison Based On Exergetic Analyses of Two Hot Air Engines: A Gamma Type Stirling Engine and An Open Joule Cycle Ericsson EngineDocument18 pagesComparison Based On Exergetic Analyses of Two Hot Air Engines: A Gamma Type Stirling Engine and An Open Joule Cycle Ericsson EngineEfe TurkyılmazNo ratings yet

- Combine Gas Cycle TurbineDocument20 pagesCombine Gas Cycle Turbinekts700175% (4)

- A Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationFrom EverandA Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationNo ratings yet

- Geothermal Energy: From Theoretical Models to Exploration and DevelopmentFrom EverandGeothermal Energy: From Theoretical Models to Exploration and DevelopmentNo ratings yet

- Solar Cell StirlingDocument3 pagesSolar Cell StirlingJude Sisca SinagaNo ratings yet

- Jha 2017Document21 pagesJha 2017bepol88No ratings yet

- Renewable and Sustainable Energy Reviews: Normazlina Mat Isa, Chee Wei Tan, A.H.M. YatimDocument28 pagesRenewable and Sustainable Energy Reviews: Normazlina Mat Isa, Chee Wei Tan, A.H.M. Yatimbepol88No ratings yet

- ICGET2014 Design StirlingengineDocument7 pagesICGET2014 Design Stirlingenginebepol88No ratings yet

- Accepted Manuscript: 10.1016/j.renene.2017.06.081Document25 pagesAccepted Manuscript: 10.1016/j.renene.2017.06.081bepol88No ratings yet

- 11 Physics Test Paper Ch3 1Document4 pages11 Physics Test Paper Ch3 1Devendar SharmaNo ratings yet

- Lista Arancelaria EUADocument547 pagesLista Arancelaria EUAvilisbeth18No ratings yet

- The Storage Handling and Transportation of Ammonium Nitrate Based Fertilisers 2015Document58 pagesThe Storage Handling and Transportation of Ammonium Nitrate Based Fertilisers 2015Minh Đức TạNo ratings yet

- Differences in Left Ventricular and Left Atrial FuDocument10 pagesDifferences in Left Ventricular and Left Atrial FueugeniaNo ratings yet

- MetdsgffggDocument263 pagesMetdsgffggVishal Singh GaharwarNo ratings yet

- Terpin Hydrate Oral SolutionDocument1 pageTerpin Hydrate Oral SolutionAbelard Maria EscrivaNo ratings yet

- Taylors 10 Minute Diagnosis Manual Symptoms and Signs in The Time Limited Encounter PDFDocument656 pagesTaylors 10 Minute Diagnosis Manual Symptoms and Signs in The Time Limited Encounter PDF19marvoloNo ratings yet

- Parapsychology QP - WikiDocument371 pagesParapsychology QP - WikiAdamNo ratings yet

- Lecture No.3 Part 1 (Fan)Document6 pagesLecture No.3 Part 1 (Fan)Mohsen HassanNo ratings yet

- 30-300 MHZ Transmission Line Trainer Tla05Document1 page30-300 MHZ Transmission Line Trainer Tla05Kishor HandoreNo ratings yet

- Mass DisasterDocument70 pagesMass DisasterJoseph RadovanNo ratings yet

- EniSpA - The Corporate Strategy of An International Energy Major PDFDocument24 pagesEniSpA - The Corporate Strategy of An International Energy Major PDFAnonymous 9ZMbuR75% (4)

- HydrotherapyDocument52 pagesHydrotherapyMpt Sports100% (1)

- Sliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallDocument4 pagesSliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallAbdul Aziz Julkarnain ZulkifliNo ratings yet

- XR5 9 Element 5 Band Yagi 20-17-15-12-10MDocument16 pagesXR5 9 Element 5 Band Yagi 20-17-15-12-10Msboonuy331No ratings yet

- Shock Classification and PathophysiologyDocument40 pagesShock Classification and PathophysiologyErick Anca100% (2)

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet

- Hydraulic Excavator RH 200 1,568 kW 30.5 m3Document8 pagesHydraulic Excavator RH 200 1,568 kW 30.5 m3mchan1965100% (1)

- 2a CTRL DecDocument75 pages2a CTRL Decramanathan balamoorthyNo ratings yet

- EU Food Label GuidanceDocument99 pagesEU Food Label GuidanceMunteanu CristianNo ratings yet

- IGCSE Biology 4325 2H Mark SchemeDocument14 pagesIGCSE Biology 4325 2H Mark SchememuhajireenNo ratings yet

- Preliminary Evaluation On Vegetative of Rambutan (Nephelium Lappaceum) in Sandy Tin-Tailing SoilDocument7 pagesPreliminary Evaluation On Vegetative of Rambutan (Nephelium Lappaceum) in Sandy Tin-Tailing SoilAJAST JournalNo ratings yet

- Acknowledgement For Project Report SampleDocument23 pagesAcknowledgement For Project Report SampleSiddhesh BhavsarNo ratings yet

- Deks Olje ArticleDocument5 pagesDeks Olje ArticleTomMacNaughtonNo ratings yet

- Understanding The Nature of ReligionDocument41 pagesUnderstanding The Nature of Religioneden l. abadNo ratings yet

- Top 21 Largest EMS Companies in WorldDocument22 pagesTop 21 Largest EMS Companies in WorldjackNo ratings yet