Professional Documents

Culture Documents

Straight Shell D-1.0 & 0.7 M-L

Uploaded by

Deep SherawatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Straight Shell D-1.0 & 0.7 M-L

Uploaded by

Deep SherawatCopyright:

Available Formats

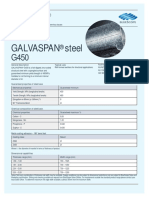

TECHNICAL SPECIFICATIONS

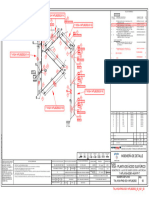

Confirming to IS:2062 /2011, Gr.E-250, Quality - C (YPS - 250

Steel Plates

MPa min. & UTS - 410 MPa min.)

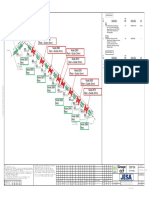

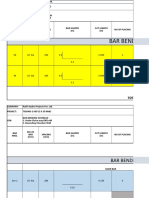

BILL OF MATERIAL

3 max

INSIDE INSIDE

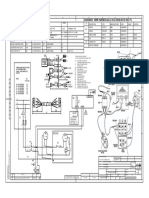

Welding As per IS:2825, IS:9595, ASME-Section VIII

60d

S. Size (LXWXT) Qty.

Description Nos. Remarks For SMAW:- AWS E7018 and For SAW:-AWS-A-5.17-80 or

No. mm (MT) Electrodes

equivalent

10

10

One plate of this size will Non (a) All longitudinal joints, all circular joints and all "T" Joints in

give 2 shells. One of 1000 3 BACK GAUGING

1 MS Plate 6300X2000X10 30 29.67 mm and another of 700 mm 4 to 6 Destructive shop shall be 100% ultrasonically tested (b) All circular joints in

3 max

dia. Testing of field shall be 100% ultrasonically tested (c) DP Test after back

Welds gauging of root

DETAIL OF SHOP LONG JOINT

Hydrostatic

Not required.

Test in Shop

Surface All interior and exposed exterior surface shall be 100% sand

Preparation blasted

3 max

INSIDE INSIDE

INSIDE 60d INSIDE

30d 30d (a) Exterior Surfaces to be embedded in concrete :Cement

wash with 5% potassium dichromate - 1 coat in shop and 1

coat in field after erection (b) Interior Surfaces: Zinc rich

10

10

10

10

Surface primer - 2 coats and cold applied coal tar epoxy paint - 2 coats

Painting

3

3

in shop and 1 coat in field after erection. ( The band shall be left

3 BACK GAUGING

4 to 6 unpainted from inner and outer side for a length of 150 mm from each ends which shall be

DETAIL - M

3 max

DETAIL - L painted with requisite paints after erection. However, 1 coat of primer can be applied over

this 150 mm patch to avoid rusting).

DETAIL OF FIELD CIRCULAR JOINT

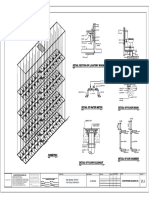

Notes :

(1) All dimensions are in mm.

(2) No dimensions is to be scaled out.

10

X M L

10

X M L (3) TOP, BOT shall be marked over plate before bending.

(4) "ID" stands for internal diameter, "OD" stands for outer diameter, "SCJ"

SLJ

stands for shop circular joint, "SLJ" stands for shop longitudinal joint,

OD=720

SLJ

ID=700

OD=1020

ID=1000

"FCJ" stands for field circular joint

X

Reference Drawings:(1) P1143-CC-307, Rev. 1

2000 ID=700

(2) P1143-CC-320, Rev.1

10

X OD=720

2000 ID=1000

VIEW X-X

10

OD=1020

VIEW X-X 700 mm DIA. ST. SHELL Issued for fabrication

1000 mm DIA. ST. SHELL 0 04.08.2020 and erection

Rev. Date Revision Note

SHEET 1 0F 1

=3

74

8

=

29

96

YAMUNA FABRICATORS

TH TH

2000

2000

NG NG

LE LE

AL L

AG

ON NA Contractor:- Rathi Hydro Projects Pvt. Ltd.

TOP

TOP

O

BOT

BOT

D I G

A

DI

CLIENT:- Tidong Power Generation Pvt. Ltd.

PROJECT:- TIDONG - 1 H.E.P.

792.5 1585 792.5 558 1115 558

MEAN CIRCUMFERENCE = 3170 MEAN CIRCUMFERENCE = 2230

PLATE MARKING DETAIL PLATE MARKING DETAIL STRAIGHT SHELL

FOR 1000 mm DIA. SHELL FOR 700 mm DIA. SHELL (700 & 1000 mm DIA.)

DRWN: DEGN: CHKD:

V.K.Pandey V.K.Pandey V.K.Pandey

TIDONG-SS-12 04 Aug. 2020 REV-0

You might also like

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- 4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Document2 pages4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- 0127 R8B 03 WP 311 01Document1 page0127 R8B 03 WP 311 01ABDERRAZZAKNo ratings yet

- J3BGDF02BR005 01 01Document1 pageJ3BGDF02BR005 01 01saleem naheedNo ratings yet

- Tal Wsa PNG Iso 1afl062502 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1afl062502 - 00 - A01 - 00landeopauloNo ratings yet

- 4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Document5 pages4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- APPENDIX-IDocument6 pagesAPPENDIX-IkarthickmectrNo ratings yet

- Tal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- MC Cylinder Accessories Clevis Brackets Pins Rod EyesDocument1 pageMC Cylinder Accessories Clevis Brackets Pins Rod EyesCAT CYLINDERNo ratings yet

- Valve Schedule - 10.5.2021 (LATEST)Document83 pagesValve Schedule - 10.5.2021 (LATEST)rvkheavenNo ratings yet

- 0468 Asom20 00TQ 0001 001 BDocument14 pages0468 Asom20 00TQ 0001 001 BDenny AgusNo ratings yet

- Piping Isometric - 3Document1 pagePiping Isometric - 3CosminMarianNo ratings yet

- Piping Isometric - 7Document1 pagePiping Isometric - 7CosminMarianNo ratings yet

- Material For-Springs enDocument2 pagesMaterial For-Springs enMuharrem BeyogluNo ratings yet

- Fabrication Materials ListDocument1 pageFabrication Materials ListSaptarshi MandalNo ratings yet

- Fabrication Materials: Saudi Arabian Oil CompanyDocument8 pagesFabrication Materials: Saudi Arabian Oil CompanyD7mey XNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- Under-Sluice Gate DrawingsDocument1 pageUnder-Sluice Gate DrawingsSandeep VaishnavNo ratings yet

- HPU P&ID Rev 1Document6 pagesHPU P&ID Rev 1AzhaghiaNo ratings yet

- Field / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5022 0Document2 pagesField / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5022 0hugoNo ratings yet

- Field / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5042 0Document2 pagesField / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5042 0hugoNo ratings yet

- Renr5807renr5807 01 Sis PDFDocument2 pagesRenr5807renr5807 01 Sis PDFLeonardo Romero JimenezNo ratings yet

- Sistema Eléctrico Del Tractor Sobre Orugas D3G PDFDocument2 pagesSistema Eléctrico Del Tractor Sobre Orugas D3G PDFAdrian Fernando Astrada Contreras100% (1)

- Bill of Materials: 331U15-OWS-002-02-1Document1 pageBill of Materials: 331U15-OWS-002-02-1PT Bumi Liputan PusakaNo ratings yet

- How To Select ElectrodeDocument2 pagesHow To Select Electrodesbmmla100% (1)

- Typical Instantaneous Time-Phase Current Characteristics BasedDocument3 pagesTypical Instantaneous Time-Phase Current Characteristics BasedgabitteNo ratings yet

- Tal Wsa PNG Iso 1CS106701 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106701 - 01 - A01 - 00landeopauloNo ratings yet

- Manual Valve List - FS-554!18!19Document1 pageManual Valve List - FS-554!18!19Ajay PrajapatiNo ratings yet

- Issued For Construction Modular Isometrics: Piping Isometric DrawingDocument1 pageIssued For Construction Modular Isometrics: Piping Isometric Drawing86tejasNo ratings yet

- Terminal Block LegrandDocument1 pageTerminal Block LegrandRava OshopNo ratings yet

- Tal Wsa PNG Iso 1SF058302 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1SF058302 - 01 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- NN BlokDocument3 pagesNN BlokMarko ŽivkovićNo ratings yet

- Section table for structural steel componentsDocument1 pageSection table for structural steel componentsCwm MmrNo ratings yet

- UntitledDocument2 pagesUntitledMohamed GamalNo ratings yet

- Lista de Materiales: Item Diam Cant DescripcionDocument1 pageLista de Materiales: Item Diam Cant DescripcionMarcia IturraNo ratings yet

- Jis B2316 PDFDocument1 pageJis B2316 PDFOluwachidiNo ratings yet

- Versamatic MetalicaDocument12 pagesVersamatic MetalicaJahaziel VegaNo ratings yet

- GT1015Document1 pageGT1015Basten M H SilitongaNo ratings yet

- FABRICATION MATERIALS AND COMPONENT LISTDocument7 pagesFABRICATION MATERIALS AND COMPONENT LISTCLS AKNo ratings yet

- MECHANICAL PROPERTIES of TitaniumDocument6 pagesMECHANICAL PROPERTIES of TitaniumAmr FawzyNo ratings yet

- 50 10xaa1 He40 22RDCH 1016Document1 page50 10xaa1 He40 22RDCH 1016uma raneNo ratings yet

- Selection of Welding ElectrodeDocument3 pagesSelection of Welding ElectrodeDuc ThinNo ratings yet

- HK 0FH 1027Document1 pageHK 0FH 1027PaoloNo ratings yet

- MMT Ed2 01 PC FX 0004 - 0Document1 pageMMT Ed2 01 PC FX 0004 - 0Thalles ResendeNo ratings yet

- STR 2883Document4 pagesSTR 2883eng.yehia.omara.kbhNo ratings yet

- A2 PDFDocument1 pageA2 PDFEMERSON GAPUZNo ratings yet

- 3D PV 2017 BrochureDocument6 pages3D PV 2017 BrochurehabilNo ratings yet

- 2205020250-01 DWGDocument1 page2205020250-01 DWGJuan Carlos TolabaNo ratings yet

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocument1 page01 E02STB007-W146693-03-0 - BC - Stress Update86tejasNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher NikhilNo ratings yet

- Bldg planDocument1 pageBldg planMax BenizaNo ratings yet

- Weld MapDocument3 pagesWeld Mapeffiezool mohdNo ratings yet

- 2SB1587 PDFDocument1 page2SB1587 PDFisaiasvaNo ratings yet

- Concrete Beam Rebar Table (Seismic) : CC1 CC2 CC3 CC4 Concrete Column ScheduleDocument1 pageConcrete Beam Rebar Table (Seismic) : CC1 CC2 CC3 CC4 Concrete Column Schedulesikandar abbasNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Product Cart 1300Document2 pagesProduct Cart 1300VTMS INNOVATIONNo ratings yet

- At Intersection: Wall Base ReinforcingDocument9 pagesAt Intersection: Wall Base ReinforcingJet ArcaNo ratings yet

- Flange PDFDocument1 pageFlange PDFDeep SherawatNo ratings yet

- B-1 TO B-1B Excavation QtyDocument1 pageB-1 TO B-1B Excavation QtyDeep SherawatNo ratings yet

- RAMS For Concrete (Overt and Invert Lining) Repair WorksDocument16 pagesRAMS For Concrete (Overt and Invert Lining) Repair WorksDeep Sherawat100% (1)

- OC TunnelDocument1 pageOC TunnelDeep SherawatNo ratings yet

- JSA For UNDERCUT REMOVALDocument2 pagesJSA For UNDERCUT REMOVALDeep SherawatNo ratings yet

- Biil of V. H. WaniDocument16 pagesBiil of V. H. WaniDeep SherawatNo ratings yet

- BS 417-1 - 1964 Specification For Galvanized Mild Steel Cisterns and Covers Tanks and CylindersDocument30 pagesBS 417-1 - 1964 Specification For Galvanized Mild Steel Cisterns and Covers Tanks and Cylinderspaul reyesNo ratings yet

- Parts List Item QTY Name Description Material: PROBLEM 15.7Document1 pageParts List Item QTY Name Description Material: PROBLEM 15.7rbNo ratings yet

- New BortechCatalog PDFDocument16 pagesNew BortechCatalog PDFGeovanny SanjuanNo ratings yet

- Steel StacksDocument44 pagesSteel StacksNitish saini100% (1)

- Ijser: Development Design For Jaw Crusher Used in Cement FactoriesDocument12 pagesIjser: Development Design For Jaw Crusher Used in Cement FactoriesCarlos Ediver Arias RestrepoNo ratings yet

- 4980weldingpiping Rev7-140915Document8 pages4980weldingpiping Rev7-140915PeterDonerNo ratings yet

- Acoples Kop-Flex Serie ElastomericaDocument14 pagesAcoples Kop-Flex Serie Elastomericamarcelo castilloNo ratings yet

- Aircraft PlumbingDocument17 pagesAircraft PlumbingJuan Pa MelenNo ratings yet

- Tender Accuracy of FabricationDocument8 pagesTender Accuracy of FabricationAdamNo ratings yet

- Galvaspan G450Document2 pagesGalvaspan G450khurshedlakhoNo ratings yet

- Training Manual On CNC Plasma MachineDocument35 pagesTraining Manual On CNC Plasma Machinetesfaye gurmesaNo ratings yet

- W.1.29.01 Butterfly Control ValveDocument2 pagesW.1.29.01 Butterfly Control ValveCarlos RodriguezNo ratings yet

- Nippon Company Profile-Unlocked PDFDocument30 pagesNippon Company Profile-Unlocked PDFAthul T.NNo ratings yet

- Welding Standard Requirements SummaryDocument6 pagesWelding Standard Requirements SummaryAob April100% (1)

- Superalloys 2004 553 561Document10 pagesSuperalloys 2004 553 561MAV TAWNo ratings yet

- Brisko Structural Steel BrochureDocument5 pagesBrisko Structural Steel Brochureyousef alfrkhNo ratings yet

- Mo 881Document2 pagesMo 881Vasile TipcuNo ratings yet

- 01 - Operating InstructionsDocument74 pages01 - Operating InstructionsАндрей100% (1)

- Fior Corporate Brochure 2021Document8 pagesFior Corporate Brochure 2021Ana KhanNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- ArcelorMittal - High-Rise Buildings - WebDocument80 pagesArcelorMittal - High-Rise Buildings - WebAndrei MurariuNo ratings yet

- BS en 14399-6-2015 - TC - (2021-05-23 - 05-17-39 PM)Document28 pagesBS en 14399-6-2015 - TC - (2021-05-23 - 05-17-39 PM)EmreNo ratings yet

- Welder Semester 1 NSFQ Books PDFDocument233 pagesWelder Semester 1 NSFQ Books PDFAPPI NAIDU75% (40)

- Top 6 Hydrogen Cracking - Cswip 3.1 Course Questions and AnswersDocument3 pagesTop 6 Hydrogen Cracking - Cswip 3.1 Course Questions and AnswersJlkKumarNo ratings yet

- Cast Copper Alloy Solder Joint Pressure Fittings: ASME B16.18-2018Document41 pagesCast Copper Alloy Solder Joint Pressure Fittings: ASME B16.18-2018crescon designNo ratings yet

- Nubirox 302 in High Gloss Solvent Based Alkyd DTM (Formula AC 19630F)Document3 pagesNubirox 302 in High Gloss Solvent Based Alkyd DTM (Formula AC 19630F)MONEMNo ratings yet

- 04 IndustrialDocument14 pages04 IndustrialΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- CE Equations For Weldability of SteelsDocument1 pageCE Equations For Weldability of SteelsVivek Panse100% (1)

- 3d CatalogueDocument55 pages3d CatalogueSURJIT SINGH100% (2)

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet