Professional Documents

Culture Documents

50 10xaa1 He40 22RDCH 1016

Uploaded by

uma raneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50 10xaa1 He40 22RDCH 1016

Uploaded by

uma raneCopyright:

Available Formats

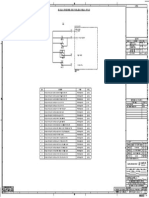

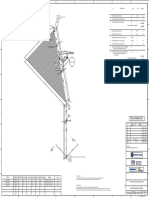

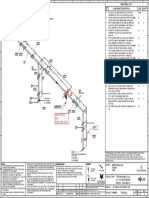

1 2 3 4 5 6 7 8

CONN. TO

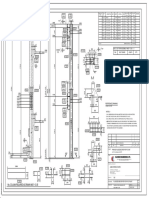

MATERIAL LIST

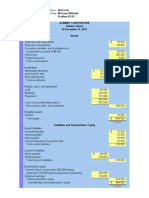

N 150-10XAA1-H50-22RDCH-1006/GASKET

E 244.938M PART

NO. COMPONENT DESCRIPTION SIZE QUANTITY

N 184.707M

1 11

EL+102.838M 1 CONC. REDUCER, CS, 150NB X 50NB, SCH 40, ASTM 150X50 1

NB 150X50 KH-22024

A234 GR.WPB-S/PTFE LINED, FLGD. AS PER ASME B16.5

INSULATION (168.3x)

A G10 A

H50

G10 229 2 SPACER, 50NB, SCH 40,VIRGIN SOLID PTFE UPTO 50MM 50 1

THK AND LIED SPACER ABOVE 50MM L=16(60.3x)

Node no: 3025 3 PIPE, CS, SMLS, 50NB, SCH 40, FOExLOE, ASTM A106 50 1

952 GR. B/PTFE LINED TO ASTM D4895, FLGD. ENDS TO

Rest, Mu= 0.3

NB 50

178 INSULATION

9 B16.5, ASME B36.10 / ASTM F1545 L=450(60.3x)

HE40

600 Guide, Gap= 3mm 4 ELBOW 90°, CS, 50NB, SCH 40, ASTM A234 50 2

400

INSULATION GR.WPB/PTFE LINED, FLGD. AS PER ASME B16.5

(60.3x) 90

INSULATION

8 25 5 PIPE, CS, SMLS, 50NB, SCH 40, FOExLOE, ASTM A106 50 4

Node no: 3024 INSULATION G10

INSULATION GR. B/PTFE LINED TO ASTM D4895, FLGD. ENDS TO

HE40 B16.5, ASME B36.10 / ASTM F1545 L=3000(60.3x)

Rest, Mu= 0.3 6 PIPE, CS, SMLS, 50NB, SCH 40, FOExLOE, ASTM A106 50 1

G10 INSULATION

HE40 GR. B/PTFE LINED TO ASTM D4895, FLGD. ENDS TO

114

B B

500 INSULATION G10 INSULATION

B16.5, ASME B36.10 / ASTM F1545 L=1100(60.3x)

7 SPACER, 50NB, SCH 40,VIRGIN SOLID PTFE UPTO 50MM 50 1

7 4 HE40

1000 THK AND LIED SPACER ABOVE 50MM L=20(60.3x)

8 SPACER, 50NB, SCH 40,VIRGIN SOLID PTFE UPTO 50MM 50 1

INSULATION

2000 1500 6 11

4 THK AND LIED SPACER ABOVE 50MM L=25(60.3x)

G10 INSULATION 9 PIPE, CS, SMLS, 50NB, SCH 40, FOExLOE, ASTM A106 50 1

INSULATION HE40

GR. B/PTFE LINED TO ASTM D4895, FLGD. ENDS TO

Node no: 3023 G10

INSULATION B16.5, ASME B36.10 / ASTM F1545 L=400(60.3x)

00 HE40 10 FLAT RING,GASKET, 50NB, 3MM THK., CLASS 150, 50 14

11

Rest, Mu= 0.3 INSULATION PTFE, TO SUIT ASME B16.5 150# RF FLG., ASME

20

HE40 B16.21

00 11 BALL VALVE, CS, FF, 50NB, CLASS 150, BODY-A216 50 1

00 30

G10 CONN. TO

150-10XAA1-H50-22RDCH-1017/TEE

30

5

274 INSULATION

HE40 GR.WCB/PTFE LINED, TRIM-SS304/PTFE LINED, BS EN

C 5 C

E 231.569M ISO 17292, LEVER OPER.

INSULATION

N 184.707M 12 PIPE CLAMP SHOE, REST, PCS-2-2-A2 50 2

INSULATION G10 HE40

EL+102.470M

HE40 G10

INSULATION

99

INSULATION Node no: 3055

INSULATION G10 59

HE40 3200

HE40

Rest, Mu= 0.3

17 2 5

INSULATION

2400 INSULATION Guide, Gap= 3mm

450

INSULATION

30

00

HE40 INSULATION

Limit, Gap= 5mm

NB 50

HE40

SUPPORT12 INSULATION

3

INSULATION 00 5 HE40 INSULATION

30

HE40 HE40

INSULATION

G10 INSULATION Node no: 2985

Rest, Mu= 0.3

114

HE40

D D

G10

G10 INSULATION Guide, Gap= 3mm

HE40

SUPPORT12

Node no: 2950

4

4 11

79 INSULATION Rest, Mu= 0.3

13

EL+101.880M HE40

Guide, Gap= 3mm

INSULATION

INSULATION

HE40

Limit, Gap= 5mm

1579

E E

This drawing and /or it's contents, information and concepts of design are the exclusive

property of DCM Shriram Ltd. and prepared by Triplan India Pvt. Ltd. Contents

of this drawing shall not be reproduced in any manner, copied or modified in part or in

whole to any other firm or individual for any other project except by written agreement with

DCM Shriram Ltd.

NOTES: 7. SHIM PLATES TO BE PROVIDED BELOW PIPE SUPPORT SHOE FOR REFERENCE LIST: LEGENDS:

1. ALL DIMENSIONS AND CO-ORDINATES ARE IN MM

CLIENT : DCM Shriram Ltd.

HOT INSULATION LINES,TO ADJUST WORKING POINT ELEVATION OF

1.PIPING MATERIAL SPECIFICATION ( T70210122-02-TD-SP-0012)

UNLESS NOTED OTHERWISE. LINE. ALLUMINIUM FOIL TO BE PROVIDED BELOW SS BARE PIPE. Gujarat,

2.VALVE MATERIAL SPECIFICATION (T70210122-02-TD-SP-0016) : PIPE REST

2. ALL DIMENSIONS ARE UP TO PIPE CENTER LINES 8. WORKING POINT ELEVATION DENOTES,THE ELEVATION AT THE

UNLESS SPECIFIED OTHERWISE. 3. LINE LIST (T70210122-01-TD-LI-0004/0006) SUPPORT

AXIAL STOP India.

CENTER POINT OF PIPE.

1 4. PRIMARY SUPPORT STANDARD (T70210122-02-TD-SP-0010)

3. DIMENSIONS FOR LINES 1 2" AND BELOW TO BE 9. UNLESS OTHERWISE STATED FLANGE DRILLING TO BE OFF

CHECKED AT SHOP BEFORE FABRICATION. CENTER. 5. SECONDARY SUPPORT STANDARD (T70210122-02-TD-SP-0011)

1

DIMENSIONS ARE FOR GUIDANCE ONLY. LINES 1 2" 10. DIMENSION TO BE VERIFIED AT SITE BEFORE FABRICATION. 6. HOOKUP DRAWING (T70210122-05-TD-DR-0004) CONSULTANT : TRIPLAN India Pvt Ltd,

BELOW TO BE FIELD SUPPORTED. 11. ALL INLINE INSTRUMENTS, CONTROL VAVE, STRAINER SIGHT : PIPE GUIDE

4. HYDROSTATIC VENT/ DRAIN SHALL BE DECIDED GLASS, PSV DIMENSIONS ARE INDICATIVE.CONTRACTOR TO SUPPORT REST+GUIDE+AXIAL STOP

Tel : +91 020 67080300 TRIPLAN

VERIFY THE SAME ON SITE AND MODIFY THE ADJACENT SPOOLS (PARTIAL ANCHOR)

AND INCORPORATED BY CONTRACTOR IN Website : www.triplan.in

CONSULTATION WITH SITE ENGINEER.CAP SHALL ACCORDINGLY. SERVICE: REACTION_MIXTURE_DICHLORHYDRIN

F F

BE WELDED AFTER TESTING. 12. FOR GUIDE SUPPORTS, GUIDE GAP OF 3MM TO BE CONSIDERED.

PIPING SPECIFICATION: 10XAA1 LINE NO : 50-10XAA1-HE40-22RDCH-1016

5. FIELD WELD TO BE DECIDED BY THE FABRICATION

13. HOOKUP DRAWINGS TO BE REFERRED FOR ALL INSTRUMENT

CONTRACTOR. 0 10/01/2023 ISSUED FOR CONSTRUCTION DMV PSR LRB INSULATION SPECIFICATION:

CONNECTIONS MATERIAL TO BE TAKEN FROM STORE SHEET REV.

6. VALVE HANDLE ORIENTATION SHALL BE DECIDED ACCORDINGLY.

REV. DATE DESCRIPTION PREP.CHKD.APPR.P&ID NO: DCM243-VRI-0004 22-ECH/60

PROJECT NUMBER: T70210122

AT SITE. 1 OF 1 0

A3

You might also like

- 50 10xaa1 He40 21RDCH 1016Document1 page50 10xaa1 He40 21RDCH 1016uma raneNo ratings yet

- 25 10xaa1 H40 22RDCH 1014Document1 page25 10xaa1 H40 22RDCH 1014uma raneNo ratings yet

- 150 10xaa1 H50 21RDCH 1004 1Document1 page150 10xaa1 H50 21RDCH 1004 1uma raneNo ratings yet

- So6625 61DD3 61DD3L So6625-Eh0d-Iso-61dd3l-015 03 Er-000 03Document2 pagesSo6625 61DD3 61DD3L So6625-Eh0d-Iso-61dd3l-015 03 Er-000 03Erick's Cer'LpzNo ratings yet

- BILL OF MATERIALSDocument1 pageBILL OF MATERIALSABAID ULLAHNo ratings yet

- FABRICATION MATERIALS LISTDocument1 pageFABRICATION MATERIALS LISTSaptarshi MandalNo ratings yet

- 2HH-38A-R4-V2 Line DrawingDocument1 page2HH-38A-R4-V2 Line DrawingDaniel Heitor Silva AssisNo ratings yet

- RHHTT-65A-R4-V2 PlanimetriaDocument1 pageRHHTT-65A-R4-V2 PlanimetriaRicardo Christian Santis TorresNo ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- South Refineries Company: Basrah Refinery Upgrading Project ProjectDocument5 pagesSouth Refineries Company: Basrah Refinery Upgrading Project ProjectBasem AlsaftliNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Tal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Use of Crane: 5T Stahl CranesystemsDocument2 pagesUse of Crane: 5T Stahl CranesystemsАсема АселяNo ratings yet

- Lista de Materiales: Item Diam Cant DescripcionDocument1 pageLista de Materiales: Item Diam Cant DescripcionMarcia IturraNo ratings yet

- AT Series Gear Box BroctureDocument2 pagesAT Series Gear Box BroctureabhinitindiaNo ratings yet

- J3BGDF02BR012 01 05Document1 pageJ3BGDF02BR012 01 05Naheed AkhtarNo ratings yet

- 40-Point Tack Weld DrawingDocument1 page40-Point Tack Weld DrawingAhmad LabiibNo ratings yet

- Hy000-B0001 - 0 Skiving DeflectorDocument2 pagesHy000-B0001 - 0 Skiving DeflectorAnyNo ratings yet

- CA01 L-ZL (34) 34CW01.002 - 1 Isometric CA01-L-ZL (34) 34CW01.002Document1 pageCA01 L-ZL (34) 34CW01.002 - 1 Isometric CA01-L-ZL (34) 34CW01.002Kreshna Wisnu BrataNo ratings yet

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Document1 page13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6No ratings yet

- Load shedding panel documentationDocument1 pageLoad shedding panel documentationAnonymous BZQOJwWIh6No ratings yet

- Fabrication Materials ListDocument1 pageFabrication Materials ListSaptarshi MandalNo ratings yet

- JI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1Document1 pageJI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1weerachai phosoongNo ratings yet

- 3X-RRZZHHTTS4-BR24-LDocument1 page3X-RRZZHHTTS4-BR24-LhenriquemmfNo ratings yet

- 115/13.8kV TRANSFORMER (T602) PROTN. SET-1 PANEL-1 +TRPA.21Document1 page115/13.8kV TRANSFORMER (T602) PROTN. SET-1 PANEL-1 +TRPA.21Anonymous BZQOJwWIh6No ratings yet

- Earthing Cable Tray Layout - Rev1Document5 pagesEarthing Cable Tray Layout - Rev1BumiLangitNo ratings yet

- Material List for Piping ComponentsDocument1 pageMaterial List for Piping Componentsvishwas salunkheNo ratings yet

- WABBDocument16 pagesWABBhanungNo ratings yet

- 115Kv Busbar & BF Proection Panel-1 (D01/D02) : A P HA556 3-1313003.05 4400004657 EA-381637Document1 page115Kv Busbar & BF Proection Panel-1 (D01/D02) : A P HA556 3-1313003.05 4400004657 EA-381637Anonymous BZQOJwWIh6No ratings yet

- Sump Discharge Piping - ISOMETRIC DrawingDocument9 pagesSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNo ratings yet

- Selection of Welding ElectrodeDocument3 pagesSelection of Welding ElectrodeDuc ThinNo ratings yet

- NNH4 65B R6Document1 pageNNH4 65B R6billfreelyNo ratings yet

- Riau GFPP (275Mw) Ipp Project: Pt. Medco Ratch Power Riau Lotte Engineering & ConstructionDocument1 pageRiau GFPP (275Mw) Ipp Project: Pt. Medco Ratch Power Riau Lotte Engineering & ConstructionFebri NuansaNo ratings yet

- 10GHA25BR501 Sheet1 ModelDocument1 page10GHA25BR501 Sheet1 ModelFebri NuansaNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- ISOMETRIC SST36M - NEWLIGHT 4LEG SHOP DRAWINGDocument14 pagesISOMETRIC SST36M - NEWLIGHT 4LEG SHOP DRAWINGyuwonoNo ratings yet

- P Okitm07 329 03 Eqd 2003 1Document1 pageP Okitm07 329 03 Eqd 2003 1ismiasyofNo ratings yet

- Eep000093 14700510 Mearr 0003 - 00Document1 pageEep000093 14700510 Mearr 0003 - 00Simran singhNo ratings yet

- Power Schematic Diagram: (TV MT PCB)Document1 pagePower Schematic Diagram: (TV MT PCB)alanNo ratings yet

- La233r1.ca100v-000 R03Document1 pageLa233r1.ca100v-000 R03Ricardo TurinNo ratings yet

- Mach 10465657 A PDFDocument1 pageMach 10465657 A PDFshahanarab934No ratings yet

- Agitator Backtank PartsDocument1 pageAgitator Backtank PartsRomly MechNo ratings yet

- Extract Page 4Document1 pageExtract Page 4Damiano DaidoneNo ratings yet

- Chwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)Document1 pageChwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)vishwas salunkheNo ratings yet

- Issued For Construction Modular Isometrics: Piping Isometric DrawingDocument1 pageIssued For Construction Modular Isometrics: Piping Isometric Drawing86tejasNo ratings yet

- HK 0FH 1027Document1 pageHK 0FH 1027PaoloNo ratings yet

- Chwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)Document1 pageChwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)vishwas salunkheNo ratings yet

- GD Frac ValvesSeats Spec-SheetDocument2 pagesGD Frac ValvesSeats Spec-SheetbayuNo ratings yet

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocument1 pagePesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNo ratings yet

- F.T - ARNES QR TIPO X ANTICAIDAS Y SUJECION PARA KIT ALPINISMODocument6 pagesF.T - ARNES QR TIPO X ANTICAIDAS Y SUJECION PARA KIT ALPINISMOSOCORRO RENDONNo ratings yet

- COMMSCOPE EGZHHTT-65B-R6 (Disegno)Document1 pageCOMMSCOPE EGZHHTT-65B-R6 (Disegno)21n23mNo ratings yet

- 1C25 (KSS021-D-549) - Column-R0.1Document1 page1C25 (KSS021-D-549) - Column-R0.1mo3azNo ratings yet

- Reverse Engineering PLTA Kaluku: PT - PLN (Persero) Sektor Pembangkitan BakaruDocument1 pageReverse Engineering PLTA Kaluku: PT - PLN (Persero) Sektor Pembangkitan Bakarusyaifulfuad19No ratings yet

- 25 10xaa1 H40 21RDCH 1014Document1 page25 10xaa1 H40 21RDCH 1014uma raneNo ratings yet

- For Construction: 2 No V - Brace Required As Drawn MKD ' L0R0470Vb104PDocument1 pageFor Construction: 2 No V - Brace Required As Drawn MKD ' L0R0470Vb104PrajendraNo ratings yet

- New Wellhead 10 PH4589 01 STKUPDocument2 pagesNew Wellhead 10 PH4589 01 STKUPNguyen Binh PhuongNo ratings yet

- 5-C0003 - Pga1002413340010-02 SH - 1Document2 pages5-C0003 - Pga1002413340010-02 SH - 1Aswindana Ibnu SenaNo ratings yet

- Longitudinal detail section 1-1Document1 pageLongitudinal detail section 1-1Mwesigwa DaniNo ratings yet

- 07 Safety Culture Informed Just and FairDocument49 pages07 Safety Culture Informed Just and FairDaniel Gaspar SilvaNo ratings yet

- Scarola Motion Hague Convention RequestDocument14 pagesScarola Motion Hague Convention RequestPaulWolfNo ratings yet

- Microsoft Test4prep AI-900 v2020-09-07 by Abdullah 25qDocument19 pagesMicrosoft Test4prep AI-900 v2020-09-07 by Abdullah 25qANIMESH301No ratings yet

- UI UX Research DesignDocument7 pagesUI UX Research DesignSomya ShrivastavaNo ratings yet

- 9 Principles of Income Tax LawsDocument82 pages9 Principles of Income Tax LawsVyankatesh GotalkarNo ratings yet

- Nano-technology for Post-Harvest Management of Fruits and VegetablesDocument3 pagesNano-technology for Post-Harvest Management of Fruits and VegetablesArin RujinNo ratings yet

- AI Story WritermnfyaDocument2 pagesAI Story Writermnfyafrenchrugby98No ratings yet

- Activity#tachometer - MEC 0326.1-2Document4 pagesActivity#tachometer - MEC 0326.1-2MarkJude MorlaNo ratings yet

- Judicial Watch Vs State Dept Stephen Mull DepositionDocument415 pagesJudicial Watch Vs State Dept Stephen Mull DepositionThe Conservative Treehouse100% (1)

- PPM Advance Android Application - User ManualDocument22 pagesPPM Advance Android Application - User ManualmayckerNo ratings yet

- PATHFit 4 Volleyball BSEDDocument7 pagesPATHFit 4 Volleyball BSEDJULIUS JIM CREDONo ratings yet

- Ryanair Strategic AnalysisDocument36 pagesRyanair Strategic AnalysisAlmas Uddin100% (1)

- IPUMS CPS Exercise 2 For RDocument7 pagesIPUMS CPS Exercise 2 For RKateO838No ratings yet

- Seatwork 12 Analysis of Variance ANOVA Simple Linear RegressionDocument17 pagesSeatwork 12 Analysis of Variance ANOVA Simple Linear RegressionDanrey PasiliaoNo ratings yet

- TBelt - 02Document46 pagesTBelt - 02prasanthme34No ratings yet

- ESG PresentationDocument16 pagesESG Presentationsumit100% (1)

- Basic IT Tutorial 2 - No Answer, Candidates Are To Work Out The Answers ThemselveDocument3 pagesBasic IT Tutorial 2 - No Answer, Candidates Are To Work Out The Answers ThemselveTri Le MinhNo ratings yet

- Forms6i 10GDocument42 pagesForms6i 10GRolando OcañaNo ratings yet

- ETL Process in Data WarehouseDocument40 pagesETL Process in Data WarehouseshariqatariqNo ratings yet

- C2 - Knowledge - and - Process - Management - v25 - n3 - Fernanda 2018 PDFDocument12 pagesC2 - Knowledge - and - Process - Management - v25 - n3 - Fernanda 2018 PDFThomazNo ratings yet

- Viewing Partition of India as an Imperfect SolutionDocument36 pagesViewing Partition of India as an Imperfect Solutionsingh1910511753No ratings yet

- VALS System: Presented By: Atul Agarwal Balu K Thomas Dhiraj BhabhulgaonkarDocument18 pagesVALS System: Presented By: Atul Agarwal Balu K Thomas Dhiraj BhabhulgaonkarBalu K Thomas100% (1)

- Guidelines For The Design and Construction of Suspension FootbridgesDocument141 pagesGuidelines For The Design and Construction of Suspension Footbridgesjavali2100% (2)

- BSBPMG534 Task 2 - V2.4Document9 pagesBSBPMG534 Task 2 - V2.4Anoosha MazharNo ratings yet

- Tekla - DocumentDocument2,005 pagesTekla - DocumentTranタオNo ratings yet

- Combinational CircuitsDocument18 pagesCombinational CircuitsSalil TimalsinaNo ratings yet

- IH May-June 2022Document60 pagesIH May-June 2022Omkar R PujariNo ratings yet

- Group 3 - Brand Architecture Assignment IDocument9 pagesGroup 3 - Brand Architecture Assignment IShijin SreekumarNo ratings yet

- Unit 1Document176 pagesUnit 1kassahun meseleNo ratings yet

- Chapter 3 - Excel SolutionsDocument8 pagesChapter 3 - Excel SolutionsHalt DougNo ratings yet