Professional Documents

Culture Documents

Class NK - FPI AD - Marine Type Approval - Wavistrong PDF

Uploaded by

ATT20160 ratings0% found this document useful (0 votes)

26 views3 pagesOriginal Title

Class NK - FPI AD- Marine Type Approval - Wavistrong.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views3 pagesClass NK - FPI AD - Marine Type Approval - Wavistrong PDF

Uploaded by

ATT2016Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

NIPPON KAldI KYOKAL OP

Catfleate

Cortifteate No.

‘Ta201598(AL) ad

APPROVAL

tem Plastic Pipe and Fittings

(Glass Reinforced Plastic Pipe and Fittings)

Product name Wavistrong

Applicant Future Pipe Industries LLC

Sector MAL, Plot 1P1, 2F1 & SP, Mussafah,

TCAD-1, Abu Dhabi, UAE

Manufacturers: See Annex.

Spocifiations Seo Annex,

‘Testing standard Chap. Part 6 of “GUIDANCE FOR THE APPROVAL,

AND TYPE APPROVAL OF MATERIALS AND

EQUIPMENT FOR MARINE USE"

Condition for use See Annex

‘THIS 15 TO CERTIFY that the above type of products has been approved by

[Nippon Kaiji Kyokai with type approval No. NKPPOGI as complying with che relevant

requirements of the Society's Rules for che Survey and Construction of Stee! Ships,

‘This cortficate is valid from 10 February 2020 until § February 2024

Isgued at Tokyo on 10 February 2020,

Goneral Manager

Material and Equipment Department

‘Annex tothe Certificate No, TAZ0159E(Al

PD Future Pipe Industries

SIL Raya Serang Km, 30 Deea Cangkudu dan Gembong, Kecematan Balaraja

‘Tangerrang 15610, Banten- Indonosia

Future Pipe Industries LLC

Sector Ml, Plot IPI, 2F1 & 31, Mussafah ICAD1, Abu Dhabi, UAB

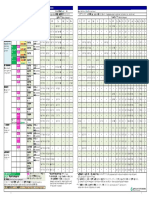

2. Specifications

Type Wavinron

Resin Epon

ix Working

‘Temperature () oe se

Nominal Diameter | 1399 - 1500 | 350-1600 | 250-1500 | 150-1500 | 25-1200

peony ye Ge 125 16 20 2

Pressure

eta eed o4 oa 05-06 | 10-400

Wall Thiceness (om) | w21-140 | 35-162 | 33-105 | 25-245 | 18-26

Category oD

ie Endurance wo

Ii Category symbol "@” means that this mataral has “low flame spread characteristic’

snd “D" means that have electrically conductive,

"2; "La" moans that this material ie satisfied with fire endurance test (IMO

Res.A759(18) Appendix 2)

3. Condition for use

8.1. On Plastic Pipes, the followings should be markod.

() Wade name andlor product name

@) Nis approval, such as “NK-Approved"

@) Nominal pressure

(® Symbol "Gr-D"

(6) Fire Endurance Lovel“L3"

(©) Material of which pipe oF tsuing is made

3.2, Particulars, manufacturing method and material of Plastic Pipes should be samo as

‘those in the original approval testa. Any alternation to the above items should >e

informed to the Society for approval. Our surveyor reserves the right to accoss to tho

‘manufacturing facltios and may require furthr test and/or examination where deemed

necessarily.

3.3, Plastic Pipes should be tested after manufacture in accordance with Annex

D12..6-2 “Shop Tests” of "GUIDANCE FOR THE SURVEY AND CONSTRUCTION

OF PLASTIC PIPES” in the prosence of surveyor

‘34. The installation ofthe piping eystom isto be carried out in accordance with ANNEX

D12..6-2, “GUIDANCE FOR THE SURVEY AND CONSTRUCTION OF PLASTIC

PIPES,

£86. Plastic Pipes should be subject tothe periodical examination at interval of five years

after the date of approve.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ABB Motor SpecDocument16 pagesABB Motor SpecATT2016No ratings yet

- Copper Alloy Casting JIS H5120Document4 pagesCopper Alloy Casting JIS H5120ATT2016No ratings yet

- Mariners Repository - Propeller Inspection, Defects and RepairsDocument13 pagesMariners Repository - Propeller Inspection, Defects and RepairsATT2016No ratings yet

- Basic Principle of Ship PropulsionDocument45 pagesBasic Principle of Ship PropulsionShengte Hsu100% (7)

- Design of COW MachineDocument27 pagesDesign of COW MachineATT2016100% (1)