Professional Documents

Culture Documents

SINOXX 4122 Steel: Designation by Standards

Uploaded by

abdelkader benabdallahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SINOXX 4122 Steel: Designation by Standards

Uploaded by

abdelkader benabdallahCopyright:

Available Formats

SINOXX 4122 Steel

Designation by Standards

Brand Name Ravne Mat. No. DIN EN AISI/SAE

SINOXX 4122 PK335 1.4122 X39CrMo17-1 † X39CrMo17-1 -

Chemical Composition (in weight %)

C Si Mn Cr Mo Ni V W Others

0.39 max. 1.00 max. 1.00 16.50 1.05 max. 1.00 - - -

Description

Stainless steel with very good wear, corrosion reistance and industrial polishability.

Applications

PK335 is used for pump shafts, fitting and compressor parts, as well as steam and water control valves and boat shafts for use in fresh

water.

Physical properties (average values) at ambient temperature

Modulus of elasticity [103 x N/mm2]: 223

Density [g/cm3]: 7.71

Thermal conductivity [W/m.K]: 15

Electric resistivity [Ohm mm2/m]: 0.80

Specific heat capacity[J/g.K]: 0.43

Coefficient of Linear Thermal Expansion 10-6 oC-1

20-100oC 20-200oC 20-300oC 20-400oC 20-500oC 20-600oC 20-700oC 20-800oC

10.7 11.7 11.7 11.7 11.8 11.9 12.4 12.9

Modulus of Elasticity [103 N/mm2]

100oC 200oC 400oC

223 205 190

Thermal conductivity [W/m.K]

20-200oC 20-200oC 20-400oC

10.4 10.8 11.6

Continuous Cooling Transformation (CCT) Diagram

Time-Temperature Transformation (TTT) Diagram

Soft Annealing

Heat to 750-880oC, cool slowly in furnace or air. Structure is ferrite with spherical carbides. This will produce a maximum Brinell

hardness of 250.

Hardening

Harden from a temperature of 980-1050oC followed by oil quenching. Hardness after quenching is 49 HRC.

Tempering

Tempering temperature: 150-200oC, 650-750oC

Mechanical Properties at Room Temperature

Notch

Tensile strength Elongation impact

Size range mm Heat treatment condition 0.2 % proof stress (N/mm2)

(N/mm2) (%) energy

(ISO-V) (J)

d<=60 Q+T 750 500 750-950 12 (Long) 20 (Long)

61<d<=160 Q+T 750 500 750-950 12 (Long) 14 (Long)

0.2 % Proof Stress (N/mm2) at Elevated Temperatures

100oC 150oC 200oC 250oC 300oC 350oC 400oC

540 535 530 520 510 490 470

Tempering Diagram

Forging

Hot forming temperature: 1100-800oC, slow cooling.

Machinability

Metal-cutting machining is the same as for special engineering steel grades of corresponding strength.

Welding

Limited weldability using the manual arc and TIG welding processes, as hardening occurs in the heat-affected zone. Preheat to between

300 and 400oC. Filler metals: 1740, Nicro82.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values.

Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to

make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is

no representation that the recipient of this literature will receive updated editions as the become available.

Unless otherwise specified, registered trademarks are property of SIJ Metal Ravne company. Copyright 2016 by SIJ Metal Ravne d.o.o.

All rights reserved. Contact our Sales Office for more information.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

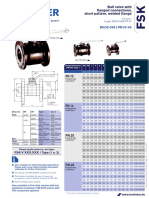

- Boehmer FSK V DN32-200 PN10-40 EN PDFDocument1 pageBoehmer FSK V DN32-200 PN10-40 EN PDFabdelkader benabdallahNo ratings yet

- Reverse Osmosis Desalination: Our Global Expertise To Address Water ScarcityDocument9 pagesReverse Osmosis Desalination: Our Global Expertise To Address Water Scarcityabdelkader benabdallahNo ratings yet

- Brochure - Manual Control MonitorDocument5 pagesBrochure - Manual Control Monitorabdelkader benabdallahNo ratings yet

- Pert Project Reference List PDFDocument4 pagesPert Project Reference List PDFabdelkader benabdallahNo ratings yet

- Inspection Checklist For: Control ValvesDocument2 pagesInspection Checklist For: Control Valvesabdelkader benabdallahNo ratings yet

- Flange Adapters: F L A N GE AdapterDocument3 pagesFlange Adapters: F L A N GE Adapterabdelkader benabdallahNo ratings yet

- High-Density Polyethylene: What Is HDPE?Document2 pagesHigh-Density Polyethylene: What Is HDPE?abdelkader benabdallahNo ratings yet

- Baffle Curtain BrochureDocument14 pagesBaffle Curtain Brochureabdelkader benabdallahNo ratings yet

- Fasek Engineering and Production GMBH Catalogue PDFDocument134 pagesFasek Engineering and Production GMBH Catalogue PDFabdelkader benabdallahNo ratings yet

- ATI Brochure Web 2015 07 02 PDFDocument12 pagesATI Brochure Web 2015 07 02 PDFabdelkader benabdallahNo ratings yet

- Line Breaking Procedure - Sp#15: 5/20/2010 Tim Vodopivec Kathy KiestlerDocument6 pagesLine Breaking Procedure - Sp#15: 5/20/2010 Tim Vodopivec Kathy Kiestlerabdelkader benabdallahNo ratings yet

- Quarter Turn & Linear Steel Actuators: General CatalogueDocument48 pagesQuarter Turn & Linear Steel Actuators: General Catalogueabdelkader benabdallahNo ratings yet

- BG Tun Mish Pi 10 03 00001 0 PDFDocument9 pagesBG Tun Mish Pi 10 03 00001 0 PDFabdelkader benabdallahNo ratings yet

- Five-Offset Butterfly ValvesDocument13 pagesFive-Offset Butterfly Valvesabdelkader benabdallahNo ratings yet

- Annex1 - Technical Specifications PDFDocument64 pagesAnnex1 - Technical Specifications PDFabdelkader benabdallahNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Example 4.1: School of Engineering - EN334Document7 pagesExample 4.1: School of Engineering - EN334Ismail DoğanNo ratings yet

- Fluid Solutions World of ApplicationsDocument4 pagesFluid Solutions World of ApplicationsMagin Idelfonso TorreblancaNo ratings yet

- 69 RNC Owners e F 0Document24 pages69 RNC Owners e F 0Frank GrenierNo ratings yet

- 10 IGCSE Physics Study Stack - Forces & MotionDocument4 pages10 IGCSE Physics Study Stack - Forces & MotionpixelhoboNo ratings yet

- Distillation - Lectures 1 To 6 PDFDocument45 pagesDistillation - Lectures 1 To 6 PDFMayank PrasadNo ratings yet

- Soil Model Okt 2010Document22 pagesSoil Model Okt 2010HawaiiChongNo ratings yet

- C8 Cussler PDFDocument33 pagesC8 Cussler PDFRaisa LopezNo ratings yet

- Sap ConcDocument192 pagesSap ConcJose SanchezNo ratings yet

- 10.1007@978 94 024 0867 6 PDFDocument735 pages10.1007@978 94 024 0867 6 PDFutsav_koshtiNo ratings yet

- Thermal Conductivity Measurement For Poor Conductor - Lee's DiscDocument17 pagesThermal Conductivity Measurement For Poor Conductor - Lee's Discibnu_iman810% (2)

- LevellingDocument15 pagesLevellingpushpakbhawgati27No ratings yet

- Damage Mechanics Present and FutureDocument15 pagesDamage Mechanics Present and FutureNoushad Bin Jamal Structural EngineerNo ratings yet

- Characterization TechniquesDocument8 pagesCharacterization TechniquesAyush SinghNo ratings yet

- Extra High Strength Steels - Strenx vs. HardoxDocument1 pageExtra High Strength Steels - Strenx vs. Hardoxdavid blecicNo ratings yet

- Microsoft Word - CH 12 Worksheet 2-2 - DocDocument7 pagesMicrosoft Word - CH 12 Worksheet 2-2 - DocAhmad RezaNo ratings yet

- Cristy Nicole Buiza ChE 130 Problem Set 5A 1Document13 pagesCristy Nicole Buiza ChE 130 Problem Set 5A 1Xavier AbainzaNo ratings yet

- OBrien 1998 Laboratory Analysis of Mudflow PropertiesDocument11 pagesOBrien 1998 Laboratory Analysis of Mudflow PropertiesDiego CasasNo ratings yet

- Definitions and MCQs of Ninth Class Chemistry (Solution and Suspension)Document6 pagesDefinitions and MCQs of Ninth Class Chemistry (Solution and Suspension)Sajid AliNo ratings yet

- 18) UC203x203x46toUC254x254x73-B2CF - MCDocument125 pages18) UC203x203x46toUC254x254x73-B2CF - MCAsaru DeenNo ratings yet

- Sophisticated ChemistryDocument9 pagesSophisticated ChemistryKingsleyNo ratings yet

- Literature ReviewDocument32 pagesLiterature ReviewMathew Sebastian100% (6)

- Lecture On Diffusion in SolidsDocument31 pagesLecture On Diffusion in SolidsSiva Kumar RajuNo ratings yet

- ASA - Temperature Sensor - ILLZTT5069K - enDocument1 pageASA - Temperature Sensor - ILLZTT5069K - enKrum KashavarovNo ratings yet

- Avantespricelist0109 2Document11 pagesAvantespricelist0109 2scribdleser4No ratings yet

- Tickling Test of RC1536 With Z&S Water Based Ink Rev05Document10 pagesTickling Test of RC1536 With Z&S Water Based Ink Rev05casanovaNo ratings yet

- Pressure Switch (Refrigerant Pressure Cutoff)Document2 pagesPressure Switch (Refrigerant Pressure Cutoff)allan lariosaNo ratings yet

- Kishen Hydormechanics in Dentine Role of Dentinal Tubules and Hydrostatic Pressure On Mechanical Stress-Strain DistributionDocument11 pagesKishen Hydormechanics in Dentine Role of Dentinal Tubules and Hydrostatic Pressure On Mechanical Stress-Strain DistributionОлександр БайдоNo ratings yet

- Pressure Relief ValveDocument24 pagesPressure Relief Valvevinoth.kumarNo ratings yet

- Physics Investigatory ProjectDocument14 pagesPhysics Investigatory Project09shasNo ratings yet

- Daouadji 2016Document29 pagesDaouadji 2016Zahra ZahraNo ratings yet