Professional Documents

Culture Documents

ASTM-C140-12 (Block and Interlock Testing Procedures) Poor Quality PDF

ASTM-C140-12 (Block and Interlock Testing Procedures) Poor Quality PDF

Uploaded by

HaniAmin0 ratings0% found this document useful (0 votes)

12 views16 pagesOriginal Title

ASTM-C140-12 (Block and Interlock Testing Procedures) poor quality copy.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views16 pagesASTM-C140-12 (Block and Interlock Testing Procedures) Poor Quality PDF

ASTM-C140-12 (Block and Interlock Testing Procedures) Poor Quality PDF

Uploaded by

HaniAminCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

Designation: C140 - 12

Standard Test Methods for

Sampling and Testing Concrete Masonry Units and Related

Units"

“This saad ie esud under the fed designation C0 the number immediatly following de designation inate the yar of

Tahal adoption rn the case af eso, te year f lst revision. A number in parentheses nike the year of ast reapproval. A

‘operat ein (6) indicates an sora change since te ast revision ce approval.

1. Scope*

1.1 These test methods provide various testing procedures

commonly used for evalvsting characteristics of concrete

‘masonry units and related concrete units. Methods are provided

for sampling, measurement of dimensions, compressive

strength, absorption, unit weight (density), moisture content,

flexural load, and ballast weight. Not all methods are appli-

cable to all unit types, however.

1.2 Specific testing and reporting procedures are included in

annexes to these test methods for the following specific unit

types:

sonex A1—Conert masonry nt (Speieatons C20, C129)

‘nex Ad—Conrly and calsum suoat oe

{Gooctcatons C25, 7, C168)

Aoton 0" Segrenal ing wa un (Spesiatoo C1572)

snnox Cone iting paving ws

(Spoarcaton Caes220N)

Annex adConeret pong wits (Speciation C1215)

Annex Ab—Coneret ol pov (peateaten C51)

‘ono ?—Dry est reusing coer Hck

"Bpeofenton 384)

1.3 The test procedures included in these test methods are

also applicable to other types of units not referenced in these

test methods, but specific testing and reporting requirements

for those units are not included.

1.4 These test methods include the following sections:

‘secton

Scope

Referenced Deoumonts

Terminology

Signifoanes an Use

Sanoing

‘Measurement of Dmonsons

(Compressive Strength

‘sorptn

Catcustons

Report

Keywords

"ese test methods under the jarniion of ASTM Commitee C15 on

Manfactued Mascnry Units and ze the diet responsbiliy of Sbsommiter

C1503 on Conerete Maronty Units and Related Units.

‘Cuvet elton approved Feb 1, 2012. Pablished Febery 2012, Orgy

approve in 1938, Lat prosius eon approved i 2011 as CH40~ Ila. DOM:

10.152010014012.

Annoxae Tost Procedures

Corerate Masonry Unis annex

Cconerate and Gala Sa Aer

cae orck ne

‘Segnoral Retaining nes

‘Wall Unis S

‘conerteIntrocking Paving Unis soex

Coverta Gre Paving Aone

tunes a

concrete Ret Pav: Amex

oe ne

Dyecast aricultng Annes

‘Concrte Block "7

Determning Pato Treknoss Annex

Requramert for m8

Comoressinn Tasting

Weoekehoat ane Test port for Apper:

‘Coreete Masoney Unis a

[Nore I—The testing laboratory performing these test methods shou!

be evaluated in accordance with Practice C1083

1.5 ‘The values stated in inch-pound units are to be regardec

as the standard, except in Annex Ad, where either SI units

inch-pound units are to be regarded separately as standard. Th:

values given in parentheses throughout are mathematic

conversions to SI units that are provided for information onl:

‘and are not considered standard.

1.6 This standard does not purport 10 address ail of ti

safety concems, if any, associated with tis use. It is th

responsibility of the user of this standard to establish appro

priate safety and health practices and determine the applica

bility of regulatory limitations prior to use.

2. Referenced Documents

2

ASTM Standards:?

(C55 Specification for Concrete Building Brick

3 Specification for Calcium Silicate Brick (Sand-Lim

Brick)

> or referoced ASTM stands, vst the ASTM website, warastm.og

conta ASTM Customer Service at sorvise asc. For Annual Book of AST

Standards volume infcrmaon few he standards Document Sommary page

the ASTM website

A Summary of Changes section appears atthe end ofthis standard,

conyctt © AST Hrs 10 Ba Hor Dive, PO Bex C70, Meet Concho, PA 1826252, Ute Ses

fly c140- 12

C90 Specification for Loadbearing Conerete Masonry Units

C129 Specification for Nonloadbearing Conerete Masonry

Units

Ci43/C143M Test Method for Slurp of Hydraulic-Cement

Concrete

C936/C936M Specification for Solid Concrete Interlocking

Paving Units

©1093 Practice for Accreditation of Testing Agencies for

Masonry

21232 Terminology of Masonry

C1319 Specification for Concrete Grid Paving Units

1372 Specification for Dry-Cast Segmental Retaini

Wall Units

491 Specification for Concrete Roof Pavers

2 Practice for Capping Conerete Masonry Units, Re-

jated Units and Masonry Prisms for Compression Testing

C1634 Specification for Concrete Facing Brick

55684 Specification for Materials and Manufacture of Ar-

culating Concrete Block (ACB) Revetment Systems

Practices for Force Verification of Testing Machines

‘Terminology Relating to Methods of Mechanical Testing

| Terminology

1 Terminology defined in Terminologies C1232 and E6

‘all apply for these test methods.

« Significance and Use

+1 These test methods provide general testing requirements

f application to a broad range of concrete products. Those

fesral testing requirements are included in the body of this

edad.

2—Consult manufacturer, supplier, product specifications, or

fb resources for more specific measurement or testing guidelines for

‘Es products not adcressed withthe annex ofthis standard

+2 These test methods provide specific testing requirements

| vo distinct sections, the requirements applicable to all units

fered by these test methods and those applicable to the

fevtie unit types. The requirements applicable to all units are

‘lade im the body of these test methods and those applicable

specific unit types are included within the annexes.

Sampling

Selection of Test Specimens:

1 For purposes of testing, full-sized units shall be

-d by the purchaser or authorized representative. The

'd_specimens shall be of similar configuration and

=xsions. Specimens shall be representative of the whole lot

' from which they are selected.

The term “lot” refers to any number of concrete

‘Ssonry units of any configuration or dimension manufactured

Se producer using the same materials, concrete mix design,

uectacturing process, and curing method.

Number of Specimens:

Unless specified otherwise in the applicable annex, a

units shall consist of six full-size units,

Unless specified otherwise in the applicable annex, for

compressive strength, absorption, unit weight (density),

( soisture content determinations, one set of units shall be

9

selected from each lot of 10 000 units or fraction thereof and

two sets of units from each lot of more than 10.000 and less

than 100 000 units. For lots of more than 100 000 units, one set

Of units shall be selected from each 50 000 units or fraction

thereof contained in the lot. Additional specimens shall be

taken if directed by the purchaser.

5.3 Remove loose material from the specimens (including

the cores) prior to determining the received weight.

Nore 3—An abrasive stone o wire brush is typically used vo remove

loose materia

54 Identification—Mark each specimen so that it may be

identified at any time. Markings shall cover not more than 5 %

of the surface area of the specimen.

5.5 Received Weight—Weigh each specimen immediately

after sampling and marking, and record as W, (received

‘weight). Record time and place W, was measured.

Nove 4—Received weights often have direct relationships with other

uni ropenies and are therefore a useful method of evaluating results or

for sorting purposes. The weight of a conree masonry unit and elated

unt changes with ime and exposure conditions, ratily asa test of

the moisture within the unit Therefore, to understand the context of a

received weight vale itis als immporare to understand the point in ime

and the fame of reference when that weight was detemnine. Time and

lace” should not refer when and where the unit was sampled but when

nd where the recived weights were determined. In atin to date and

time references, itis albo import to know if thse weighs were

determined after units reached equilibrium with lab environments oe

before units were shipped, or ater delivery tothe job ste, and so for

6. Measurement of Dimensions

6.1 Apparatus

6.1.1 Measurement Devices—Devices used to measure

specimen dimensions shall have divisions aot greater than 0.1

in. (25 mm) when the dimension is to be reported to the

nearest 0.1 in, (2.5 mm) and not greater than 0.01 in. (0.25 mm)

‘when the dimension is to be reported to the nearest 0,01 in.

(0.25 mm),

6.1.2 Measuting devices shall be readable and accurate to

the division required to be reported, Accuracy shall be verified

at least once annually. Verification record shall include date of

verification, person or agency performing verification, identi-

fication of reference standard used, test points used during

Verification, and readings attest points.

62 Specimens—Three full-size units shall be selected for

‘measurement of dimensions.

63 Measurements—Measure specimens in accordance with

the applicable annex of this standard, For those products not

covered by the annexes of this standard, measure overall

‘dimensions (width, height, length) in at least two locations on

‘opposite sides ofthe specimen to the nearest division required

to be reported, Document location of each measurement on a

sketch or photograph of the specimen,

Nore $—Specimens wsed for measurement of dimensions may be sed

in other tests,

Nore 6—Calipers, micrometsrs, sn sto! scales and dividers of the

spproprate accuracy and readability have been shown tobe adequate for

these messuremans

7. Compressive Strength

7.1 Test Apparatus:

Aly 140-12

7.lel The testing machine shall have an accuracy of 1.0 %

over the anticipated load range. The upper platen shall be a

spherically seated, hardened metal block firmly attached atthe

center of the upper head of the machine. The center of the

sphere shal ie a the center of the surface held in its spherical

seat but shall be free to turn in any direction, and its perimeter

shall have at least Y in. (6.3 mm) clearance from the head to

accommodate specimens whose bearing surfaces are not par-

allel. The diameter of the upper platen (determined in accor-

dance with Annex A8) shall be at least 6 in. (150 mm). A

hardened metal bearing plate may be used beneath the speci-

‘men to minimize wear of the lower platen of the machine.

7.1.2. When the bearing area of the upper platen or lower

platen is not sufficient to cover the area of the specimen, @

single steel plate with a thickness equal to at least the distance

from the edge of the platen to the most distant comer of the

specimen shall be placed between the platen and the capped

specimen. ‘The length and width of the steel plate shall be at

jeast ¥ in, (6 mm) greater than the length and width of the

units.

7.13 The surfaces ofthe platen o plate intended for contact

with the specimen shall have a hardness not less than HRC 60)

(BHN 620). The surfaces of the platen and plate shall not

Gepar. from plane surfaces by more than 0.001 in, (0.03 mm)

in any 6 in. (150 mm) dimension

Nore 7—Reserch has shown that thickness of Bearing plates has

significant eect on the tested compressive strength of masonry units

‘when the bearing aes the platen st sucen to cover the area of the

Specinen, Plate bending esl a nonanform stress dstribaons that an

inoence the faire mechanisms ofthe wsted specimens, The magnitude

Of this fect is controlled by the stiffness of the plate, the size ofthe

Specimen tested, and the sengih of the specimen. Tested compresive

Seagits will typically ineesse with increased plate thickness and with

reduced distance 0 the fares corer of the Specimen. Some testing

Inhoratoes have iitaions that mit the practicality of eliminating

Tending ently. Therefore the plate thickness requirements in

{intended to provide an adequate Level of accuracy in the compression test

resus so a 10 conform to the his of pratcalty of the testing

Inbortory

Nore §—Annex AS includes guidance on determining the required

lat thickness based on the configuration ofthe test specimen and the test

machine

7.14 The testing machine shall be verified in accordance

with Practices Es! ata frequency defined by Practice C1093,

1.2 Test Specimens

72.1 Unless specified otherwise in the applicable annex,

test three specimens in compression.

7.2.2 When possible and unless specified otherwise in the

applicable annex, specimens shall be full-sized units. When the

Units cannot be feted full-size due to specimen configuration

or testing machine requirements, reduce the specimen size in

accordance with Annex Al.

7.2.3 after delivery 10 the laboratory, store compression

specimens (unstacked and separated by not less than 0.5 in. (13

mm) on all sides) continuously in air ata temperature of 75

15°F (24 = 8°C) and a relative humidity of less than 80 % for

rot less than 48 h. Alternatively, if compression results are

Tequited sooner, store units unstacked inthe same environment

Geseribed above with a current of air from an clectric fan

ing over them for a period of not less than 4 h. Continue

Pare

passing air over the specimens until two successive weigt

at intervals of 2 h show an increment of loss not greater

02 % of the previously determined weight of the specimes

until no moisture or dampness is visible on any surface 0

unit. Specimens shall not be subjected to oven-drying.

[Nore 9—In this test method, net area (other than certain solid ni

191) 8 determined from specimens othe than those subjected 0 cor

sion testing The compressive strength method is based on te assun

that units wsed for determining net volume (absorption specimens’

the same net volume as units used for compression testing. Sample

face units. which have iregor surfaces, should be divided a th

they are sample from the lt, such thatthe absorption test specimen

‘2 net volume tha is visually representative and a weight ¢

representative ofthe compression tet specimens,

7.2.4 Where saw-cutting of test specimens is allow:

required by the standard or applicable annex, sawing shi

performed in an accurate, competent manner, subjectin

specimen to as little saw vibration as possible. Use 2 dia

saw blade of proper hardness. Ifthe specimen is wetted ¢

sawing, allow the specimen to dry to equilibrium with lz

tory air conditions before testing, using the procedures ou

in 7.23

7.2.5: If compression test specimens have been saw-cut

full-sized units and the net area of the compressio:

specimens can not be determined by 4.1, saw-cut an

tional three units to the dimensions and configuration

three compression test specimens, The average net area f

‘saw-cut compression specimens shall be taken as the a

net area of the additional three saw-cut units calcula

required in 9.4. Caleulated net volumes of saw-cut spec

shall not be used in calculating equivalent thickness

7.3. Capping—Cap test specimens in accordance with

tice C1552,

14 Compression Testing Procedure:

7A.1 Position of Specimens—Test specimens with th

roid of their bearing surfaces aligned vertically with the

of thrust of the spherically seatéd steel bearing block

testing machine (Note 10). Except for special units intenc

use with their cores in a horizontal direction, test all J

‘concrete masonry units with their cores in a vertical dir

‘Test masonry units that are 100 % solid and special

units intended for use with their hollow cores in a hor

direction in the same direction as in service. Prior to

‘each unit, ensure that the upper platen moves freely Wi

spherical seat to attain uniform seating during testing.

[Nore 10--For those masonry units that are symmetical about

the location of that axis can be determined geometrically by divi

Report

[627.1 Test reports shall include all of the information in

feos 102, 10.3, and the following:

40-12,

A6.7.2 The flexural load to the nearest I Ib (5 N) required to

fail a specimen separately and as the average for the sot of three

units tested.

AG.7.3 Ballast weight to the nearest 1 psf (5 kg/m?) sepa-

rately for each specimen and as the average for the set of three

specimens tested.

FIG. A6.1 Compressive Strength Test Setup for Conereto

oot Pavers

verre noe EE — mney

roma rn

FIG. A6.2 Flexural Strength Test Setup for Concrete Roo! Pavers

A7. TEST PROCEDURES FOR DRY CAST ARTICULATING CONCRETE BLOCK

£ Scope

~ 1.1 This annex includes testing requirements for dry cast

clating concrete block that are manufactured for comy

‘vith the following unit specification: D684,

2 Measurement of Dimensions

72.1 Measure each unit and record the width (W) across

and bottom bearing surfaces at mid-length, height (#2)

length of each face, and length (L) at mid-height of each

9 the nearest division required to be reported.

109

AT3 Compressive Strength Testing

AT3.1 Test Specimens —Specimens shall be a saw-cut cou-

pon with an aspect ratio (height divided by its least lateral

dimension, Ivi) of 2.0 + 0.1 before capping and length to

thickness ratio (V#) of 4.0 * 0.1. The coupon width shall in no

‘case be less than 1.5 in, (37 mm). Coupon dimensions shall not,

differ by more than ¥% in, (3 mm) from the targeted dimension.

‘Coupons shall be 100 % solid and not contain cable holes or

other voids. The compressive strength of the coupon shall be

Ay c140-12

considered 10 be the compressive strength of the whole unit.

Saw-cutting shall be performed in accordance with 7.2.4 and

725,

Nore A7.1—The compressive strength of coupons sa-cut from articu-

lating conerete blocks can be measurably inluenced by the unit conigu-

‘ation and location of the sample, Duo tothe variety of unit configurations

available, it is not possible 10 specify exact locations for obsining

‘coupons. In order to compare results within a set or between indepen

‘denily performed tests, coupons should be consistently obtained from the

same location for a given unit coniguration. Supplies should be con-

sulted for the recommended coupon sample Toeation for a given unit

configuration.

A732 Testing—Cap and test specimens in accordance with

7.3 and 7.4,

ATA Absorption Testing

ATA. Test Specimens—Specimens shall be in accordance

with 8.2

A7.4.2 Testing—Pesform absorption tests in accordance

with 8.3.

ATS Caleulations

ATS.1 Calculate absorption, density, net area, and net are

compressive strength in accordance with Section 9.

A76 Report

A7.6.1 Test reports shall include all of the information i

Sections 10 and 10.3.

AS. DETERMINING PLATE THICKNESS REQUIREMENTS FOR COMPRESSION TESTING

AB.1 Scope

8.1.1 This annex provides additional information to assist

in determining the plate thickness requirements for compres-

sion testing as written in 7.1

A82 Terminology

A821 Fig. A8.1 shows the location of the referenced test

equipment as used in the compression testing of units,

A83 Determining the Diameter of the Upper Platen

‘A83.1_ As shown in Fig, A8.2, the diameter of the upper

platen is considered in this test method t0 be equal £0 the

maximum horizontal dimension measured scross the circle

created by the sphetical portion of the upper platen (this,

measured diameter may differ from the actual geometric

diameter of the sphere based on its curvature). If the upper

platen includes a nonspherical section that was manufactured

integrally with the spherical head from a single piece of stel,

the diameter of the upper platen is considered to be the

diameter ofthe spherical seat on the upper surface of the upper

platen plus the thickness of the monspherical section (tp,).

However, the diameter of the upper platen shall not be greater

than the minimum horizontal dimension of the upper platen.

no

A84 Distance from the Edge of Platen to Furthermost

Corner of Test Specimen (See Fig. A8.3)

A8.4.1 Determine the distance from the edge of the platen (

the furthermast comer of the specimen as follows:

A8.4.2 Locate the specimen’s center of mass, and mark it o

top of the specimen,

‘A8.4.3 Determine to the nearest '4 in, (3 mm) the distanc

from the center of mass of the specimen to the furthermo,

corner or edge of the test specimen. Record this distance as

A844 The distance from the platen to the furthermo

comer of the test specimen is obtained by the followin

equation:

as.

where:

d= distance from the platen tothe furthermost comer 0

the test specimen, in, (mm),

A = distance from the center of mass of the specimen

the furthermost comer of the test specimen, in

(mm), and

Dy, = calculated diameter of the upper platen, in. (mm).

Aly c140-12

‘SPHERICAL HEAD

UPPER PLATEN

|+—— UPPER BEARING PLATE

— LOWER BEARING PLATE

7A

“———— Lower PLATEN

FIG. A8.1 Equipment Used for Compression Testing

IF THIS PIECE IS INTEGRAL

i Soe

Dp, = Dss + ten,

woh ase,

peare

A

Ba

ee

TT

‘measured diameter of spherical seat,

calculated diameter of upper platen,

‘measured minimum width of upper platen, and

‘measured thickness of nonspherical section of upper platen.

FIG. A8.2 Dlameter of the Upper Platen

SPECIMEN LENGTH

d

eT

i

F

SPECIMEN WIDTH

FIG. A8.3 Distance from Platen to Furthermost Corner of Test Specimen

un

at

se posn 9q 0} are Suto} 959411, "960 wonPoYtoads tna souByd

Pasay Sutoq suowttoods — woo stay euusarep o1 suum Aiwosew! srarueD jeuONUAAUOD

dads aip or Aidde Aayi se spoypau a1 oy Jo siueW oj oFBUIOsUl 1s0) SuALodax pue Fuypuodax us osn 30} podo

bar ayy ssauppe o1 pur sasodind sayy ys 0} swu0y asaq —-faxap aam sajdues asauy, wo} u0ds1 1891 8 puv aysY0M

‘out so 2sn eur sporjou 85) 2s019 J0 S196f]“K[uo SoULjapIMS —_KAOFBIOgE] jduuS w SI ONS sHP UE PepAPUT TTX

SLIND RINOSVWN ALTADNOD AOA IAS LSTL ANY LATHSMAOM “1X

(wonemuoyur <0yepumaI0N)

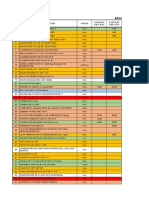

ASTM C 140 Worksheet

My crao-12

‘Sampling ana Testing Concrete Masonry Unite

Lab Pro, No~ 08-100

(ate Received: 6/1/2008

Chen Big Block Port Testing Agency: ‘Accurat Testing Laboratory

Astros: 111 Block Drv

Anytown, USA 12345, Adatess: 123 Main Steet

‘Anytown, USA, 12545,

‘ob No Description: Standard Run Sampling Pary: Bia Block Plant

Unt Designation Description Overall Nominal Dimensions: within) 8.00

xa 16 nn Heghton) 8.00

ConereteRlasonry Unit Lengts tin} 16.00

Compression Units

(Outermine he owing norton ach eee uns se ea conpresson)

a 2 *®

Recelved Waight (WR) mde 3122 om. ate 22008

Mox Compressive Load x) 12079 119960 114690. Date: 61872008

Absorption Units

‘Geamine he fooningfematon or be oe tee us tobe inmasedin ater ses ang)

4s *

Wien (7) @ Top 72 77

@ Bottom 73 785753 in

Hot (8) @ Face | TH 781 76 in

@ Foca? T2761 7e7 in

Length (L) @ Face 1 1962 18511582 in. Measurements

@Face2 155015821553 ae: 1172008

Facosnall Thekness (FST)

@Fnce 1 1201384 in

Face? satin

Web Thickness WT)

@Web 1 10 2k in

@veb 2 1 01m ik

@vieb 3 om 1 ein

@wens in

Received Weigh Wa) 207 3128 go Date 61172008

Imvmersed Weg (i) 1885 622s

Saturated Wei (W.) 327 27 RST Date 22008

Final Oven-Dry Weigh (Ws) 308 2033 ats Date, 61572008

Intermediate Drying Weigmts (st rdading after a least 24 hours dying, successWe readings at2 hr intervals)

ist3022 29432023 Time 1130am

nd 30.18 2933 20.18 te Time 200 pm

310 bb Time

FIG. X1.1 Example CMU Workshoot

13,

ily c140-12

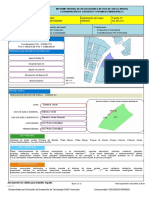

asta e 1 Test Raper ot, coca

Fepatate: 8102008

coe eg seccrine ‘etry agency ‘curt Testing Laborstany

aes: ‘oc Ove Dates {22a Set

‘vena USA 1366 ‘ron, USA, 12345,

space asmconas sanping Pty: ple Pnt

mtcesteabegtin te sanplesRecebed) e098

Suna of Test Rese

nerone

spectes “Test

esc 0ety Noues esas sales

Net Conese Sena sshd 0 pq) Hn Fceset Tes)

(css Conese Srongh = Om pean Web Tse)

‘ensty “ 1119 pet eet eb Tames

espn 125 gf Egnaent Toes

Pernt Sa faa % av varsom epee Omaneone

nec Une Test Rests

Crom secon coneesave

ecened aa oe ‘Seen

capresson Speen Wee Geico ines

wae Won shor ero koa

Size iat mores)

ae Testet moss Nat oles) Seat

eae Sis Hoat ent Tauro ono 180

+ unt rae teins ete avrage cet tre teomten ne sae sere tee ae thse es sed compression

[a ee He

asco ‘Specimen Vian Hegh Length ‘

‘ae en & s

es ee 1

7s a7 156 1a 12

Weems te Test 8

nese une porto opts ae seks er floes es 025i, or Menem re IE

Reeves arsed Satucied O1enry net Percent

specmen WR WL, ile, LNs) ABS Deny vole ald

sane a ea air wast 307

© m ona 2 2 mes Bs 20s: So

esa ‘em ee es; ee 02606 489

a a a a re

Sar

abeaoyy nea

FIG. X1.2 Example CMU Test Report

aa

Ap c140-12

SUMMARY OF CHANGES

‘Committee C15 has identified the location of selected changes to this standard since the last issue (C140 — 11a)

that may impact the use of this standard. (Approved Feb. 1, 2012.)

| The determination of equivalent web thickness was ments for balance of pavers were added to Annex Ad.

‘zed to a determination of nonmalized web area. (B) Subsection 7.4.3 was revised and Nove || was added

Salance requirements in 8.1 were revised and new require- regarding specimen load rates.

‘Committee C15 has identified the location of selected changes to this standard since the last issue (C140 — 11)

that may impact the use of this standard. (Approved Aug. 1, 2011.)

ections 10.3 and A4.6 were revised, (@) Added minimum immersion depth for absorption testing in

Added section 8.2.2.1 on minimum specimen size for subsection 8.3.1.

‘ecption testing and a new Note 12,

‘Committee C15 has identified the location of selected changes to this standard since the last issue (C140 ~ 10)

that may impact the use of this standard. (Approved Feb. I, 2011.)

| Changes to reporting requirements were made to Section (3) Revised Note A3.1 and Note A7.1.

aad Annex Al-Annex A7. (@) Revised Annex AS.

| Changes were made to 6.1.2 to clarify language.

ASM itematonal aks 70 postion respecting he validly of any patent ighs assented i canaction wth any em mentioned

inti stancara. Uses of mis stad aro exeessly ached ht dolamination of vali of any such pant rs ade ek

of ngement of such gs, are ently Ma own responsi.

‘This standard i eunjoct o reision at any tne by the response lena committee and must be reviewed every ve yours and

\Yootreisd, eter reapproved ar miarewn. Your conan are ede or revision o tis standart oor acca tas

and shoud De adessed fo ASTM Intemational Hoadquarirs. Your commons wil rcaive caret corsdoraton a2 meeting ee

‘esposibelectnica cme, whch you may atend. yas feel ht your comments have na ees far hearing you shod

‘make your views known othe ASTM Coramiee on Standart the addr sown Dat

‘Thi stance copyrighted by ASTM ltemational, 100 Bar Harber rive, PO Box C700, West Conshabcken, PA 19428-2058,

LUntes States. Initial reps (Sgle or mull copies) ofthis standard may bo oblaned by contacting ASTM a he eb0%e

adirss or at 610-832-2505 (phone), s10A%28555 (le), or senicedasin.og (emai): or trough the ASTM websts

Gmc. Pemision apis © sroospy re sacid may ako be sacied fom th ASTM nebo nano

us

You might also like

- LT200HP 140610 EsDocument73 pagesLT200HP 140610 Esfaviojjgl71% (7)

- C 174 .C 174M Test Method For Measuring Length of Drilled Concrete CoresDocument2 pagesC 174 .C 174M Test Method For Measuring Length of Drilled Concrete Coresjjaavenido100% (1)

- Experimento III - Destilação FracionadaDocument11 pagesExperimento III - Destilação FracionadaMurilo MaioliNo ratings yet

- Informes de Practicas Segundo Semestre de Laboratorio UmngDocument19 pagesInformes de Practicas Segundo Semestre de Laboratorio UmngAlex Garcia RiosNo ratings yet

- Special and Different: The Autistic Traveler: Judgment, Redemption, & VictoryFrom EverandSpecial and Different: The Autistic Traveler: Judgment, Redemption, & VictoryNo ratings yet

- Extreme Rhyming Poetry: Over 400 Inspirational Poems of Wit, Wisdom, and Humor (Five Books in One)From EverandExtreme Rhyming Poetry: Over 400 Inspirational Poems of Wit, Wisdom, and Humor (Five Books in One)No ratings yet

- Strangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindFrom EverandStrangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindNo ratings yet

- What Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoFrom EverandWhat Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoNo ratings yet

- If I Were Born Here Volume II (Greece, India, Kenya, Mexico, Israel)From EverandIf I Were Born Here Volume II (Greece, India, Kenya, Mexico, Israel)No ratings yet

- Standard Test Method For Measuring Length of Concrete Cores (C 1542.c1542m)Document2 pagesStandard Test Method For Measuring Length of Concrete Cores (C 1542.c1542m)jjaavenidoNo ratings yet

- Manual For Modulus of Rupture Flexural Test (4-Pt Bending) of 6x6 InchDocument5 pagesManual For Modulus of Rupture Flexural Test (4-Pt Bending) of 6x6 InchjjaavenidoNo ratings yet

- Making and Curing Concrete BeamsDocument5 pagesMaking and Curing Concrete BeamsjjaavenidoNo ratings yet

- Humboldt Relative Density ApparatusDocument8 pagesHumboldt Relative Density ApparatusjjaavenidoNo ratings yet

- Rapid Determination of Percent Compaction: Standard Test Method ForDocument8 pagesRapid Determination of Percent Compaction: Standard Test Method ForjjaavenidoNo ratings yet

- Work Sheet For Soil TestingDocument5 pagesWork Sheet For Soil TestingjjaavenidoNo ratings yet

- 3 Sieve AnalysisDocument54 pages3 Sieve AnalysisjjaavenidoNo ratings yet

- Masonry Joint Reinforcement: Standard Specification ForDocument6 pagesMasonry Joint Reinforcement: Standard Specification ForbvsubramanyamNo ratings yet

- 06 - The BIW of The New BMW 5 Series Gran TurismoDocument25 pages06 - The BIW of The New BMW 5 Series Gran TurismoSilverio AcuñaNo ratings yet

- Troubleshooting Vacuum SystemsDocument6 pagesTroubleshooting Vacuum SystemsAlex100% (2)

- Req CompletoDocument20 pagesReq CompletoDwg Chinguel CorreaNo ratings yet

- Danfoss - Mcontro&marve Danfoss Refrig 2012Document139 pagesDanfoss - Mcontro&marve Danfoss Refrig 2012Carlos D LicetNo ratings yet

- AMTEC Threaded Inserts PDFDocument36 pagesAMTEC Threaded Inserts PDFdlstoneNo ratings yet

- Equipos de LaboratorioDocument6 pagesEquipos de LaboratorioFany CmNo ratings yet

- BPS Arp - Ss-01aDocument9 pagesBPS Arp - Ss-01asparkCENo ratings yet

- Conductividadtermica PDFDocument1 pageConductividadtermica PDFEsther PacaNo ratings yet

- Welding Defect - ISO6520Document3 pagesWelding Defect - ISO6520manojballaNo ratings yet

- Sloution 5.2 FrictionDocument2 pagesSloution 5.2 FrictionShyamala Manjunath33% (3)

- Siemens EsterbrochureDocument6 pagesSiemens EsterbrochurePradeep NairNo ratings yet

- ProjectDocument37 pagesProjectHarsha vardhanNo ratings yet

- Irrur 3Document10 pagesIrrur 3Sebastián CedeñoNo ratings yet

- Stresses Around Underground OpeningsDocument116 pagesStresses Around Underground OpeningsBhaskar ReddyNo ratings yet

- ABY Lead Foot PedalDocument1 pageABY Lead Foot Pedaljpineda_907436No ratings yet

- Flair 279 User ManualDocument18 pagesFlair 279 User ManualRazvan MaresNo ratings yet

- Exposicion OsmosisDocument12 pagesExposicion OsmosisGvrNo ratings yet

- Sika Greenstreak Waterstops Brochure EngDocument20 pagesSika Greenstreak Waterstops Brochure EngGustavo Polo Luque100% (1)

- Investigacion Previa CromatografiaDocument13 pagesInvestigacion Previa Cromatografiajulio vazquezNo ratings yet

- Astm D3722Document1 pageAstm D3722deivisbtsNo ratings yet

- Carta de Presentación TodosDocument17 pagesCarta de Presentación TodosMauro JimenezNo ratings yet

- Four À Induction ÉlectrothermiqueDocument3 pagesFour À Induction ÉlectrothermiqueAyoub LaouinateNo ratings yet

- Tipos de Controle - FortecDocument7 pagesTipos de Controle - FortecRenato De Azevedo FroesNo ratings yet

- Materiales Compuestos en BarcosDocument82 pagesMateriales Compuestos en Barcosyeehaw123100% (1)

- Tubo TechDocument33 pagesTubo Techricardo_prado6342No ratings yet

- DigiTRON eDocument60 pagesDigiTRON eRich FurtNo ratings yet