Professional Documents

Culture Documents

Name: Gunardi Sihombing No - ID: 024 Date: 2016-08-04: Working of Steam and Water Boiler System

Uploaded by

Gunardi Hombing880 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

GUNARDI SIHOMBING

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesName: Gunardi Sihombing No - ID: 024 Date: 2016-08-04: Working of Steam and Water Boiler System

Uploaded by

Gunardi Hombing88Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Name : GUNARDI SIHOMBING

No.ID : 024

Date : 2016-08-04

Working of steam and water boiler system :

For the first,we are start of “ Feedwater then forwarded to economizer,then to drum. For

drum steam and water separator with steam flow temperature 540 derajat celcius,with pressure

16,7 Mpa , go to HP Turbine and entry to reheater. From reheater entered into low medium

pressure Turbine,with temperature 300-350 derajat celcius, with about 8-12 Mpa. From IP steam

directly flow to LP turbine,the last stage of LP cylinder have very low pressure,therefore we

have vacuum pump to building vacuum in condenser.

As we know,the function of condenser is to condensate steam become water ( make up

water ). Outlet of condenser have hotwell tank to collect water it necessary requirement to

increase head pressure of extrac,Pump and prevent cavitation of extrac pump. From extraction

pump discharge the water flow to the LP heaters.

So,from LP to Deaerator,which function to removed Oksigen,Nitrogen and another

substance from the water. From deaerator the water flow to storage tank, with Note: Deaerator

also necessary use to building positive suction of Feed Water Pump. Outlet of storage tank flow

to the suction of Boiler Feed Pump by used booster pump to increase head pressure of Feed

water pump. From,Boiler feed pump the water discharge to HP heater have 3 stage and than go

to economizer or Boiler to reheat water to produce reheat steam.

QUESTION :

1. Deaerator feedwater is to prevent…..?

2. Dissolved oxygen can be removed from the boiler water by…..?

3. Foaming in the boiler water is a result of…..?

4. Incomplete combustion due to insufficient air yields an excess amount of……?

You might also like

- High Pressure BoilerDocument10 pagesHigh Pressure Boilershpaly67% (6)

- MArine Boiler Steam and WaterDocument3 pagesMArine Boiler Steam and Watermohammed ramzi CHAHBINo ratings yet

- HRSGDocument24 pagesHRSGsathishsggsNo ratings yet

- PPS Steam Boiler Operation and AuxiliariesDocument9 pagesPPS Steam Boiler Operation and AuxiliariesAraNo ratings yet

- Steam Boiler Operation and AuxiliariesDocument9 pagesSteam Boiler Operation and Auxiliariesshin deiruNo ratings yet

- What Is Lamont Boiler?Document3 pagesWhat Is Lamont Boiler?Muhammad Fahmi HidayatullohNo ratings yet

- Steam Jet RefrigerationDocument3 pagesSteam Jet RefrigerationParag ParekhNo ratings yet

- Boiler:: Heat Exported by Outlet Steam Heat Supplied by The FuelDocument13 pagesBoiler:: Heat Exported by Outlet Steam Heat Supplied by The FuelBrijesh SrivastavNo ratings yet

- EED Ater Eaters: Prepared by Arjun Thakur, Referred From Wikipedia & P.K NagDocument17 pagesEED Ater Eaters: Prepared by Arjun Thakur, Referred From Wikipedia & P.K NagVinod MahajanNo ratings yet

- High Pressure BoilersDocument15 pagesHigh Pressure BoilersChaitanya MsrkNo ratings yet

- High Pressure BoilerDocument10 pagesHigh Pressure BoilerSudarshan PawarNo ratings yet

- Boiler Exp 2Document9 pagesBoiler Exp 2Naimul Hoque Shuvo100% (1)

- Thermal Power Plant: 17 Mechanical by Engr. Anas Ahmed Department of Mechanical EngineeringDocument16 pagesThermal Power Plant: 17 Mechanical by Engr. Anas Ahmed Department of Mechanical EngineeringTarvesh KumarNo ratings yet

- Schmidt Hartmann Boiler 1Document24 pagesSchmidt Hartmann Boiler 1Varun KarriNo ratings yet

- Basics of Thermal Power PlantDocument119 pagesBasics of Thermal Power Plantsiva7448163No ratings yet

- Thermal Power StationDocument13 pagesThermal Power StationUdayNo ratings yet

- Power Generation Notes PDFDocument44 pagesPower Generation Notes PDFGunjan VijayVargiyaNo ratings yet

- All Boilers 2 PDFDocument7 pagesAll Boilers 2 PDF222Gaurav AherNo ratings yet

- High Pressure BoilerDocument58 pagesHigh Pressure BoilerPATIL YASH SANJAYNo ratings yet

- Lecture 5Document18 pagesLecture 5Saleem KhanNo ratings yet

- A.D.Patel Institute of Technology: Power Plant Engineering (2171910)Document10 pagesA.D.Patel Institute of Technology: Power Plant Engineering (2171910)Raj JoshiNo ratings yet

- Power Plant OperationDocument6 pagesPower Plant OperationSidhant BhayanaNo ratings yet

- 30 MW Power Generation ProcessDocument11 pages30 MW Power Generation ProcessMohan PNo ratings yet

- AES Thermal Power Plant, Lalpir, District Muzaffargarh: Prepared byDocument25 pagesAES Thermal Power Plant, Lalpir, District Muzaffargarh: Prepared byIrfan UllahNo ratings yet

- Thermal PlantDocument4 pagesThermal PlantHanan Tariq QasuriaNo ratings yet

- Fresh Water GeneratorDocument22 pagesFresh Water GeneratorCungkringNo ratings yet

- Boiler AccessoriesDocument16 pagesBoiler AccessoriesdumpyNo ratings yet

- Boiler and Turbine For BOE ExamDocument71 pagesBoiler and Turbine For BOE Examkeerthi dayarathnaNo ratings yet

- BKLT DeaeratorDocument24 pagesBKLT Deaeratormalikgaurav01No ratings yet

- Feed Water HeaterDocument19 pagesFeed Water HeaterMarzouk Abdel Wahed Marzouk100% (1)

- Iare Epgs LNDocument53 pagesIare Epgs LNPrema MahadikNo ratings yet

- GE2152 BCM Power Plant Engineering Notes 2Document13 pagesGE2152 BCM Power Plant Engineering Notes 2Alagar SamyNo ratings yet

- 5 HRSG 11 12Document7 pages5 HRSG 11 12M Moarraf Naeem100% (1)

- Boiler Design and Operation PDFDocument8 pagesBoiler Design and Operation PDFChungNguyenNo ratings yet

- Training Report - Docx SarasDocument48 pagesTraining Report - Docx SarasIpshita RanjanaNo ratings yet

- JPCL Internship Report Farhan Hussain JamaliDocument11 pagesJPCL Internship Report Farhan Hussain JamaliFarhan Hussain100% (1)

- Steam Power Plant For 60 Bar SystemDocument3 pagesSteam Power Plant For 60 Bar SystemGnana Subramanian ArumugamNo ratings yet

- Steam Jet Refrigeration System SeminarDocument16 pagesSteam Jet Refrigeration System SeminarAmit Prakash100% (2)

- Ppe 2m - OptDocument15 pagesPpe 2m - OptAnonymous gAVMpR0aNo ratings yet

- Mech NotesDocument8 pagesMech NotesNihal AhamedNo ratings yet

- 6 Boiler Feedwater PumpsDocument20 pages6 Boiler Feedwater PumpsCristhian Garcia VillarroelNo ratings yet

- BoilersDocument5 pagesBoilersNisarg ModiNo ratings yet

- Power Plant Systems Operation: Steam Turbine Operation Overview and Water and Steam Cycle (Part 2)Document28 pagesPower Plant Systems Operation: Steam Turbine Operation Overview and Water and Steam Cycle (Part 2)نهاد نهادNo ratings yet

- HRSG1 (终版)Document120 pagesHRSG1 (终版)Atif KhanNo ratings yet

- How Does A Thermal Power Plant Work - Learn Engineering PDFDocument9 pagesHow Does A Thermal Power Plant Work - Learn Engineering PDFferayiNo ratings yet

- Us DixitDocument10 pagesUs Dixitmusu MukeshNo ratings yet

- Types of Feed Water Heaters (With Operation) - Rankine Cycle - ThermodynamicsDocument7 pagesTypes of Feed Water Heaters (With Operation) - Rankine Cycle - ThermodynamicsSurjit DuttaNo ratings yet

- Expt. # 03 Study of A Steam Turbine Power PlantDocument6 pagesExpt. # 03 Study of A Steam Turbine Power PlantSajeeb SarkerNo ratings yet

- Turbine AuxillariesDocument139 pagesTurbine AuxillariesAwez RanaNo ratings yet

- Philipp Loos GMBHDocument21 pagesPhilipp Loos GMBHfakhirkz37100% (1)

- Power Plant EngineeringDocument16 pagesPower Plant EngineeringAshok PradhanNo ratings yet

- FreshWater Generator On ShipsDocument22 pagesFreshWater Generator On Shipschristian pope100% (1)

- Refrigeration and Air ConditioningDocument9 pagesRefrigeration and Air ConditioningLuis Enrique Cervantes DominguezNo ratings yet

- Power Plant Interview Questions & AnswersDocument33 pagesPower Plant Interview Questions & AnswersSantosh Kumar JaiswalNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

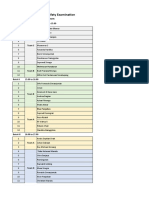

- 20200415-SEPC Safety Examination ArrangementV2Document4 pages20200415-SEPC Safety Examination ArrangementV2Gunardi Hombing88No ratings yet

- 20200415-SEPC Safety Examination ArrangementV2Document4 pages20200415-SEPC Safety Examination ArrangementV2Gunardi Hombing88No ratings yet

- Logsheet CCR Turbin Unit 3Document192 pagesLogsheet CCR Turbin Unit 3Gunardi Hombing88No ratings yet

- Logsheet CCR Turbin Unit 3Document192 pagesLogsheet CCR Turbin Unit 3Gunardi Hombing88No ratings yet