Professional Documents

Culture Documents

ConocoPhilips Addendum To Norsok E-001

ConocoPhilips Addendum To Norsok E-001

Uploaded by

XamiPatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ConocoPhilips Addendum To Norsok E-001

ConocoPhilips Addendum To Norsok E-001

Uploaded by

XamiPatiCopyright:

Available Formats

PPCoN Additional Technical Requirements

Electrical System

ADDITIONAL REQUIREMENTS

TO

NORSOK STANDARD

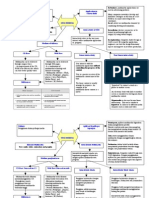

NORSOK Standard Cross Reference List

E-001, Electrical Systems, Rev. 3, Dec. 1997

For information please contact the following:

O. J. Hana – ojhana@ppco.com Tlf.: (+47) 52 02 16 36

G. Gundersen – ggunder@ppco.com Tlf.: (+47) 52 02 14 55

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 1 of 21

PPCoN Additional Technical Requirements

Electrical System

CONTENT PAGE

1 INTRODUCTION ...................................................................................................................................4

1.1 PURPOSE AND SCOPE ..........................................................................................................................4

1.2 RESPONSIBILITY .................................................................................................................................4

1.3 APPROVAL ..........................................................................................................................................4

1.4 DISTRIBUTION/REVISION ....................................................................................................................4

1.5 FILING/RETRIEVING ............................................................................................................................4

1.6 REGISTRATION ....................................................................................................................................4

1.7 HANDLING OF NON-CONFORMANCES .................................................................................................5

1.8 ABBREVIATIONS/DEFINITIONS ............................................................................................................5

1.8.1 Abbreviations.................................................................................................................................5

1.8.2 Definitions ...................................................................................................................................5

1.9 NORMATIVE REFERENCES ..................................................................................................................5

2 TECHNICAL REQUIREMENTS .........................................................................................................6

2.1 GENERAL ............................................................................................................................................6

2.1.1 Climatic conditions........................................................................................................................6

2.1.2 Hazardous atmospheres.................................................................................................................6

2.1.3 Responsibility of area classification ..............................................................................................6

2.1.4 Interface and replacement of existing equipment and systems......................................................6

2.1.5 Use of annexes ...............................................................................................................................7

2.2 E-001 ELECTRICAL SYSTEMS.....................................................................................................7

2.2.1 5.1 System voltages and frequency ................................................................................................7

2.2.2 6.3 Uninterruptible power supply (UPS) system ...........................................................................7

2.2.3 5.4 Earthing ..................................................................................................................................7

2.2.4 5.5 Lighting system ........................................................................................................................8

2.2.5 5.5.2 Lighting equipment ...............................................................................................................8

2.2.6 7.1 High voltage switchboard........................................................................................................8

2.2.7 6.2 Low voltage switchboard.........................................................................................................8

2.2.8 6.5 Motors......................................................................................................................................9

2.2.9 7 RELAYS AND PROTECTION ....................................................................................................9

2.2.10 Other requirements......................................................................................................................10

2.3 OTHER REQUIREMENTS.............................................................................................................11

2.3.1 Junction boxes .............................................................................................................................11

2.3.2 Equipment to be taken permanently out of service ......................................................................11

2.3.3 Preventive maintenace (PM) requirements .................................................................................11

2.4 CABLE TRANSITS, TYPICAL DETAILS ................................................................................................12

2.4.1 Typical welding instruction of Roxtec frames..............................................................................13

2.4.2 Flanged steel frames, insulation level A-0...................................................................................14

2.4.3 Steel frames, insulation class A-0................................................................................................15

2.4.4 Steel frames, insulation class A-60 deck......................................................................................17

2.4.5 Steel frames, insulation class A-60 bulkhead ..............................................................................18

2.4.6 Steel frames, insulation class A-60 bulkhead ..............................................................................19

2.4.7 Steel frames, insulation class H-60 and H-120, bulkhead...........................................................20

2.4.8 Penetration for a single cable, insulation class A-0 – A-60, deck and bulkhead ........................21

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 2 of 21

PPCoN Additional Technical Requirements

Electrical System

ANNEXES:

Annex 5:2:2:A: Uninterruptible power supply system

Annex 5:2:9:A: Operating circuit for ESD system battery isolating breaker(s)

Annex 5:2:9:B: Power supply to ESD system - drilling and platform

Annex 5:3:1:A: Trace heating installation details

Annex 5:3:5:A: Glanding & earthing details

Annex 5:3:5:B: Earthing & bonding

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 3 of 21

PPCoN Additional Technical Requirements

Electrical System

1 INTRODUCTION

1.1 Purpose and Scope

These additional technical requirements are developed by Phillips Petroleum Company

Norway E&P. These additional technical requirements cover requirements additional to

the NORSOK Standards as listed under Normative References.

1.2 Responsibility

The Section Leader for Electrical & Automation systems is responsible for this document

and for ensuring that it is updated or revoked when required by organizational or

operational conditions.

1.3 Approval

The document shall be approved by the Director, Technical Support Department.

1.4 Distribution/revision

This document is distributed in accordance with the distribution list. Those persons

specified on the distribution list are responsible for inserting revised pages when received

and for removing obsolete. In addition they are responsible for informing Information

Logistics, lost manuals, changes in address and for returning the manual when no longer

required. This document is also available on NORSOK homepage:

http://www.nts.no/norsok/implementation

1.5 Filing/retrieving

The record copy (RC) is filed be the Competence Area for Information Logistics.

1.6 Registration

This document as well as the directives are registered with an individual document number

in the company's document administration system (FYI) which is managed by the

Competence Area for Information Logistics.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 4 of 21

PPCoN Additional Technical Requirements

Electrical System

1.7 Handling of non-conformances

Deviations shall be handled in accordance with guideline CP-217, "Reporting and Handling

of Non-Conformance and Deviation Permit". All approved/rejected deviations shall be sent

to the Technical Document Center for registering and filing.

1.8 Abbreviations/definitions

1.8.1 Abbreviations

CCR Central Control Room

ESD Emergency Shut Down

LER Local Equipment Room

UPS Uninterruptible Power Supply

YESD Yellow Emergency Shut Down (NAS 1)

NAS "Nødavstengning"

1.8.2 Definitions

1.9 Normative References

NORSOK Standards:

E-001 Electrical Systems

E-002 Adjustable Speed ac Motor Drives

H-001 Heating, Ventilation & Air Conditioning (HVAC)

Z-010 Installation of Electrical, Instrument & Telecommunication

Z-015 Temporary Equipment

PPCoN References:

CP 217 Guidelines for the Control of Non-Conformance

3826 Area Classification.

4672 Heating, Ventilation & Air-Conditioning (HVAC)

4676 Field Instrumentation

4675 Safety Shutdown Systems

2169 PPCoN Engineering Numbering System (PENS)

3599 “Arbeid på elektrisk utstyr”

3093 Notification of ESD Design & Modification (CP 501)

4584 Electrical, Instrumentation & Telecommunication Installation

4085 Pre-Commissioning, Commissioning and Handover Manual

4086 Mechanical Completion Manual

3801 Notification of Electrical Installation

Other References:

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 5 of 21

PPCoN Additional Technical Requirements

Electrical System

2 TECHNICAL REQUIREMENTS

2.1 General

2.1.1 Climatic conditions

The installation shall operate satisfactory under the following environmental conditions:

Maximum sea temperature: : + 18oC

Minimum sea temperature: : + 2oC

Maximum air temperature: : + 25oC

Minimum air temperature: : - 10oC

Maximum indoor temperature: : + 35oC

Maximum relative humidity : : 100% (condensing in field)

Minimum relative humidity : : 28%

Atmosphere: : Saltine and corrosive

Wind velocity: : 25m/sec gusting to 45m/sec

for more detail information see

Structural Design of Modules (currently

being prepared, contact discipline)

2.1.2 Hazardous atmospheres

All equipment to be in operation during situation of hazard and accident, except where

located in CCR, LER, in emergency switch room, emergency generator room, battery

charger and UPS room or living quarters, shall as a minimum be suitable for zone 1 area,

gas group IIA, temperature class T3 hazardous atmosphere.

Note: Battery room installation shall be approved for gas group IIC.

2.1.3 Responsibility of area classification

When determining area classifications all proposals should be made to the E&P Safety

Engineering Section before approval from electrical responsible person.

See Engineering Directives 3826 Area Classification.

2.1.4 Interface and replacement of existing equipment and systems

Interface to- or replacement of existing equipment and/or systems should comply with the

philosophy used on the platform involved. Anyhow a case by case evaluation shall be

done to evaluate use of NORSOK or old specifications. An evaluation shall be done in

close co-operation with responsible discipline and shall be approved by responsible

discipline.

Reference between drawings (existing platform drawings and new drawings) is mandatory.

This is applicable for all drawings, also standard vendor package drawings. These

requirements also apply between different types of drawings, ie. electrical, mechanical and

instrument. If vendors standard drawings contain different symbols or signs than those

used on PPCo facilities, a legend explaining symbols shall be used.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 6 of 21

PPCoN Additional Technical Requirements

Electrical System

2.1.5 Use of annexes

The content of all annexes in this additional technical requirement are PPCoN

interpretation of roles and regulations and shall as such be considered normative. The

drawings in the annexes give more detailed information than NORSOK and include

valuable installation and design information. Anyhow the layout of the drawings shall be

considered as guidelines only.

2.2 E-001 ELECTRICAL SYSTEMS

The alpha/numeric headings in the following chapter reference the headings in NORSOK

standard E-001.

2.2.1 5.1 System voltages and frequency

Distribution systems on existing platforms are not uniform. Differences are found in

generated voltages and frequency, distribution voltages and system earthing. D.C. system

voltages also vary from platform to platform. Reference shall be made to Company for

details of the system in use on a particular platform.

All electrical equipment shall be specified at the rated voltage and frequency (if applicable)

of the system it is connected to. Equipment that does not have the correct ratings shall not

to be used. Manufacturers + or - variations of the equipment marked ratings cannot be

allowed as a justification for use if the marked ratings do not match the system ratings e.g.

460 volts motors are not to be used on 480 volt systems, 230 volt lighting fittings are not to

be used on 240 volt systems, equipment rated for 50 Hz cannot be used on 60 Hz

systems. Exception to the above may be allowed for US manufactured equipment but only

with regard to voltage variations. The Company shall be contacted for clarification should

this question arise.

2.2.2 6.3 Uninterruptible power supply (UPS) system

See annex 5:2:2:A

2.2.3 5.4 Earthing

See also NORSOK Z-010 Electrical, Instrumentation and Telecommunication Installation.

Additions to existing earthing systems should comply with the philosophy used on the

platform involved. However, the vendors earthing system may be accepted if it can be

documented that this is required for the CE-marking.

Different distribution systems

The requirements for the PE system are applicable irrespective of the type of distribution

system employed i.e. solidly earthed neutral, high resistance earthed neutral, floating

neutral, etc.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 7 of 21

PPCoN Additional Technical Requirements

Electrical System

2.2.4 5.5 Lighting system

Design/earth leakage protection

Normal lighting services shall be designed in accordance with FEA-M § 1621.9 (TN-S),

§ 1623 and each circuit shall be fitted with earth fault protection with a rated sensitivity of

30 mA, see FEA-M § 1653.6. A common alarm signal for earth-fault to be distributed to

central control room (CCR).

Emergency lighting circuits and other important equipment feeded from emergency

distribution boards will only require a common alarm (CCR) for earth leakage. Earth

leakage monitoring of each circuit are preferred. Emergency lightig circuit and other

important equipment shall be equipped with signal contacts who activates both on

manually and automatically operation of the breakers (to off position). A common alarm

signal to be distributed to CCR. Signal contacts can be voided if actual consumers have its

own internal alarm facilities which provide external alarms on lack of power.

Helideck, sea surface, aircraft warning, crane alarm lights

Helideck lighting, sea surface lighting, aircraft warning lights and crane alarm lights shall

be powered from the emergency generator.

2.2.5 5.5.2 Lighting equipment

Floodlights & control gear

Floodlights & control gear shall be mounted in locations where they can be easily

maintained and mounted in groups for a particular area. Flood lighting shall not be

controlled by photo-electric cell or contactor.

Gauge glass, panel lights

Where general illumination is insufficient for the reading of gauge glass, panels etc. then

these shall be provided with dedicated local fixtures classified for the pertinent area.

2.2.6 7.1 High voltage switchboard

Key lockers

A key locker shall be provided in switchgear areas for use in conjunction with lock-out

isolation procedure. For further details see HMS Procedures & PPCoN Procedures Manual

chapter 5.

2.2.7 6.2 Low voltage switchboard

Key lockers

A key locker shall be provided in switchgear areas for use in conjunction with lock-out

isolation procedure. For further details see HMS Manual & PPCoN Procedures Manual

chapter 5.

Motor starters shall have a thorough coordination. The type of coordination used shall be

agreed upon.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 8 of 21

PPCoN Additional Technical Requirements

Electrical System

2.2.8 6.5 Motors

Rating and supply fluctuations

Before an existing motor is being replaced with a motor built to a different standard (E.G.

replacing a US NEMA standard motor with a European CENELEC standard motor) the

actual starting and running loads of the existing machine shall be measured and these

values used when selecting the replacement motor. It is not sufficient to only use the

nameplate ratings on the existing motor since safety factors and operating characteristics

may require a larger replacement motor if built to a different standard. Mechanical,

Process and/or Drilling Departments should also be consulted prior to selecting a

replacement motor. Precautions must be taken with regards to axial thrust and tolerances

if the new motor shall be used on a US NEMA pump without thrust bearings. Flange

adaptors can be manufactured to fit European flanged motors to US NEMA pumps.

If the old motor is damaged, measures should be taken to verify if the old motor was

correctly rated.

Starting torque shall be adequate for each particular application.

2.2.9 7 RELAYS AND PROTECTION

Undervoltage release for "ESD" tripping

Where "ESD" tripping is required, the circuits concerned shall have disconnecting device

who operates/trips circuits controlled by a relay which trips the disconnecting device when

the relay coil is de-energized. i.e. a fail safe system (UVT). The operating voltage of this

relay to be taken from an external source and as stated in the data sheets. The remote

ESD signal shall de-energize the trip relay.

In case of high voltage motor starter circuits who require "ESD" tripping, the contactor

operating coil shall be controlled by an undervoltage release relay. This relay shall isolate

the supply to the motor anti-condensation heater when its coil is de-energized.

NOTE: Shunt trip devices shall not to be used.

ESD system battery Ex isolating breaker

The ESD system batteries shall be isolated after a YESD by tripping the Ex circuit breaker

connected downstream of the batteries. The circuit breaker shall be tripped by de-

energizing its undervoltage release relay. To enable this breaker to be reset, a special

reset circuit is required.

This allows the undervoltage release relay to be energized for some minutes so that the

breaker can be closed and the ESD system reset.

See annex 5:2:9:A

ESD power supply, drilling/platform

See annex 5:2:9:B for arrangement of ESD power supplies for platform ESD systems and

drilling ESD systems.

Air flow, safety device

All duct heaters shall be safety interlocked with the air flow sensor in the ventilation duct to

disconnect heaters on loss of air flow. Motor starter contacts are not acceptable as an

interlock device. Local resetting of the heaters is required due to safety precautions.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 9 of 21

PPCoN Additional Technical Requirements

Electrical System

2.2.10 Other requirements

Ventilation, alarms

Air flow is to be monitored by an air flow sensor and not by an auxiliary contact on the fan

motor starter. An alarm shall be given on ventilation failure & the boost charge feature

shall be inhibited on all chargers feeding batteries within the room.

Batteries

The batteries shall be installed within a battery room or a battery locker.

Starting batteries for fire pumps, emergency generators and other mechanical equipment

shall not be mounted on the unit. They shall be allocated in a clean, dry location with

suitable mechanical protection.

Vendor recommendations for care and maintenance of batteries shall be displayed in a

prominent position in the battery room.

Separation, different types of battery

Nickel-cadmium batteries and lead acid batteries should not normally be located in the

same battery room. However, on upgrading projects where existing battery rooms are

utilized, batteries with different kinds of electrolyte may be placed in the same room

providing the batteries are mounted on separate battery racks. Each rack is to be clearly

marked as to which type of electrolyte it contains and to be spaced so far from each other

that no misunderstanding about the types is possible.

NOTE: The 20 mm or 50 mm air circulation gap between cells of battery banks, as stated

in FEA-M 1451.3 is not required. Use manufacturers recommendations.

Open lead/acid batteries are preferred.

Battery rooms

All walking areas in battery rooms to be covered with non-slip rubber matting.

An emergency eye wash station shall be installed in battery rooms or areas where battery

electrolyte is being handled or mixed, or personnel should have in their possession, small

personal eye wash bottles.

All materials used for battery rooms and lockers shall be corrosion resistant or protected

against corrosion by suitable painting. The battery short circuit protection switchgear

(typically an Ex(de) circuit breaker) shall be installed in the nearest room adjacent to the

battery room, see FEA-M paragraph 1457.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 10 of 21

PPCoN Additional Technical Requirements

Electrical System

2.3 OTHER REQUIREMENTS

2.3.1 Junction boxes

For junction boxes, a space heater is not normally required, but a drain plug should be

fitted to larger junction boxes. When it is considered necessary to fit heaters (JB's with

volume above 50 litre) they shall be certified for the classification of the area involved and

shall not affect the certification of the box.

The selection of metal inside a housing must correspond to the requirements for the

housing. A stainless steel box shall have non-corrosive terminal blocks etc.

Panels containing equipment who generates electromagnetic interference (EMI) or is

vulnerable to EMI should be installed in metal panels who achieves Faraday's cage.

2.3.2 Equipment to be taken permanently out of service

See guideline: 2805 "Utstyr som settes permanent ut av drift".

2.3.3 Preventive maintenace (PM) requirements

Vendor documentation must contain recommended PM-routines.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 11 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4 Cable transits, typical details

NOTES:

1. Transit used with single core AC-cables to have non-magnetic stayplates.

2. All transits to be seal welded both sides. See vendor instructions.

All welding to be shown on structural drawing.

3. Frames including compression plates, bolts and end packing to be stainless

steel. Other materials may be accepted in dry and safe area if EMC protection

isn’t required.

4. Cable number tags are to be fixed to every cable on both sides of every transit or

penetration. They are to be located so that if insulation is used, it does not obscure

the tag.

5. These details indicate the type ROXTEC transit (or equal) to be used.

Other types of transit frame e.g. Hawke and Brattberg can equally be used.

Transits and insert modules must be approved together.

6. Detail ‘A’, ‘B’ and ‘C’ cannot be used in class ‘A’, ‘B’ or ‘H’ fire walls.

7. For definition of fire walls, see N.P.D. regulations explosion and fire protection

etc. issued 07.02.92 and associated guidelines.

8. Fire patings stated for each detail are the maximum rating within that particular

class of fire wall.

9. Company will specify the type/details of the fire protection materials that will be

applied to steel bulkheads, e.g. mineral wool mandolite, pyrocrete, etc.

Company will also specify to which side of the bulkhead the material will be applied.

However the transit frames are always to be located on the non-exposed side of the

bulkhead.

10 Halogenfree insert modules shall be used.

11 To accomplish EMC-protection, EMC-insert modules must be used. Two types of

insert modules are available – double sided water protection and single sided water

protection. The installation must strictly be done acc. to vendors instructions.

12 When EMC-insert modules are used, it is important that tension in the cable is

taken in to consideration before dismantling both sides of the mantle. If not, the

dismantled area might be to long.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 12 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4.1 Typical welding instruction of Roxtec frames.

Note: Specific instructions must be taken from the certificate of the transit.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 13 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4.2 Flanged steel frames, insulation level A-0

Ref. DNV-certificate No.: F-14818 issued 02.05.98.

Insulation / installation drawing: Roxtec dwg. 81060120-004 page 1 and 2.

Hazard side Safe side

Detail A

Non-classified transit

Flanged frames must be continous welded from both sides. Welding must not be

performed inside the transit.

The frames should be fitted to the non hazard side of the bulkhead or deck.

Typical penetration of non-classified bulkhead & deck, see note 6.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 14 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4.3 Steel frames, insulation class A-0

Ref.: DNV-certificate No.: F-14818 issued 02.05.97.

Insulation / installation drawing: Roxtec dwg. 81060120-004 page 1 and 2.

Hazard side Safe side

Detail B

Non-classified transit

Frames must be continous welded on both sides. Welding must not be

performed inside the transit.

The frames should be fitted to the non hazard side of the bulkhead or deck.

Typical penetration of non-classified bulkhead & deck, see note 6.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 15 of 21

PPCoN Additional Technical Requirements

Electrical System

Steel frames, insulation class A-0

Ref.: DNV-certificate No.: F-14818 issued 02.05.97.

Insulation / installation drawing: Roxtec dwg.: 81060120-004 page 1 and 2.

Hazard side Hazard side

Detail C

Flanged frames installed as in detail C must be continous welded from both sides.

Welding must not be performed inside the transit.

If both sides are fire hazard or safe, it can be installed in the middle.

Typical penetration of non-classified bulkhead & deck, see note 6.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 16 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4.4 Steel frames, insulation class A-60 deck

Ref.: DNV-certificate No.: F-14818 issued 02.05.97.

Insulation / installation drawing: Roxtec dwg. 81060120-001 page 1/2.

Safe side

Hazard side

Detail D

Deck and frame of transit to be insulated with type approved A-60 class of insulation on

the exposed side.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 17 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4.5 Steel frames, insulation class A-60 bulkhead

Ref.: DNV-certificate No.: F-14818 issued 02.05.97.

Insulation / installation drawing: Roxtec dwg.: 81060120-008 page 1/1.

Hazard side Safe side

Detail E

Bulkhead and frame of transit to be insulated with type approved A-60 class of insulation

on the exposed side.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 18 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4.6 Steel frames, insulation class A-60 bulkhead

Ref.: DNV-certificate No.: F-14818 issued 02.05.97.

Insulation / installation drawing: Roxtec dwg.: 81060120-001 page 2/2.

Min. 300 mm.

Hazard side Hazard side

Detail F

This frame can be installed acc. to detail ‘A’, ‘B’ and ‘C’ as long as both sides of the bulkhead

are fire hazard sides.

Deck and frame of transit to be insulated on one side with type approved A-60 class insulation.

In addition the same insulation must be applied on the other side at least 300 mm out from the

transit and covering the frame of the transit.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 19 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4.7 Steel frames, insulation class H-60 and H-120, bulkhead

Ref.: DNV-certificate No.: F-14819 issued 02.05.97.

Insulation / installation drawing: Roxtec dwg.: 81060120-006 page 1/1.

Hazard side Safe side

Detail G

Bulkhead and frame of transit to be insulated with type approved H-60 / H-120 class of

insulation on the exposed side.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 20 of 21

PPCoN Additional Technical Requirements

Electrical System

2.4.8 Penetration for a single cable, insulation class A-0 – A-60, deck and bulkhead

Ref. DNV-Certificate No. F-14294 issued 14.06.96.

Insulation / installation drawing: Roxtec dwg.: 81060120-003 page 1 and 2.

81060110-007 page 1 and 2.

Safe side Hazard side

Detail G

Deck to be insulated with approved insulation according to classification covering the steel

egde of the steel sleeve.

Bulkhead to be insulated on fire hazard side with approved insulation according to

classification covering the steel edge of the sleeve.

Transits used with single core AC-cables to have non-magnetic steel sleeves.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 – PAGE 21 of 21

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 1 OF 2

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 2 OF 2

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 1 OF 5

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 2 OF 5

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 3 OF 5

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 4 OF 5

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 5 OF 5

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 1 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 2 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 3 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 4 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 5 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 6 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 7 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 8 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 9 OF 9

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 1 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 2 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 3 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 4 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 5 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 6 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 7 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 8 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 9 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 10 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 11 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 12 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 13 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 14 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 15 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 16 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 17 OF 188

PPCoN Additional Technical Requirements

Electrical System

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

4574 01 01.03.99 Director, Technical Support Dept.

4574 PAGE 18 OF 188

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Honda Odyssey. 2007-10 Factory Service Manual. Volume 1 (PDFDrive) - 2Document1,368 pagesHonda Odyssey. 2007-10 Factory Service Manual. Volume 1 (PDFDrive) - 2Ronel Buenviaje100% (2)

- This Drawing Is The Property of MIKANO International Limited. and Must Not Be Re Issued, Copied or Reproduced Without Their Consent in WritingDocument2 pagesThis Drawing Is The Property of MIKANO International Limited. and Must Not Be Re Issued, Copied or Reproduced Without Their Consent in WritingXamiPati50% (2)

- ConocoPhilips Addendum To Norsok Z-010Document11 pagesConocoPhilips Addendum To Norsok Z-010XamiPatiNo ratings yet

- Isa 5.1 PDFDocument72 pagesIsa 5.1 PDFXamiPatiNo ratings yet

- Tema IDocument158 pagesTema IXamiPatiNo ratings yet

- Logist. Intern. 01 2019 2BDocument4 pagesLogist. Intern. 01 2019 2BXamiPatiNo ratings yet

- MIP19A9-C-3120-15S-102 Rev-0Document1 pageMIP19A9-C-3120-15S-102 Rev-0XamiPatiNo ratings yet

- Using PTW32 Project in Multi-User Mode: InstructionsDocument2 pagesUsing PTW32 Project in Multi-User Mode: InstructionsRicardo LopezNo ratings yet

- Iso7816 3Document15 pagesIso7816 3Tolu CollinsNo ratings yet

- CloudWorx For Revit Release NotesDocument10 pagesCloudWorx For Revit Release NotesPros Cons StatementNo ratings yet

- Feu Institute of Technology Mechanical Engineering DepartmentDocument21 pagesFeu Institute of Technology Mechanical Engineering DepartmentKATHLEEN DEL PILARNo ratings yet

- Catalog Modicon TM5 - High Performuance and Safe IP20 Modular IO System - January 2023Document44 pagesCatalog Modicon TM5 - High Performuance and Safe IP20 Modular IO System - January 2023Hugo ArmeroNo ratings yet

- Compressor For Model: Asy295Bmcbcabr: Engr. Mohamed HammadDocument3 pagesCompressor For Model: Asy295Bmcbcabr: Engr. Mohamed HammadMohamed HamadNo ratings yet

- PCAB List of Licensed Contractors For CFY 2017-2018 As of 12 Jun 2018Document960 pagesPCAB List of Licensed Contractors For CFY 2017-2018 As of 12 Jun 2018Crystal DNo ratings yet

- TrixBox IAXModem HylaFaxDocument9 pagesTrixBox IAXModem HylaFaxDalasterisk LoteroNo ratings yet

- Conceptual Design of Hybrid Scooter PDFDocument16 pagesConceptual Design of Hybrid Scooter PDFAbdelmajid AittalebNo ratings yet

- SAM@OWS Guideline (2023)Document13 pagesSAM@OWS Guideline (2023)rachmatlindu17No ratings yet

- Business InfographicsDocument15 pagesBusiness InfographicsDung Pham NgocNo ratings yet

- Sie Bro ZP d43 PDFDocument4 pagesSie Bro ZP d43 PDFAsterix IDNo ratings yet

- Rehva 2023 - 01Document84 pagesRehva 2023 - 01JurisĶigursNo ratings yet

- M.M Rishad-Unit-01 Programming AssignmentDocument30 pagesM.M Rishad-Unit-01 Programming AssignmentRishad JobbsNo ratings yet

- Enhancing Safety of Navigation by Incorporation of Additional DataDocument116 pagesEnhancing Safety of Navigation by Incorporation of Additional DataKaimul BhuiyanNo ratings yet

- Colombo Twin ManualDocument47 pagesColombo Twin ManualzbhabhaNo ratings yet

- Name-Priyesh Bane Roll No - 01 PGDM Marketing Summary - Netapp and The Challenge of Global LeadershipDocument2 pagesName-Priyesh Bane Roll No - 01 PGDM Marketing Summary - Netapp and The Challenge of Global LeadershipPriyeshNo ratings yet

- Amplitude Modulation and DemodulationDocument3 pagesAmplitude Modulation and DemodulationRaj Mehra MeharNo ratings yet

- Fast Easy Money Autopilot MethodDocument4 pagesFast Easy Money Autopilot MethodZALAAM TRENDSNo ratings yet

- 2010 08 8 Speed Automatic Gearbox PDFDocument22 pages2010 08 8 Speed Automatic Gearbox PDFJOHNNY5377No ratings yet

- Telephoning and Writing 2Document17 pagesTelephoning and Writing 2LY HOANG THU NGAN NGAN.L5vus.edu.vnNo ratings yet

- MH-22 Rebuild (Shooting Bridle) V1.7Document1 pageMH-22 Rebuild (Shooting Bridle) V1.7Jose Antonio AcostaNo ratings yet

- Charpy Test With Genesis HighSpeed Data Acquisition Modules From HBMDocument2 pagesCharpy Test With Genesis HighSpeed Data Acquisition Modules From HBMEnrique de AguileraNo ratings yet

- Multimedia F5 Mind MapDocument2 pagesMultimedia F5 Mind MapHerdiey HaronNo ratings yet

- Risks and Benefits of ERPDocument13 pagesRisks and Benefits of ERPDevanarayanan SajiNo ratings yet

- 4kW 28vdc Electric Motor Specification SheetDocument2 pages4kW 28vdc Electric Motor Specification SheetVinay KashyapNo ratings yet

- Class XI (As Per CBSE Board) : Computer ScienceDocument16 pagesClass XI (As Per CBSE Board) : Computer ScienceJasbir MannNo ratings yet

- Jurnal Riset Sains Manajemen: Volume 3, Nomor 1, 2019Document19 pagesJurnal Riset Sains Manajemen: Volume 3, Nomor 1, 2019Hanny Tri MeilindaNo ratings yet

- Load Calculation 5Document21 pagesLoad Calculation 5Royce PaladaNo ratings yet