Professional Documents

Culture Documents

Check List Material Takoff 1

Uploaded by

vipul gandhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List Material Takoff 1

Uploaded by

vipul gandhiCopyright:

Available Formats

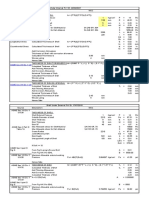

Sr Check Item Done

1 Team for MTO has read and working as per guidelines provided Guide Piping Material Take-off.

2 P&ID master set for MTO is Maintained, marked up with assumptions/ comments and

Highlighted when MTO done.

3 Notes in the P&Ids including legends are fully read and accounted for in the MTO as applicable.

4 Pipe routing CAD/hand sketches for pipe sizes 2 and above with CS/SS materials and All pipe

sizes for exotic materials are prepared and used for manual bulk MTO.MTO for below 2? pipe size with

CS/SS material is considered either by preparing sketches or by experience.

5 Ensure the following are taken care while preparing MTO file- Area 1 column is filled based on

project requirement (e.g. WHP, LQ, etc.).- Area 2 column is filled with respective equipment

Tag/Name/Piping system as applicable(e.g. separator, desander, bath heater, drain system, flare system,

etc.).- Area 3 column is filled with module Name/ Number if and when modularization is planned(e.g.

North module, South Module, etc.) or deck name if platform contains many deck levels.

6 Ensure that MTO is not considered for items in P&IDs which are shown within battery limit.

(vendor scope/scope by others/future equipments).

7 Ensure that during material take-off, no margins (spares) are considered in the quantities and

Margins are added after summary level based on the total quantity.

8 100 % Contingency is considered in Stud bolt & Gasket MTO.(To be discussed with project

manager)

9 HOLD on the MTO items due to P&ID holds, Equipment/Packages, Instrumentation, Routing

finalization, control valves, PSVs, etc. shall be identified.

10 MTO for all SS/DSS/Exotic materials and higher sizes for other materials (10 and above) shall be

reviewed by concerned Area Engineer/Lead engineer.

etc. are considered.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PHE1Document3 pagesPHE1vipul gandhiNo ratings yet

- Date: 14.10.22: Revised OnDocument1 pageDate: 14.10.22: Revised Onvipul gandhiNo ratings yet

- BOILER AREA Cable Tray BOM - KCL 03.02.2023Document6 pagesBOILER AREA Cable Tray BOM - KCL 03.02.2023vipul gandhiNo ratings yet

- UntitledDocument2 pagesUntitledvipul gandhiNo ratings yet

- FINAL Cable - Schedule - KCL 16.03.2023 R1Document14 pagesFINAL Cable - Schedule - KCL 16.03.2023 R1vipul gandhiNo ratings yet

- ReceiverDocument1 pageReceivervipul gandhiNo ratings yet

- No. of Units 2: No. Description Unit Parameters Per UnitDocument1 pageNo. of Units 2: No. Description Unit Parameters Per Unitvipul gandhiNo ratings yet

- Asme Sec Viii Div 1 Ug-27Document17 pagesAsme Sec Viii Div 1 Ug-27vipul gandhiNo ratings yet

- UntitledDocument2 pagesUntitledvipul gandhiNo ratings yet

- No. of Units 2: No. Description Unit Parameters Per UnitDocument3 pagesNo. of Units 2: No. Description Unit Parameters Per Unitvipul gandhiNo ratings yet

- Sr. No. Description Drg. No. Schedule Date 1 DrawingsDocument4 pagesSr. No. Description Drg. No. Schedule Date 1 Drawingsvipul gandhiNo ratings yet

- PAROC Calculus: Calculation 1: Rectangular TankDocument2 pagesPAROC Calculus: Calculation 1: Rectangular Tankvipul gandhiNo ratings yet

- Volume UGSTDocument9 pagesVolume UGSTvipul gandhiNo ratings yet

- Mto Check List1Document4 pagesMto Check List1vipul gandhi100% (1)

- PAROC Calculus: Calculation 1: Rectangular TankDocument2 pagesPAROC Calculus: Calculation 1: Rectangular Tankvipul gandhiNo ratings yet

- General Notes-MSGL TANKDocument1 pageGeneral Notes-MSGL TANKvipul gandhiNo ratings yet

- General Notes-MS TANKDocument2 pagesGeneral Notes-MS TANKvipul gandhiNo ratings yet

- Attachment 1 Datasheet For Fire Fighting Equipment 180118 Rev 0Document28 pagesAttachment 1 Datasheet For Fire Fighting Equipment 180118 Rev 0vipul gandhiNo ratings yet