Professional Documents

Culture Documents

General Notes-MSGL TANK

General Notes-MSGL TANK

Uploaded by

vipul gandhi0 ratings0% found this document useful (0 votes)

10 views1 pageThis document provides general notes for an MSGL tank, including:

1. Specify units of pressure as kg/cm2 or bar.

2. Provide dimensions in mm unless otherwise specified.

3. Maintain all distances with respect to centerlines/baselines/equipment top lines.

4. All bolt holes must straddle the principal axis of equipment.

5. Nozzles above DN 50 must be reinforced with pads calculated by vendor.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides general notes for an MSGL tank, including:

1. Specify units of pressure as kg/cm2 or bar.

2. Provide dimensions in mm unless otherwise specified.

3. Maintain all distances with respect to centerlines/baselines/equipment top lines.

4. All bolt holes must straddle the principal axis of equipment.

5. Nozzles above DN 50 must be reinforced with pads calculated by vendor.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageGeneral Notes-MSGL TANK

General Notes-MSGL TANK

Uploaded by

vipul gandhiThis document provides general notes for an MSGL tank, including:

1. Specify units of pressure as kg/cm2 or bar.

2. Provide dimensions in mm unless otherwise specified.

3. Maintain all distances with respect to centerlines/baselines/equipment top lines.

4. All bolt holes must straddle the principal axis of equipment.

5. Nozzles above DN 50 must be reinforced with pads calculated by vendor.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

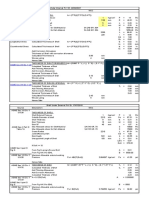

GENERAL NOTES FOR MSGL TANK

1. Please mention unit of pressure as kg/cm2 g or in bar g.

2. All dimension are in mm. unless otherwise specified.

3. All distance to be maintained w.r.t. Center line/ base line/ t.l. of equipment

4. All bolt holes to straddle the principal axis of equipment

5. All nozzles above DN 50 to be reinforced with pads. RF pad thickness to be calculated by

vendor.

6. Nozzle orientation shall be submitted along with the approval of fabrication drawing.

7. Lifting lugs and other fittings to have pad plates of equal thickness and material as base.

8. Hydro test (after lining) as per ASME sce viii div -1 code.

9. Radiography: 100% t joint & 10 % spot for all main seams of inner vessel including nozzle size

dn250 (10”nb) and above or nozzle neck thickness 29mm above.

10. Insulation cleat and insulation ring 6mm thick.

11. Cleats welded on jacket.

12. Leg supports in two piece - 6” sch-80 Smls pipe , moc- sa 106 gr.b & (Bottom Leg Adjustable

Standard Provided).

13. Ladder support cleat.

14. Platform support cleat

15. Lifting lug 4 Nos on top dish side

16. Tailing lug 4 Nos on bottom dish side

17. Earthling boss ( total 4 Nos . 2 Nos on lug support and 2 Nos on bottom leg support)

18. Cleaning - as per vender standard.

19. Zinc plated yellow Passivated “c “clamp & fasteners

20. For painting

Surface: short blasting for cs surface.

Primer: one coat of epilux 610 (Gray), dft 25-35 micron/coat.

Intermediate: one coat of epilux x 155 high build mio coating (grey), dft 110-125

micron/coat.

Final : two coat of eplilux 4 chemical resisting enamel, dft 25-35 micron/coat, shade

:ral5002 ( blue )

21. Provide cap on c-clamp ( Colour -Blue , MOC-Light density poly ethylene )

22. Nozzle bolts - is 1363/1367 cl .4.6/4

23. Manhole c-clamps- ( j housing bolt -sa 307 gr. b ),( nut- sa 563 gr. b )

24. Bottom diaphragm ring on jacket -sa240 tp 304

25. Coupling & plug - sa105 (3000 #).

26. SS tray to be provided on top head to protect insulation from dripping.

27. Welding procedure- as per vender standard.

28. Name plate should be screwed to bracket.

29. All process side nozzle covered with MSGL blind and utility side nozzle covered with wooden

blank.

30. Gasket for manhole cover : PTFE enveloped caf with SS corrugated ring insert

31. All nozzles, baffles shall be provided with PTFE bushes and with PTFE enveloped gasket.

32. All Flanges as per ANSI b 16.5 150# SORF

You might also like

- Telecom Duct BanksDocument16 pagesTelecom Duct Bankssethu1091100% (1)

- A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedDocument8 pagesA E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedMiller Andres Ladino Fernandez100% (1)

- Cable Tray Load Factor and Spec PDFDocument7 pagesCable Tray Load Factor and Spec PDFÖmer EmelNo ratings yet

- For Harsh and Hazardous Locations: Exe EnclosuresDocument79 pagesFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonNo ratings yet

- Specification For Wrapping TapeDocument17 pagesSpecification For Wrapping TapeGalih Prianggodo100% (2)

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Rachem GuideDocument156 pagesRachem GuideeliahudNo ratings yet

- Mto Check List1Document4 pagesMto Check List1vipul gandhi100% (1)

- Technical Specification For 33 KV Aerial Bunched Cable - 2Document7 pagesTechnical Specification For 33 KV Aerial Bunched Cable - 2BijuNo ratings yet

- Pikotek Vcs Tech SpecsDocument2 pagesPikotek Vcs Tech SpecsBaskar KannaiahNo ratings yet

- Hollow Core Planks Application and Design GuideDocument46 pagesHollow Core Planks Application and Design Guidemixi1978100% (1)

- Fiberstrong Piping System Above Ground Installation ManualDocument32 pagesFiberstrong Piping System Above Ground Installation ManualIbrahim Habiba100% (1)

- General Notes-MS TANKDocument2 pagesGeneral Notes-MS TANKvipul gandhiNo ratings yet

- Catalogue Ipsi EpDocument70 pagesCatalogue Ipsi EprachedscribNo ratings yet

- Ficha Tecnica PikotekDocument2 pagesFicha Tecnica Pikoteking_arriagaNo ratings yet

- DB Tech Specs - BDDocument5 pagesDB Tech Specs - BDDarshit VyasNo ratings yet

- Cu 19/33kV: MV Cables With Longitudinal Water-Blocking SystemDocument4 pagesCu 19/33kV: MV Cables With Longitudinal Water-Blocking Systembalwant_negi7520No ratings yet

- Mangas PDFDocument14 pagesMangas PDFluisfer811No ratings yet

- Terminales Termocontractiles PDFDocument18 pagesTerminales Termocontractiles PDFcbeltranochoaNo ratings yet

- Marine-Offshore Cable & Pipe Penetration DossierDocument39 pagesMarine-Offshore Cable & Pipe Penetration DossierHonka VoxNo ratings yet

- MCTDocument8 pagesMCTTimothy LeonardNo ratings yet

- Cable Tray - SpecDocument5 pagesCable Tray - SpecNael SwedanNo ratings yet

- A1200 Red Thread II PipingDocument0 pagesA1200 Red Thread II PipingjimmycabreraNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Gujarat Technological University: Subject Code:2170502 Date:21/11/2016 Subect Name:Process Equipment Design - IIDocument2 pagesGujarat Technological University: Subject Code:2170502 Date:21/11/2016 Subect Name:Process Equipment Design - IIPrabhat SinghNo ratings yet

- Sample Specification From Monoxivent Corrosion Composites: SECTION 15800Document4 pagesSample Specification From Monoxivent Corrosion Composites: SECTION 15800Ahmed NabilNo ratings yet

- Raychem Heat Shrink Terminations HVTDocument18 pagesRaychem Heat Shrink Terminations HVTgerardoNo ratings yet

- Gall5231328512232fip PDFDocument15 pagesGall5231328512232fip PDFAndres CortezNo ratings yet

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pages(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Canusa Wrap Benzi Termocontractibile Izolatii Conducte OtelDocument2 pagesCanusa Wrap Benzi Termocontractibile Izolatii Conducte Oteleugen_alexutzNo ratings yet

- LT Power Cable - Data SheetDocument9 pagesLT Power Cable - Data SheetAnagha DebNo ratings yet

- Heat Shrink Cable Joints & Cable Terminations LV HV, 6.6kV 11kV 33kV SPS CatalogueDocument63 pagesHeat Shrink Cable Joints & Cable Terminations LV HV, 6.6kV 11kV 33kV SPS CatalogueBasman GeorgeNo ratings yet

- SHD GC 2000V PDFDocument1 pageSHD GC 2000V PDFJulio MontalvoNo ratings yet

- Garnituri Flanse SAEDocument85 pagesGarnituri Flanse SAEcudalbgeoNo ratings yet

- DS HLTP 60 Rev12 1107Document2 pagesDS HLTP 60 Rev12 1107Luisito Aguilar RojasNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- 0421 Roofing - CombinedDocument6 pages0421 Roofing - CombinedRiski SuhardinataNo ratings yet

- Sectional Pipe InsulationDocument2 pagesSectional Pipe InsulationjackwpsoNo ratings yet

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Document9 pagesHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilNo ratings yet

- World Standard Performance: Waterproof Jelly FormulationDocument32 pagesWorld Standard Performance: Waterproof Jelly FormulationHOFFERNo ratings yet

- P8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Document4 pagesP8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Shruti SrinivasNo ratings yet

- Specification SmartFenceDocument3 pagesSpecification SmartFenceVimala PonnusamyNo ratings yet

- Igus CDocument4 pagesIgus CJames ValenzuelaNo ratings yet

- Steel Cord - Vulcanized SpliceDocument16 pagesSteel Cord - Vulcanized Splicebogeyman666No ratings yet

- Amphennot Connectors CatalogDocument68 pagesAmphennot Connectors Catalogrr0bertNo ratings yet

- Steam TrapDocument2 pagesSteam TrapAmpornchai PhupolNo ratings yet

- Type 501 453 UniversalDocument1 pageType 501 453 Universalrambala123No ratings yet

- Viking Extended Coverage Quick Respons SidewallDocument6 pagesViking Extended Coverage Quick Respons SidewallguspriyNo ratings yet

- Section 233116Document4 pagesSection 233116Ahmed NabilNo ratings yet

- Energy Cable Accessories Epp1984 EngDocument156 pagesEnergy Cable Accessories Epp1984 EngSathiyanathan ManiNo ratings yet

- Dynaflow Lecture Presentation Gaskets 7-10-2010Document125 pagesDynaflow Lecture Presentation Gaskets 7-10-2010Jan SmitNo ratings yet

- DSI Plastic InsulatorsDocument27 pagesDSI Plastic InsulatorsxzaimNo ratings yet

- Codeline Drawing 80S45 Non CodedDocument2 pagesCodeline Drawing 80S45 Non CodedoctavioNo ratings yet

- QCS 2010 Section 21 Part 9 Cable TraysDocument8 pagesQCS 2010 Section 21 Part 9 Cable Traysbryanpastor106100% (1)

- PPC Catálogo Aislador Soporte ANSIDocument28 pagesPPC Catálogo Aislador Soporte ANSIMateo AlvezNo ratings yet

- A Casa SaddleDocument2 pagesA Casa SaddlesalamrefighNo ratings yet

- Polyken 934 TapeDocument2 pagesPolyken 934 TapeKyaw Kyaw AungNo ratings yet

- Tender SpecificationDocument19 pagesTender SpecificationManoj RanaNo ratings yet

- FINAL Cable - Schedule - KCL 16.03.2023 R1Document14 pagesFINAL Cable - Schedule - KCL 16.03.2023 R1vipul gandhi100% (1)

- BOILER AREA Cable Tray BOM - KCL 03.02.2023Document6 pagesBOILER AREA Cable Tray BOM - KCL 03.02.2023vipul gandhiNo ratings yet

- Date: 14.10.22: Revised OnDocument1 pageDate: 14.10.22: Revised Onvipul gandhiNo ratings yet

- PHE1Document3 pagesPHE1vipul gandhiNo ratings yet

- ReceiverDocument1 pageReceivervipul gandhiNo ratings yet

- UntitledDocument2 pagesUntitledvipul gandhiNo ratings yet

- No. of Units 2: No. Description Unit Parameters Per UnitDocument3 pagesNo. of Units 2: No. Description Unit Parameters Per Unitvipul gandhiNo ratings yet

- Asme Sec Viii Div 1 Ug-27Document17 pagesAsme Sec Viii Div 1 Ug-27vipul gandhiNo ratings yet

- UntitledDocument2 pagesUntitledvipul gandhiNo ratings yet

- Sr. No. Description Drg. No. Schedule Date 1 DrawingsDocument4 pagesSr. No. Description Drg. No. Schedule Date 1 Drawingsvipul gandhiNo ratings yet

- Volume UGSTDocument9 pagesVolume UGSTvipul gandhiNo ratings yet

- No. of Units 2: No. Description Unit Parameters Per UnitDocument1 pageNo. of Units 2: No. Description Unit Parameters Per Unitvipul gandhiNo ratings yet

- PAROC Calculus: Calculation 1: Rectangular TankDocument2 pagesPAROC Calculus: Calculation 1: Rectangular Tankvipul gandhiNo ratings yet

- Attachment 1 Datasheet For Fire Fighting Equipment 180118 Rev 0Document28 pagesAttachment 1 Datasheet For Fire Fighting Equipment 180118 Rev 0vipul gandhiNo ratings yet

- PAROC Calculus: Calculation 1: Rectangular TankDocument2 pagesPAROC Calculus: Calculation 1: Rectangular Tankvipul gandhiNo ratings yet