Professional Documents

Culture Documents

CMVA CAT I Performance Objectives 2019 EN PDF

CMVA CAT I Performance Objectives 2019 EN PDF

Uploaded by

Samir GajeraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CMVA CAT I Performance Objectives 2019 EN PDF

CMVA CAT I Performance Objectives 2019 EN PDF

Uploaded by

Samir GajeraCopyright:

Available Formats

CMVA Certification Program

Category 1 – Data Collection

Performance Objectives

Basis

These performance objectives define what an individual certified at Category 1 should be able to

do, on the job. They are based directly on the ISO standard 18436-2:2014(E) and were prepared

by members of CMVA’s Training and Certification Committee.

Titles are from the ISO standard Annex A Table A.1 and are reprinted by permission. The

full text of the standard is available to CMVA members under licence on www.cmva.com by

clicking on the Members Only tab.

The major (but not exclusive) focus of each category is as shown in the title. Vocabulary is part

of the required knowledge at each category.

The noted percentages are derived roughly from the ISO standard, which indicates the number of

hours during a 30 hour course to spend on each topic.

Examination and Certification

Anyone who has mastered the indicated performance should be able to pass the

associated test.

In general, there will be approximately the same percentage of exam questions on each topic as

the study time suggested in the ISO standard. Each exam consists of 50 multiple choice or

true/false questions, and the exam is different each time it is given.

Exam questions are straightforward. Don’t look for hidden meanings. If you think a question is

tricky or badly worded or unfair, note that fact on the test; it may be taken into consideration in

the marking and the question will certainly be reviewed before the test is given again.

Terms in <angle brackets> are codes for the evaluation of questions after the exams are

written. Ignore them.

Certification at the Category 1 level also requires the completion of a data collection

practicum.

Number of Hours Allowed To Write the Exam

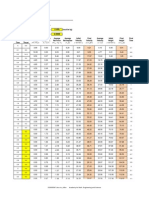

Category 1 2 3 4

# of questions 60 100 100 60

# of hours allowed 2 3 4 5

CMVA Performance Objectives CAT I Version : 2018-12-20 at 9:38 AM Page 1 of 7

1. Principles of Vibration 20% - about 10 questions per exam

Throughout this section, be prepared to use both English (mils, inches per second) and metric

(micrometres [μm], millimeters per second) units, as appropriate.

Definitions, Relationships

Define vibration, periodic vibration, and sine wave.

Define period and frequency. Define “1X”. Define amplitude. Define overall, RMS, peak,

and peak-to-peak readings.

Define time domain, time waveform, spectrum, frequency domain, and orders.

Define displacement, velocity, and acceleration, and relate them to the appropriate units, both

English and metric. Identify the most typical uses for acceleration, velocity, and displacement

readings both in components and frequency range of interest.

Define cycles per minute (CPM), kilocycles per minutes (KCPM), Hertz (Hz), revolutions per

minutes (RPM), inches per second (in/s), millimeters per second (mm/s), centimeters per second

(cm/s), mils, and micrometers.

Define natural frequency, resonance and critical speed in physical terms.

Relate real-world events to conventional patterns

Observe a periodically vibrating item such as a pendulum or spring-mass system, identify its

period and frequency, and indicate its peak velocity, acceleration and displacement.

Draw the vibrating item's displacement waveform, velocity waveform, and acceleration

waveform, and label the curves with the above information.

Draw the vibrating item's spectrum.

Illustrate with reference to the time waveform the use of the true peak (zero to peak) amplitude

convention for obtaining overall vibration velocity and acceleration measurements.

Illustrate with reference to the time waveform the use of the peak to peak amplitude convention

for overall vibration for both seismic (housing) vibration displacement measurements and shaft-

relative displacement measurements.

Illustrate the use of the root mean square (RMS), peak and peak-to-peak amplitude conventions

in vibration spectra (displacement, velocity and acceleration).

Recognize that some instruments take an RMS reading and multiply it by the square root of 2 to

get an estimate of peak reading (often called pseudo-peak), and identify the limitations of this

approach.

Calculations

Convert from Hertz (Hz) to cycles per minute (CPM), and from CPM to Hz, and be able to relate

either of them to revolutions per minute (RPM) if appropriate.

CMVA Performance Objectives CAT I Version : 2018-12-20 at 9:38 AM Page 2 of 7

Convert from in/s to mm/s and back.

Convert from cm/s to mm/s or in/s and back.

Convert from mils to micrometers and back.

For single frequency components, calculate the root mean square (RMS) from the peak reading,

and the peak reading from the RMS reading.

Calculate period from frequency and frequency from period, and read them from graphs.

2. Data Acquisition 25% - about 12 questions per exam

Safety

Pay due care and attention to the safety of yourself and others. Your safety is your responsibility.

Instrument

Take good care of your instrument, paying attention to transducers, cables, batteries, and

recommendations in its User’s Manual.

Recognize and trouble-shoot accelerometer or cable problems by properly using the

instrument's built-in check features.

Check the calibration of your instrument with its sensors periodically, as recommended in its

manual, and whenever you have reason to suspect the quality of data it is generating (such as if

the accelerometer was dropped). If it is not within specs, have it calibrated before collecting

more data.

Sensors

Describe different types of vibration sensors and the parameter(s) they measure

(accelerometer, velocity transducer, eddy probe, displacement).

Be able to identify common vibration sensors (e.g. and relate them to the type of measurement

required.

Identify the physical limitations of different sensors, including frequency response and

temperature limitations.

Determine when sensors need power.

Sensor Mounting; Mounted Natural frequency

Define different sensor mounting techniques and their uses. Consider handheld (probe, stinger),

magnet, adhesive, wax, and stud. Name potential problems associated with different mountings.

Use the correct sensor mounting technique for the frequency range required.

Data Collecting Technique

Presence in the Plant

Make sure the appropriate people know you are collecting data at this time, as defined by plant

policy (e.g. work permit, hot work permit, conversation, etc.)

CMVA Performance Objectives CAT I Version : 2018-12-20 at 9:38 AM Page 3 of 7

Personal Observations

In addition to collecting vibration data with your instrument, make systematic observations of

the machine and its environment using eyes, ears, nose and touch. Record anything that might

be affecting the machine, such as speed, load, temperature, fluid, size of wood chips, position of

louvers, etc. (if and only if these items change from time to time).

Observe and record potential problems. If a potentially serious problem arises (e.g.

unusual loud noise, major oil leak), interrupt data collection and report it.

Collecting Vibration Data

Identify and use the proper sensor orientation for radial (horizontal and vertical) and axial

readings on both vertical and horizontal units.

Acquire valid repeatable data in the correct direction at the correct test point on the correct

machine, using the correct transducer and the correct frequency range, for the appropriate

length of time.

Use a measurement point that provides best possible transmission of the vibration signal

– e.g. solid steel between housing and bearing – and use the identical test point each time. Mark

the points.

Place the accelerometer on the test point carefully, without banging it.

For hand-held readings, hold the probe firmly enough to get the reading to steady out, and keep

holding it the same way until data collection on that test point is complete. Use the same

technique for every reading, and make sure other data collectors at your site also use the same

technique. If different people can take data 2 or 3 times in a row, and get the same result, your

technique is good.

For other mounting types, make sure mounting surface on machine is clean and dry and

appropriate.

Observe reading and compare to previous reading on same test point (if instrument allows) as

data is being collected. If there are serious discrepancies, check further: instrument, cable,

sensor in good shape, test point right, technique right, what else is going on that might cause the

difference? is the unit running? – i.e. try not to go back to the office and then have to wonder

about all these things.

For variable speed machines, sample speed automatically if the route is set up to do this and

the appropriate speed signal (one pulse per revolution) is available, or enter speed manually as

a variable or a note from a local display where appropriate.

Obtain accurate speed using strobe light when appropriate.

Collect data from any permanently mounted transducer (including continuous monitoring

systems), based on the capabilities of the instrument you are using.

Computer Interaction

Take good care of your computer, paying attention to data backup (including off-site), file

management, virus checking, proper storage of disks and CD's, etc.

Load the appropriate route from the computer into the instrument.

Transfer the acquired data into the computer and verify that it is appropriate and

recoverable, before erasing it from the instrument.

Ensure that the database has only good data; delete any data that is shown to be

erroneous.

Ensure that alarms are recorded in the database.

CMVA Performance Objectives CAT I Version : 2018-12-20 at 9:38 AM Page 4 of 7

Data Quality

Be able to suggest bad data due to hand motion, clipped signal, improper frequency range,

insufficient settling time, conflicting information, bad mounting, inappropriate scale, machine

not running, vibration picked up from another machine, or instrument problems (e.g.

accelerometer overload or bounce (looseness).)

.

Evaluate route data and determine that it is most likely valid.

Read a spectrum and determine (on the basis of a comparison of known runspeed and

frequencies apparent in the plot) that this spectrum could not have been taken on "this"

machine.

If data is suspected of being bad, retake the data and review for repeatability. If possible, correct

the cause.

If quality data cannot be collected, record this fact and the reasons, and do not collect data on

that point.

3. Signal Processing 6% about 3 questions per exam

Define FFT.

Calculate “1X” from speed, or determine from spectrum, in CPM and Hertz.

Know the basic concept of an FFT representing the amplitudes and frequencies of the frequency

components of a time waveform.

Identify frequency from a spectrum.

Identify overall versus waveform versus spectrum Identify

vertical and horizontal scales.

4. Condition Monitoring 6% about 3 questions per exam

Recognize basic measurement trends that indicate developing machine faults. Identify

changes in readings and patterns that may indicate faults.

For machines that have exceptions, compare current readings to their history, to related readings

on similar machines, and to records of process variables that may affect vibration, and inform

designated person of the results.

Generate Exception Reports and send to people designated by supervisor, as per schedule.

Typically, these reports would be comprised of a list of machines that exceed alert or alarm

levels, complete with the test points that exceeded limits and the overall values of the readings in

question.

5. Fault Analysis 6% about 4 questions per exam

Know that spectrum analysis is used, in conjunction with other data, to identify common

machinery faults.

Recognize spectrums typical of mass unbalance, misalignment, mechanical looseness, or journal

or rolling element bearing defects.

CMVA Performance Objectives CAT I Version : 2018-12-20 at 9:38 AM Page 5 of 7

6. Corrective Action 6% about 3 questions per exam

Follow all safety and other plant procedures.

Generate a work order (for approval by Category 2 person or supervisor) for further analysis

when exceptions are identified.

Generate a work order (for approval by Cat 2 person or supervisor) (or follow other clearly

defined plant procedures) on identification of any of the following issues:

Safety Issues, e.g.

poor access to test point

potential for tripping the unit

missing or loose guards

possibility of steam burn, etc.

leaks of oil, water, steam, H2S, NH3, etc.

Process, e.g.

needed lubrication

needed replacement of oil or air filters

dirty fan blades

improperly adjusted valves

Machine Mounting Problems, e.g.

loose grout

cracked or damaged machinery base

loose bolts, etc.

broken foundation

Piping Problems, e.g.

broken clamps

cracks in piping

need for adjustment in pipe supports

pipe strain

Needed Investigations, e.g.

checking journal bearing clearances

unusual noises

hot spots

Work orders or similar plant procedures are important, because they ensure that everyone in the

plant knows what is required. Properly executed and finished off, they constitute a machine

history that is essential for efficient teamwork and effective analysis.

Shut-down work orders are especially likely to be written by data collectors, since they are

things to do when the plant is shut down for some other reason. Even lubricating something on

an ad hoc basis is done via work order, since it might mean that the existing lubrication schedule

needs to be altered.

CMVA Performance Objectives CAT I Version : 2018-12-20 at 9:38 AM Page 6 of 7

In many cases, operators have to issue permits for specific work to be done; this practice ensures

that operators know when the data collector is in the plant collecting data. Since they are

specific, you cannot do any other work on the same permit. Even if the plant does not require

formal work permits, it is important to let operators know you are working around the

machinery.

7. Equipment Knowledge 25% about 12 questions per exam

Define and understand basic operating principles of electric motors, generators and drives; fans,

pumps, compressors (not recips); rolling mills, paper machines; machine tools and gearboxes.

Within each machine identify the forces that generate vibration, both normal and abnormal.

Understand the most basic principles of machine structures and piping, and their vibration.

Know that solid steel between the machine casing and bearing provides the best transmission of

the vibration signal, and mark and use that transmission path for data collection.

Identify variations in operating conditions that can affect vibration.

Define unbalance and misalignment.

Recognize how machine RPM is related to the principal frequencies at which vibration due to

unbalance and misalignment show up in the spectrum.

8. Acceptance Testing 6% 3 questions per exam

Be able to carry out a vibration test procedure as defined by others.

Take due care for the specifics of using a formal procedure, following directions exactly, and

recording results accurately and according to the specifications in the procedure, in enough detail

that you can testify about the test and its results at a later date.

Use of this CMVA Copyrighted Material

The material in this document is meant for the free use of members of CMVA.

CMVA Performance Objectives CAT I Version : 2018-12-20 at 9:38 AM Page 7 of 7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Solubility of Salt, Sugar and Baking SodaDocument24 pagesSolubility of Salt, Sugar and Baking SodaPhi Nguyen0% (1)

- 43 Turbomachinery & 30 Pump Users Symposia (Pump & Turbo 2014) September 23-25, 2014 - Houston, TX - Pumpturbo - Tamu.eduDocument12 pages43 Turbomachinery & 30 Pump Users Symposia (Pump & Turbo 2014) September 23-25, 2014 - Houston, TX - Pumpturbo - Tamu.edukglorstadNo ratings yet

- Powder Flow-20230407Document22 pagesPowder Flow-20230407alhyarylyn3No ratings yet

- Fundamental Aspects of VLS Growth PDFDocument11 pagesFundamental Aspects of VLS Growth PDFcbs78No ratings yet

- BARTOLO M1 Chemistry and Materials ScienceDocument14 pagesBARTOLO M1 Chemistry and Materials ScienceHABIB MAHMUDNo ratings yet

- Project: KLA Pile Type: Bored Pile Ref.: Diameter: 0.60 M Pile Properties Calc. Method: Based On N-SPTDocument8 pagesProject: KLA Pile Type: Bored Pile Ref.: Diameter: 0.60 M Pile Properties Calc. Method: Based On N-SPTEndiarto Budi RaharjoNo ratings yet

- Prepared By: Engr. Jude L. RosalesDocument3 pagesPrepared By: Engr. Jude L. RosalesjlNo ratings yet

- 210 Multi Stage EN 150521 PDFDocument12 pages210 Multi Stage EN 150521 PDFMahendra PuguhNo ratings yet

- Global Warming: P.Nandhini Ece - BDocument28 pagesGlobal Warming: P.Nandhini Ece - BMoorthy KesavanNo ratings yet

- Seamless Red Brass Pipe, Standard SizesDocument7 pagesSeamless Red Brass Pipe, Standard SizesAbid HussainNo ratings yet

- Application of X-RaysDocument22 pagesApplication of X-RaysAlex N. Allan100% (1)

- Solutions Homework 13 Physics 486, Fall 2014 University of Illinois at Urbana-ChampaignDocument5 pagesSolutions Homework 13 Physics 486, Fall 2014 University of Illinois at Urbana-ChampaignJason HuaNo ratings yet

- Measurements and Dimensional AnalysisDocument29 pagesMeasurements and Dimensional AnalysisXainNo ratings yet

- CE5601-CE5010-Lecture 1Document34 pagesCE5601-CE5010-Lecture 1OmaidTanhaNo ratings yet

- Simplified Approach For Soil-Spring Stiffness Prediction of Pile GroupDocument12 pagesSimplified Approach For Soil-Spring Stiffness Prediction of Pile Groupabualamal100% (1)

- Natures Numbers by Ian StewartDocument10 pagesNatures Numbers by Ian StewartZaber 025purpleNo ratings yet

- AnalysisDocument2 pagesAnalysisJosef CatiggayNo ratings yet

- Rocket Height Prediction SpreadsheetDocument5 pagesRocket Height Prediction Spreadsheetapi-251710818No ratings yet

- Behavior and Design of Corner Joints Under Opening Bending MomentDocument39 pagesBehavior and Design of Corner Joints Under Opening Bending MomentpaulkohanNo ratings yet

- Momentum Equation.Document8 pagesMomentum Equation.Ayub Ali WehelieNo ratings yet

- L1 Water HammerDocument19 pagesL1 Water HammerOPONo ratings yet

- Newton's Law of InertiaDocument3 pagesNewton's Law of InertiaRickiNo ratings yet

- Problem 130Document6 pagesProblem 130Karl Angelo CuellarNo ratings yet

- HVAC Chilled Water Distribution SchemesDocument56 pagesHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- Investigating Three-Dimensional and Rotational Effects On Wind Turbine Blades by Means of A Quasi-3D Navier-Stokes Solver - ChaviaropoulosDocument7 pagesInvestigating Three-Dimensional and Rotational Effects On Wind Turbine Blades by Means of A Quasi-3D Navier-Stokes Solver - ChaviaropoulosJose Da SilvaNo ratings yet

- Factors For Load Combinations BS 8110Document3 pagesFactors For Load Combinations BS 8110yin hoe ongNo ratings yet

- Is 1734 1-20 1983 PDFDocument78 pagesIs 1734 1-20 1983 PDFison0% (1)

- Abstract of ASTM F912 2000Document5 pagesAbstract of ASTM F912 2000Jesse ChenNo ratings yet

- Selecting The Right Industrial Gear Oil: Lube SelectionDocument3 pagesSelecting The Right Industrial Gear Oil: Lube SelectionPuchit SpkNo ratings yet

- Notio SN Presentation PDFDocument20 pagesNotio SN Presentation PDFA MahmoodNo ratings yet