Professional Documents

Culture Documents

United States Patent (19) : Siegmund 11) 4,175,940

Uploaded by

markokoc0 ratings0% found this document useful (0 votes)

15 views4 pagesOriginal Title

US4175940

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views4 pagesUnited States Patent (19) : Siegmund 11) 4,175,940

Uploaded by

markokocCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

United States Patent (19) 11) 4,175,940

Siegmund 45 Nov. 27, 1979

54 METHOD FOR MAKING FIBER OPTICS 3,554,720 l/1971 Crepet ................................. 65/38 X

FUSED ARRAYS WITH IMPROVED 3,607,197 9/1971 Ballantine .......................... 65/4 B X

4,026,693 5/1977 Sato ................................. 65/DIG. 7

BLEMISH QUALITY

(75 Inventor: Walter P. Siegmund, Woodstock, Primary Examiner-S. Leon Bashore

Conn. Assistant Examiner-F. W. Miga

Attorney, Agent, or Firm-Jeremiah J. Duggan; Alan H.

73) Assignee: American Optical Corporation, Spencer; Stephen A. Schneeberger

Southbridge, Mass.

57 ABSTRACT

(21) Appl. No.: 916,980

Blemish quality of fused fiber optics faceplates, tapers,

22 Filed: Jun. 19, 1978 image inverters and other arrays of multifibers is im

51 Int. C.’...................... CO3C 23/20; CO3C 15/00; proved by protecting outer fibers of the multifibers

CO3B 11/08 from excessive heating and/or contamination during

52 U.S. C. ....................................... 65/4 A; 65/4 B; their fabrication. A preform of a multiplicity of optical

65/4. R; 65/31; 65/38 fibers is covered with a protective layer of removable

58) Field of Search............... 65/DIG. 7, 31, 38, 4 B, material while being fused into a building block. The

65/4A, 3 A, 4 R protective layer is removed from each of the building

56) References Cited blocks and the blocks are subsequently assembled into a

U.S. PATENT DOCUMENTS juxtaposition and fused into a fiber optic array. Multifi

bers so fabricated and used as component building

3,140,528 7/1964 Hildebrand, Jr. et al. ........ 65/4B X blocks for the arrays uniquely minimize traditional

3,331,670 7/1967 "chicken wire" blemishing.

3,350,183 10/1967

3,455,667 7/1969 10 Claims, 10 Drawing Figures

3,505,046 4/1970

U.S. Patent Nov. 27, 1979 4,175,940

4,175,940

1. 2

FIGS. 3, 4, 5 and 6 are cross-sectional views of pre

METHOD FOR MAKNG FBER OPCS FUSED forms of multifibers from which improved component

ARRAYS WITH IMPROVED BLEMISH. QUALITY building blocks of fused fiber optics arrays may be pro

duced according to the invention;

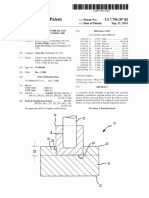

BACKGROUND OF THE INVENTION 5 FIG. 7 is a diagrammatic illustration of an operation

1. Field of the Invention of drawing a multi or multi-multifiber preform;

This invention relates to the manufacture of fused FIG. 8 is a cross-section taken approximately along

fiber optics faceplates, tapers, image inverters and like line 8-8 of FIG. 7;

arrays of fused multifibers with particular reference to FIG. 9 diagrammatically illustrates a treatment af.

method for improving blennish quality. O forded multi or multi-multifiber components prior to

2. Discussion of the Prior Art use thereof; and

In the manufacture of a fused fiber optics array such FIG. 10 is a cross-section of one such component

as a faceplate certain aspects of the process result in taken after practice of the treatment shown in FIG. 9.

blennish defects within the plate. One type of blemish is 15 DESCRIPTION OF THE PREFERRED

commonly referred to as "chicken wire'. It is charac EMBOOMENTS

terized by reduced transmission in those fibers at or near Referring more particularly to the drawings, the fiber

the boundries of the component building blocks known optics arrays, (faceplates 10 and 12) of FIGS. 1 and 2

as multifibers or multi-multifibers. Quite often only the are made up of component multifiber building blocks 14

outer most row of fibers is affected but in severe cases 20 and 16 respectively.

the effect may extend into the next row, rarely deeper. In usual fashion, multifiber blocks 14 or 16 are juxta

Since a major cause of "chicken wire' blennishing is positioned and fused tightly together whether hexago

the increased exposure to heat and contamination of the nal, square or of other shapes not shown, e.g. triangular,

outer rows of fibers in the multi or multi-multifiber diamond, circular or simply rectangular.

drawing process, it is a principle object of this invention 25 Heretofore, the sides of multifiber building blocks

to provide for protection against excessive heating or have been exposed to excessive heating and environ

contamination of such outermost fibers of component mental contamination during fabrication which ad

building blocks for fiber optics arrays during the pro versely affect the light-transmitting properties of their

cess of drawing the building blocks to desired cross outermost fibers.

sectional sizes. With such blemishing extending through one or more

Another object is to afford protection against exces layers of outer fibers, juxtapositioning of the blocks 14

sive surface heating and contamination of multi or mul or 16 doubles the width of the band of poorly conduc

ti-multifiber components in a manner compatible with tive fibers and produces the well known "chicken wire"

usual optical fiber processing and with minimal compli effect. These poorly light-conductive fibers between

cation and/or additional operational expendure. 35 component building blocks of prior art fused fiber op

Other objects and advantages of the invention will tics adversely affect resolution and definition of images

become apparent from the following description. conveyed therethrough.

SUMMARY OF THE INVENTION The reference to "chicken wire' herein is intended to

include all configurations of poorly conductive lines of

The aforesaid and corollary objects are accomplished fibers in fused multifiber arrays. The "chicken wire”

by providing a removable layer of protective material, patterning will conform to the cross-sectional geometry

e.g. leachable glass, around a multi or multi-multifiber of multifiber building blocks used. It may be hexagonal,

preform prior to its drawing to reduced cross sectional triangular, circular, rectangular or of other shapes.

size. In so doing, both excessive surfacing heating and In minimizing, if not eliminating, "chicken wire'

contamination during drawing may be greatly reduced 45 blemishing the present invention protects outer fibers of

to preserve the light-conducting capabilities of outer multi and multi-multifibers against overheating and

most fibers of the resultant multi or multi-multifibers. contamination during their fabrication.

Removal, of the protective layer from the fibers after For Example, multifiber preforms to be drawin into

drawing renders them adaptable to use as component. multifiber component building blocks are each pro

building blocks for fiber optics arrays. The improved 50 vided with an outer protective layer of leachable or

transmission properties at edges of the multi or multi otherwise removable material having a softening tem

multifibers minimizes chicken wire blemishing in fused perature and coefficient of expansion, suitable for heat

assemblies thereof. ing and drawing with the multifibers of the preform. An

It is contemplated that the aforesaid protective layers acid soluble glass or metal may be used and those inter

be applied to the multi or multi-multifiber preform as a 55 ested in details of selecting and using such materials

row of square fibers, series of plates or strips of material, may refer to one or more of U.S. Pats. Nos. 3,004,368;

a frit or a specially formed sleeve or tube. 3,624,816 and 3,669,772.

Details of the invention will become more readily As illustrated in FIG. 3, multifiber preform 14 is

apparent from the following description when taken in layered with a number of juxtaposition relatively small

conjunction with the accompanying drawings. square fibers 18 of leachable material, e.g. a high borax

IN THE DRAWINGS content glass. As an alternative to the use of fibers 18,

the fabrication of layer 26 may comprise plates or strips

FIG. 1 is a fragmentary elevational view of a fused 20 (FIG. 4) of leachable material, a surrounding sleeve

fiber optics array which is exemplary of a type of struc or tube 22 (FIG. 5) or a coating of glass frit 24 (FIG. 6).

ture having particular pertinence to matters of the pres 65 It is to be understood, however, that the aforesaid pro

ent invention. tective layer of fibers 18, strips 20, tube 22 or frit 24 may

FIG. 2 is an illustration similar to FIG. 1 of another be similarly applied to cross-sectionally square, circular,

form of fused fiber optics array; triangular, rectangular or differently shaped multifiber

4,175,940 4.

3

preforms. The fabrication of multi and/or multi-multifi covering the sides of said preform with a layer of

ber structures will not be dealt with herein but those removable material having a melting temperature

interested in such details may refer to one or more of and coefficient of expansion compatible with said

U.S. Pats. Nos. 2,992,516; 3,837,727; 3,196,738; preform;

3, 193,363. 5 heating and drawing said covered preform into a

According to the present invention the selected mul section having a reduced cross-sectional size which

tifiber preform with protective layer 26, e.g. preform corresponds to that desired of said building blocks;

14a of FIGS. 3 or 4-6, is heated zonally with heating separating a length of said drawn section from said

coils 28 or other such means commonly used in the art preform;

and is progressively drawn to the reduced cross-sec 10 removing said layer of covering material from said

tional size (FIG. 7) desired of building blocks 14. separated length of said drawn section;

The drawn multifiber component 30 (FIG. 8) is re dividing said length of said drawn section into a plu

moved from preform 14a and sections 32 of its length rality of relatively short building blocks each of a

are immersed in a leaching medium 34 (FIG. 9) to re length approximately corresponding to the thick

move layer 26 which served to protect their outermost 15 ness desired of said fused array;

fibers against excessive heating and/or contamination tightly juxtapositioning said number of said shorter

during the drawing operation. Sections 32 may be of sections;

lengths corresponding to the thickness desired of face said step of dividing of said length of said drawn

plate 10, for example, or longer and subsequently fin section being performed at a preselected stage be

ished to desired size. 20 tween said step of drawing said preform and said

Following removal of protective layer 26 from sec step of juxtapositioning said shorter building block

tion 32, they are thoroughly cleansed of residues from sections; and

leaching by whatever means may be appropriate includ fusing said tightly juxtapositioned shorter sections

ing the use of ultrasonics. Suitable cleaning procedures together to produce said array.

are disclosed in the aforementioned U.S. Pats. Nos. 25 2. The method according to claim 1 wherein said step

3,004,368 and 3,624,816. of dividing said length of said drawn section is per

If cut to lengths corresponding to the thickness of formed prior to performance of said step of removing

faceplate 10 for example, the leached and cleaned sec said layer of covering material. .

tions 32 (FIG. 10) may be directly utilized as building 3. The method according to claim 1 wherein said step

blocks 14 for faceplate 10. If longer, sections 32 may be 30 of dividing said length of said drawn section is per

cut or ground to finished size. formed subsequent to performance of said step of re

Those interested in details of methods of fabricating moving said layer of covering material.

faceplates and similar fiber optics arrays of multi or 4. The method according to claim 1 wherein said

multi-multifiber building blocks may refer to U.S. Pats. layer of covering material is leachable and said step of

Nos. 3,395,006; 3,626,040; 3,625,669; 4,002,452. 35 removing same is performed by a leaching operation.

From the foregoing, it can be seen that "chicken 5. The method according to claim 1 wherein said

wire' blemishing of fused fiber optics faceplates and layer of removable material on said preform initially

like arrays which heretofore caused reduced light-trans comprises a multiplicity of fibers.

mission of fibers adjacent boundries of the multi and 6. The method according to claim 1 wherein said

multi-multifiber components may be minimized, if not layer of removable material on said preform initially

eliminated. Those skilled in the art, however, will comprises a succession of plates.

readily appreciate that there may be various other forms 7. The method according to claim 1 wherein said

and adaptations of the invention which may be made to layer of removable material on said preform is initially

suit particular requirements and the foregoing illustra in the form of a sleeve.

tions need not be interpreted as restrictive of the inven 45 8. The method according to claim 1 wherein said

tion beyond that necessitated by the following claims. layer of removable material on said preform initially

I. claim: w comprises a glass frit.

1. The method of making a fused fiber optics array 9. The method according to claim 1 wherein said

with improved blemish quality comprising: optical fibers are formed of glass and said layer of re

tightly juxtapositioning a multiplicity of optical fibers 50 movable material is glass.

into the overall cross-sectional configuration de 10. The method according to claim 9 wherein said

sired of component building blocks of said array, layer of removable material is a high borax containing

said juxtapositioned fibers constituting a preform of glass. the

said building blocks;

55

65

You might also like

- Composite Fiberboard with Improved Acoustic PropertiesDocument8 pagesComposite Fiberboard with Improved Acoustic PropertiesGuillermoNo ratings yet

- As Virk 2010Document133 pagesAs Virk 2010virk_70No ratings yet

- Appendix H Defect Detection During Manufacture of Composite Wind Turbine Blade With Embedded Fiber Optic Distributed Strain SensorDocument15 pagesAppendix H Defect Detection During Manufacture of Composite Wind Turbine Blade With Embedded Fiber Optic Distributed Strain SensormusaNo ratings yet

- Wang POWAG Poster July 2004Document3 pagesWang POWAG Poster July 2004Manish TiwariNo ratings yet

- Developments in Glass Yarns and Fabric ConstructionsDocument9 pagesDevelopments in Glass Yarns and Fabric ConstructionsЛеонид ЗоринNo ratings yet

- US5513743Document6 pagesUS5513743AdailsonNo ratings yet

- United States PatentDocument8 pagesUnited States PatentGersonNo ratings yet

- ch5 SolutionDocument11 pagesch5 Solutionfatimah.albadiri.ms9No ratings yet

- United States Patent (19) : Atkinson (45) Aug. 10, 1976Document9 pagesUnited States Patent (19) : Atkinson (45) Aug. 10, 1976zgregzNo ratings yet

- United States Patent (191: Sandell Et AlDocument6 pagesUnited States Patent (191: Sandell Et AlwjzabalaNo ratings yet

- Dual Rings CollectorDocument4 pagesDual Rings CollectormartinqNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- Belum Baca FeltDocument6 pagesBelum Baca FeltMita PutriNo ratings yet

- United States Patent (19) : Aerospatiale, FranceDocument7 pagesUnited States Patent (19) : Aerospatiale, Franceingeniomeca8800No ratings yet

- United States PatentDocument11 pagesUnited States PatentffontanaNo ratings yet

- US4229241Document11 pagesUS4229241mohd iqbalNo ratings yet

- Glass Fiber-Reinforced Plastic Poles For TransmissDocument10 pagesGlass Fiber-Reinforced Plastic Poles For TransmissAlex AraújoNo ratings yet

- United States Patent (19) 11) Patent Number: 5,224,356: Bryant James C. Mulligan, Both of 3. - SE 5ta. IIDocument7 pagesUnited States Patent (19) 11) Patent Number: 5,224,356: Bryant James C. Mulligan, Both of 3. - SE 5ta. IIVansala GanesanNo ratings yet

- Fiber Length Distribution Measurement For Long GlaDocument12 pagesFiber Length Distribution Measurement For Long GlaGabriel AlbornozNo ratings yet

- 2 SIM124 Freeform 3D Printing - Towards A Sustainable Approach To Additive Manufacturing Without Support MaterialsDocument5 pages2 SIM124 Freeform 3D Printing - Towards A Sustainable Approach To Additive Manufacturing Without Support Materialsryangy0919No ratings yet

- High Temperature Superconducting Cable US6794579Document10 pagesHigh Temperature Superconducting Cable US6794579Leon MutambalaNo ratings yet

- Us5098778 PDFDocument7 pagesUs5098778 PDFAl Saraaf MohammedNo ratings yet

- Load-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresFrom EverandLoad-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresNo ratings yet

- Fine-Pitch Capabilities of The Flat Ultra-Thin Chip Packaging (UTCP) TechnologyDocument7 pagesFine-Pitch Capabilities of The Flat Ultra-Thin Chip Packaging (UTCP) TechnologySuresh SkvNo ratings yet

- Constructional Features of Optical Fibre Cable: in This ChapterDocument6 pagesConstructional Features of Optical Fibre Cable: in This ChapterlvsaruNo ratings yet

- Block Copolymer Latex Composition - Asahi Kasei PatentDocument13 pagesBlock Copolymer Latex Composition - Asahi Kasei PatentPothiraj KrishnanNo ratings yet

- 03 TextilesDocument17 pages03 TextilesGayathri NNo ratings yet

- United States Patent (19) : 11 Patent Number: 4,479,990 45 Date of Patent: Oct. 30, 1984Document7 pagesUnited States Patent (19) : 11 Patent Number: 4,479,990 45 Date of Patent: Oct. 30, 1984Vansala GanesanNo ratings yet

- Pultrusion of Composites - An OverviewDocument15 pagesPultrusion of Composites - An OverviewAkhil DayaluNo ratings yet

- United States Patent (191: Kroon Et A1. (11) Patent Number: (45) Date of PatentDocument13 pagesUnited States Patent (191: Kroon Et A1. (11) Patent Number: (45) Date of PatentasdsdaNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2006/0048881 A1Document6 pagesPatent Application Publication (10) Pub. No.: US 2006/0048881 A1FernandoNo ratings yet

- Us 4975922Document5 pagesUs 4975922Umar JuttNo ratings yet

- United States Patent Office: Patented July 9, 1974Document5 pagesUnited States Patent Office: Patented July 9, 1974Patrick MackNo ratings yet

- Fiber Test2 1Document9 pagesFiber Test2 1Mohamed Gamal100% (1)

- Basalt Fiber As A Reinforcement of Polymer CompositesDocument12 pagesBasalt Fiber As A Reinforcement of Polymer CompositesAfsin Ecer.No ratings yet

- Smart Textiles: Wearable NanotechnologyFrom EverandSmart Textiles: Wearable NanotechnologyNazire D. YilmazNo ratings yet

- Ktab Mo3ama9 Fih KolachDocument186 pagesKtab Mo3ama9 Fih KolachMustapha OuldacheNo ratings yet

- USP Solvent Based CADocument6 pagesUSP Solvent Based CAMohammadJavad FotrosNo ratings yet

- Fiber Test2Document2 pagesFiber Test2Mohamed GamalNo ratings yet

- EP0836928A1Document19 pagesEP0836928A1Phu, Le HuuNo ratings yet

- Coir Fiber Reinforced Concrete-ReviewDocument6 pagesCoir Fiber Reinforced Concrete-ReviewIJRASETPublicationsNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiNo ratings yet

- Saudi 33kV XLPE Cable SpecificationDocument12 pagesSaudi 33kV XLPE Cable SpecificationAhmed EzzatNo ratings yet

- Recent Progress in Microstructured Polymer Optical Fibre FabricationDocument11 pagesRecent Progress in Microstructured Polymer Optical Fibre FabricationmanrajkmrNo ratings yet

- Patent for Multimanifold Extrusion Die and Coextrusion Process that Eliminates Curtaining EffectDocument9 pagesPatent for Multimanifold Extrusion Die and Coextrusion Process that Eliminates Curtaining EffectJoe budarNo ratings yet

- Carbon Fiber Manufacture and Surface Treatment: June 1988Document85 pagesCarbon Fiber Manufacture and Surface Treatment: June 1988DILIGENT AM11No ratings yet

- OutDocument150 pagesOutajaykumarNo ratings yet

- US5335644Document7 pagesUS5335644Radek HoffmannNo ratings yet

- DK2032 ch07Document47 pagesDK2032 ch07LukmanCibroNo ratings yet

- Determination of Material Properties For Short Fibre Reinforced C/C-SicDocument14 pagesDetermination of Material Properties For Short Fibre Reinforced C/C-Sicvivek dasNo ratings yet

- Stereoloithography Patent-3D SystemsDocument16 pagesStereoloithography Patent-3D SystemsRaheel AhmedNo ratings yet

- A PM 07 Copper PillarsDocument7 pagesA PM 07 Copper PillarsSieww GlenNo ratings yet

- United States Patent 19: May 7, 1981 (Del Fed. Rep. of Germany. 3118130Document4 pagesUnited States Patent 19: May 7, 1981 (Del Fed. Rep. of Germany. 3118130Vansala GanesanNo ratings yet

- Hybrid Thermoplastic Composite Ballistic Helmet Fabrication StudyDocument11 pagesHybrid Thermoplastic Composite Ballistic Helmet Fabrication Studyt_unamNo ratings yet

- United States Patent (10) Patent No.: Us 7,799,187 B2: Dimilia Et Al. (45) Date of Patent: Sep. 21, 2010Document6 pagesUnited States Patent (10) Patent No.: Us 7,799,187 B2: Dimilia Et Al. (45) Date of Patent: Sep. 21, 2010turnipNo ratings yet

- Modeling and Simulation For A Drop-Impact Analysis of Multi-Layered Printed Circuit BoardsDocument16 pagesModeling and Simulation For A Drop-Impact Analysis of Multi-Layered Printed Circuit BoardsPravinJadhavNo ratings yet

- United States Patent (19) : Argo Et Al. (11) 4,086,070Document16 pagesUnited States Patent (19) : Argo Et Al. (11) 4,086,070esiNo ratings yet

- Introduction To Open-End SpinningDocument25 pagesIntroduction To Open-End SpinningGarmentLearnerNo ratings yet

- Uticaj VakuumaDocument5 pagesUticaj VakuumamarkokocNo ratings yet

- Optical and Photonic Glasses Lecture OverviewDocument17 pagesOptical and Photonic Glasses Lecture OverviewmarkokocNo ratings yet

- Data Sheet Schott PDFDocument76 pagesData Sheet Schott PDFmarkokoc0% (1)

- An Introduction To Fiber Optic Imaging: by SCHOTT North AmericaDocument93 pagesAn Introduction To Fiber Optic Imaging: by SCHOTT North AmericamarkokocNo ratings yet

- Synchronous Servo Motor For Screw Drives (Direct Drive For Threaded Nut)Document20 pagesSynchronous Servo Motor For Screw Drives (Direct Drive For Threaded Nut)markokocNo ratings yet

- SolidworkDocument0 pagesSolidworksharontanasNo ratings yet

- Night Vision Goggles Market PotentialDocument58 pagesNight Vision Goggles Market PotentialmarkokocNo ratings yet

- Night Vision Technology Seminar Report PDF 130805071844 Phpapp01Document31 pagesNight Vision Technology Seminar Report PDF 130805071844 Phpapp01pinkysushuNo ratings yet

- NABARD Dairy Farming Project - PDF - Agriculture - Loans PDFDocument7 pagesNABARD Dairy Farming Project - PDF - Agriculture - Loans PDFshiba prasad panjaNo ratings yet

- Retrenchment StrategiesDocument3 pagesRetrenchment StrategiesSABRI AKBAL MOHAMED HASSAN100% (3)

- Mark Wildon - Representation Theory of The Symmetric Group (Lecture Notes) (2015)Document34 pagesMark Wildon - Representation Theory of The Symmetric Group (Lecture Notes) (2015)Satyam Agrahari0% (1)

- MCQs on PharmacologyDocument101 pagesMCQs on PharmacologyMohammad Rashid88% (8)

- 2 Both Texts, and Then Answer Question 1 On The Question Paper. Text A: Esports in The Olympic Games?Document2 pages2 Both Texts, and Then Answer Question 1 On The Question Paper. Text A: Esports in The Olympic Games?...No ratings yet

- Cyrustek ES51966 (Appa 505)Document25 pagesCyrustek ES51966 (Appa 505)budi0251No ratings yet

- MINTZBERGDocument32 pagesMINTZBERGgeezee10004464100% (2)

- Creating Literacy Instruction For All Students ResourceDocument25 pagesCreating Literacy Instruction For All Students ResourceNicole RickettsNo ratings yet

- Psych 1xx3 Quiz AnswersDocument55 pagesPsych 1xx3 Quiz Answerscutinhawayne100% (4)

- FIL M 216 2nd Yer Panitikan NG PilipinasDocument10 pagesFIL M 216 2nd Yer Panitikan NG PilipinasJunas LopezNo ratings yet

- Technology Class ResumeDocument4 pagesTechnology Class Resumeapi-259588430No ratings yet

- Fellowship in OncotherapeutDocument3 pagesFellowship in OncotherapeutNayan ChaudhariNo ratings yet

- Multibody Simulation of A Freight Bogie With Friction DampersDocument10 pagesMultibody Simulation of A Freight Bogie With Friction DampersGermán GoñiNo ratings yet

- Compare The Political System of Kazakhstan, USA, UK PresentationDocument19 pagesCompare The Political System of Kazakhstan, USA, UK PresentationAiganym OmiraliNo ratings yet

- VIP 32 Hybrid VentDocument8 pagesVIP 32 Hybrid VentsagarNo ratings yet

- Unit Rates and Cost Per ItemDocument213 pagesUnit Rates and Cost Per ItemDesiree Vera GrauelNo ratings yet

- USP FriabilityDocument2 pagesUSP Friabilityshdph100% (1)

- NOV Completion ToolsDocument12 pagesNOV Completion Toolsfffggg777No ratings yet

- Sunera Best Practices For Remediating SoDsDocument7 pagesSunera Best Practices For Remediating SoDssura anil reddyNo ratings yet

- Ap4955 PDFDocument4 pagesAp4955 PDFGilvan HenriqueNo ratings yet

- Reporte Corporativo de Louis Dreyfus Company (LDC)Document21 pagesReporte Corporativo de Louis Dreyfus Company (LDC)OjoPúblico Periodismo de InvestigaciónNo ratings yet

- Dedicated Teacher ResumeDocument2 pagesDedicated Teacher ResumeLei Pitallano ComboyNo ratings yet

- Arduino Programming Step by Step Guide To Mastering Arduino Hardware and SoftwareDocument109 pagesArduino Programming Step by Step Guide To Mastering Arduino Hardware and SoftwareMohan100% (3)

- Finding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Document39 pagesFinding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Jernel Raymundo80% (5)

- SolidWorks2018 PDFDocument1 pageSolidWorks2018 PDFAwan D'almightyNo ratings yet

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixNo ratings yet

- Map Project Rubric 2018Document2 pagesMap Project Rubric 2018api-292774341No ratings yet

- 24.ratios, Rates and Proportions PDFDocument9 pages24.ratios, Rates and Proportions PDFMilsonNo ratings yet

- SMC Dialog Plus Conversion To Another SMC 8 - 22 - 2014Document15 pagesSMC Dialog Plus Conversion To Another SMC 8 - 22 - 2014vivek kumarNo ratings yet

- Batt ChargerDocument2 pagesBatt Chargerdjoko witjaksonoNo ratings yet