Professional Documents

Culture Documents

S-849 - December 2018 Page - 5

Uploaded by

paniyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S-849 - December 2018 Page - 5

Uploaded by

paniyaCopyright:

Available Formats

Spray finishing

4) Those employees who are spray finishing must be provided with, and wear,

appropriate respiratory protection (as determined by air monitoring results) unless

exhaust ventilation is provided and reduces employee exposure to any material in

the finish or reduces its solvent to below the limits established for air contaminants

(see Resources section at the end of this guide).

Combustible materials

1) Do not store, or allow combustible materials to accumulate, in the spraying and

overspray area unless specifically authorized in writing by the local fire authority.

2) The spraying and overspray area should receive daily housekeeping and

maintenance while in use and be kept free of any accumulation between uses.

3) Use only non-sparking tools for cleaning.

4) Combustible material, such as paper, may be used to cover floors and walls in the

spray and overspray area, but must be removed between uses. Check with your fire

department and get written approval if combustible material is to remain in place

after more than one use.

Spray booths

Spray booths are generally premanufactured, although some are actually constructed

on-site by employers. Below are the OSHA requirements on spray booths:

1. Spray booths for construction must meet the following regulations:

a) It must be constructed of substantially supported steel, concrete, or masonry.

b) When used only for intermittent or low volume spraying, other substantial

noncombustible material may be used.

c) It must be designed to sweep air currents toward the ventilation exhaust outlet.

d) Construction materials must have fire resistance rating of at least one hour, or

as otherwise required by the Oregon Building Codes Division.

2. The interior surfaces must be smooth and continuous without edges, and surfaces

must be designed to prevent residue build-up and for easy cleaning and washing.

3. When the floor surface of a spray booth and the working area is combustible, it

must be covered with a noncombustible material designed to prevent residue build-

up and ease cleaning and washing.

4. A spray booth should have:

a) A water washing system to minimize dusts or residues entering exhaust ducts

and to recover overspray, or

b) Distribution or baffle plates to create even flow of air through the booth or

remove overspray before it enters the exhaust duct, or

c) Overspray dry filters to minimize dusts or residues entering exhaust ducts

S-849 | December 2018 Page | 5

You might also like

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- MS1 (Painting)Document5 pagesMS1 (Painting)Zubair Ahmed KhaskheliNo ratings yet

- S-849 - December 2018 Page - 6Document1 pageS-849 - December 2018 Page - 6paniyaNo ratings yet

- TG13 PDFDocument8 pagesTG13 PDFzahid_497No ratings yet

- DM-Envrt TG - 30 Paint Spray BoothsDocument6 pagesDM-Envrt TG - 30 Paint Spray Boothsaspire79No ratings yet

- Dust Control Measures For Construction Projects Rev. November 2009Document2 pagesDust Control Measures For Construction Projects Rev. November 2009Janice Reyes De OcampoNo ratings yet

- Occupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationDocument26 pagesOccupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationipliprensNo ratings yet

- Mos Spuf 450 PolycellDocument4 pagesMos Spuf 450 PolycellHurin AufaNo ratings yet

- DragX Specification 01092019Document6 pagesDragX Specification 01092019Atharva UlangwarNo ratings yet

- DM-PH&SD-P4-TG07 - (Technical Guidelines For Paint Spray Booths)Document6 pagesDM-PH&SD-P4-TG07 - (Technical Guidelines For Paint Spray Booths)zahid_497No ratings yet

- Interline 984: Working ProceduresDocument12 pagesInterline 984: Working Procedurescaod1712No ratings yet

- Dust-Control DenrDocument3 pagesDust-Control DenrJan Christer Dela RosaNo ratings yet

- HPCL - Painting - Procedure ScannedDocument17 pagesHPCL - Painting - Procedure ScannedmanishkapriNo ratings yet

- Procedure PaintingDocument5 pagesProcedure Paintingjakka101No ratings yet

- Air and Noise: Abrasive Blast CleaningDocument5 pagesAir and Noise: Abrasive Blast CleaningBharathNaikPanjaNo ratings yet

- EBVMBDocument5 pagesEBVMBBaugh Graphic DesignNo ratings yet

- 2-ABRASIVE-BLASTING ProcedureDocument4 pages2-ABRASIVE-BLASTING ProcedureFaisal NadoNo ratings yet

- Section 013543 Sustainability and Environmental Construction Procedures - Rev0Document3 pagesSection 013543 Sustainability and Environmental Construction Procedures - Rev0Al LopezNo ratings yet

- Nfca 300 FinalDocument5 pagesNfca 300 Finalbatteekh100% (1)

- Et&t General Structural Remediation GuidelinesDocument5 pagesEt&t General Structural Remediation GuidelineskatilicousNo ratings yet

- BLTN 03Document5 pagesBLTN 03saji84No ratings yet

- NAPCA CoaltarDocument6 pagesNAPCA CoaltarminhnnNo ratings yet

- Painting - Method StatementDocument6 pagesPainting - Method Statementjakka10150% (2)

- GMS PU Flooring2Document12 pagesGMS PU Flooring2Ahmed AssafNo ratings yet

- Lecture 42 Indoor Environmental Quality - IIDocument19 pagesLecture 42 Indoor Environmental Quality - IInikita chawlaNo ratings yet

- Paint ProcedureDocument4 pagesPaint ProcedureAndre Yosi100% (1)

- Surface Preparation and Painting Procedure Rev.01 PDFDocument23 pagesSurface Preparation and Painting Procedure Rev.01 PDFSaid Alauddeen Faisz100% (1)

- 039-Procedure Liquid Penetrant Testing PDFDocument13 pages039-Procedure Liquid Penetrant Testing PDFKöksal Patan100% (3)

- Painting ProcedureDocument10 pagesPainting ProcedureSajid ShaikhNo ratings yet

- Method Statement: Nitoflor FC130Document4 pagesMethod Statement: Nitoflor FC130Karen MiradNo ratings yet

- Painting Specification PDFDocument17 pagesPainting Specification PDFGaurav TripathiNo ratings yet

- Firestone UltraPly TPO Roofing Systems Application Guide Installation Instructions 960823Document20 pagesFirestone UltraPly TPO Roofing Systems Application Guide Installation Instructions 960823داروین پرزNo ratings yet

- Florock Seamless Flooring Systems: Page 1 of 6 Florock Architectural Specification - Floroshop 8/16Document6 pagesFlorock Seamless Flooring Systems: Page 1 of 6 Florock Architectural Specification - Floroshop 8/16shashibagewadiNo ratings yet

- IMS BM-I DP-05 Metal Spray CoatingDocument3 pagesIMS BM-I DP-05 Metal Spray CoatingElangoNo ratings yet

- 1.0 Description: Specifications For Coating Structural SteelDocument11 pages1.0 Description: Specifications For Coating Structural SteelCrni LabudNo ratings yet

- Wrapping MethodDocument5 pagesWrapping Methodnnuek67% (3)

- Method Statement: Nitoflor SL2000Document4 pagesMethod Statement: Nitoflor SL2000Karen MiradNo ratings yet

- Coating Procedure Hydac PL2653 Siemens D Ineos 1Document6 pagesCoating Procedure Hydac PL2653 Siemens D Ineos 1rjgoonerNo ratings yet

- Nullifire Application Instructions SC800 Series 2021-07-19Document3 pagesNullifire Application Instructions SC800 Series 2021-07-19Saed ShaikNo ratings yet

- Ventilation System in Confined SpaceDocument6 pagesVentilation System in Confined Spacecaleb_yangNo ratings yet

- Application Specification Guide: Section 17: Rubber LiningDocument7 pagesApplication Specification Guide: Section 17: Rubber LiningEdgarDavidDiazCamposNo ratings yet

- Prime Coat Material Ton: Section 411: Hot-Poured Crack Sealant Page 163Document2 pagesPrime Coat Material Ton: Section 411: Hot-Poured Crack Sealant Page 163Opata OpataNo ratings yet

- Fluid Applied WaterproofingDocument8 pagesFluid Applied WaterproofingHamza MamiNo ratings yet

- Specification For FRP DuctDocument6 pagesSpecification For FRP DuctAli HassanNo ratings yet

- Anti Termite MosDocument4 pagesAnti Termite Mosmki_dpaNo ratings yet

- Building Standard Office Design Criteria PDFDocument24 pagesBuilding Standard Office Design Criteria PDFIgnacio Jr Ramiento PaguyoNo ratings yet

- Ventilation in Confined SpaceDocument6 pagesVentilation in Confined SpaceTS Wong100% (1)

- ENGI 273 Lec 4Document46 pagesENGI 273 Lec 4Haidy T. SakrNo ratings yet

- Fire Protection DesignDocument32 pagesFire Protection Designcoolth2100% (1)

- Recommended Practices For BlastingDocument9 pagesRecommended Practices For Blastingclarisse1293No ratings yet

- ASTEC ® Re-Ply™ Roof System For Asphalt & Modified Bitumen Roofs©Document5 pagesASTEC ® Re-Ply™ Roof System For Asphalt & Modified Bitumen Roofs©Robert J. BullockNo ratings yet

- DM Code of Construction Safety 195-292 PDFDocument98 pagesDM Code of Construction Safety 195-292 PDFDANo ratings yet

- InternalPainting PDFDocument9 pagesInternalPainting PDFPhilip LonerganNo ratings yet

- A Guidance Note On The Best Practicable Means FOR Iron and Steel WorksDocument7 pagesA Guidance Note On The Best Practicable Means FOR Iron and Steel WorksVinod Kumar VermaNo ratings yet

- 4415 SpecDocument9 pages4415 SpecYopy PrasetyaNo ratings yet

- Methodology Water ProofingDocument4 pagesMethodology Water ProofingTVS GRCNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Handbook of Adhesive Bonded Structural RepairFrom EverandHandbook of Adhesive Bonded Structural RepairRating: 5 out of 5 stars5/5 (1)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Gree Manual p4Document13 pagesGree Manual p4paniyaNo ratings yet

- Rugged 5-In-1 Environmental MeterDocument1 pageRugged 5-In-1 Environmental MeterpaniyaNo ratings yet

- Brass Low Pressure Ball ValvesDocument1 pageBrass Low Pressure Ball ValvespaniyaNo ratings yet

- ZLT s10 Dialog UsermanualDocument2 pagesZLT s10 Dialog Usermanualpaniya100% (1)

- Gree Manual p3Document13 pagesGree Manual p3paniyaNo ratings yet

- Gree Manual p1Document13 pagesGree Manual p1paniyaNo ratings yet

- Removal & Installation: Suspension Tire Pressure Monitoring System - Service Information - HR-VDocument1 pageRemoval & Installation: Suspension Tire Pressure Monitoring System - Service Information - HR-VpaniyaNo ratings yet

- DTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationDocument32 pagesDTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationpaniyaNo ratings yet

- Description: Eps System Description - Eps ControlDocument34 pagesDescription: Eps System Description - Eps ControlpaniyaNo ratings yet

- Gree Manual p5Document13 pagesGree Manual p5paniyaNo ratings yet

- Description: Steering Steering Column - Inspection & Adjustment - HR-VDocument4 pagesDescription: Steering Steering Column - Inspection & Adjustment - HR-VpaniyaNo ratings yet

- Torque Specifications (Ka/Kc Models)Document5 pagesTorque Specifications (Ka/Kc Models)paniyaNo ratings yet

- Removal & Installation: Steering EPS Motor / Control Unit - Service Information - HR-VDocument2 pagesRemoval & Installation: Steering EPS Motor / Control Unit - Service Information - HR-VpaniyaNo ratings yet

- Datenblatt / Data Sheet U51DL-012KK-5Document6 pagesDatenblatt / Data Sheet U51DL-012KK-5paniyaNo ratings yet

- Diaphragm Pump - CompressorDocument2 pagesDiaphragm Pump - CompressorpaniyaNo ratings yet

- Ambu PEEP ValvesDocument2 pagesAmbu PEEP ValvespaniyaNo ratings yet

- Ordering Specifications: Item No. DescriptionDocument1 pageOrdering Specifications: Item No. DescriptionpaniyaNo ratings yet

- Datenblatt / Data Sheet U51DL-012KK-5Document6 pagesDatenblatt / Data Sheet U51DL-012KK-5paniyaNo ratings yet

- S-849 - December 2018 Page - 3Document1 pageS-849 - December 2018 Page - 3paniyaNo ratings yet

- Helix Portable Ventilators: Sustainable First Choice FlexibleDocument3 pagesHelix Portable Ventilators: Sustainable First Choice FlexiblepaniyaNo ratings yet

- Sash Cross SectionDocument2 pagesSash Cross Sectionpaniya100% (1)

- Arici CHP VIIDocument44 pagesArici CHP VIIpaniyaNo ratings yet

- AUS PEEPValves 493480097 V02 0712Document2 pagesAUS PEEPValves 493480097 V02 0712paniyaNo ratings yet

- 02 Lectures OpenFOAM Solver ModificationDocument33 pages02 Lectures OpenFOAM Solver ModificationpaniyaNo ratings yet

- Chem101103 Summerfinalexam SolutionDocument5 pagesChem101103 Summerfinalexam SolutionbrianNo ratings yet

- Chemistry Vocabulary-1Document2 pagesChemistry Vocabulary-1api-535412468No ratings yet

- ASTM Tests For Petroleum and Its ProductsDocument26 pagesASTM Tests For Petroleum and Its ProductsMuhammadTanzeeLUsman100% (3)

- 9005.1202EEII Chapter3 6Document108 pages9005.1202EEII Chapter3 6पाँशुल जम्वाल राजपूतNo ratings yet

- AmeerDocument1 pageAmeerامير الحدادNo ratings yet

- Anup Calculation SheetDocument33 pagesAnup Calculation SheetAziz AndriyantoNo ratings yet

- Recovery Boiler Floor Inspection Experience TAPPI2004Document31 pagesRecovery Boiler Floor Inspection Experience TAPPI2004delta_scopeNo ratings yet

- Instructions: Please Do Not Write Anything On The Questionnaires. The Correct Answer and Write in The Answer Sheet Provided. Multiple ChoicesDocument4 pagesInstructions: Please Do Not Write Anything On The Questionnaires. The Correct Answer and Write in The Answer Sheet Provided. Multiple ChoicesemeraldNo ratings yet

- PrepPaper XI Chem Ch#01 Answer KeyDocument4 pagesPrepPaper XI Chem Ch#01 Answer Keyssat commerceNo ratings yet

- Sampling TechniquesDocument17 pagesSampling TechniquesDebjyoti SanyalNo ratings yet

- The Production of Cumene Using Zeolite Catalyst Aspen Model DocumentationDocument16 pagesThe Production of Cumene Using Zeolite Catalyst Aspen Model Documentationديانا محمدNo ratings yet

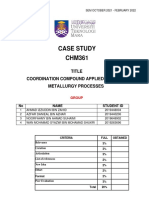

- CHM361 Case StudyDocument8 pagesCHM361 Case StudyFahmy AmyNo ratings yet

- Transport in PlantsDocument14 pagesTransport in PlantsMuhammad Faizan KaleemNo ratings yet

- Your Company Name: COMPRESS Pressure Vessel Design CalculationsDocument4 pagesYour Company Name: COMPRESS Pressure Vessel Design Calculationsdskr fkshNo ratings yet

- FREEMIUM - 11th JEE - Hinglish - Valence Bond Theory - 53Document35 pagesFREEMIUM - 11th JEE - Hinglish - Valence Bond Theory - 53Rathana sabpathyNo ratings yet

- Q3 G11 Physical Science Module 2Document22 pagesQ3 G11 Physical Science Module 2Lebz Ricaram89% (19)

- ExerciseDocument42 pagesExerciseMoneyNo ratings yet

- QZ 13.PDF Desmoldante HutsmanDocument4 pagesQZ 13.PDF Desmoldante HutsmanRomario Kreyder Rojas HuaynalayaNo ratings yet

- Model S30: Metallic Design Level 1Document23 pagesModel S30: Metallic Design Level 1Tho HoangNo ratings yet

- NEMA TCB 2 2017 WatermarkedDocument35 pagesNEMA TCB 2 2017 WatermarkedjovenlouNo ratings yet

- Coatings and Waterproofing: KhalafDocument19 pagesCoatings and Waterproofing: KhalafmohamedNo ratings yet

- All India Test Series: JEE (Advanced) - 2022 Open Test - IDocument29 pagesAll India Test Series: JEE (Advanced) - 2022 Open Test - IHarshit SharmaNo ratings yet

- Gas Exchange in PlantsDocument2 pagesGas Exchange in PlantsWhat do you mean mhNo ratings yet

- G. T. N. ARTS COLLEGE (Autonomous)Document1 pageG. T. N. ARTS COLLEGE (Autonomous)Katrina KatNo ratings yet

- C-K 201 Chemical CompositionDocument1 pageC-K 201 Chemical CompositionManoj KumarNo ratings yet

- Acid Rain - English For Science 1 - Desak Gede Celsy Adnya Margaretta - 2013071023 - 2B Pendidikan IPADocument2 pagesAcid Rain - English For Science 1 - Desak Gede Celsy Adnya Margaretta - 2013071023 - 2B Pendidikan IPADesak Gede Celsy Adnya MargarettaNo ratings yet

- Boltzmann Molecular SpeedDocument51 pagesBoltzmann Molecular SpeedCarolina SilvestreNo ratings yet

- Sample Preparation - Compaction of Asphalt Slabs Suitable For CharacterisationDocument7 pagesSample Preparation - Compaction of Asphalt Slabs Suitable For Characterisationतिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- Important Question ICSE 2010 Class 10th Mole Concept and Stoichiometry ADocument6 pagesImportant Question ICSE 2010 Class 10th Mole Concept and Stoichiometry Aspurohit1991100% (1)

- Safety Hazards: Section IVDocument17 pagesSafety Hazards: Section IVSooraj RajanNo ratings yet