Professional Documents

Culture Documents

Pyrocrete 241: Selection & Specification Data

Uploaded by

santhoshkumarplOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pyrocrete 241: Selection & Specification Data

Uploaded by

santhoshkumarplCopyright:

Available Formats

®

Pyrocrete 241

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

High density cementitious fireproofing designed for the fire protection of exterior and interior

Generic Type

structural steel.

A 55 lb./ft³ (881 kg/m³) density, Portland cement based, cementitious fireproofing. It provides both

hydrocarbon and cellulosic fire protection for structural steel and can also be used to upgrade

Description the fire resistance of existing concrete. Recommended areas of application include refineries,

petrochemical, pharmaceutical facilities, pulp and paper mills, offshore platforms, nuclear and

conventional power plants, factories, warehouses, institutional and biomedical facilities.

• Over 39 years of proven performance

• Exceptional durability and toughness

• UL 1709 hydrocarbon fire rated up to 4 hours

• BS 476 hydrocarbon fire rated up to 4 hours

• Jet fire rated up to 2 hours

• ASTM E119 cellulosic fire rated up to 4 hours

• Cryogenic protection against LNG spills and immersion exposures

• Resistant to 3 bar blast overpressure

Features • Hose stream resistant

• Tolerant to wide range of climates

• Lightweight – one-fifth the weight of concrete for equal fire protection

• Ideal for onsite and offsite application

• Easy application by spray or trowel

• Nonflammable – during or after application

• Chloride and sulfide free – no special priming required

• Asbestos-free – complies with EPA and OSHA regulations

• Non-friable – high impact strength

Non-Uniform Speckled Gray

Color

Product color may vary due to variations in color of Portland cement.

Textured

Finish

If a smooth finish is required, this may be done by trowel, roller or brush typically within 1 to 2 hours

after final application of Pyrocrete 241.

Pyrocrete 241 neither promotes nor prevents corrosion. The fireproofing should not be considered

as part of the corrosion protection system. For applications where primers are required, use a

Primer Carboline approved, alkaline resistant primer. Pyrocrete 241 must meet minimum UL bond strength

criteria for contour applications where primers are used. Contact the Carboline Fireproofing

Technical Service for further information and approved primers.

Application Thickness 1/2" - 5/8" (12.7 - 15.9 mm) on initial pass

13.3 board foot per bag @ 55 pcf

(1.23 m² @ 25.4 mm thick @ 881 kg/m³)

Theoretical Coverage

Field results will vary depending upon application parameters. Coverage based on theoretical gross

Rates

yield without loss. Material losses during mixing and application must be taken into account when

estimating project requirements. Coverage based on 50 lb. (22.7 kg) bags (one board ft = one ft² of

material at one inch thick or 0.9 m² of material at 25.4 mm thick.

Not recommended for use as a refractory cement or where continuous operating temperatures

Limitations

exceed 200°F (93°C).

February 2020 0148 Page 1 of 7

®

Pyrocrete 241

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generally not required. In severely corrosive atmospheres, topcoats may be used for added

durability and chemical resistance. consult Carboline Fireproofing Technical Service for selection of

the coating most suitable for the operating environment.

Seal Coat – In corrosive environments, use an appropriate topcoat. If topcoating is required, apply

Carboguard 1340 as a seal coat. Carboguard 1340 shall be thinned 25% with Carboline Thinner

#2. Carboguard 1340 may be applied after 24 hours of final application of Pyrocrete 241. Consult

Topcoats the Carboguard 1340 Product Data Sheet for minimum and maximum cure times.

Top Coat – Surface hardness should be a minimum Shore DO 64 as measured with a durometer

prior to application of the topcoat. Normally, this minimum dry time is 10 days at 70°F (21°C) and 40

days at 40°F (4°C), for thickness of 1” (25.4 mm) or less.

Caulking – For exterior installations, Acrilast caulk, TREMstop® Fyre-Sil GG or equivalent should

be applied at all termination joints between Pyrocrete 241 and the substrate. Contact Carboline

Fireproofing Technical Service for full information.

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

Before applying Pyrocrete 241, the substrate coating must be free of all oil, grease, condensation,

General

or other contamination.

If primer is required, steel preparation before priming should be done in accordance with the

Steel recommended primer’s product data sheet. Contact Carboline Fireproofing Technical Service for

approved primers.

Pyrocrete 241 is usually applied directly over galvanized surface. If priming is required, contact

Galvanized Steel

Carboline Fireproofing Technical Service for recommendations.

Concrete The recommended primer to seal concrete prior to applying Pyrocrete 241 is Carboguard 1340.

Aluminum, copper and other non-ferrous metals shall be primed with one coat of Carboline's

Non-Ferrous Metals

Rustbond Penetrating Sealer.

3.4 lb./yd² (1.85 kg/m²) galvanized metal lath, may be pre-bent and tie-wired into place for

appropriate design. Optionally, beam furring clips or electrically welded, pneumatic or self-tapping

screws or studs, may be used.

Contour Design - 3.4 lb./yd² (1.85 kg/m²) galvanized metal lath wrapped around the flange edges

toward the web approximately 1½” (38 mm). Contour column designs allow the use of 2"x 2" (50.8

mm x 50.8 mm) galvanized or PVC coated hexagonal metal mesh with beam furring clips as an

alternate to the 3.4 lb./yd² (1.85 kg/m²) galvanized metal lath. Plastic-nosed corner beads may also

be used for better thickness control and aesthetics on flange edges of steel. Please refer to design

details. For contour applications on structural members with web span greater than 16” (406 mm)

or flange widths greater than 12” (304 mm) refer to the UL Fire Resistance Directory under “Coating

Materials” section.

Lathing & Attachments Boxed Design - 3.4 lb./yd² (1.85 kg/m²) galvanized metal lath wrapped around member spanning

the web, overlapped 1” (25.4 mm) and tie-wired on the flange face 12” (304 mm) on center. For

large webbed members, additional support for lath may be needed for ease of installation. Plastic-

nosed corner beads may also be used for better thickness control and aesthetics.

Tower Skirts and Flat Surfaces - Require that 3.4 lb./yd² (1.85 kg/m²) galvanized metal lath

be anchored on 12” to 24” (304 mm to 610 mm) centers depending upon requirements. The lath

should overlap and be tie-wired. On tower skirts only, PVC coated mesh can be used in lieu of 3.4

lb./yd² (1.85 kg/m²) galvanized lath. Mesh shall be 2” x 2” (50.8 mm x 50.8 mm) 20 gauge wire

coated with PVC as furnished by Carboline.

When ram set or welding is prohibited; a pneumatic fastener may be used. On very large areas,

control joints are made by scoring halfway through the thickness of Pyrocrete. This is achieved

by using the trowel blade edge or an appropriate scoring tool. A preferred option would be the

February 2020 0148 Page 2 of 7

®

Pyrocrete 241

PRODUCT DATA SHEET

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

use of plastic-nosed corner beads. Spacing should be on 10’ (3 m) centers, both horizontally and

vertically. Please refer to design details or contact Carboline Fireproofing Technical Service.

P E R F O R M A N C E D ATA ( T Y P I C A L VA L U E S )

All test data was generated under laboratory conditions. Field testing results may vary.

Test Method Results

ASTM D2240 Durometer Hardness (Shore DO) 83

ASTM D2794 Impact Resistance Pass (No cracking at 20 foot pounds)

1 55 lb./ft³ (881 kg/m³) (minimum average)

ASTM E605 Density

2 22,026 psf (1,054 kPa)

ASTM E736 Bond Strength (Unprimed Steel)

ASTM E759 Deflection Pass

ASTM E760 Bond Impact Pass

ASTM E761 Compressive Strength 1,111 psi (7.6 MPa)

ASTM E84 Flame Spread 0

ASTM E84 Smoke Development 0

ASTM E937 Corrosion 0.00 gm/mm²

Coverage 50 lb. (22.7 kg) bag 13.3 Bd.Ft. (1.23 m² @ 25 mm)

Explosion Resistance 3 bar

Hose Stream Resistance Pass

Shrinkage <0.5%

1 Air dry at ambient conditions until constant weight is achieved. Do not force dry.

2 Bond strength testing performed utilizing ASTM E736 with AWCI Technical Manual 12-A modifications.

All test data above was generated under laboratory conditions. Field testing results may vary. Physical property data was derived

using 4.5 gallons of water per 50 lb. (22.7 kg) bag.

Material shall reach a hardness of Shore DO 64 prior to handling and topcoating.

Test reports and additional data available upon written request.

MIXING & THINNING

Use a heavy-duty mortar mixer rotating at 40 rpm with rubber tipped blades that will scrape the

Mixer sides and bottom of the mixer. A 50 lb. (22.7 kg) bag of Pyrocrete 241 typically requires a mixer

volume of 8 ft³ (227 L) minimum and mixer . Do not use pan type mixers.

Target water level: 4.5 gallons (17 liters)

Add 4.5 gallons (+/- 0.5 gallons) of clean, potable water to a mortar mixer with rubber tipped

blades. With mixer running slowly, add powder and mix for 5 minutes (10 minutes maximum) until

Mixing

a homogeneous mortar-like consistency is achieved. Longer mixing times may result in lower

densities. Total water must not exceed 5 gallons (19 liters) per 50 lb. (22.7 kg) bag. In cool weather,

warm water may be used to enhance application. In hot weather, cold water may be used.

2 hours at 70°F (21°C) and less at higher temperatures. Pot life ends when the material thickens

Pot Life

and becomes unusable. Do not re-temper material.

Target wet density:

76 - 82 lb./ft³ (1,217-1,313 kg/m³). Wet density measurements are critical to obtaining correct dry

densities. When checking wet densities, use the following procedures:

Density

Equipment needed:

• 1 liter (1000 cc) polyethylene cup

• Small metal spatula

February 2020 0148 Page 3 of 7

®

Pyrocrete 241

PRODUCT DATA SHEET

MIXING & THINNING

• Scale accurate to 1 gram

Determination of Pyrocrete wet density:

• Weigh the empty cup to the nearest gram, then tare the scale.

• Use the spatula to fill the cup completely with mixed material (do not tamp cup).

• Remove the excess material on top by placing the vertical edge of the spatula on the top edge of

the cup. Use a sawing motion to level the mixed Pyrocrete material flush with the top of the cup.

• Weigh the filled cup to the nearest gram.

• Record the weight of material in grams. This value equals the wet density in grams/liter and kg/m³

• To calculate the wet density of the material in lb./ft³, multiply the value in grams/liter by 0.0624.

Contact Carboline Fireproofing Technical Service for additional details.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

This material can be pumped with a wide range of piston, rotor stator and squeeze pumps designed

to pump cement & plaster materials including:

Essick - model# FM9/FM5E (Rotor Stator/2L4)

Putzmeister - model# S5EV(Rotor Stator/2L6)

Hy-Flex - model# HZ-30E(Rotor Stator/2L6)

Pump

Hy-Flex - model# H320E (Piston)

Strong Mfg. - model# Spraymate 60 (Rotor Stator/2L6)

Airtech - model# Swinger (Piston)

Mayco - model# PF30 (Dual Piston)

Thomsen - model# PTV 700 (Dual Piston)

Trowel Standard plasterers’ hawk and trowel may be used. A rubber float may also aid in finishing.

Minimum 1” (25.4 mm) I.D. hose with 300 psi minimum bursting pressure. For lengths over 50' (15

m) use 1½” (38 mm) I.D. hose. Do not reduce hose diameter by more than ¼’ (6.4 mm) per 25’ (7.6

Material Hose

m) unless a tapered conical reducer equipped with swivel fitting is used. A 10’ (3m) length of

1” (25.4 mm) I.D. hose may be added at the gun for use as a whip.

Binks - part# 7E2 (47-49 fluid tip / 3/8"-1/2" air cap)

Graco - part# 204000(3/8" - 1/2" fluid tip / air cap)

Nozzle/Gun Speeflow - part# 701(3/8" - 1/2" fluid tip / air cap)

Airtech - Internal mix with 3/8" - 1/2" fluid tip

Standard plasterers gun with 3/8" - 1/2" fluid tip

Be certain that the air supply is a minimum 22 cfm at 100 psi (689 kPa) and higher when distances

Compressor

longer than 75’ (22 m) are required.

Air Line Use ½” (12.7 mm) I.D. line, with a minimum bursting pressure of 100 psi (689 kPa).

February 2020 0148 Page 4 of 7

®

Pyrocrete 241

PRODUCT DATA SHEET

A P P L I C AT I O N P R O C E D U R E S

Pyrocrete 241 may be applied by spray and/or trowel. Material build will depend on application

method, weather conditions and equipment used. For application overhead, a scratch coat of up

to ½” (12.7 mm) is recommended to key into the lath. Allow to set for approximately 1 to 2 hours

at 70°F (21°C) before applying the subsequent coats. It is recommended that the total required

thickness be applied within a 24 hour period. If this is not possible, the preceding coats should be

left as sprayed or scored after application. Product must be dampened with water before application

General

of additional coats.

• Maximum time to achieve the full thickness is 3 days at 70°F (21°) and 50% relative humidity. This

would be less at higher temperatures.

• All additional coats are applied monolithically to the entire perimeter of the member.

• At no time shall Pyrocrete 241 be applied at a thickness less than ¼” (6.4 mm) or “skim”

coated.

Finishing Material can be left as sprayed or finished with a trowel for better aesthetics.

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 40°F (4°C) 40°F (4°C) 40°F (4°C) 0%

Maximum 100°F (38°C) 125°F (52°C) 110°F (43°C) 95%

CURING SCHEDULE

Surface Temp. Dry to Recoat

70°F (21°C) 2 Hours

Fresh Pyrocrete 241 must be protected from rain or running water for 24 hours at 70°F (21°C). In low humidity, high temperature,

direct sun or wind, the Pyrocrete surface should be kept damp for at least 12 hours by applying a water mist or wrapping in plastic

sheets to reduce rapid water loss.

Caution: Do not start work if ambient temperatures are expected to drop below 35°F (2°C) for 24 hours after application.

Material shall reach a hardness of Shore DO 64 prior to handling and topcoating. For shipping and handling instructions

of shop applied Pyrocrete 241 Series materials to individual steel members or modular steel sections, please contact you

local Carboline Sales Representative or Carboline Fireproofing Technical Service.

CLEANUP & SAFETY

Pump, mixer and hose should be cleaned with clean, potable water at least once every 4 hours at

70°F (21°C), and more often at higher temperatures. Sponges should be run through the hoses to

Cleanup

remove residual material. Wet Pyrocrete 241 overspray must be cleaned up with soapy or clean,

potable water. Cured overspray may require chipping and/or scraping to remove.

Read and follow all caution statements on this product data sheet and on the SDS for this product.

Safety Employ normal workmanlike safety precautions. Use adequate ventilation. Keep container closed

when not in use.

Adjacent surfaces shall be protected from damage and overspray. Sprayed fireproofing materials

Overspray may be difficult to remove from surfaces and may cause damage to architectural finishes. Cured

overspray may require chipping and/or scraping to remove.

When used in enclosed areas, thorough air circulation must be used during and after application

Ventilation

until the product is dry.

February 2020 0148 Page 5 of 7

®

Pyrocrete 241

PRODUCT DATA SHEET

T E S T I N G / C E R T I F I C AT I O N / L I S T I N G

Pyrocrete 241 has been tested by Underwriters Laboratories, Inc. and is classified for exterior or

interior use by UL in the following designs:

UL 1709

Rapid temperature rise hydrocarbon fire exposure

Columns – XR701, XR702, XR734, XR738

BS 476: Part 20: Appendix D

hydrocarbon fire exposure

Columns – Report No. R11193

Cryogenic Testing

Tested in accordance to “Specification for Cryogenic Protection and Passive Fire Protection of

Underwriters Structural Members", dated March 2006 from South Hook LNG Terminal Company Ltd. Additional

Laboratories, Inc. splash and spill testing perform at varying flow rates. All testing has been witnessed by UL.

ASTM E119 (UL 263, NFPA 251)

Cellulosic fire exposure

Columns - X732, X733, X735, X736, X743, X744, Y707, Y708

Roof Assembly – P734, P735, P736, P737, P738, P739, P926, P927, P928, P929, G706, G707,

G708, J713, J714, J715, J716

Beams – N715, N716, N717, N718, N771, N772, N773, N774, N775, S706, S713, S731, S732,

S733

Floor Ceiling Assembly – D744, D767, D768, D769, D770, D771, D772, D773, D774, D775,

D776, D777, D927, D928

Walls – U704

MEA No. 172-80-M (Columns)

City of New York MEA No. 173-80-M (Columns W14x233)

MEA No. 174-80-M (Beams)

City of Los Angeles RR24763

Tested and listed by FM Global for structural Test and LPG vessels at 3/8” (10mm) thickness from

FM Global

face of metal lath for 2 hour rating, including hose stream endurance test.

City of San Francisco 164 C57.7A

Det Norske Veritas 3 bar overblast protection

Lloyd's Register J-120 jet fire protection - certificate No. SAS F180103

PA C K A G I N G , H A N D L I N G & S T O R A G E

Packaging 50 lb. (22.7 kg) bags

Shelf Life 24 months (minimum) when kept at recommended storage conditions.

Store indoors in a dry environment between -20°F - 150°F (-29°C - 66°C)

Storage

Material must be kept dry or clumping may occur.

Shipping Weight 50 lb. (22.7 kg)

(Approximate)

February 2020 0148 Page 6 of 7

®

Pyrocrete 241

PRODUCT DATA SHEET

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject

to change without prior notice. User must contact Carboline Company to verify correctness before specifying or ordering. No

guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no

responsibility for coverage, performance, injuries or damages resulting from use. Carbolines sole obligation, if any, is to replace

or refund the purchase price of the Carboline product(s) proven to be defective, at Carbolines option. Carboline shall not be liable

for any loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

February 2020 0148 Page 7 of 7

You might also like

- Specification - Small Integral Pressurised Water Reactor Basic Principles Simulator Custom Software PDFDocument90 pagesSpecification - Small Integral Pressurised Water Reactor Basic Principles Simulator Custom Software PDFsanthoshkumarplNo ratings yet

- Flow Meter Type Recordall (RCDL) : FeaturesDocument4 pagesFlow Meter Type Recordall (RCDL) : FeaturessanthoshkumarplNo ratings yet

- LEWA Ecoflow Variable Eccentric Pump Drive Type LDE: PerformanceDocument2 pagesLEWA Ecoflow Variable Eccentric Pump Drive Type LDE: PerformancesanthoshkumarplNo ratings yet

- Charms Cabinet CatalogueDocument14 pagesCharms Cabinet CataloguesanthoshkumarplNo ratings yet

- Suez MSDS Petroflo 20Y600Document11 pagesSuez MSDS Petroflo 20Y600santhoshkumarplNo ratings yet

- LEWA Ecoflow Variable Eccentric Pump Drive Type LDC: PerformanceDocument2 pagesLEWA Ecoflow Variable Eccentric Pump Drive Type LDC: PerformancesanthoshkumarplNo ratings yet

- 8101 Ice BreakerDocument23 pages8101 Ice BreakerAnonymous 0FIwxrWLaKNo ratings yet

- Maha-Si Insight Meditation - Daham Vila - Http://dahamvila - Blogspot.comDocument0 pagesMaha-Si Insight Meditation - Daham Vila - Http://dahamvila - Blogspot.comDaham Vila BlogspotNo ratings yet

- LEWA Ecoflow Variable Eccentric Pump Drive Type LDB: PerformanceDocument2 pagesLEWA Ecoflow Variable Eccentric Pump Drive Type LDB: PerformanceIoana PopescuNo ratings yet

- KANDHA SASHTI KAVACHAM: A POWERFUL PRAYER FOR PROTECTIONDocument4 pagesKANDHA SASHTI KAVACHAM: A POWERFUL PRAYER FOR PROTECTIONsweetykrshNo ratings yet

- 16 - Buddhist Vipassana MeditationDocument12 pages16 - Buddhist Vipassana MeditationRudrani SarkarNo ratings yet

- KANDHA SASHTI KAVACHAM: A POWERFUL PRAYER FOR PROTECTIONDocument4 pagesKANDHA SASHTI KAVACHAM: A POWERFUL PRAYER FOR PROTECTIONsweetykrshNo ratings yet

- Month by MonthDocument28 pagesMonth by MonthChoi Han KimNo ratings yet

- Vipassana MeditationDocument242 pagesVipassana MeditationIlya Olshanetskiy100% (3)

- 1111 Distinguished Club Program and Club Success PlanDocument38 pages1111 Distinguished Club Program and Club Success PlanAkshay SoniNo ratings yet

- Leser PSV Type 447Document4 pagesLeser PSV Type 447santhoshkumarplNo ratings yet

- Club Leadership Handbook PDFDocument68 pagesClub Leadership Handbook PDFFlorin MariusNo ratings yet

- Coping with panic attacksDocument5 pagesCoping with panic attacksThomas ScottNo ratings yet

- Advantages of Magnetically Driven Gear PumpsDocument5 pagesAdvantages of Magnetically Driven Gear PumpsLuis PetittNo ratings yet

- Pumpapi675presentation 150805065440 Lva1 App6891 PDFDocument42 pagesPumpapi675presentation 150805065440 Lva1 App6891 PDFsanthoshkumarplNo ratings yet

- A-LOK Wallchart - SP3 - Parker FittingsDocument1 pageA-LOK Wallchart - SP3 - Parker FittingssanthoshkumarplNo ratings yet

- G-Lok Clamps SelectionDocument1 pageG-Lok Clamps SelectionsanthoshkumarplNo ratings yet

- Pulsation Damper Specification FormDocument1 pagePulsation Damper Specification FormsanthoshkumarplNo ratings yet

- D6 400 LEWA Oil Gas Industry enDocument24 pagesD6 400 LEWA Oil Gas Industry ensanthoshkumarplNo ratings yet

- GE McKinsey Matrix PowerPointDocument9 pagesGE McKinsey Matrix PowerPointMike Teng Keat Hui100% (1)

- Your Awesome Presentation Title: An Even More Amazing SubtitleDocument31 pagesYour Awesome Presentation Title: An Even More Amazing SubtitleByron TorresNo ratings yet

- Non-Metallic Sealless Main BrochureDocument4 pagesNon-Metallic Sealless Main BrochuresanthoshkumarplNo ratings yet

- Carbothane 134 HG PDSDocument5 pagesCarbothane 134 HG PDSsanthoshkumarplNo ratings yet

- PESO Approval ProcessDocument8 pagesPESO Approval ProcesssanthoshkumarplNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sae Astm Aisi ChartDocument1 pageSae Astm Aisi ChartOmar Jesus CocaNo ratings yet

- Civil Fiber Reinforced Concrete ReportDocument12 pagesCivil Fiber Reinforced Concrete ReportPANKAJ KUMAR BTechNo ratings yet

- Structural PathologyDocument12 pagesStructural PathologyAndres ForeroNo ratings yet

- Facts Type 455 - 456Document9 pagesFacts Type 455 - 456DanielNo ratings yet

- Beechwood Primary School Structural CalculationsDocument28 pagesBeechwood Primary School Structural CalculationsRonnie SmithNo ratings yet

- Composite MaterialsDocument8 pagesComposite MaterialsSunny Gaekwad100% (1)

- Comparative Study of Epoxy and Polyester Resin-Based Polymer ConcreteDocument7 pagesComparative Study of Epoxy and Polyester Resin-Based Polymer Concretemohamadi42No ratings yet

- Objective (MCQ) Chemical Engineering Chemical Engineering Objective Questions With Answers PDFDocument2,046 pagesObjective (MCQ) Chemical Engineering Chemical Engineering Objective Questions With Answers PDFToba100% (4)

- Spec - 2017-02 - A00 SHOP AND FIELD PRESSURE TESTING OF PIPING SYSTEMSDocument30 pagesSpec - 2017-02 - A00 SHOP AND FIELD PRESSURE TESTING OF PIPING SYSTEMSAL Rajhi Zakaria67% (3)

- Sector 7 Infrastructure Cost AnalysisDocument129 pagesSector 7 Infrastructure Cost AnalysisSunil Kumar GeraNo ratings yet

- Evaluation of The Bulk Specific Gravity For Granular MaterialsDocument1 pageEvaluation of The Bulk Specific Gravity For Granular MaterialsProf. Prithvi Singh KandhalNo ratings yet

- Report - Summer Training: Sushant KumarDocument25 pagesReport - Summer Training: Sushant KumarAbhishek MishraNo ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument3 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemharikrishnanNo ratings yet

- Fuel Pipe - Fuel TankDocument2 pagesFuel Pipe - Fuel TankPower MobileNo ratings yet

- Table K-1 Allowable Stresses in Tension For Metals For Chapter IXDocument2 pagesTable K-1 Allowable Stresses in Tension For Metals For Chapter IXricardoNo ratings yet

- AWS - PHB-3-2004 The Everyday Pocket Handbook On Welded Joint Details For Structural Applications PDFDocument30 pagesAWS - PHB-3-2004 The Everyday Pocket Handbook On Welded Joint Details For Structural Applications PDFahmedabdelaziz851647No ratings yet

- VIKING JOHNSON - MaxiFit, MaxiStep y MaxiAdaptadoresDocument19 pagesVIKING JOHNSON - MaxiFit, MaxiStep y MaxiAdaptadoresop.im.bkp.1No ratings yet

- Post TreatmentDocument23 pagesPost TreatmentVishnu VardhanNo ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- Analysis and Design of G+1 Hospital Building: A Project ReportDocument44 pagesAnalysis and Design of G+1 Hospital Building: A Project ReportSri Amarnath BirlaNo ratings yet

- Plastid RainDocument8 pagesPlastid Rainkkppkk1No ratings yet

- Piping Progress Measurement (In Dia and in Meter)Document6 pagesPiping Progress Measurement (In Dia and in Meter)bumkj100% (1)

- Flexi PlywoodDocument11 pagesFlexi Plywoodkkinfra005No ratings yet

- Refractory Ceramic Fiber BlanketDocument2 pagesRefractory Ceramic Fiber BlankethailmarylugoNo ratings yet

- PSC NotesDocument77 pagesPSC NoteschanakyaNo ratings yet

- BLAST FURNACE OPERATIONS-TATA STEEL - Dipika Sinha - 5.6.20 PDFDocument22 pagesBLAST FURNACE OPERATIONS-TATA STEEL - Dipika Sinha - 5.6.20 PDFGAGAN SOLANKINo ratings yet

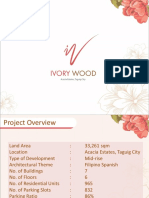

- IVW Ivory Wood Project BriefDocument72 pagesIVW Ivory Wood Project BriefJ SalesNo ratings yet

- NDT Defects RecordsDocument1 pageNDT Defects RecordsAnonymous OEUUoKHYRNo ratings yet

- Metal WareDocument47 pagesMetal Waremukesh guptaNo ratings yet

- Tiles Marbels CostDocument16 pagesTiles Marbels CostJASH INFRA AND HOME SERVICESNo ratings yet