Professional Documents

Culture Documents

Conc-03 Ex

Conc-03 Ex

Uploaded by

shoeb0 ratings0% found this document useful (0 votes)

13 views10 pagesOriginal Title

CONC-03 EX

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views10 pagesConc-03 Ex

Conc-03 Ex

Uploaded by

shoebCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

Project:

Project no; [[xT=) StatiCa®

Author: ‘te maa te

Project data

Project name

Project number

Author

Description

Date wwnaro17

Design code AISC 360-16

Material

Steel STEEL

1110

Project:

Project no:

‘Author:

Project item Con 245

Design

Name con 245

Descinton

Analysis Joint design resistance

Design code Isc “ASD

Beams and columns

a ron ®-Diteotion y Pitch

tl 1

Mi 1-1PET40 09-900

126 UPN200 2-UNP200 20, 00

138 UPN200 2 UNP200 660

122 UPN200 2-UNP200 “797-409

a

a Pc

Cross-sections

Name

1-IPE140

2- UNP200

2- UNP200

2- UNP200

Bolts

Name Bolt assembly

16.A325M 16 325M

(T=) StatiCa®

Rotation Offset ex Offset ey Offset ez

nl

1800

00

00

180.0

(emmy

Material

STEEL

STEEL

STEEL

STEEL

Diameter

[mm]

16

fu

[MPa]

530.0

{rm

Forces in

Position

Position

Postion

Postion

Gross area

{nm

ol>|o|olae

Biio

Project:

Project

tor

Load effects:

5

— =

kN]

roususisy szpuPvaco 7)

‘35 uPva00 =

sm2uPuz00 =a

Check

Joint design resistance

=

soususy

20) aT

‘sno

Fl

Fro

a

<1 |

to oa SS

oa

St ceman nga okey

sur

= =

res ee

a ae

oe asco

wo oe

[ )

os) 02

48 02

61) 30

Resistance

4)

PI Masial

WePiPons = 43%

Epiwells 08%

oK

oK

OK

([[aT=E] StatiCa”

Mx My Me

kNm] IkNm] [kNm]

00 os 04

00 4 03

00 18 a

1927

check status

a0

Project:

Project no:

‘Author:

Plates

DMt-bn 1

Mind

DMtew1

126 UPN200-6n1 1

126 UPN2004N 1

126 UPN200W 1

138 UPN200-bn 1

138 UPN2004n 4

198 UPR200-W 1

422 UPN200-bN1

122 UPN2004n 1

122 UPN200W1

FP

FP2

FPS

Design data

Material

STEEL

‘Symbol explanation

"1

oe

K

(Overall check, 1DLHILLHSY

Thickness

{rom

68

69

47

15

"8

a5

ns

ns

35

ns

18

as

100

100

100

Eq, strass

Load:

ADLFILL+ISY

ADLHLLHSY

TDLHLLHISY

TDLHILLHISY

ADLILL#ISY

ADLHLLHSY

TDLHILLHISY

ADLHLLHSY

SDLFTLLISY

ADLHLLHSY

ADLILL+1SY

ADLHLLHSY

ADLHLLHSY

ADLHLLHISY

TDLHLLHISY

3447

Sea

MPa)

455

1654

208.6

204

390

1183

219

304

752

aa

75

372

168.0

1657

472.

my

teal

00

00

a4

00

00

00

00

00

00

00

00

00

04

00

00

ok

OK

ok

ok

OK

OK

ok

OK

ok

OK

ok

ok

‘ok

OK

OK

(T=) StatiCa”

Check status

500.0

410

Project:

Project no [==] StatiCe’

Author: ne ea atte

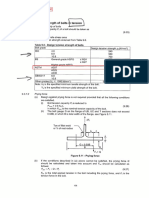

Strain check

[%]

> 150%

100%

6.00)

0.09 Ll oy,

‘Stan check, {DL¥ALL#1SY

Equivalent stress

[MPa]

206.4

180

160

140

120

100

8

20

00

&

Equivalent stress, 1DL+1LL+1SY

5/10

Project:

Project no:

‘Author:

Bolts

tem

816385 TDL ILL+iS¥

516386 1DL+ILLHSY

516367 1DL#ILL¥1S¥

516368 T1DL#ILL¥1S¥

816388 1DL+ILL+is¥

516390 1DL+ILLHSY

516391 1DL#ILLHISY

16322 1DLHILLHSY

Design date

Grade

16 A325M-1

‘Symbol explanation

F

v

RriOrenion

Rrra

Friern

uy

Us

Welds

tem Edge

Mint FPT

DMiew1 — FP2

DMibnt FPS

‘symbol explanation

Xu

&

L

Le

Fy

Raa

uw

70x

70x

70x

70x

E700

70x

Roo

toads orm ga?

66 00106734

8300 asa

610098784

590098784

1 oo AA

060010

0300 eR

0700 aan

RO eion

may

3

Twin

Resuitant of shear forces Wy, V2in bolt

Bolt tension resistance AISC 360-18 J3.6

Bot shear esiatanee NISC 260 1 8.0

Bott bearing resistance

Utiization in tension

Utiization in shear

Utilization in tension and shear

Th

Imm]

45

oa

457%

“ame

457%

oa

Ls

[our

eh

ae ik

a78e,

are

48.08

48.08

Filler meta tensile strength

“Throat thickness of wele

Lag size of wold

Lenatn of weld

Length of weld ertical element

Force in weld ertical element

Weld resistance AISC 360-16 12.4

Utiization

L

Imm

185

173

169

189

236

233

le

[rom

2

"

"

2

8

18

Loads

ADL#ILL+1SY

ADLHLLHSY

ADLHLLHSY

1DL+ILL+ISY

1DLHTLL+ISY

ADL+ILLe1SY

ut,

ra

160

tet

152

123

125

985

184

130

Fy

(kN)

35

62

44

38

60

40

ut

ra

00

00

oo

oo

00

00

00

00

(TE) StatiCa”

ok

OK

ok

ok

OK

OK

ok

OK

RAO s0ap

(KN)

Fala.

i)

128

124

126

140

216

21.8

ut

i)

286

496

353

273

23

182

ut

ra SMe

374

‘Status

oK

ok

ok

ok

oK

ok

6/10

Project:

Project no:

‘Author:

Bill of material

Manufacturing operations

Piates Welds

Ne,

tome ee shape ae

FP1 —Pr0.0x1005-180.0 (STEEL) 1

FP2 —P10,0x103 6-180.0 (STEEL) 1 Double fet

FP3_—P10,0x3096-180.0 (STEEL) FF satiate:

++

Welds

thickness

Type Material wee

Double et E70x« 87

Doub filet ETOxx 87

Doubi et ETOx« 87

Bolts

heme pio

16A926M 18

16A326M 19

Drawing

FPA

(T=) StatiCa”

tng Bolts Ne

1e00 16 As25M 2

ye00 16 A325 2

57 2350 16 ADEM

Leg size Length

[ron] Imm]

80 1800

80 1800

20 236.0

Count

7110

Project:

Project no [==] StatiCe’

Author: iene

Po,oxteo-101 (STEEL)

8)

see

©

50 80 so

FP2

P10.0x180-106 (STEEL)

©

so 0 so

e/10

Project:

Project no (=T=E] Statice”

Author: ae

FP3

0,0xt60-210 (STEEL)

126 UPN200, UNP200 - Web 1:

oe

@

9/10

Project:

Project no: [=T=F] StatiGe’

inanor: ere ay te

138 UPN200, UNP200 - Web 1:

us 45

422 UPN200, UNP200 - Web 1:

Code settings

Hem Value Unit Reference

Friction coetcient- concrete 240 + Aci aga B64

Friction coefcient in sipresistance 330 + AISc 360-16 -J3.8

Limit plastic strain 2.05 :

‘Wold stress evaluation Plastic redistibution

Detailing No

Distance between bots [4] 266 AISC 360-168-433

Distance between bots and edge [4] 1.25 AISC 360-16 -J3.4

Concrete breakout resistance ves

Base metal capacty check at veld fusion face No AISC 360-16-J22 10/10

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Room Legend: Door ElevationsDocument1 pageRoom Legend: Door ElevationsshoebNo ratings yet

- Curriculum Vitae: Career ObjectiveDocument5 pagesCurriculum Vitae: Career ObjectiveshoebNo ratings yet

- RS IO N: Project DataDocument13 pagesRS IO N: Project DatashoebNo ratings yet

- D UC AT IO NA: Project DataDocument13 pagesD UC AT IO NA: Project DatashoebNo ratings yet

- Calculation Sheet For Spit Anchors: ProjectDocument4 pagesCalculation Sheet For Spit Anchors: ProjectshoebNo ratings yet

- L VE R IO N ID EA: Project DataDocument15 pagesL VE R IO N ID EA: Project DatashoebNo ratings yet

- DC Ratio With Aisc LRFD Design Manual:-: W.G Engr. ShoebDocument1 pageDC Ratio With Aisc LRFD Design Manual:-: W.G Engr. ShoebshoebNo ratings yet

- Calculation Sheet For Spit Anchors: ProjectDocument4 pagesCalculation Sheet For Spit Anchors: ProjectshoebNo ratings yet

- Untitled Extract PagesDocument2 pagesUntitled Extract PagesshoebNo ratings yet

- Mmax 0.054 KN.M 0.75 XFY 0.75X0.240 0.18: UC - SDBDocument1 pageMmax 0.054 KN.M 0.75 XFY 0.75X0.240 0.18: UC - SDBshoebNo ratings yet

- DC Ratio With Aisc LRFD Design Manual:-: W.G Engr. ShoebDocument1 pageDC Ratio With Aisc LRFD Design Manual:-: W.G Engr. ShoebshoebNo ratings yet

- Section-B: Fabricated Angle 44x37x5mmDocument4 pagesSection-B: Fabricated Angle 44x37x5mmshoebNo ratings yet

- Hilti GlassDocument7 pagesHilti GlassshoebNo ratings yet

- Wind ASCE7 05Document1 pageWind ASCE7 05shoebNo ratings yet

- Design Specifications: AnchorDocument7 pagesDesign Specifications: AnchorshoebNo ratings yet