0% found this document useful (0 votes)

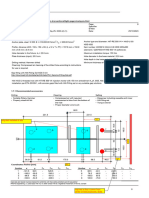

1K views1 pageTypical Micropile Capacity (Eurocode)

This document provides typical bored micropile capacities based on grout grade and micropile diameter and reinforcement. It recommends limitations on unfactored design actions on each micropile based on diameter. It also provides minimum recommended headroom above micropiles. The micropile ultimate capacities are calculated based on grout and reinforcement properties. Designers should ensure micropile capacity exceeds load combinations and this is a general guide subject to site-specific soil conditions.

Uploaded by

SantosoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views1 pageTypical Micropile Capacity (Eurocode)

This document provides typical bored micropile capacities based on grout grade and micropile diameter and reinforcement. It recommends limitations on unfactored design actions on each micropile based on diameter. It also provides minimum recommended headroom above micropiles. The micropile ultimate capacities are calculated based on grout and reinforcement properties. Designers should ensure micropile capacity exceeds load combinations and this is a general guide subject to site-specific soil conditions.

Uploaded by

SantosoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd