Professional Documents

Culture Documents

Copper Waterstop

Uploaded by

SantosoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Copper Waterstop

Uploaded by

SantosoCopyright:

Available Formats

®

INSTALLATION PROCEDURES

1. Joining of the Copper Waterstop shall be carried out by the contractor as shown in the drawings.

2. The contractor shall provide all necessary joining materials and equipment.

3. The joining procedure shall be carried out by the brazing welding method.

4. The brazing alloy used for brazing shall be silver brazing alloy 250 (SBA 250) or an approved quivalent by the

superintendent may be used.

5. All areas to be joined shall be thoroughly cleaned and dried before undertaking the process.

6. The Copper Waterstops shall be lapped by 100mm at the join areas.

7. Parts to be joined shall be clamped together such, that the gap between the areas to be Brazed, are within the range

of 0.05 - 0.10mm. Importance and extra care must be take when brazing the expansion bulb area of the waterstop so

as to make sure that it is fully welded and sealed.

8. Brazing flux shall be silver brazing flux no. 2 or equivalent and shall be applied to the parts to be joined and to the

brazing rods.

2/2

9. The parts to be joined must be pre-heated with a neutral flame and when the correct temperature is achieved

(recommended by the manufacturer), the brazing alloy shall be applied, keeping the torch in a constant moving motion.

NOTE: Minimum penetration of bronzing alloy shall be 10mm.

HEALTH AND SAFETY INFORMATION

For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products,

please refer to the most recent product Material Safety Data Sheet (MSDS), which is available upon request.

The information and the recommendations relating to the application and end use of this product are given in good faith and are based on the information

provided by the manufacturer of the product and / or the Company’s current knowledge and experience in connection with the product when properly stored,

handled and applied under normal conditions and no liability of final function at the job site is assumed. In practice, the differences in materials, substrates and

actual site conditions are such that no warranty in respect of merchantability of or fitness for a particular purpose, nor any liability arising out of any legal

relationship whatsoever, can be inferred either from this information, or from any written and / or oral recommendations, or from any other advice offered by

the Company. No responsibility or liability by the Company will be accepted for misuse, misreading or derivation from the recommended guidelines in respect

of this product and the user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith. The

information contained in this brochure may change at any time without notice.

Effective Date: 01 January 2014

CORKJOINT (MALAYS I A) S D N BH D 38 31 02 -H CORKJOI NT ( S I N GAPORE ) PTE LTD 2 00716724-K

No.51, Jalan BRP 8/2, Bukit Rahman Putra Industrial Park 10 , A d mir a lty Stre et, #03-8 2 N o r th Link Build ing

47000 Sungai Buloh, Selangor Darul Ehsan, Malaysia Sing apo re 757695

Tel +603 6148 8010 Tel +65 6455 9331

Fax +6 03 6148 8020 Fa x + 65 645 5 8 53 5

info@corkjo int.c o m

www.co rk jo in t.c o m © Corkjoint 2012. All Rights Reserved.

You might also like

- CJEpoxy AdhesiveDocument2 pagesCJEpoxy AdhesiveSantosoNo ratings yet

- Nitoseal 280 Method StatementDocument3 pagesNitoseal 280 Method StatementKris SiregarNo ratings yet

- BOC MIG 320R 420R ManualDocument16 pagesBOC MIG 320R 420R ManualKenninho100% (1)

- Sika PDS - E - SikaProof SB TH PDFDocument3 pagesSika PDS - E - SikaProof SB TH PDFlwin_oo2435No ratings yet

- Method Statement: Asian Insulation Co.-QatarDocument6 pagesMethod Statement: Asian Insulation Co.-QatarErin JohnsonNo ratings yet

- Nitoproof 280 Method StatementDocument3 pagesNitoproof 280 Method StatementBramandito DamarNo ratings yet

- Sure-Stop PVC Waterstop Site Joining GuidelineDocument1 pageSure-Stop PVC Waterstop Site Joining Guidelinemyke_0101No ratings yet

- Ratchet Tie Down SopDocument5 pagesRatchet Tie Down SopBasyeer SuhaimiNo ratings yet

- INCO-MS-PIP-0009-SAFE WORK Method Statement For Piping Support FabricationDocument8 pagesINCO-MS-PIP-0009-SAFE WORK Method Statement For Piping Support FabricationHichem BklNo ratings yet

- 34 5381 01 Instructions Cable CableDocument2 pages34 5381 01 Instructions Cable Cabletecknotron2072No ratings yet

- Soldering ReportDocument8 pagesSoldering ReportParthaS HukaiNo ratings yet

- Low Hydrogen Handling, Rev. A 19-6-10Document10 pagesLow Hydrogen Handling, Rev. A 19-6-104romi89No ratings yet

- Thermobreak Solarblock Installation Instructions 260221EDocument3 pagesThermobreak Solarblock Installation Instructions 260221ETrương Tấn KhoaNo ratings yet

- Ferco Doors-Fire Shutter Installation Insulated Manual Rev 01Document13 pagesFerco Doors-Fire Shutter Installation Insulated Manual Rev 01Ziaul HaqNo ratings yet

- Compatibility For Vendor's Coating System B1 (BR-CDZZZZ-MT-SPE-5037) SP4241 Valves - 03.07.2018Document3 pagesCompatibility For Vendor's Coating System B1 (BR-CDZZZZ-MT-SPE-5037) SP4241 Valves - 03.07.2018natig samedovNo ratings yet

- Cw-002 - GQ Projects - Axminster Method StatementDocument5 pagesCw-002 - GQ Projects - Axminster Method StatementMinhHyNo ratings yet

- J-Seal Primer: Polyurethane Joint Sealant PrimerDocument2 pagesJ-Seal Primer: Polyurethane Joint Sealant PrimerSantosoNo ratings yet

- Operation Precautions: Application NoteDocument2 pagesOperation Precautions: Application NoteAmandeepNo ratings yet

- Method Statement For Insulation WorksDocument7 pagesMethod Statement For Insulation WorksRachel Flores100% (2)

- FI726 Installation Procedure Rev. 0Document7 pagesFI726 Installation Procedure Rev. 0BinhNo ratings yet

- Method Statement For Roof CoveringDocument6 pagesMethod Statement For Roof CoveringCalvin OhNo ratings yet

- (MS) LokfixDocument3 pages(MS) Lokfixherwin hanafiahNo ratings yet

- Sika PDS - E - Sigunit D54 AFDocument2 pagesSika PDS - E - Sigunit D54 AFlwin_oo2435No ratings yet

- Submittal - Bitumode Flex-P - Alternative ProposalDocument25 pagesSubmittal - Bitumode Flex-P - Alternative ProposalJason RazatlabNo ratings yet

- E1294W-WWEN NVent ERICO Cadweld Installation and Inspection Guide - NventDocument56 pagesE1294W-WWEN NVent ERICO Cadweld Installation and Inspection Guide - NventmaungmaunglattNo ratings yet

- 4 - MS-Installation GI Cable Tray, Trunking & PipesDocument7 pages4 - MS-Installation GI Cable Tray, Trunking & PipesAraf KalamNo ratings yet

- E1294w WwenDocument21 pagesE1294w WwenerikNo ratings yet

- Inst HacDocument4 pagesInst HacVũ Hằng PhươngNo ratings yet

- Nur Aqilah Binti Adnan - 2021505009Document17 pagesNur Aqilah Binti Adnan - 2021505009cactuswillsaNo ratings yet

- Pin Brazing Gun - Electrobraze ZE7000Document16 pagesPin Brazing Gun - Electrobraze ZE7000GlennSymingtonNo ratings yet

- Fosroc Nukote JFHMDocument2 pagesFosroc Nukote JFHMBalasubramanian AnanthNo ratings yet

- Ceiling Vent Fan GuideDocument3 pagesCeiling Vent Fan GuideOliver HermosaNo ratings yet

- BITUBOARDDocument2 pagesBITUBOARDjovindhaNo ratings yet

- 186 Soldering Flux: Mildly Activated Rosin Liquid FluxDocument4 pages186 Soldering Flux: Mildly Activated Rosin Liquid FluxAmirNo ratings yet

- DTR Eng RollformDocument3 pagesDTR Eng RollformMichał ŚwiątekNo ratings yet

- MSDS For MegohmmeterDocument6 pagesMSDS For MegohmmeterMohamad Abdelhakim Qamrah - 5583No ratings yet

- Method Statement For Insulation WorksDocument7 pagesMethod Statement For Insulation WorksMoezNo ratings yet

- 7095Document2 pages7095scorpionbadshahNo ratings yet

- Nitomortar TSDocument2 pagesNitomortar TSBalasubramanian AnanthNo ratings yet

- Method Statement Cathodic ProtectionDocument10 pagesMethod Statement Cathodic Protectionkamil67% (3)

- Sikagard-670 WMYDocument3 pagesSikagard-670 WMYNARUdaARCNo ratings yet

- Procedure For Storage PreservationDocument4 pagesProcedure For Storage Preservationriyas.hvacworkNo ratings yet

- Issuance of Curfew Passes For Critical/Essential Employees of BOI EnterprisesDocument5 pagesIssuance of Curfew Passes For Critical/Essential Employees of BOI EnterprisesGalkandaNo ratings yet

- Cadweld EricoDocument40 pagesCadweld EricoAnonymous BBX2E87aHNo ratings yet

- Sika PDS - E - Sika Hydrotite DSHT 0522 15 I GRDocument2 pagesSika PDS - E - Sika Hydrotite DSHT 0522 15 I GRlwin_oo2435No ratings yet

- Lead-Tin-Copper Slotolet CSP 10 1Document1 pageLead-Tin-Copper Slotolet CSP 10 1Burak ÖZBAKIRNo ratings yet

- Hokushin A686 Dockleveller-80000020Document6 pagesHokushin A686 Dockleveller-80000020budiNo ratings yet

- Chai Wah Trading - FullDocument3 pagesChai Wah Trading - FullAkmal AzlanNo ratings yet

- Intertherm 838Document4 pagesIntertherm 838Ashta VakrNo ratings yet

- Flame Retardant Polystyrene (Fr-Hips) : Processing: Applications: CharacteristicsDocument2 pagesFlame Retardant Polystyrene (Fr-Hips) : Processing: Applications: CharacteristicsSuchita SamalNo ratings yet

- Earthing and Lightning ProtectionDocument10 pagesEarthing and Lightning ProtectionqaqcmepteamNo ratings yet

- JCR-190623-TTSB-F3201-signed For Insulation WorksDocument12 pagesJCR-190623-TTSB-F3201-signed For Insulation WorksFadzil AmalludinNo ratings yet

- Contractor Safety Guidelines 3Document12 pagesContractor Safety Guidelines 3Jurie_sk3608No ratings yet

- WHD250 Worldpoly Operation ManualDocument34 pagesWHD250 Worldpoly Operation ManualalejandroNo ratings yet

- 9619 Hisense LTDN32K316AM LTDN32K310WAM Chassis MSD1328 Ver 1.0 2012.07 Televisor LCD Manual de ServicioDocument48 pages9619 Hisense LTDN32K316AM LTDN32K310WAM Chassis MSD1328 Ver 1.0 2012.07 Televisor LCD Manual de ServicioAndreskoiraNo ratings yet

- Specification For Wrapping TapeDocument17 pagesSpecification For Wrapping TapeGalih Prianggodo100% (2)

- Coral Sand: DescriptionDocument1 pageCoral Sand: DescriptionMego PlamoniaNo ratings yet

- Genral Terms & ConditionsDocument23 pagesGenral Terms & Conditionsnambi.kumaresanNo ratings yet

- Osh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakFrom EverandOsh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakRating: 5 out of 5 stars5/5 (1)

- Global Floor ScreedDocument5 pagesGlobal Floor ScreedSantosoNo ratings yet

- Linde 1 - Wall-AngleDocument11 pagesLinde 1 - Wall-AnglepradeeshNo ratings yet

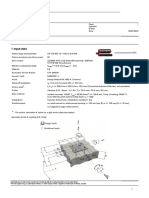

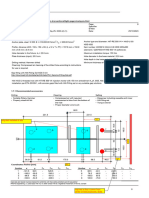

- Hilti PROFIS Engineering 3.0.88: WWW - hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/malaysia - HTMLDocument1 pageHilti PROFIS Engineering 3.0.88: WWW - hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/malaysia - HTMLSantosoNo ratings yet

- ABC CU4 - 6&7 May 2024Document7 pagesABC CU4 - 6&7 May 2024SantosoNo ratings yet

- Hilti PROFIS Engineering 3.0.88: WWW - hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/malaysia - HTMLDocument1 pageHilti PROFIS Engineering 3.0.88: WWW - hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/malaysia - HTMLSantosoNo ratings yet

- ABC EU4 - 11 June 2024Document6 pagesABC EU4 - 11 June 2024SantosoNo ratings yet

- 2008KlarRandolph - Laterally Loaded Piles Clays - Geot58-815Document6 pages2008KlarRandolph - Laterally Loaded Piles Clays - Geot58-815SantosoNo ratings yet

- 20221215-Circular ECM Scoring System - Final (Signed)Document4 pages20221215-Circular ECM Scoring System - Final (Signed)SantosoNo ratings yet

- Ivf and Icsi Consent FormDocument10 pagesIvf and Icsi Consent FormSantosoNo ratings yet

- Usr Local Temp PanelClinic C 79300 20230131091554239Document48 pagesUsr Local Temp PanelClinic C 79300 20230131091554239SantosoNo ratings yet

- Ay2022 2023Document2 pagesAy2022 2023SantosoNo ratings yet

- Prof (1) - Zahid Ahmad Siddiqi Formwork Design-IDocument53 pagesProf (1) - Zahid Ahmad Siddiqi Formwork Design-ISantosoNo ratings yet

- Financial Counseling For IVF (Resident)Document2 pagesFinancial Counseling For IVF (Resident)SantosoNo ratings yet

- Detail 61Document5 pagesDetail 61SantosoNo ratings yet

- Lec17 Bearing CapacityDocument57 pagesLec17 Bearing CapacityMuhammad EhtshamNo ratings yet

- 2006 Poulos Settlement Prediction PDFDocument22 pages2006 Poulos Settlement Prediction PDFSantosoNo ratings yet

- Design For NSF by Harry PoulosDocument7 pagesDesign For NSF by Harry PoulosSantosoNo ratings yet

- Lecture 4 - Jack-In PileDocument52 pagesLecture 4 - Jack-In PileAyingaran Thevathasan100% (3)

- Design of MicropilesDocument38 pagesDesign of MicropilesHRCNo ratings yet

- Typical Micropile Capacity (Eurocode)Document1 pageTypical Micropile Capacity (Eurocode)SantosoNo ratings yet

- Foundations - PE Civil Exam ReferenceDocument14 pagesFoundations - PE Civil Exam ReferenceSantosoNo ratings yet

- Negative Skin Friction and Settlement of Piles PDFDocument12 pagesNegative Skin Friction and Settlement of Piles PDFpkNo ratings yet

- Prof (1) - Zahid Ahmad Siddiqi Formwork Design-IIDocument30 pagesProf (1) - Zahid Ahmad Siddiqi Formwork Design-IISantosoNo ratings yet

- CE5107 HC 2011 L1b Handout - SupplementaryDocument6 pagesCE5107 HC 2011 L1b Handout - SupplementarySantosoNo ratings yet

- Design of Piles Using Euro Code-7Document29 pagesDesign of Piles Using Euro Code-7GEOMAHESH0% (1)

- Code ExcavationDocument115 pagesCode ExcavationHerschelSt100% (2)

- Deep ExcavationDocument34 pagesDeep ExcavationsafrasacmNo ratings yet

- Sure Stop PVC Waterstop BrochureDocument4 pagesSure Stop PVC Waterstop Brochurekiet eelNo ratings yet

- Differences Between CP4 and Eurocode 7: Background of Singapore Codes of PracticeDocument15 pagesDifferences Between CP4 and Eurocode 7: Background of Singapore Codes of PracticeSantosoNo ratings yet

- SX T Acrylic Gel: Injection Sealing MaterialDocument4 pagesSX T Acrylic Gel: Injection Sealing MaterialSantosoNo ratings yet

- Chapter 1.4Document11 pagesChapter 1.4Gie AndalNo ratings yet

- La Bugal-b'Laan Tribal Association Et - Al Vs Ramos Et - AlDocument6 pagesLa Bugal-b'Laan Tribal Association Et - Al Vs Ramos Et - AlMarlouis U. PlanasNo ratings yet

- VRIODocument3 pagesVRIOJane Apple BulanadiNo ratings yet

- Summary - A Short Course On Swing TradingDocument2 pagesSummary - A Short Course On Swing TradingsumonNo ratings yet

- Saic-M-2012 Rev 7 StructureDocument6 pagesSaic-M-2012 Rev 7 StructuremohamedqcNo ratings yet

- SCHEDULE OF FEES - FinalDocument1 pageSCHEDULE OF FEES - FinalAbhishek SunaNo ratings yet

- Chap 06 Ans Part 2Document18 pagesChap 06 Ans Part 2Janelle Joyce MuhiNo ratings yet

- 1 075 Syn4e PDFDocument2 pages1 075 Syn4e PDFSalvador FayssalNo ratings yet

- Gogte Institute of Technology: Karnatak Law Society'SDocument33 pagesGogte Institute of Technology: Karnatak Law Society'SjagaenatorNo ratings yet

- It14 Belotti PDFDocument37 pagesIt14 Belotti PDFHolis AdeNo ratings yet

- Applications of MathematicsDocument35 pagesApplications of MathematicsRamdas Sonawane100% (1)

- CW February 2013Document60 pagesCW February 2013Clint FosterNo ratings yet

- Marshall Baillieu: Ian Marshall Baillieu (Born 6 June 1937) Is A Former AustralianDocument3 pagesMarshall Baillieu: Ian Marshall Baillieu (Born 6 June 1937) Is A Former AustralianValenVidelaNo ratings yet

- Reverse Osmosis ProcessDocument10 pagesReverse Osmosis ProcessHeshamNo ratings yet

- Chapter 11 Walter Nicholson Microcenomic TheoryDocument15 pagesChapter 11 Walter Nicholson Microcenomic TheoryUmair QaziNo ratings yet

- Starrett 3812Document18 pagesStarrett 3812cdokepNo ratings yet

- Land Use Paln in La Trinidad BenguetDocument19 pagesLand Use Paln in La Trinidad BenguetErin FontanillaNo ratings yet

- Andrews C145385 Shareholders DebriefDocument9 pagesAndrews C145385 Shareholders DebriefmrdlbishtNo ratings yet

- Reflection Paper 1Document5 pagesReflection Paper 1Juliean Torres AkiatanNo ratings yet

- Central Banking and Monetary PolicyDocument13 pagesCentral Banking and Monetary PolicyLuisaNo ratings yet

- Rhino HammerDocument4 pagesRhino HammerMichael BNo ratings yet

- Divider Block Accessory LTR HowdenDocument4 pagesDivider Block Accessory LTR HowdenjasonNo ratings yet

- Faida WTP - Control PhilosophyDocument19 pagesFaida WTP - Control PhilosophyDelshad DuhokiNo ratings yet

- Seminar Report of Automatic Street Light: Presented byDocument14 pagesSeminar Report of Automatic Street Light: Presented byTeri Maa Ki100% (2)

- The Website Design Partnership FranchiseDocument5 pagesThe Website Design Partnership FranchiseCheryl MountainclearNo ratings yet

- Sem 4 - Minor 2Document6 pagesSem 4 - Minor 2Shashank Mani TripathiNo ratings yet

- 01 RFI Technical Form BiodataDocument8 pages01 RFI Technical Form BiodataRafiq RizkiNo ratings yet

- CoP - 6.0 - Emergency Management RequirementsDocument25 pagesCoP - 6.0 - Emergency Management RequirementsAnonymous y1pIqcNo ratings yet

- SDM Case AssignmentDocument15 pagesSDM Case Assignmentcharith sai t 122013601002No ratings yet

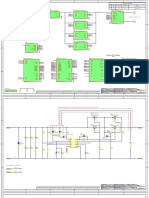

- Scheme Bidirectional DC-DC ConverterDocument16 pagesScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaNo ratings yet