Professional Documents

Culture Documents

Effect of Flowrate and Circulation Time On Fractionation of Refined Bleached and Deodorised Palm Oil Using Progressive Freeze Concentration Method

Uploaded by

Fachri BachtiarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Flowrate and Circulation Time On Fractionation of Refined Bleached and Deodorised Palm Oil Using Progressive Freeze Concentration Method

Uploaded by

Fachri BachtiarCopyright:

Available Formats

1 Mazura Jusoh et al.

/ Jurnal Teknologi (Sciences & Engineering) 67:3 (2014), 117–122

Jurnal Full paper

Teknologi

Effect of Flowrate and Circulation Time on Fractionation of Refined

Bleached and Deodorised Palm Oil using Progressive Freeze Concentration

Method

Mazura Jusoh*, Norshafika Yahya, Zaki Yamani Zakaria

Chemical Engineering Department, Faculty of Chemical Engineering, Universiti Teknologi Malaysia, 81310 UTM Johor Bahru, Johor, Malaysia

*Corresponding author: mazura@cheme.utm.my

Article history Abstract

Received :23 October 2013 This research concerns on the possibility of separating refined, bleached and deodorised palm oil (RBDPO)

Received in revised form : into olein and stearin using another alternative through Progressive Freeze Concentration (PFC) to replace

14 December 2013 the conventional process of dry fractionation. The process was carried out in stainless steel coil crystalliser

Accepted :10 January 2014 and the quality of olein and stearin and the performance of crystalliser to purify the olein were analysed.

The quality of oil was evaluated through iodine value (IV) and Slip Melting Point (SMP), while for the

performance of PFC, effective partition constant, K, and yield of olein were used to determine the system

efficiency. The purified olein were obtained for IV and SMP at higher flowrate (2800 mL/min) and longer

period of time (60 min) are 55.87wijs and 23.04°C, 55.89wijs and 23.08°C, respectively. Meanwhile, the

best K and yield of olein were obtained at higher flowrate and time, giving values of 0.2369, 67.99% and

0.238 and 67.93%, respectively.

Keywords: Progressive freeze concentration; palm oil; refined bleached and deodorised palm oil; iodine

value; slip melting point; crystallization

Abstrak

Kajian ini tertumpu kepada kebolehan pemisahan bagi minyak kelapa sawit yang ditapis, diluntur dan

dinyah bau (RBDPO) kepada olein dan stearin menggunakan alternatif lain melalui Pemekatan Pembekuan

Progresif (PFC) untuk menggantikan proses pemisahan konvensional. Proses ini telah dijalankan di dalam

penghablur gegelung keluli tahan karat dan kualiti olein dan stearin dan prestasi penghablur untuk ketulenan

olein telah dianalisis. Kualiti minyak telah dinilai melalui Nilai Iodin (IV) danTakat Lebur Gelincir (SMP),

manakala bagi pelaksanaan PFC, pemalar permisahan berkesan, K dan hasil olein telah digunakan untuk

menentukan kecekapan sistem. Olein yang tulen diperolehi bagi IV dan SMP pada kadar aliran yang lebih

tinggi (2800 mL/min) dan tempoh masa yang lebih lama (60 min) pada 55.87 wijs dan 23.04°C, 55.89 wijs

dan 23.08°C. Sementara itu, K terbaik dan hasil olein telah diperolehi pada kadar aliran dan masa yang

lebih tinggi memberikan nilai sehingga 0.2369, 67.99% dan 0.238 dan 67.93% masing-masing.

Kata kunci: Pemekatan pembekuan progresif; minyak kelapa sawit; minyak kelapa sawit yang ditapis;

diluntur dan dinyah bau; nilai iodin; takat lebur gelincir; penghabluran

© 2014 Penerbit UTM Press. All rights reserved.

1.0 INTRODUCTION fractionation is the most common process used, which involves

crystallisation of olein at its freezing/melting temperature (20-

Palm oil is one of the well-known edible oils worldwide besides 24°C).2 Dry fractionation is mostly used in Malaysia’s refinery

coconut oil, palm kernel, or olive oil, which is used as raw industries because of its own advantages in the process compared

material for food or non-food industries. Prior to consumption as to detergent and solvent fractionation. In particular, solvent and

edible oil, crude palm oil has to go through various processes detergent fractionation required a greater capital investment than

including refining, bleaching, deodorizing and finally dry fractionation3 and dry fractionation only requires crystalliser,

fractionation.1 There are three types of fractionation, which are filter and washing unit.

dry fractionation, detergent fractionation, and solvent The fractionation process is more or less similar to a process

fractionation. Among the three fractionation processes, dry known as suspension freeze concentration (SFC), which is a

67:3 (2014) 117–122 | www.jurnalteknologi.utm.my | eISSN 2180–3722 |

118 Mazura Jusoh et al. / Jurnal Teknologi (Sciences & Engineering) 67:3 (2014), 117–122

process of aqueous solution concentration, where water

molecules are crystallised out as a suspension in the mother

liquor, whilst leaving behind a more concentrated solution. 3SFC

is a process based on melt crystallisation principle where

substance with higher melting/freezing point in the mixture

would be crystallised first by bringing down the temperature of

the mixture/solution to the melting/freezing point while stirring.

This will eventually leave behind the substance with lower

melting/freezing temperature in the form of mother liquor and the

substances of higher melting/freezing point in solid form.4

In this type of crystallization process, subsequent processes

to obtain optimum separation of the crystals from the solution

involve several unit operations including filters and washers,

which add to the capital investment. Therefore, another Figure 1 Coil crystallizer

alternative method called progressive freeze concentration (PFC)

could provide a better alternative. PFC is also a process which

uses the concept of melt crystallisation where the separation

occurs based on melting point of crystal. The component with

higher melting pointis firstly crystallised layer by layer from

themixture and a single block of crystal will be produced at the

end of the process.5 Meanwhile, the component with lower

melting point will remain in liquid form. Separation of crystals is

then easier, just by draining off the resulted concentrate from the

system. In fractionation of palm oil, the entity that would be

crystallised is the stearin, which would leave behind a more

purified olein.

Although the process is simpler, the problem faced by PFC

Figure 2 Stainless steel

is that it gives lower productivity. This research assess the

performance of a relatively new design of crystalliser for PFC

process in separating olein from refined, bleached and deodorized

After that, the process was proceeded to a designated

palm oil (RBDPO). In addition, it is a simpler and cheaper

analysis on the effect of circulation flowrate, in which the

alternative for fractionation of palm oil.

circulation flowrate were varied from 2000 ml/min to 2800

ml/min, while circulation time, initial IV and water temperature

were fixed at 60 minutes, 52.5 wijs and 28°C, respectively. The

2.0 EXPERIMENTAL fixed value of circulation time and water temperature were

selected based on the best results obtained from the preliminary

The crystalliser is called a coil crystalliser (CC), that could

screening, meanwhile the standard initial IVof 52.5 wijs used in

provide higher productivity and efficiency for progressive freeze

refinery industry of palm oil was chosen as the fixed value of

concentration process due toits higher surface area. For this study,

initial IV for this study.7 In addition, the melting point of olein

the CC made of stainless steel as shown in Figure 1 and 2 was

and sterinare 48°C and 24°C, respectively.2 The circulation

used to carry out the separation process of RBDPO. Before the

flowrate of RBDPO from 2000 ml/min to2800 ml/min in CC

real experiment was carried out, preliminary screening

would cause the formation of stearin layer at the inner wall

experiment was carried out to determine the suitable range of two

surface of the CC and leaving behind a more purified olein. The

parameters which are circulation flowrate and time. The range of

process was also carried out at different circulation times ranging

these parameters was also considered based on the extensive

from 40 to 60 minutes and the other three parameters were fixed

reading from previous literature.

at circulation flowrate of 2800 ml/min, initial IV of 52.5 wijs and

To start the operation, RBDPO obtained from a local palm

water temperature of 28°C.

oil refinery was pumped by a peristaltic pump into the CC. After

Throughout the process, eight different points of the CC

the CC was filled with RBDPO; the CC was then immersed in a

were equipped with thermocouples to measure the temperature of

water bath. The CC was connected to a peristaltic pump via

the water, the RBDPO and the CC wall. The measured data was

silicone tube and the RBDPO was circulated in the system for a

logged to the computer via PicoLog recorder for easy process

period of time. Before circulating at the desired temperature, the

monitoring. After the desired temperature has been reached for a

CC which is full of RBDPO must firstly be heated at a

certain period of time, the circulation was stopped and the

temperature of 70°C to avoid the formation of unwanted crystal

purified olein was drained out, which leaves behind the stearin

and to remove previous thermal history.6

layer as shown in Figure 3, which has to be melted or thawed and

analysed for its purity. For the next experiment, the CC was

flushed with hot water. The temperature of the waterbath then

will be increased to 48°C to enable the stearin to melt and detach

from the CC wall. The experimental set-up is shown in Figure 4.

67:3 (2014) 117–122 | www.jurnalteknologi.utm.my | eISSN 2180–3722 |

119 Mazura Jusoh et al. / Jurnal Teknologi (Sciences & Engineering) 67:3 (2014), 117–122

where,

C= Concentration of sodium thiosulfate solution (mole

L-1);

V1= Volume (mL) of sodium thiosulfate solution for

The blank test;

V2= Volume (mL) of sodium thiosulfate solution for

The sample; and

m= Mass(g) of the sample

The determination of IV is crucial to give a measurement of

unsaturated oil, and saponification value, which will give a

measure of the average molecular weight of the constituent fatty

acid. The lower fatty acid in the palm oil gives better quality and

high IV olein.13 Meanwhile SMP is defined as the temperature of

a column of fat in an opened capillary tube, which moves up when

it is subjected to a controlled heating in waterbath. Palm oil

consists of fats that have a complex mixture of glycerides,

therefore does not have sharp melting points, unlike pure

Figure 3 Close-up of stearin crystal layer formed

chemical substance.

All the graphs below show the results of IV and SMP in palm

olein and palm stearin as affected by circulation flowrate and

circulation time. The data collected is a little bit different from

the standard reference of dry fractionation but is still acceptable

according to the trend when the data is plotted.

Usually the standard reference data collected from Palm Oil

Research Institute of Malaysia (PORIM) for IV olein is 56.0-57.0

wijs, IV stearin is 33.0-48.0 wijs, SMP olein is 24.0-19.9oC, and

SMP stearin is 53.4-44oC.7,10,14 The less satisfactory data might

due to the fact that the final product was not filter pressed due to

the high cost of the filter press and a multicomponent melt may

fail to produce a pure crystalline product at a single stage. This

phenomenon can be best described either by the incorporation of

Figure 4 Experimental setup impurities into the growing crystals due to kinetic effect or an

equilibrium distribution of impurities in the liquid and the

crystalline phase (thermodynamic)15 Hence, recrystallization step

3.0 RESULTS AND DISCUSSION which could increase the purity of crystal is required in order to

obtain a pure product. If the solubility of the crystal component

In this study, the quality of palm oil was determined by iodine decreases considerably with the decreasing temperature, a high

value (IV) and slip melting point (SMP) while the efficiency of yield can be expected.

PFC system was determined by yield and effective partition In Figure 5 and Figure 6, IV and SMP for palm olein and

constant, K. The yield and K of the product could be influenced stearin are plotted against circulation flowrate. The trend for IV

by the type of fractionation process, cooling rates, temperature of data is in contrast with SMP data for both olein and stearin. It

fractionation,6 circulation time and circulation flowrates. The appears that, high circulation flowrate gives high olein IV and

quality of oil is measured based on the degree of unsaturation or low stearinIV, which opposes the SMP result where high

double bond of oils and fats, as indicated by the IV. It also circulation flowrate gives low SMP of olein and high SMP of

indicates the ease of oxidation of oils and fats.8 Meanwhile, the stearin. The crystallization of fat is a slow process due to the high

SMP is an indicator to measure the characteristic of the melting viscosity of liquid fat and relatively a large size of molecule, so

and solidification properties of oils and fats. The chain length of the process needs at high flowrate in order to make a pure

fatty acids, trans fatty acid content, unsaturation rations, and the crystalline product.

position fatty acids in glycerol backbone are changed relying on

the value of SMP.9 Other than that, the SMP of fat is an important

attribute of many specification trade of quality oil and in some

country it is an element of the legal definition of food product.10

A. Quality of Palm Oil

Quality of palm oil relies on the IV and SMP of olein and stearin.

The IV olein and stearin were measured using MPOB Test

Methods of p3.2-2004 and p4.2:2004,11 respectively. The p3.2-

2004 method is technically equivalent to ISO 3961:1996, while

MPOB Test Method p4.2-2004 is originated from AOCS Official

Method Cc3-25.12The IV is calculated by the following equation:

𝑔 12.69𝐶 (𝑉1 − 𝑉2 )

𝐼𝑉 ( )= (1)

100𝑔 𝑚

67:3 (2014) 117–122 | www.jurnalteknologi.utm.my | eISSN 2180–3722 |

120 Mazura Jusoh et al. / Jurnal Teknologi (Sciences & Engineering) 67:3 (2014), 117–122

gives high IV for olein and low for stearin of55.89 wijs and 23.1

wijs 45.32°C, respectively, as illustrated in Figure 7. Meanwhile

in Figure 8, it is shown that circulation time of 60 minutes gives

a low value of SMP for olein and high value of SMP for stearin

of 45.32°C and 51.63°C, respectively. Besides, it appears that low

circulation time results in a low IV olein, low SMP stearin, high

IV stearin and high SMP olein. This is in agreement with the

findings from previous researchers, where it was found that for

palm olein, it is evident that the short tempering period does not

always allow adequate crystallization of RBDPO. It was also

mentioned that 1 hour is proven to be insufficient but 8 hours or

more is adequate for complete crystallization.11

Nevertheless, this studied process is using a completely

different equipment and the circumstantial of equipment

distinguishes the operating condition for circulation or tempering

time. Therefore, if the longer circulation time is used in this

process, more crystalline solid will be developed on the inner wall

surface of the crystalliser.

Figure 5 Iodine value for olein and stearin versus circulation flowrate Compared to the previous research which used dry fractionation,

the results from PFC in this research are still highly acceptable in

terms of IV and SMP.16

55

50

Slip Melting Point ( C)

45

o

40

Olein

Stearin

35

30

25

20

1800 2000 2200 2400 2600 2800 3000

Circulation Flowrate (ml/min)

Figure 6 Slip melting point for olein and stearin versus circulation

flowrate

Figure 7 Iodine value for olein and stearin versus circulation time

Although the process of this fractionation needs a high

flowrate, the higher flowrate of 3000ml/min and above would

give insufficient result of olein and stearin due to entrapment of 55

olein in the stearin crystal layer and this would dramatically break

50

down the crystal of stearin aggregates according to the

preliminary experiments carried out.

45

Slip Melting Point( C)

Fractionation of RBDPO into olein and stearin is classified

o

as fractional crystallization from the melt. Therefore, to develop

40

crystalline phase into the high growing crystals, a fast kinetic

(nucleation and growth) effect is a vital role as important 35

Olein

Stearin

parameter in crystallization from the melt. The flow of slurry or

RBDPO creates an optimal supersaturation and rates of 30

nucleation and growth. It also enhances the heat transfer between

the RBDPO and the cooling surface, while giving the optimal 25

rates of crystal growth and producing a compact layer of suitable

morphology and sufficient purified of olein and thus achieving 20

high IV.15 However, it is necessary to handle the flowrate at only 35 40 45 50 55 60 65

certain desired flowrate and not too high due to small diameter of Circulation Time (min)

the crystallizer only about 0.8 mm. The liquid olein might be Figure 8 Slip melting point for olein and stearin versus circulation time

trapped in the crystal layer of stearin, which could result in less

pure stearin layer.

A long circulation time is needed to completely build the

crystal layer of stearin, which would result in a complete

separation of olein and stearin. Circulation time of 60 minutes

67:3 (2014) 117–122 | www.jurnalteknologi.utm.my | eISSN 2180–3722 |

121 Mazura Jusoh et al. / Jurnal Teknologi (Sciences & Engineering) 67:3 (2014), 117–122

B. Effect of Operating Condition on Yield and K together and will strongly build the triglyceride (palmitic acid)

bone according to the different melting point.

The quality of palm oil and effectiveness of the process of PFC Furthermore, olein in the mother liquor of RBDPO is prone

depends on the value of yield and effective partition constant, K. to entrapment in the stearin crystal layer, thus increasing the

This correlation of yield and K relies on circulation flowrate and concentration of stearin and produces higher K value. K value is

circulation of time. This research also focuses on the yield of found to be inversely proportional to the circulation flowrate and

olein rather than yield of stearin because olein is the premium circulation time.

product of RBDPO fractionation.

Palm oil is a highly efficient producer of vegetable oil

compared to other vegetable oil crops.17 Hence, it is significant to

measure the yield of olein in order to know the finest and best

quality palm olein based on the manipulated operating condition

of circulation flowrate and time. The yield is calculated by using

the following equation:

(2)

Results for yield and K against circulation flowrate and

circulation time are plotted in the graphs below. Figures 9 and 10

show that the yield becomes higher when circulation flowrate and

circulation time are increased. This obeys the theory which

indicates that the yield has a correlation with flowrate and time,

where a better yield needs a high range of flowrate and long

operation time. The common yield of olein from dry fractionation

or conventional fractionation using vacuum suction filter gives a Figure 9 Yieldof olein and K-value against circulation flowrate

yield of 65-68%.18 Therefore, the results obtained from this study

are completely acceptable.

The speed of RBDPO going through the CC during

operation will affect the end product, if the speed is too slow, the

slurry or stearin crystal layer will become hard and brittle as the

fat is cooled rapidly when it touches the wall of the crystalliser.

Meanwhile, if it is too fast, the crystals would attach to each other

instead of orientating themselves in the right position.19 On the

other hand, too high or too slow of a feeding and circulation

flowrate gives insufficient cooling, promoting post-

crystallization, weak triglyceride backbone or hardening.20

In Figure 9, high yield is shown at flowrate of 2800 ml/min,

thus is the best and the most suitable flowrate for this process.

Meanwhile from Figure 10, it is evident that the higher yield

(67.92%) is obtained at 60 minutes of circulation time. Similar to

circulation flowrate, in order to get high yield of olein, longer

contact time is required.

In PFC system, the effective partition constant, K is a crucial Figure 10 Yieldof olein and K-value against circulation time

indication of successful separation. From the K value, the

performance of the PFC system can be evaluated. The values of

K are calculated using the equation21 below: 4.0 CONCLUSION

K=1-[(log(Co/CL))/(log(VL/Vo))] (3) Fractionation of RBDPO through PFC system is completely

different from the conventional system but the process still relies

where Co is concentration of the initial solution of RBDPO, CL is on the influence of circulation flowrate and circulation time

concentration of the purified olein, Vo is the initial volume of which possibly can produce the best quality at the flowrate of

RBDPO, and VL is the volume of purified liquid (olein). But 2800ml/min and circulation time of 60 minutes. Meanwhile,

before calculation, firstly the concentration of solute is calculated higher percentage of yield at 66-68% is obtained for both

based on the percentage of C18:1 (oleic acid), which is commonly operating parameter. For IV and SMP, the result obeys the quality

high in palm olein. of palm based-standard reference, thus could serve as an

It is found that K decreases with increasing circulation attractive alternative for fractionation of RBDPO.

flowrate and time as illustrated in Figure 9 and Figure 10. The

best performance is at flowrate of 2800 ml/min and 60 minutes

Acknowledgement

circulation time. Higher growth rate and nucleation of stearin

crystal is caused by high flowrate and long circulation time which

The financial supports from the Government of Malaysia and

is undesirable to produce a low K value for this system. The

Universiti Teknologi Malaysia through research grants are highly

higher the crystal growth rate, the more stearin would be trapped

appreciated.

67:3 (2014) 117–122 | www.jurnalteknologi.utm.my | eISSN 2180–3722 |

122 Mazura Jusoh et al. / Jurnal Teknologi (Sciences & Engineering) 67:3 (2014), 117–122

References [11] Berger, K. Siew, W., Oh, F. 1982. Factors Affecting Slip Melting Point

of Palm Oil Products. J. Am. Oil Chem. Soc. 59: 244–249.

[1] Morad, N. A., Aziz, A. M. K. andMohdZin, R. 2006. Process Design in [12] Ainie, K., Siew, W. L., Tan, Y. A. 2004. Test Methods-A Compendium

Degumming and Bleaching of Palm Oil. UniversitiTeknologi Malaysia. of Test on Palm Kernel Products, Fatty Acids, Food Related Products

[2] Chong, C. L. Ed. 1993. Selected Reading On Palm Oil And Its Uses. and Others. Malaysian Palm Oil Board, Selangor.

Palm Oil Research Institute of Malaysia (PORIM). [13] Firestone, D. 1998. Offical Method and Recommended Practices of the

[3] Hamm, W. 2005. Fractionation Technology [Online]. United Kingdom: AOCS. In: cd, t. (ed.) Am.Oil Chem. Soc., Champaign.

http://www.britanniafood.com/english/invite_03.htm. [Accessed]. [14] Rossell, J. B., King, B., Downes, M. J. 1985. Composition Oil. J. Am.

[4] Jusoh, M., MohdYunus, R. and Abu Hassan M. A. 2008. Development Soc. 62: 221–230.

of a New Crystallisation Chamber for a Progressive Freeze [15] Toyokura, K.,Hirasawa, I.,Wintermantel,K.,Wellinghoff, G. 1995.

Concentration. Rec. Adv. in Tech. 33: 588–599. Crystallization from The Melt. In: Mersmann, A. (ed.) Crystal. Tech.

[5] Jusoh, M., Mohd Yunus, R. and Abu Hassan M. A. 2008. Effect of Handbook. Marcel Dekkar, Inc.

Flowrate and Coolant Temperature on The Efficiency of Progressive [16] Jacobsberg,B., Ho, O. C. 1976. Studies in Palm Oil Crystallization. J.

Freeze Concentration on Simulated Wastewater. World Academy of Sc. Am. Oil Chem. Soc. 53: 609–617.

Eng.& Tech. 47: 75–78. [17] Basiron, Y. 2005. Palm Oil. Bailey's Industrial Oil and Fat Products.

[6] Siew, W. L., Ng. W.-L. 1996. Crystallisation Behaviour of Palm Oleins. John Wiley & Sons, Inc.

Elaeis. PORIM. 8: 75–82. [18] Nagendran, B. 1997. Introduction to Production and Processing of Palm

[7] Azmil Haizam, A. T., Siew, W. L. and Ainie, K. 2008. Palm-based Oil. Agrabad Hotel Chittagong: (PORIM).

Standard Reference Material for Iodine Value and Slip Melting Point. [19] Timms, R. E. 1994. Physical Chemistry of Fats. In: Moran, D. P. &

Analytical Chemistry. 3: 127–133. Rajah, K. K. (eds.) Fats in Food Products. Blackie A&P, London,

[8] Siew, W. L., Ng. W.-L. 1995. Partition Coefficient of Diglycerides in Glasgow, New York, Tokyo, Melbourne, Madras.

Crystallization of Palm Oil. J. Am. Oil Chem. Soc. 72: 591–595. [20] Miskandar, M. S., Nor Aini, I. 1999. Properties of Palm Oil Margerine

[9] Incorporated, G. W. Iodine Value with Model 412 [Online]. During Stearin: Effects of Processing Condition. Kuala Lumpur:

http://www.guided-wave.com/support/notes/. [Accessed 9 May 2011]. Malaysia Palm Oil Board.

[10] Karabulut, I., Turan, S., Ergin, G. 2004. Effect of Chemical [21] Miyawaki, O., Liu, L., Shirai, Y., Sakashita, S. and Kagitani, K. 2005.

Interestification on Solid Fat Content and Slip Melting Point of Fat/Oil Tubular Ice System for Scale-Up of Progressive Freeze-Concentration.

Blends. Europ. F. Res. and Tech. 218: 224–9. Journal of Food Engineering. 69(1): 107–113.

67:3 (2014) 117–122 | www.jurnalteknologi.utm.my | eISSN 2180–3722 |

You might also like

- Single Effect Vs Double EffectDocument11 pagesSingle Effect Vs Double EffectNallasivam Be A BizzaroNo ratings yet

- FM FM: Preparing For Flood PotentialDocument12 pagesFM FM: Preparing For Flood PotentialFachri BachtiarNo ratings yet

- Die Maintenance Handbook (2001) PDFDocument426 pagesDie Maintenance Handbook (2001) PDFFachri Bachtiar0% (1)

- Frank D Gunstone - Lipid Technologi PDFDocument849 pagesFrank D Gunstone - Lipid Technologi PDFFachri Bachtiar100% (1)

- Innovative Palm Oil Solutions PDFDocument8 pagesInnovative Palm Oil Solutions PDFDedy Rikolvman SimangunsongNo ratings yet

- Single Effect Vs Double EffectDocument11 pagesSingle Effect Vs Double EffectNallasivam Be A BizzaroNo ratings yet

- Muhammad Fachri Bachtiar Instalasi Rumah + Ac 2212039017Document2 pagesMuhammad Fachri Bachtiar Instalasi Rumah + Ac 2212039017Fachri BachtiarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 3 - Part 1 RefiningDocument46 pagesChapter 3 - Part 1 RefiningAzhan FikriNo ratings yet

- PD Ca (ClO) 2Document3 pagesPD Ca (ClO) 2Michelle MendozaNo ratings yet

- 4 - CHAPTER With NumericalsDocument356 pages4 - CHAPTER With NumericalsSindhuja PachikaNo ratings yet

- Agro Waste Materials - NiyalDocument12 pagesAgro Waste Materials - NiyalHyjan JacobNo ratings yet

- Alcohols: - Structure and BondingDocument49 pagesAlcohols: - Structure and BondingJackson UdumaNo ratings yet

- Ansi - Agma 2007-C00 - 06Document14 pagesAnsi - Agma 2007-C00 - 06gkhn100% (2)

- Moores Test and Barfoeds TestDocument3 pagesMoores Test and Barfoeds TestFrancis CaloNo ratings yet

- Microbiology With Diseases by Taxonomy 4th Edition Bauman Test Bank 1Document538 pagesMicrobiology With Diseases by Taxonomy 4th Edition Bauman Test Bank 1ricardo100% (46)

- Technical Data Sheet: For Further Information Regarding This Product Please Refer To: Tel: +49 6108 919 394Document1 pageTechnical Data Sheet: For Further Information Regarding This Product Please Refer To: Tel: +49 6108 919 394sarhan yasmenNo ratings yet

- d1291 Estimation of Cl2 Demand in WaterDocument4 pagesd1291 Estimation of Cl2 Demand in WaterArunkumar ChandaranNo ratings yet

- Experiment 1 A Silly PolymerDocument3 pagesExperiment 1 A Silly PolymerRuby GoNo ratings yet

- Biochem Pre-Lab 3bDocument2 pagesBiochem Pre-Lab 3bOla Anna GamutinNo ratings yet

- Linus Pauling PublicationsDocument108 pagesLinus Pauling PublicationsFilipos ConstantinNo ratings yet

- Aldehydes and Ketones-02 Solved ProblemsDocument13 pagesAldehydes and Ketones-02 Solved ProblemsRaju SinghNo ratings yet

- General Discussion of Lanthenides and ActinidesDocument53 pagesGeneral Discussion of Lanthenides and ActinidesFaraz SiddiquiNo ratings yet

- CHAPTER 1 Importance of PetrochemicalDocument40 pagesCHAPTER 1 Importance of PetrochemicalSyahmiNo ratings yet

- 2016 Book NewApproachesToBuildingPatholo PDFDocument214 pages2016 Book NewApproachesToBuildingPatholo PDFCarlos Augusto Sanchez RondonNo ratings yet

- BR Matacryl WS - GBDocument4 pagesBR Matacryl WS - GBNevena DelibasicNo ratings yet

- Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDocument17 pagesProf. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyNo ratings yet

- Fermentation and Distillation of Corn StarchDocument9 pagesFermentation and Distillation of Corn StarchI. Murali Krishna100% (1)

- Emulsions - Formation, Stability, Industrial Applications PDFDocument243 pagesEmulsions - Formation, Stability, Industrial Applications PDFsandy44 wankhade100% (4)

- AyushDocument19 pagesAyushgourang asatiNo ratings yet

- June 2017 Question Paper 21Document20 pagesJune 2017 Question Paper 21KaifNo ratings yet

- Introduction To Drilling FluidsDocument23 pagesIntroduction To Drilling FluidszeidisuckNo ratings yet

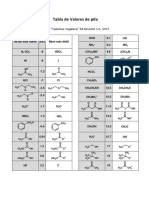

- Tabla de Valores de Pka: S. Ege "Química Orgánica" Ed Reverté S.A. 1997Document7 pagesTabla de Valores de Pka: S. Ege "Química Orgánica" Ed Reverté S.A. 1997loaca95No ratings yet

- SCOPE 21 - The Major Biogeochemical Cycles and Their InteractionsDocument205 pagesSCOPE 21 - The Major Biogeochemical Cycles and Their InteractionsAlina JalbaNo ratings yet

- PLATINGDocument1 pagePLATINGdineshNo ratings yet

- Chem 10 PDFDocument17 pagesChem 10 PDFDishank AgrawalNo ratings yet

- Isolite MSDS - 1400 SeriesDocument8 pagesIsolite MSDS - 1400 SeriesMashudi FikriNo ratings yet

- CY1001-2015 Inorganic Lecture NotesDocument16 pagesCY1001-2015 Inorganic Lecture NotesCreative ThinkerNo ratings yet