Professional Documents

Culture Documents

C - Program Files - Documents and Settings - All Users - Gerencia Dieselmotor - Mis Documentos - GERENCIA - TESTSPEC - TESTSPEC - 01EJ0081 PDF

C - Program Files - Documents and Settings - All Users - Gerencia Dieselmotor - Mis Documentos - GERENCIA - TESTSPEC - TESTSPEC - 01EJ0081 PDF

Uploaded by

Miguel RojasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C - Program Files - Documents and Settings - All Users - Gerencia Dieselmotor - Mis Documentos - GERENCIA - TESTSPEC - TESTSPEC - 01EJ0081 PDF

C - Program Files - Documents and Settings - All Users - Gerencia Dieselmotor - Mis Documentos - GERENCIA - TESTSPEC - TESTSPEC - 01EJ0081 PDF

Uploaded by

Miguel RojasCopyright:

Available Formats

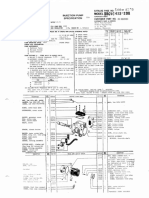

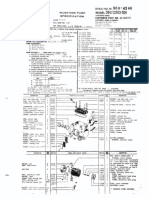

INJECTION PUMP TEST SPECIFICATIONS 096500-0080

096500-008# Governor Electronical control

INJECTION PUMP (VE4/10E2200RND008) Timer Electronical control

MANUFACTURER TOYOTA Rated Voltage 14 V

ENGINE TYPE 2L-TE Rotation Clockwise viewed from drive side

VEHICLE MODEL HILUX Injection Order A-B-C-D

Pump Select Switch No. (ECD Controller) 3 Injection Interval 90°

1. TEST CONDITIONS

1) Nozzle 093400-0540 (DN12SD12A) 4) Feed Pressure 0.2 kgf/cm2

2) Nozzle Opening Pressure 150 ± 1 kgf/cm2 5) High Pressure Pipe Ø2 × Ø6 × 840 mm

3) Test Oil SAE J967 (ISO4113) 6) Fuel Temperature 40 - 43 °C (104 - 109.4 °F)

2. BREAK-IN DRIVE

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty FCV Condition Remarks

(rpm) Selector Quantity Ratio Switch

Command Command

No fuel leaks, no abnormal

1200 — 580 — — noise, and no abnormal Drive more than 5 minutes.

temperature rising.

3. INSPECTION OF FUEL TEMPERATURE SENSOR — : Not Applicable

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty FCV Sensor Resistance Remarks

(rpm) Selector Quantity Ratio Switch (k )

Command Command

— — — — — — —

4. INSPECTION OF Ne SENSOR

ECD CONTROLLER SETTING

Pump Sensor Output

Speed Display Injection Duty FCV Voltage Remarks

(rpm) Selector Quantity Ratio Switch (V)

Command Command

50 Np — — — 0.1 or more

5. ADJUSTMENT OF PUMP INTERNAL PRESSURE

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty FCV Internal Pressure

(kgf/cm2) Remarks

(rpm) Selector Quantity Ratio Switch

Command Command

2000 — 4DB 0 — 8.3 ± 0.2

1200 — 580 0 — 7.2 ± 0.4

50 — 6E0 0 — 2.0 or more

6. OVERFLOW QUANTITY CHECK

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty Ratio FCV Overflow Quantity

(cc/1000st) Remarks

(rpm) Selector Quantity Command Switch

Command

The overflow valve belonging to the

2000 — 4DB 0 — 150 - 250 pump should be used for checking.

096500-0080

7. ADJUSTMENT OF TIMER

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty FCV Timer Stroke

(mm) Remarks

(rpm) Selector Quantity Ratio Switch

Command Command

1200 — 580 0 — 9.4 ± 0.4 Select shim

30 — 5.4 ± 1.0

1200 — 580 60 — 1.5 ± 0.9

100 — 0

200 — 6E0 0 — 3.6 or more

2000 — 4DB 0 — 10.3 ± 0.4

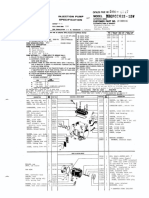

8. ADJUSTMENT OF FUEL DELIVERY

ECD CONTROLLER SETTING Max.

Pump Delivery Spread

Speed Display Injection Duty FCV Quantity Remarks

In Delivery

(rpm) Selector Quantity Ratio Switch (cc/200st) (cc)

Command Command

350 — 55E 0 — 2.6 ± 0.2 0.5 By replacing correction resistor

2000 — 4DB 0 — 12.9 ± 0.3 0.7 By adjusting screw

1200 — 580 0 — 14.2 ± 0.4 0.6

2400 — 2A4 0 — 5.3 ± 1.5 —

100 — 6E0 0 — 14.8 ± 1.2 1.4

600 — 5C5 0 — 11.1 ± 0.5 0.7

850 — 517 0 — 7.2 ± 0.4 —

1900 — 170 0 — 0.8 or less —

2450 — 16C 0 — 4.8 or less —

Correction Resistor

Resistance Value Mark Parts No. Resistance Value Mark Parts No.

(k ) (Last 3 Digits) (k ) (Last 3 Digits)

0.154 001 096526-0011 0.681 017 096526-0171

0.174 002 096526-0021 0.732 018 096526-0181

0.196 003 096526-0031 0.782 019 096526-0191

0.221 004 096526-0041 0.866 020 096526-0201

0.243 005 096526-0051 0.931 021 096526-0211

0.267 006 096526-0061 1.020 022 096526-0221

0.294 007 096526-0071 1.100 023 096526-0231

0.316 008 096526-0081 1.210 024 096526-0241

0.348 009 096526-0091 1.330 025 096526-0251

0.383 010 096526-0101 1.430 026 096526-0261

0.412 011 096526-0111 1.580 027 096526-0270

0.453 012 096526-0121 1.780 028 096526-0281

0.487 013 096526-0131 1.960 029 096526-0291

0.523 014 096526-0141 2.210 030 096526-0301

0.576 015 096526-0151 2.490 031 096526-0311

0.619 016 096526-0161

NOTE :

When the resistance value of correction resistor is raised by 1 level, the injection quantity is increased as follows,

0.08 cc/200st (pump speed at 350 rpm), 0.12 cc/200st (pump speed at 1000 rpm).

096500-0080

9. INSPECTION OF FUEL CUT SOLENOID — : Not Applicable

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty FCV Remarks

(rpm) Selector Quantity Ratio Switch

Command Command

— — — — — —

10. ADJUSTMENT OF CAM ANGLE

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty Ratio FCV Cam Angle Remarks

(rpm) Selector Quantity Command Switch (°)

Command

CAM

350 ANGLE 55E 100 — Shown in display

Adjustment :

Select the cam angle correction resistor ( ) so that the difference between the cam angle shown on display and CA in the

table below is -0.5 to 0.5.

CA Correction Resistor Resistance Value CA Correction Resistor Resistance Value

(°) Parts No. (k ) (°) Parts No. (k )

2.68 096525-0230 0.068 5.93 096525-0081 0.453

3.07 096525-0240 0.085 6.09 096525-0091 0.487

3.30 096525-0250 0.100 6.32 096525-0101 0.523

3.42 096525-0260 0.121 6.49 096525-0111 0.576

3.64 096525-0270 0.133 6.72 096525-0121 0.619

3.83 096525-0280 0.154 6.89 096525-0131 0.681

4.03 096525-0290 0.174 7.06 096525-0141 0.732

4.24 096525-0300 0.196 7.23 096525-0151 0.787

4.42 096525-0310 0.221 7.28 096525-0161 0.866

4.61 096525-0011 0.243 7.45 096525-0171 0.931

4.80 096525-0021 0.267 7.66 096525-0181 1.020

4.95 096525-0031 0.294 7.82 096525-0191 1.100

5.16 096525-0041 0.316 8.03 096525-0201 1.210

5.38 096525-0051 0.348 8.23 096525-0211 1.330

5.54 096525-0061 0.384 8.37 096525-0221 1.430

5.76 096525-0071 0.412

11. SERVICE STANDARD

Dimension KF (mm) : 5.8 - 6.0 Drive Shaft Diameter (mm) : Ø 20

Dimension K (mm) : 3.3 ± 0.1 Delivery Valve Holder Installation Torque (kgf m) : 5.5 - 6.5

Timing mark re-marking position : Based on cylinder A, cam lift distance (plunger) should be 2.44 mm

12. NOTES FOR ADJUSTMENT

Keep the height of the SPV screw (shown in the figure) at 3.0 - 5.2 mm.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Instruction Book L58 - 64 1110118Document808 pagesInstruction Book L58 - 64 1110118GiovanniJaraNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual Ambac Actuator Agd130Document6 pagesManual Ambac Actuator Agd130GONZALO100% (1)

- For Training Only! Oral QuestionsDocument32 pagesFor Training Only! Oral Questionsvetsa737No ratings yet

- International StandardsDocument93 pagesInternational StandardsakashdadNo ratings yet

- 8 - FPCL Lab Manual Complete PDFDocument69 pages8 - FPCL Lab Manual Complete PDFakshay DandadeNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument3 pagesDpico: Inj. Pump Calibration DataMiguel Rojas100% (1)

- EN Zexel Stamping Reference 2013 NZ EL DV PDFDocument170 pagesEN Zexel Stamping Reference 2013 NZ EL DV PDFMiguel Rojas100% (2)

- Positive Displacement CompressorDocument30 pagesPositive Displacement CompressorchaitanyaNo ratings yet

- RMS Olympic 1910 Rms T 1911: ItanicDocument38 pagesRMS Olympic 1910 Rms T 1911: ItanicDafnie Valley AdorNo ratings yet

- Sistema Fire PumpsDocument44 pagesSistema Fire PumpsMohamadIbnuHassanNo ratings yet

- Design of Water Distribution System Using Epanet and Gis 3Document62 pagesDesign of Water Distribution System Using Epanet and Gis 3saikumar33% (3)

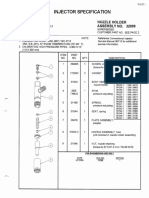

- Injector Specification: Assembly No: 32144Document1 pageInjector Specification: Assembly No: 32144Miguel RojasNo ratings yet

- DBGVC231 6BMDocument3 pagesDBGVC231 6BMMiguel RojasNo ratings yet

- Model DBGVCC42!3-8AJ: - Customer Part NoDocument2 pagesModel DBGVCC42!3-8AJ: - Customer Part NoMiguel RojasNo ratings yet

- DBGVC231 7BMDocument3 pagesDBGVC231 7BMMiguel RojasNo ratings yet

- DBGV (X429 - 3cli: ModelDocument2 pagesDBGV (X429 - 3cli: ModelMiguel RojasNo ratings yet

- Dbwcc42Wcm: ModelDocument3 pagesDbwcc42Wcm: ModelMiguel RojasNo ratings yet

- Injector Specification: Stanadyne"Document2 pagesInjector Specification: Stanadyne"Miguel Rojas100% (1)

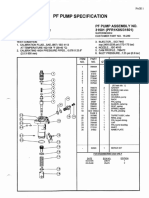

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- Cmi+9/643-H: Descrlptlon AMTDocument2 pagesCmi+9/643-H: Descrlptlon AMTMiguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification: STM - Ynee"Document2 pagesPF Pump Specification: STM - Ynee"Miguel RojasNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsMiguel RojasNo ratings yet

- PF Pump Specification: Stmdyne"Document2 pagesPF Pump Specification: Stmdyne"Miguel RojasNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 30163Document2 pagesInjector Specification: Nozzle Holder Assembly No. 30163Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- User's Guide: Stanadyne Diesel Fuel Filter/Water Separator SystemDocument5 pagesUser's Guide: Stanadyne Diesel Fuel Filter/Water Separator SystemMiguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- DBGVC 437 - 8af": Customer Part No. JD403F-206 Z LDocument2 pagesDBGVC 437 - 8af": Customer Part No. JD403F-206 Z LMiguel RojasNo ratings yet

- MODEL DBGFC 637-n AF: Qtilog - Page NO GDocument2 pagesMODEL DBGFC 637-n AF: Qtilog - Page NO GMiguel RojasNo ratings yet

- I ' 433'2Dlb: Model DBGVCDocument2 pagesI ' 433'2Dlb: Model DBGVCMiguel RojasNo ratings yet

- bBGFCC633 2DWDocument2 pagesbBGFCC633 2DWMiguel RojasNo ratings yet

- DBGVC 433-1DW: ModelDocument2 pagesDBGVC 433-1DW: ModelMiguel RojasNo ratings yet

- 46 Modeldbgfcc: DatedDocument2 pages46 Modeldbgfcc: DatedMiguel RojasNo ratings yet

- Spring: DlscrnpllowDocument2 pagesSpring: DlscrnpllowMiguel RojasNo ratings yet

- Stanadyne Corporation: OEM To Fuel Manager Brand Cross Reference P/Ns For Filter Elements 99642 - August 2002Document3 pagesStanadyne Corporation: OEM To Fuel Manager Brand Cross Reference P/Ns For Filter Elements 99642 - August 2002Miguel RojasNo ratings yet

- PF Pump Specification: STM - Ynee"Document2 pagesPF Pump Specification: STM - Ynee"Miguel RojasNo ratings yet

- PF Pump Specification: Stmadyne"Document2 pagesPF Pump Specification: Stmadyne"Miguel RojasNo ratings yet

- Cirus Controls Valve Assy Install and Commissioning Procedure 8.09Document2 pagesCirus Controls Valve Assy Install and Commissioning Procedure 8.09ohbabyohbabyNo ratings yet

- Reliable and Effective: CompactionDocument7 pagesReliable and Effective: CompactionMáy Công Trình DoosanNo ratings yet

- Waterjet Stinger Native Plant NetDocument6 pagesWaterjet Stinger Native Plant Netwr450No ratings yet

- BS en 14583-2004Document18 pagesBS en 14583-2004bdr85No ratings yet

- Catalog 2014 USA Glycol AminesDocument17 pagesCatalog 2014 USA Glycol Aminessopian320No ratings yet

- High Torque Radial Piston Motors MR Type: Fixed Displacement (Up To 9000 CM /rev - 550 in /rev)Document56 pagesHigh Torque Radial Piston Motors MR Type: Fixed Displacement (Up To 9000 CM /rev - 550 in /rev)Edwin Mamani DiazNo ratings yet

- Kentmaster Catalog Pork 2009Document40 pagesKentmaster Catalog Pork 2009yuNo ratings yet

- Manual 236.4Document23 pagesManual 236.4jairoNo ratings yet

- Remove & Install Fuel PumpDocument4 pagesRemove & Install Fuel PumpjasleenNo ratings yet

- 912 50 HZ Horizontal Split Case Selection TablesDocument27 pages912 50 HZ Horizontal Split Case Selection TablesMauricio FuentesNo ratings yet

- .Sand Vac - Well VacCleanoutSystems PDFDocument2 pages.Sand Vac - Well VacCleanoutSystems PDFjoseperozo45No ratings yet

- QSI750 Parts ListDocument102 pagesQSI750 Parts ListNelia ShkutNo ratings yet

- Kolmeks Manual Centrifugalpumps10enDocument8 pagesKolmeks Manual Centrifugalpumps10enMykola TitovNo ratings yet

- Centrifugal Separator: Use and Maintenance HandbookDocument85 pagesCentrifugal Separator: Use and Maintenance HandbookCentrifugal SeparatorNo ratings yet

- User Instructions: Installation Operation MaintenanceDocument44 pagesUser Instructions: Installation Operation MaintenancePhi MacNo ratings yet

- Copper Alloy C83600Document12 pagesCopper Alloy C83600guardmob-1No ratings yet

- CBZ Horizontal Self-Priming Centrifugal Pump Catalogue: (m3/h) (M) (KW) (KW) (m3/h) (M) (KW) (KW)Document2 pagesCBZ Horizontal Self-Priming Centrifugal Pump Catalogue: (m3/h) (M) (KW) (KW) (m3/h) (M) (KW) (KW)rio100% (1)

- Om Hreem Kali Kapalini Ghornadini Viswam Vimohya Jagnmohya Sarv Mohya Mohya THDocument11 pagesOm Hreem Kali Kapalini Ghornadini Viswam Vimohya Jagnmohya Sarv Mohya Mohya THindra singhNo ratings yet

- DLT 5187.2-2004Document43 pagesDLT 5187.2-2004Erlito SuperalNo ratings yet

- 110Q 3 Wheatley HP125Document2 pages110Q 3 Wheatley HP125hiltonparedes22No ratings yet

- Coiled Tubing OperationDocument3 pagesCoiled Tubing Operationgben11No ratings yet