Professional Documents

Culture Documents

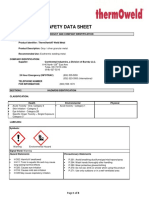

Technical Information Sheet: Harris Speedy Lead Free Solder

Uploaded by

johnsgd0 ratings0% found this document useful (0 votes)

59 views1 pageSoldering spec

Original Title

SPEEDYSpec

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSoldering spec

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

59 views1 pageTechnical Information Sheet: Harris Speedy Lead Free Solder

Uploaded by

johnsgdSoldering spec

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

TECHNICAL INFORMATION SHEET

HARRIS SPEEDY® LEAD FREE SOLDER

NOMINAL CHEMICAL COMPOSITION%: SAFETY INFORMATION:

Cu 2.5 –3.5 WARNING: PROTECT yourself and others. Read and

Sn Remainder understand this information.

FUMES AND GASES can be hazardous to your health.

PHYSICAL PROPERTIES: HEAT RAYS, (infrared radiation) from flame or hot metal can

injure eyes.

Solidus 450°F (232°C) SOLDER FLUXES may contain chlorides, acids, or other

Liquidus 550°F (290°F) ingredients that are considered hazardous via inhalation,

ingestion, or skin or eye contact.

SOLDERING PROPERTIES: Before use, read and understand the manufacturer’s

instructions, Material Safety Data Sheets (MSDS), and your

Speedy has a faster melting range which allows operators to employer's safety practices.

rapidly fill small, tight-fitting pipe connections. Speedy’s low Keep your head out of fumes.

temperature and free flowing properties reduce cycle time and Use enough ventilation, exhaust at the flame, or heat

source, to keep fumes and gases from your breathing zone

required heat input. Speedy is a lead-free solder primarily used

and the general area.

for joining copper pipe in potable water systems. This tin-based

Wear correct eye, ear, and body protection.

alloy conforms to the 1986 Federal Safe Drinking Water Act See American National Standard Z49.1, Safety in Welding,

Amendment. Cutting, and Allied Processes, published by the American

Welding Society, 8669 Doral Blvd., Doral, Florida 33166;

AVAILABLE FORMS: OSHA Safety and Health Standards, available from the U.S.

Government Office, Washington, DC 20402.

Standard diameters x spools

STATEMENT OF LIABILITY- DISCLAIMER:

FLUX:

Any suggestion of product applications or results is given without representation

or warranty, either expressed or implied. Without exception or limitation, there

Bridgit® Past Flux are no warranties of merchantability or of fitness for particular purpose or

Bridgit ® Water Soluble Paste Flux application. The user must fully evaluate every process and application in all

Stay Clean® Paste Flux aspects, including suitability, compliance with applicable law and non-

infringement of the rights of others. The Harris Products Group and its affiliates

Stay Clean® Liquid Flux (suggested for steel) shall have no liability in respect thereof.

Note: remove all flux residue after soldering

SPECIFICATION COMPLIANCE:

Harris Internal

THE HARRIS PRODUCTS GROUP

A LINCOLN ELECTRIC COMPANY

4501 Quality Place • Mason, OH 45040 U.S.A Tel: 513-754-2000 Fax: 513-754-6015

Additional information available at our web site: www.harrisproductsgroup.com

MK 10/16

You might also like

- ASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1Document5 pagesASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1David VegaNo ratings yet

- Mig Wire ER 70S-6 SpecificationsDocument2 pagesMig Wire ER 70S-6 Specificationsabhics67No ratings yet

- BATNADocument11 pagesBATNAabhi3180100% (2)

- Stay Clean Aluminum Soldering FluxDocument1 pageStay Clean Aluminum Soldering FluxaximitedzNo ratings yet

- 95 5specDocument1 page95 5specYesuaNo ratings yet

- 50 50specDocument1 page50 50specYesuaNo ratings yet

- Stay Silv White Flux SpecDocument1 pageStay Silv White Flux SpecJOHN NESTOR RAMIREZ CALDERÓNNo ratings yet

- Al Braze 1070 SpecDocument1 pageAl Braze 1070 SpecDíazGozueNo ratings yet

- Stay Silv2SpecDocument1 pageStay Silv2SpecEfraim AndersonNo ratings yet

- Cherry RedDocument1 pageCherry Redjcordon-2No ratings yet

- Sikadur PFFDocument9 pagesSikadur PFFSn AhsanNo ratings yet

- Technical Information Sheet: Stay-Silv 15 Brazing Filler MetalDocument1 pageTechnical Information Sheet: Stay-Silv 15 Brazing Filler MetalRussell ShacklefordNo ratings yet

- Pig Iron SDS PrimetradeDocument4 pagesPig Iron SDS PrimetradePravin PatilNo ratings yet

- K CC1 102 Hse MSDS 005 - R0 EaDocument8 pagesK CC1 102 Hse MSDS 005 - R0 EaWalter Gerardo BelluzNo ratings yet

- MSDS Dow-732-SealantDocument7 pagesMSDS Dow-732-Sealantrudy edwardNo ratings yet

- Dow Corning Corporation Material Safety Data SheetDocument7 pagesDow Corning Corporation Material Safety Data SheetSalvador NegreteNo ratings yet

- 11 Copper Sulphate MSDS 03Document4 pages11 Copper Sulphate MSDS 03rhama220849No ratings yet

- APArmaflex TapeSDSDocument4 pagesAPArmaflex TapeSDSREFRIFAMA SASNo ratings yet

- Msds 45 009Document8 pagesMsds 45 009junvarNo ratings yet

- Praxair Safety Data Sheet: 1. IdentificationDocument12 pagesPraxair Safety Data Sheet: 1. IdentificationZiro DeenNo ratings yet

- Hoja de Seguridad de SoldaduraDocument8 pagesHoja de Seguridad de SoldaduraYazmin Araceli Saldaña PeraltaNo ratings yet

- Baldwin G-42 MSDSDocument4 pagesBaldwin G-42 MSDSSMcNo ratings yet

- Safety Data Sheet: November 1, 2014Document8 pagesSafety Data Sheet: November 1, 2014DANY SUJINo ratings yet

- Dow Corning Corporation Material Safety Data SheetDocument7 pagesDow Corning Corporation Material Safety Data SheetkikoNo ratings yet

- Sigma M-460-tcm67-8533Document4 pagesSigma M-460-tcm67-8533dambriellyNo ratings yet

- Sulfur Dioxide So2 Safety Data Sheet Sds p4655Document10 pagesSulfur Dioxide So2 Safety Data Sheet Sds p4655Erlyn Alatraca LabasaNo ratings yet

- Jazeera Silk Finish Material Safety Data SheetDocument5 pagesJazeera Silk Finish Material Safety Data SheetMahmoud FlefilNo ratings yet

- Raychem Corporation - Heat-Shrinkable Polymeric ProductsDocument4 pagesRaychem Corporation - Heat-Shrinkable Polymeric Productsjaredf@jfelectric.com100% (1)

- Galvanized Steel Safety Data SheetDocument12 pagesGalvanized Steel Safety Data SheetBasir Abu FaqihNo ratings yet

- Lincolnweld L-S3 (LNS133U, L50M)Document17 pagesLincolnweld L-S3 (LNS133U, L50M)Jhonathan TiradoNo ratings yet

- Stay Silv White Flux SpecDocument1 pageStay Silv White Flux SpecAnte NinićNo ratings yet

- Dow Corning 704 Diffusion Pump FluidDocument7 pagesDow Corning 704 Diffusion Pump FluidumbertikNo ratings yet

- SDS271 Diamond CompoundDocument7 pagesSDS271 Diamond CompoundEsteban Vanegas AlvarezNo ratings yet

- Sigma-Aldrich: Material Safety Data SheetDocument7 pagesSigma-Aldrich: Material Safety Data SheetYoanNo ratings yet

- SDS Safety Data Sheet for Welding MaterialsDocument12 pagesSDS Safety Data Sheet for Welding MaterialsJose Antonio AlarconNo ratings yet

- Safety Data Sheet: Iron (Ii) SulfideDocument4 pagesSafety Data Sheet: Iron (Ii) SulfideAzhma UlyaNo ratings yet

- EnerSys Information For The Safe Handling of Motive Power Pb-Acid Batteries July 2021Document8 pagesEnerSys Information For The Safe Handling of Motive Power Pb-Acid Batteries July 2021daniel.mentelNo ratings yet

- Smoke Detector Tester MSDS GuideDocument7 pagesSmoke Detector Tester MSDS GuidemarckalhiNo ratings yet

- Sulfur Hexafluoride sf6 Safety Data Sheet Sds p4657Document9 pagesSulfur Hexafluoride sf6 Safety Data Sheet Sds p4657Terkel GinaNo ratings yet

- Safely Handle and Use Fluxes for Welding and BrazingDocument3 pagesSafely Handle and Use Fluxes for Welding and BrazingPaul NeedhamNo ratings yet

- Power Shine SDSDocument5 pagesPower Shine SDSJose MarinezNo ratings yet

- 37 Percent Formaldehyde Aqueous Solution Mixture of Hcho Ch3oh and H2o Sds p6224 PDFDocument12 pages37 Percent Formaldehyde Aqueous Solution Mixture of Hcho Ch3oh and H2o Sds p6224 PDFakramNo ratings yet

- 37 Percent Formaldehyde Aqueous Solution Mixture of Hcho Ch3oh and H2o Sds p6224Document12 pages37 Percent Formaldehyde Aqueous Solution Mixture of Hcho Ch3oh and H2o Sds p6224Juan Esteban LopezNo ratings yet

- Oxyde Fer Noir Sds enDocument5 pagesOxyde Fer Noir Sds enFabioNo ratings yet

- E 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet SdsDocument9 pagesE 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet Sdsjohnpatt888No ratings yet

- SDS e 5196038 20230926 0093Document10 pagesSDS e 5196038 20230926 0093datacoholicNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument6 pagesSafety Data Sheet: 1. IdentificationJessie O.BechaydaNo ratings yet

- Jazzera Primex Plus-MsdsDocument5 pagesJazzera Primex Plus-MsdsMahmoud FlefilNo ratings yet

- SDS Defoamer Safety Data SheetDocument4 pagesSDS Defoamer Safety Data SheetYoutube For EducationNo ratings yet

- Safety Data Sheet for Sullair AWFDocument6 pagesSafety Data Sheet for Sullair AWFRuben Hinojosa MamaniNo ratings yet

- Carbon Disufide (CS2)Document7 pagesCarbon Disufide (CS2)MohitNo ratings yet

- Product and Company Identification ManufacturerDocument5 pagesProduct and Company Identification ManufacturerbichojausenNo ratings yet

- Harris 5Document13 pagesHarris 5frio industrialNo ratings yet

- C10 Silicone MSDSDocument8 pagesC10 Silicone MSDSlukasjoNo ratings yet

- Material Safety Data Sheet: 1 Product IdentificationDocument3 pagesMaterial Safety Data Sheet: 1 Product IdentificationK3 RS DarmoNo ratings yet

- Molykote 1000 Paste MSDSDocument9 pagesMolykote 1000 Paste MSDSNikola Polimenov100% (1)

- Anggit Dwi - 121160165 - Msds Sulfur DioxideDocument9 pagesAnggit Dwi - 121160165 - Msds Sulfur DioxideAnggit Dwi WNo ratings yet

- MSDS - Covalance Raychem MeltstickDocument3 pagesMSDS - Covalance Raychem MeltstickjulianpirahNo ratings yet

- SryeDocument4 pagesSryeDamay KurniawanNo ratings yet

- MATERIAL SAFETY DATA SHEET CORED SOLDER WIREDocument4 pagesMATERIAL SAFETY DATA SHEET CORED SOLDER WIREIrsyad IlhamiNo ratings yet

- Construction Hazardous Materials Compliance Guide: Lead Detection, Abatement and Inspection ProceduresFrom EverandConstruction Hazardous Materials Compliance Guide: Lead Detection, Abatement and Inspection ProceduresNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Wave Propagation in Solids and FluidsDocument10 pagesWave Propagation in Solids and FluidsjohnsgdNo ratings yet

- Civil Law ActDocument54 pagesCivil Law ActjohnsgdNo ratings yet

- Ovmed®: Product BriefDocument2 pagesOvmed®: Product BriefjohnsgdNo ratings yet

- Ovmed®: Product BriefDocument2 pagesOvmed®: Product BriefjohnsgdNo ratings yet

- Ovmed®: Product BriefDocument2 pagesOvmed®: Product BriefjohnsgdNo ratings yet

- Corporate Guide Documents PDFDocument20 pagesCorporate Guide Documents PDFjohnsgdNo ratings yet

- Faster preparation time and outstanding results with DiaProDocument6 pagesFaster preparation time and outstanding results with DiaProjohnsgdNo ratings yet

- Corp Results 2020Document28 pagesCorp Results 2020johnsgdNo ratings yet

- Viton Selecting The Correct TypeDocument1 pageViton Selecting The Correct TypeHary PrasetyoNo ratings yet

- Product Brief: Cost-Effective, Ultra-Compact Camera Solution For Medical and Industrial EndoscopesDocument2 pagesProduct Brief: Cost-Effective, Ultra-Compact Camera Solution For Medical and Industrial EndoscopesjohnsgdNo ratings yet

- Corporate Guide Documents PDFDocument20 pagesCorporate Guide Documents PDFjohnsgdNo ratings yet

- European Commission Guidelines on "Use-ByDocument5 pagesEuropean Commission Guidelines on "Use-ByjohnsgdNo ratings yet

- UniCrimp 200 DS 2018 10 15 EN A4 V3Document2 pagesUniCrimp 200 DS 2018 10 15 EN A4 V3johnsgdNo ratings yet

- Manufacturing - E&O Claim ExamplesDocument6 pagesManufacturing - E&O Claim ExamplesjohnsgdNo ratings yet

- Corporate Supply Agreement Rev00Document27 pagesCorporate Supply Agreement Rev00johnsgdNo ratings yet

- AHD One Cable Selection 2017 0815Document11 pagesAHD One Cable Selection 2017 0815johnsgdNo ratings yet

- Guidelines For Keeping Laboratory NotebooksDocument3 pagesGuidelines For Keeping Laboratory NotebooksSatyam UpadhyayNo ratings yet

- Bearing A14Document2 pagesBearing A14Vignesh Raju ReddyNo ratings yet

- IodineDocument8 pagesIodineRajeev K Nair100% (1)

- Altera Medical-Grade, Thin Wall, Semirigid, Fluoropolymer Heat-Shrinkable TubingDocument2 pagesAltera Medical-Grade, Thin Wall, Semirigid, Fluoropolymer Heat-Shrinkable TubingjohnsgdNo ratings yet

- ABC Fire Extinguishers-NAFFCODocument8 pagesABC Fire Extinguishers-NAFFCORamizGollaNo ratings yet

- Brand Architecture. Tata SteelDocument15 pagesBrand Architecture. Tata SteelKaran KrNo ratings yet

- PR-1 Series Pressure Regulator Repair KitsDocument2 pagesPR-1 Series Pressure Regulator Repair KitsJames JansonNo ratings yet

- Final Examination SEMESTER I, SESSION2014/2015Document13 pagesFinal Examination SEMESTER I, SESSION2014/2015Mohamad Yusuf HelmiNo ratings yet

- ElectroscopeDocument3 pagesElectroscopeRobelle Grace M. CulaNo ratings yet

- E-21-015-CGPISL-M4-Goa-Lot PhotosDocument10 pagesE-21-015-CGPISL-M4-Goa-Lot PhotosAfzalNo ratings yet

- Flowmeter Model MP KytolaDocument2 pagesFlowmeter Model MP KytolaJimmy MirandaNo ratings yet

- Iso 05002-2013Document20 pagesIso 05002-2013mystar_bkc100% (1)

- Injection Mold Design SeminarDocument64 pagesInjection Mold Design SeminarMuhammed K MNo ratings yet

- Al Jezeera Steel Work Profile PDFDocument44 pagesAl Jezeera Steel Work Profile PDFcetc qatarNo ratings yet

- Final Report (Akash)Document36 pagesFinal Report (Akash)Akash TaradaleNo ratings yet

- Tru LaserDocument40 pagesTru LaserWilfredo A MolinaNo ratings yet

- NORSOK-M-503 (2007) Cathodic ProtectionDocument16 pagesNORSOK-M-503 (2007) Cathodic ProtectionChuck AnsphilNo ratings yet

- Poster - Welding Positions - en PDFDocument1 pagePoster - Welding Positions - en PDFmjaric8150% (2)

- PHD Thesis On WeldingDocument9 pagesPHD Thesis On Weldingdenisemillerdesmoines100% (2)

- Interior Fit-Out of Pomodoro Pizza Pasta KitchenDocument5 pagesInterior Fit-Out of Pomodoro Pizza Pasta KitchenAngel AbrajanoNo ratings yet

- A36 WPSDocument1 pageA36 WPSJamesNo ratings yet

- FC Catalogue 100112 LowDocument452 pagesFC Catalogue 100112 LowEduardo OyarzunNo ratings yet

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values - Stainless Steel T PDFDocument2 pagesISO 1302 DIN 4768 Comparison of Surface Roughness Values - Stainless Steel T PDFgalvaosilva33% (3)

- Bend Test and Ductility Test 1Document25 pagesBend Test and Ductility Test 1Novie Dave EstremaduraNo ratings yet

- Module-2 0Document10 pagesModule-2 0Prince Gerald VargasNo ratings yet

- Engineering Services by KBR Technical Services, IncDocument23 pagesEngineering Services by KBR Technical Services, IncswatkoolNo ratings yet

- Welding Calculator BOHLERDocument7 pagesWelding Calculator BOHLERKhamdi AfandiNo ratings yet

- ASTM E747-04 - Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyDocument14 pagesASTM E747-04 - Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyMelissa SammyNo ratings yet

- Fabrication & Erection of Steel Works ChecklistDocument1 pageFabrication & Erection of Steel Works ChecklisttaghlubNo ratings yet

- Inter Power Company ProfileDocument8 pagesInter Power Company ProfileVenu Kumar Reddy ChallaNo ratings yet

- A247 GrafitoDocument13 pagesA247 GrafitoCarlos Pinto PradillaNo ratings yet

- 07-Schedule A - Inspection & Test Plan ITPDocument2 pages07-Schedule A - Inspection & Test Plan ITPamir100% (1)

- Core Making ProcessesDocument10 pagesCore Making ProcessesAzhar Hussain100% (1)