Professional Documents

Culture Documents

Evaluation of Potato-Stone-Clod Separation Mechanisms

Evaluation of Potato-Stone-Clod Separation Mechanisms

Uploaded by

nicolasqkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaluation of Potato-Stone-Clod Separation Mechanisms

Evaluation of Potato-Stone-Clod Separation Mechanisms

Uploaded by

nicolasqkCopyright:

Available Formats

EVALUATION OF POTATO-STONE-CLOD SEPARATION MECHANISMS

G. C. Misener and C. D. McLeod

Research Station, Agriculture Canada, P.O. Box 20280, Fredericton, New Brunswick E3B 4Z7

Received 28 August, 1986, accepted 16 March, 1987

M^on^QG;^'and C*D'McLeod- mi- Evaluation ofpotato-stone-clod separation mechanisms. Can. Agric. Eng.

^V! lo"— 1 I \.

Methods of separating potatoes from stones and soil clods in storage were evaluated and factors affecting performance

were determined. The three methods ofseparation included a rotating brush separator, an electronic separator and an

impact roller separator. All separators effectively sorted the stones from the potatoes but the brush separator failed to

differentiate between the soil clods and potatoes. Parameters affecting the performance ofthe brush separator were the

feed rate and the brush gap while the performance of the electronic and impact roller separators was affected by the feed

rate and the stone/potato ratio, respectively.

INTRODUCTION ejected from the flow by means of high The objective of the study described in

Thedevelopment of mechanisms to sep speed pneumatic hammers. The basic pro this paper was to quantify the performance

arate potatoes from stones and clods has cess is similar to the roller with the advan of the three types of in-storage separators

been directed towards mechanical devices tage that the impact differences are in terms of their capability to separate

located on the harvesters. These devices amplified electronically as opposed to potatoes from stones and soil clods.

have been designed to separate potatoes on creating larger differences by changing the

the basis of physical differences between contact angle on the roller. Larger dif TEST PROCEDURES

the potato and the associated material. The ferences increase separating sensitivity. The laboratory arrangement included a

differences include rolling resistance, One disadvantage is having to align the feeding conveyor on which the products

elasticity, specific gravity, terminal product in order to optimize the perfor were placed and fed at controlled rates

velocity, resistance to X-ray penetration, mance of the electronic and impact ham onto each of the three separators. The

optical reflectance, and vibrational fre mer systems. A third method of separation three separators are shown schematically

quency response. Sides and Smith (1970) which is less expensive is presently at the in Figs. 1, 2 and 3. Russet Burbank

describe the mechanisms available for sep experimental stage. This method utilizes a potatoes were distributed evenly at a

arating potatoes and stones. Methods transaxial rotary brush separator in which known weight on the conveyor and then

which have been used or investigated over the material flow is across the brush axis. either stones or clods were uniformly

the past several years have also been Separation is achieved by a differential mixed with the potatoes. The conveyor

described by Story and Raghavan (1976). deflection of the bristles caused by the speed was constant during the tests while

More recently several mechanisms have difference in specific gravities of the the weight of material per unit length on

been developed to operate in storages dur potatoes, stones and soil clods as the conveyor was varied to deliver various

ing postharvest potato handling. The described by Eaton and Hansen (1969). loading rates to the separators. Prelimi-

advantage of doing a portion of the separa

tion at storage rather than on the harvester

is to reduce the number of people working

on the harvester under unfavorable condi

tions. Often in Eastern Canada from two to

four people are required to sort the ma

terial on the harvester. Two approaches

for in-storage use appear promising and

have been developed into commercial ma

chines. A commercial separator developed

by Feller et al. (1984) is based on the Figure 1. Cross-sectional view of brush separator.

difference between the coefficient of res

titution of the products being separated.

The device involves bouncing the objects DISTRIBUTION

on a revolving roller and separating them BRUSH

according to their trajectories. A second -SENSOR PLATE

type of separator available differentiates DISTRIBUTION | -REJECTION CYLINDERS

ROLLERS "

between potatoes, stones and soil clods

electronically. This separator has a series

Srfr fifcfl ffftQQvof (TV/

of sensors each consisting of a membrane

and an electromagnetic transducer. The

\

magnetic field is influenced by the vibra 1 °

tion of the membrane due to impact and %

the magnetic-field-influencing property of J

^ •

the products being separated. Using these

differences, the items not desired are Figure 2. Cross-sectional view of electronic separator.

CANADIAN AGRICULTURAL ENGINEERING, VOL. 29, NO. 2, SUMMER 1987 169

two moisture levels were included in a

Feed Conveyor

second test. The tests were randomly con

ducted at four feed rates of 9.0, 18.0, 27.0

and 36.0 t/h, two soil clod moisture levels

of 3.5% WB and 19.0% WB, and one

clod/potato ratio of 0.05.

A Roller Separator

Potatoes & Clods

Feller et al. (1984) have done an exten

sive evaluation of the roller separator sort

ing onion-clod mixtures. They found that

the separator was very effective when sep

arating the clods from the onions. Gan-

Mor et al. (1985) suggested that a machine

A similar to the roller separator will not

effectively separate the stones from the

potatoes due to the small difference in the

Figure 3. Cross-sectional view of roller separator. coefficient of restitution between potatoes

and stones. However, in order for the

machine to be useful in Eastern Canada it

nary tests were conducted to determine the low separation efficiency was achieved

must be capable of handling stones as well

range of machine settings for each with the brushes when separating these

as clods. The initial tests indicated that

machine when operating with various products. Consequently, only one set of

separation of stones from potatoes was

stone/potato and clod/potato ratios. tests was undertaken with soil clods mixed

possible; consequently, a complete series

The stones used in the tests had an aver with potatoes. The ratio of clods/potatoes

age weight of 79.4 g with standard devia

of tests was performed. The tests included

was 0.05 with feed rates of 9.0,18.0, 27.0

four feed rates of 9.0, 18.0, 27.0 and 36.0

tion of ±55.7 g. Clods were gathered in and 36.0 t/h at a brush gap setting of

the fall and stored either in opened barrels 13.0 mm.

t/h and three stone/potato ratios of 0.01,

0.055 and 0.1.

or in plastic bags in order to obtain two soil

moisture levels of 3.5 and 19.0% WB. The Electronic Separator Separation effectiveness, E, was deter

average tuber weight was 154.6 g with a Preliminary tests were conducted with mined as the product of recovery and

standard deviation of ±89.8 g. the electronic separator in order that the rejection (Brown et al. 1951). Feller et al.

The stone/potato ratios and clod/potato sensitivity (amplification) adjustments for (1984) also used this method of measuring

ratios were selected on a weight basis and clods and stones could be selected. When

separation effectiveness:

represent ratios often found under New the optimum setting was reached, tests p s

Brunswick conditions. The field stone/ were conducted at four feed rates of 9.0, Pp + Pr sr + «

potato ratio depends on the soil type as 18.0, 27.0 and 36.0 t/h over a 1.3 m width pr

well as to the extent of the stone removal with three stone/potato ratios of 0.01, (l -z——)d

Pp + Pr Sr + SD (I)

operation. The clod/potato ratio has a 0.055 and 0.1. In order to measure the

higher variability depending on soil type effect that moisture content of soil clods where Pp = potatoes in the product exit;

and moisture as well as tillage practices. going into storage in early fall and leaving = potatoes rejected with the stones;

The feed rate selected during the evalua during winter has on the performance of = stones in the reject exit; and

tion of the separator represents sufficient the electronic separator, soil clods with s„ = stones remaining with the product.

capacity to handle the output from two

harvesters under New Brunswick condi

tions. A large percentage of growers oper Brush Gap

ate two harvesters in order to meet the

requirements of a short harvest period. . . . . 10 . 0 mm 1R 171 mm

.0

—

Brush Separator L

O

"' •—^^^><^_

The critical parameter affecting ma -H

O

. 9

"^^^ •—-—

chine performance is the gap between CD

li

.8

adjacent pairs of brushes. Eaton and en

"*^-

Hansen (1969) found that the separating CO

CD . 7

efficiency was independent of brush c

CD

**N..

"^-^ . "

speed, loading rate or separator slope. .6

-• "

Tests consisting of three replications were •H

CJ "--

randomly conducted with ratios of stones/ CD

. 5

—

potatoes of 0.01, 0.055 and 0.1 over a 0-

LJ . 4

range of feed rates of 9.0, 18.0, 27.0 and

36.0 t/h over 1.3 m of brush width. The 1 1 1

. 3 1

tests included brush gap settings of 7.0, 9 18

10.0, 13.0 and 16.0 mm. Due to the small Feed Rate t/h

difference in specific gravities of soil clods

and potatoes initial tests indicated that a Figure 4. Effectiveness of the brush separator as effected by feed rate and brush gap.

170 CANADIAN AGRICULTURAL ENGINEERING, VOL. 29, NO. 2, SUMMER 1987

L

BRUSH SEPERATOR

1 .0

O -_ ELECTRONIC SEPERATOR for separating stones from potatoes,

-H

U ._ ROLLER SEPERATOR

although Gan-Mor et al. (1985) indicate

CD otherwise.

Ll The performance of the three separators

(fl

0. 9

when separating a mixture of potatoes and

CO stones is shown in Fig. 5. Overall, the

CD

C performance of the brush separator ap

CD pears superior.

>

r-i 0.8

-H

U CONCLUSIONS

CD From the results of the study, it can be

C^

Q- concluded that separating stones from

LU 0. 7 potatoes with any of the three separators is

0 18 27 36 effective. The feed rate and the width of

Feed Rate t/h the gap between brushes are factors that

affect the performance of the brush sepa

Figure 5. Comparison of the performance of the three separators over a range of feed rates.

rator with stones and potatoes. However,

this separator has limited capability to sep

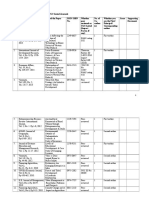

TABLE I. COMPARISON OF PARAMETERS AFFECTING PERFORMANCE OF THE THREE

arate soil clods from potatoes. The elec

SEPARATORS

tronic separator is sensitive to the feed rate

Brush separator Electronic separator Roller separator when separating mixtures of stones and

Feed rate Brush gap Feed rate Stone/potato potatoes. Moisture of soil clods multiplied

(t/h) E (mm) E (t/h) E ratio E by feed rate is a significant factor when

9.0 O.Sla 7.0 0.46a 9.0 0.89a 0.01 0.11a separating clods from potatoes. The stone/

18.0 0.11a 10.0 0.12b 18.0 0.88a 0.055 0.88/7 potato ratio becomes a significant factor

27.0 0.10b 13.0 0.90c 27.0 0.87a 0.1 0.86/7

0.826

for the roller separator when separating

36.0 0.10b 16.0 0.91c 36.0

stones from potatoes.

a-c Means notfollowed by same letter are significantly different at the 5% level of probability as judged

by Duncan's multiple range test.

REFERENCES

Analysis of variance was carried out on the mean effectiveness was only 0.15 BROWN, G. G., O. KATZ, and A. S.

the data using the program Genstat when attempting to separate the clods and FOUST. 1951. Unit operations. John Wiley

ANOVA 1982. Significant differences of potatoes. The small difference in specific and Sons, New York. p. 15.

means were examined utilizing Duncan's gravities of the two products probably EATON, F. F. and R. W. HANSEN. 1969.

multiple range test. accounts for the low performance. Mechanical separation of stones from

With the electronic grader, feed rate potatoes by means of rotary brushes. Am.

was found to be the only significant factor Soc. Agric. Eng. Paper No. 69-108.

RESULTS AND DISCUSSION

ASAE, St. Joseph, Mich.

The width of the gap between the affecting performance with a mixture of FELLER, R., O. NAHIS, and C. G. COBLE.

brushes was found to be an important stones and potatoes. Feed rates above27.0 1984. Separation of soil clods from onions

parameter for determining the separation t/h began having a negative effect on the using impact. Trans. ASAE (Am. Soc.

effectiveness of the brush separator. The effectiveness of the separator. Again, as Agric. Eng.) 27(2): 353-357.

analysis of varianceof the data which were with the brush separator, the stone/potato GAN-MOR, S., A. ZACHARIN, R. FEL

accumulated in the process of evaluating ratio did not significantly affect perfor LER, and E. MAROGOLIN. 1985. Reduc

the sensitivity of the brushes to gap and mance. Although the moisture level of the tion of the restitution coefficient for stones to

feed rate with mixtures of potato and clods was found not to be a significant enable separation from potatoes. Am. Soc.

Agric. Eng. Paper No. 85-1569. ASAE,

stones indicated that both factors, brush factor on the performanceof the electronic

St. Joseph, Mich.

gapand feedrate, werehighlystatistically separator,the interaction of moisture level SIDES, S. E. and N. SMITH. 1970. Analysis

significant. Their effects on the effec and feed rate was highly significant. and design of potato-stone separation mech

tiveness are shown graphically in Fig. 4. The test results with the roller separator anisms. Am. Soc. Agric. Eng. Paper No.

In Table I, the analysis indicates that a indicate that the stone/potato ratio was a 70-673. ASAE, St. Joseph, Mich.

brushgap ofat least 13.0mm is required to significant factor affecting performance. STORY, A. G. and G. S. V. RAGHAVAN.

maximize the effectiveness of the sepa The overall mean of the effectiveness fac 1976. Sorting potatoes from stones and soil

rator. As indicated by Eaton and Hansen tor of the roller separator for tests con clods by infrared reflectance. Quality detec

(1969), soil clods could not be separated ducted was 0.84. This value suggests that tion in foods. Am. Soc. Agric. Eng., St.

from potatoes using brushes. In our tests, the separatorcan be an effective machine Joseph, Mich. pp. 177-182.

171

CANADIAN AGRICULTURAL ENGINEERING, VOL. 29, NO. 2, SUMMER 1987

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Model 2Document5 pagesModel 2Sabari MNo ratings yet

- Economics of Organic Vegetables1 s2.0 S1877042817300241 MainDocument14 pagesEconomics of Organic Vegetables1 s2.0 S1877042817300241 MainVilma D. ConradoNo ratings yet

- AP English Language and Composition Session3 4 WorksheetDocument7 pagesAP English Language and Composition Session3 4 WorksheetDafri EsfandiariNo ratings yet

- Nilar Htike Htik TinDocument57 pagesNilar Htike Htik TinNilar hhtinNo ratings yet

- Industrial HempDocument7 pagesIndustrial HempLove GailNo ratings yet

- FinalDocument121 pagesFinalDhruvi PatelNo ratings yet

- Website Information1Document18 pagesWebsite Information1shekhar gendleNo ratings yet

- Desertification in The Sahel - An Overview of Causes, Progression, and EffectsDocument4 pagesDesertification in The Sahel - An Overview of Causes, Progression, and Effectsmel94vi100% (4)

- Paper 10 - J. SaravananDocument4 pagesPaper 10 - J. SaravananSaravanan JayabalanNo ratings yet

- High Efficiency in Vitro Whole Plant Regeneration Via Desiccated Callus in Oryza Sativa Cv. MTU1010Document6 pagesHigh Efficiency in Vitro Whole Plant Regeneration Via Desiccated Callus in Oryza Sativa Cv. MTU1010International Journal of Innovative Science and Research Technology100% (1)

- Panchal Jeegar S PDFDocument76 pagesPanchal Jeegar S PDFkajal mehtaNo ratings yet

- Assignment ON BDSDocument13 pagesAssignment ON BDSRk SharafatNo ratings yet

- Final ReportDocument37 pagesFinal ReportGaurav GuptaNo ratings yet

- Under The Supervision and Guidance of Jyothis Mary GeorgeDocument21 pagesUnder The Supervision and Guidance of Jyothis Mary GeorgeBOBBY THOMASNo ratings yet

- PublicationsDocument4 pagesPublicationsRajesh PundhirNo ratings yet

- Achieving Zero Hunger Through Zero Wastage - An Overview of Present Scenario and Future ReflectionsDocument7 pagesAchieving Zero Hunger Through Zero Wastage - An Overview of Present Scenario and Future ReflectionsSahara JiménezNo ratings yet

- How To Kill Trees and Stumps: One-Sheet AnswersDocument2 pagesHow To Kill Trees and Stumps: One-Sheet Answersxi siNo ratings yet

- GRADE-8-TLE 1st Periodical ANSWERDocument4 pagesGRADE-8-TLE 1st Periodical ANSWERJandro Kareem100% (6)

- Know Your TreesDocument80 pagesKnow Your TreesDevo_NYCNo ratings yet

- A Seminar Title On The History and Evolution of Agricultural Extension in The Ethiopia CountryDocument14 pagesA Seminar Title On The History and Evolution of Agricultural Extension in The Ethiopia CountryresearchparksNo ratings yet

- Method of Fish CultivationDocument3 pagesMethod of Fish CultivationSir RollyNo ratings yet

- Effect of Different Nitrogen Fixing Tree Species On Soil Chemical PropertiesDocument6 pagesEffect of Different Nitrogen Fixing Tree Species On Soil Chemical PropertiesGavriella RembetNo ratings yet

- Block Board From Melia DubiaDocument5 pagesBlock Board From Melia DubiaPremier PublishersNo ratings yet

- Unit 3 3.0. Land Resources Field SurveyDocument17 pagesUnit 3 3.0. Land Resources Field Surveysly gotoNo ratings yet

- A Case Study of Banaue Rice Terraces GROUP 7 MPRDocument7 pagesA Case Study of Banaue Rice Terraces GROUP 7 MPRKHAYZEKIEL ROMINNo ratings yet

- Bronze Age in KyrgyzstanDocument21 pagesBronze Age in Kyrgyzstanomurzakova.aipiNo ratings yet

- Lecture 5Document15 pagesLecture 5Isuru jayaweeraNo ratings yet

- Market Potential and Promotional Strategy For Akshay Seed Tech Co. in Sabarkantha and Gandhinagar DistrictsDocument7 pagesMarket Potential and Promotional Strategy For Akshay Seed Tech Co. in Sabarkantha and Gandhinagar DistrictskomalNo ratings yet

- Whisky Magazine - July 2023Document77 pagesWhisky Magazine - July 2023fredda1990No ratings yet

- Field Water TestDocument105 pagesField Water TestntirugiribambeNo ratings yet