Professional Documents

Culture Documents

MBAA Tool Box Talk - Keg and Valve Repair

Uploaded by

Sebastian Matias Cruz0 ratings0% found this document useful (0 votes)

14 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pageMBAA Tool Box Talk - Keg and Valve Repair

Uploaded by

Sebastian Matias CruzCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MBAA Safety Toolbox Talk

Keg and Valve Maintenance

Overview use a new lock ring, or improperly frozen and top of the neck is no longer

installing a lock ring, is the greatest keg- 0.33” from the top of the chimb. Both

A stainless steel keg is a very robust

related risk to employee and consumer measurements are standard specs used

package that should last 20-30 years if

health. A new lock ring costs less than by all keg manufacturers, and the

properly maintained. Qualified keg and

$1, and valve removal and installation racking lines are designed with these

valve repair mitigates safety risks,

training is free, so there is no excuse for specs in mind.

extends the life of a brewery’s keg float,

cutting corners.

and eliminates costly returns of

Other common defects which can cause

defective kegs from wholesalers and

Valve Removal Tools, Equipment, and a keg to fail are bent chimbs, dents, and

retailers. Before attempting to establish

Training holes.

any keg maintenance program, brewers

should have a strategy, be aware of a Valve removal and replacement can be

few guidelines, and possess the proper challenging, and doing the job How To Determine If Structural

tools and training. improperly can be hazardous. The best Damage Can Be Repaired

Strategy way to remove and install a valve is by Most structural damage is easy to

using a specially designed tool that identify, but determining if a keg can be

There are two facts that every brewery

depresses the valve into the neck and saved requires some knowledge. It

should be aware of when creating a

holds the valve body down while the doesn’t make financial sense to ship a

maintenance program: over 70% of keg

lock ring is removed or inserted. When keg to a repair facility if the keg cannot

failures are valve-related, and it is

repairing or replacing a valve, never use be repaired. Some basic guidelines are:

cheaper to ship a valve than an entire

parts that have not been supplied by the

keg. If a brewery’s staff has the tools and

correct valve manufacturer. • Any hole other than a pinhole in the

training to properly remove and reinstall

valves, a brewery should keep a small weld should not be repaired.

The most common valve part that • Any keg that has expanded in any

number of functional valves in stock and

requires replacement is the CO2 valve. way - most commonly due to

replace damaged valves when they fail.

This is the black rubber seal that freezing- should not be repaired.

Damaged valves can be repaired by

surrounds a steel ball in the center of the • If a chimb is bent to the point where

experts- the valve suppliers themselves

valve. Like many EPDM (rubber) seals, it is touching or almost touching the

are a good resource- and sent back to

these parts will usually require dome of the keg, then it is not worth

the brewery when they are functional

replacement every 5-7 years. repairing.

again.

• Any dent larger than the average

A new rubber o-ring should also be used hand is probably not worth

Kegs with more substantial structural

each time a valve is installed in a keg. repairing.

damage can be sent to a facility where

This is not a safety issue like the lock

they can be repaired by experts to their

ring, but the o-ring maintains the seal These defects are rare and will represent

original specification.

between the valve and keg neck. Failure a very small percentage of keg failure.

to use a new part will result in leaks

Safety First between the neck and the valve.

Never attempt to remove a valve unless If you have any questions regarding this,

you have been properly trained, and Common Failure Modes please see your supervisor or manager or

always depressurize the keg before a member of the Safety Committee.

In addition to valve failure, many kegs

attempting to remove the valve. If a keg

fail due to body damage. The most

is not depressurized before the valve is FOR MORE INFORMATION ON BREWERY

common cause of failure is neck

removed, the valve will become a SAFETY, PLEASE VISIT THE MBAA

damage, especially with high-speed BREWERY SAFETY WEBSITE AT:

dangerous projectile which can cause

automated racking lines. Neck damage http://www.mbaa.com/brewresources/brewsafety

substantial bodily harm. When

is usually defined in one of two ways-

reinstalling a valve, always use a new

the neck is bent more than 2 degrees out

lock ring provided by an OEM. Failure to

of perpendicular, or the keg has been

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- BearingsDocument52 pagesBearingsrahul singhNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Euphoria 2021 F K Anyone Whos Not A Sea Blob Part 2 Jules Script Teleplay Written by Sam Levinson and Hunter SchaferDocument40 pagesEuphoria 2021 F K Anyone Whos Not A Sea Blob Part 2 Jules Script Teleplay Written by Sam Levinson and Hunter SchaferMadalena Duarte7No ratings yet

- Nanotechnology in Civil EngineeringDocument22 pagesNanotechnology in Civil EngineeringNehad AhmedNo ratings yet

- Grade-9 (1st)Document42 pagesGrade-9 (1st)Jen Ina Lora-Velasco GacutanNo ratings yet

- Islamiyat O-Level Paper-1 Notes PDFDocument126 pagesIslamiyat O-Level Paper-1 Notes PDFddd80% (5)

- Ghost Hawk ExcerptDocument48 pagesGhost Hawk ExcerptSimon and SchusterNo ratings yet

- The Optimized Formulas of Rye Bread On The Sensory Properties Using RSMDocument8 pagesThe Optimized Formulas of Rye Bread On The Sensory Properties Using RSMSebastian Matias CruzNo ratings yet

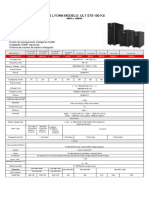

- Ups Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVADocument1 pageUps Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVASebastian Matias CruzNo ratings yet

- Training To Succeed Manual For Skillelectric: Bold Blue TextDocument22 pagesTraining To Succeed Manual For Skillelectric: Bold Blue TextSebastian Matias CruzNo ratings yet

- Acti 9 iEM3000 - A9MEM3155Document3 pagesActi 9 iEM3000 - A9MEM3155Sebastian Matias CruzNo ratings yet

- Pesos Teoricos CobreDocument10 pagesPesos Teoricos CobreSebastian Matias CruzNo ratings yet

- Automatic Transfer and Intelligent Control For Low Voltage Switchgear Pa019005enDocument6 pagesAutomatic Transfer and Intelligent Control For Low Voltage Switchgear Pa019005enSebastian Matias CruzNo ratings yet

- ZTT Compliance Rules On Employees Compliance TrainingDocument14 pagesZTT Compliance Rules On Employees Compliance TrainingSebastian Matias CruzNo ratings yet

- Tubular Push Conveyor TUBO.: LbgaDocument4 pagesTubular Push Conveyor TUBO.: LbgaSebastian Matias CruzNo ratings yet

- Lenel NVR Hardware Data Sheet 09 - 2020 WebDocument2 pagesLenel NVR Hardware Data Sheet 09 - 2020 WebSebastian Matias CruzNo ratings yet

- GWK Brewery Catalog 2017 2018 PDFDocument59 pagesGWK Brewery Catalog 2017 2018 PDFSebastian Matias CruzNo ratings yet

- Test Sieves, Sieve Shakers & Particle Analysis Equipment: AddressDocument64 pagesTest Sieves, Sieve Shakers & Particle Analysis Equipment: AddressSebastian Matias CruzNo ratings yet

- Building A Quality Lab On Any Budget: Presented By: Casey Bartman JRDocument40 pagesBuilding A Quality Lab On Any Budget: Presented By: Casey Bartman JRSebastian Matias CruzNo ratings yet

- What Is Sensory Analysis?: The Use of People As Instruments ToDocument51 pagesWhat Is Sensory Analysis?: The Use of People As Instruments ToSebastian Matias CruzNo ratings yet

- Brinkman Brewhouse LossDocument4 pagesBrinkman Brewhouse LossSebastian Matias CruzNo ratings yet

- 03 - Scheller Presentación GEADocument38 pages03 - Scheller Presentación GEASebastian Matias CruzNo ratings yet

- Water Pushes: MBAA Brewpedia, 2013 Ockert, Karl. Master Brewers Association of Americas, St. Paul, MNDocument2 pagesWater Pushes: MBAA Brewpedia, 2013 Ockert, Karl. Master Brewers Association of Americas, St. Paul, MNSebastian Matias CruzNo ratings yet

- Glazing Failures and Ways To Prevent Them BHubbsDocument12 pagesGlazing Failures and Ways To Prevent Them BHubbsSebastian Matias CruzNo ratings yet

- Approaches To Sampling MacrofungiDocument14 pagesApproaches To Sampling MacrofungiGerald GamboaNo ratings yet

- SnapManual PDFDocument77 pagesSnapManual PDFnaser150No ratings yet

- How Does Texting Worsens Our Vocabulary & Writing Skills ?Document10 pagesHow Does Texting Worsens Our Vocabulary & Writing Skills ?Manvi GoelNo ratings yet

- IOM - Recovery Through Lok Adalat - HODocument5 pagesIOM - Recovery Through Lok Adalat - HOAbhishek BarwalNo ratings yet

- Ece 250 Project PortfolioDocument7 pagesEce 250 Project Portfolioapi-511924847No ratings yet

- Rabe 1 Reviewer 2022 2023Document174 pagesRabe 1 Reviewer 2022 2023Dencel BarramedaNo ratings yet

- 2019 Admax CataDocument30 pages2019 Admax CataEVENTIA AFRICANo ratings yet

- Once Upon A Time A Hawk Feels in Love With A HenDocument2 pagesOnce Upon A Time A Hawk Feels in Love With A HenJeffri Aritonang100% (1)

- Current Logk VkbaDocument8 pagesCurrent Logk Vkba21muhammad ilham thabariNo ratings yet

- 2023 - Ver4.3 - Landslide Assessments in British Columbia Version 4.1Document184 pages2023 - Ver4.3 - Landslide Assessments in British Columbia Version 4.1yehnafarNo ratings yet

- Lecture-3: Market Equilibrium and Applications: Abdul Quadir XlriDocument37 pagesLecture-3: Market Equilibrium and Applications: Abdul Quadir Xlrianu balakrishnanNo ratings yet

- Advertising & SALES PROMOTIONAL-AirtelDocument78 pagesAdvertising & SALES PROMOTIONAL-AirtelDasari AnilkumarNo ratings yet

- NSFDCDocument10 pagesNSFDCAniket AhireNo ratings yet

- 1 Programming Model (Algorithms 1.1)Document10 pages1 Programming Model (Algorithms 1.1)HarshaSharmaNo ratings yet

- Comp2-Cause-Effect EssayDocument4 pagesComp2-Cause-Effect Essayapi-316060728No ratings yet

- Communityhealth 141122094330 Conversion Gate02Document22 pagesCommunityhealth 141122094330 Conversion Gate02Titser JoNo ratings yet

- Syllabus (Economic Analysis For Business)Document5 pagesSyllabus (Economic Analysis For Business)S TMNo ratings yet

- PPP Projects at A Glance. Madhya PradeshDocument7 pagesPPP Projects at A Glance. Madhya PradeshPPPnewsNo ratings yet

- Humanities SculptureDocument15 pagesHumanities SculpturehungrynomadphNo ratings yet

- The Aim of This Essay Is To Critically Analyse IronmanDocument4 pagesThe Aim of This Essay Is To Critically Analyse IronmanAura IonescuNo ratings yet

- Elite MindsDocument1 pageElite MindsShivaNo ratings yet

- Transurethral Resection of The Prostate Anesthetic ConsiderationsDocument25 pagesTransurethral Resection of The Prostate Anesthetic ConsiderationsSeaoon IdianNo ratings yet

- ObliCon Reviewer SMDocument111 pagesObliCon Reviewer SMJessa Marie BrocoyNo ratings yet

- An Introduction To Uhde Oil & Gas: Thyssenkrupp Uhde - Engineering With IdeasDocument40 pagesAn Introduction To Uhde Oil & Gas: Thyssenkrupp Uhde - Engineering With IdeasHany FathyNo ratings yet