Professional Documents

Culture Documents

Inclined Plane Test Method To Determine Structural Build-Up at Rest of Self-Consolidating Concrete

Inclined Plane Test Method To Determine Structural Build-Up at Rest of Self-Consolidating Concrete

Uploaded by

Salih MohayaddinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inclined Plane Test Method To Determine Structural Build-Up at Rest of Self-Consolidating Concrete

Inclined Plane Test Method To Determine Structural Build-Up at Rest of Self-Consolidating Concrete

Uploaded by

Salih MohayaddinCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/263272849

Inclined Plane Test Method to Determine Structural Build-Up at Rest of Self-

Consolidating Concrete

Article in Aci Materials Journal · January 2010

CITATIONS READS

20 670

3 authors, including:

Kamal H. Khayat Ahmed Fathy Omran

Missouri University of Science and Technology Université de Sherbrooke

481 PUBLICATIONS 7,752 CITATIONS 68 PUBLICATIONS 561 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Design sustainable SCC based on rheological properties View project

Alternative Supplementary Cementitous Materials View project

All content following this page was uploaded by Kamal H. Khayat on 27 May 2015.

The user has requested enhancement of the downloaded file.

ACI MATERIALS JOURNAL TECHNICAL PAPER

Title no. 107-M59

Inclined Plane Test to Evaluate Structural Buildup at Rest

of Self-Consolidating Concrete

by Kamal Henri Khayat, Ahmed F. Omran, and Trimbak V. Pavate

After casting, concrete flow resistance increases due to physical and in particular on: (a) the size of the floc; (b) the favorable

restructuring and cement hydration, thus affecting some key spatial distribution of particles; (c) entanglement density;

characteristics of the material, including segregation resistance, and (d) molecular association in polymer solutions.

lateral pressure exerted on formwork, and bond between successive Thixotropic behavior is encountered in some solid dispersion

lifts. A systematic program was undertaken to evaluate the structural systems where bond between various molecules, leading to

buildup of self-consolidating concrete (SCC) using a novel

inclined plane method. The critical angle of the plane at the

a rise in cohesiveness, can correspond to hydrogen or ionic

commencement of movement of the sheared material placed onto a bond on the molecular level and internal friction from solid

roughened surface is used to determine static yield stress. Repetitive particles.2,3 Such bond is predominant at a low shear rate and

tests carried out on SCC indicate that the rate of structural buildup can be destroyed by mixing at a high shear rate. The

has a relative error of 7 to 9%, depending on thixotropic level and reagglomeration and recovery of bond between adjacent

shear history. Comparisons carried out with 29 SCC mixtures of molecules can be established following a rest period.

various compositions demonstrate that yield stress characteristics Cementitious systems are non-Newtonian fluids exhibiting

determined using the inclined plane method are comparable to a τ0rest that must be surmounted for flow to occur.

those measured using a concrete rheometer (R2 = 0.82). Frequently, the literature describes the flow curves of

concrete as conforming to the Bingham model. This

Keywords: inclined plane; rheology; self-consolidating concrete; structural approximation is probably only valid for a low shear rate. In

breakdown; structural buildup; thixotropy; viscosity; yield stress. fact, yield stress and plastic viscosity values are shown to be

exponential functions of water content and the flow

INTRODUCTION characteristics related to structural breakdown (that is,

The yield stress of viscoelastic materials, such as breakdown of existing bonds due to hydration and hydrogen

cosmetics, mayonnaise, paint, quick clays, snow slides, and and van der Waals bonds on a molecular scale).4 This is

flowable cement-based materials, exhibit a solid-like manifested by a decrease of the external energy that keeps

behavior under small applied stresses and a liquid-like the concrete in a fluid state and gives rise to the development

behavior when the applied shear stress exceeds the intrinsic of hysteresis loops. Hysteresis loops are typical of thixotropic

yield stress of the material. In spite of the macroscopic materials. In the presence of water, a large number of very

similarities between these materials, the microscopic small particles in a cementitious system interact via colloidal

behavior mechanisms are quite different. The increase of forces (van der Waals, double layer, steric), whereas bigger

viscosity of a sample left at rest is termed as “aging,” grains interact via direct contact (friction and collision).

whereas the decrease of viscosity with mixing time under a Thus, there are networks of colloidal interaction and grain-

given shear rate is termed as “shear rejuvenation.”1 Thixotropy to-grain interaction. The addition of chemical admixtures,

can be defined as a decrease of viscosity of the material with such as high-range water-reducing admixtures (HRWRAs)

time when the material is made to flow under a given shear and viscosity-modifying admixtures (VMAs), can alter the

rate.1 Thixotropy is a reversible phenomenon, meaning that rheological properties of the system. Therefore, highly flowable

the viscosity begins to increase following a given period of materials made with a low water-cementitous material ratio

rest or when the material is subjected to a very low shear rate (w/cm), HRWRAs, and VMAs can behave differently than

over a certain lapse of time. This is referred to as structural conventional cement-based systems with respect to rest time.

recovery or structural buildup at rest and is related to the

coagulation of the material, leading to an increase in internal Evaluation of thixotropy

shear resistance, or static yield stress (τ0rest), which increases The proper evaluation of structural breakdown and

with rest time.2 Thixotropy and the related structural buildup at rest of highly flowable concrete, including self-

buildup at rest are prominent features of many complex consolidating concrete (SCC), is important because these

fluids and appear to be present when the τ0rest is also time-dependent rheological properties can affect a number

present. Theoretically, τ0rest is defined as the stress at of key properties of concrete, including static stability,

which viscosity changes from being infinite to having a maximum formwork pressure and its decay after casting, air

finite value. τ0rest and thixotropy are not inherent material entrapment and surface finish, and interlayer bond strength

properties because they depend on the shear history of the between successive concrete lifts in the absence of mechanical

system. τ0rest can vary more than one order of magnitude,

depending on measurement technique and duration.2

Both thixotropy and structural buildup at rest are intimately ACI Materials Journal, V. 107, No. 5, September-October 2010.

MS No. M-2009-372 received November 5, 2009, and reviewed under Institute

linked and are generated from the same cause: the interplay publication policies. Copyright © 2010, American Concrete Institute. All rights reserved,

between flow and structure (restructuring) of a fluid.1 The including the making of copies unless permission is obtained from the copyright proprietors.

Pertinent discussion including authors’ closure, if any, will be published in the July-August

magnitude of thixotropy is dependent on the microstructure, 2011 ACI Materials Journal if the discussion is received by April 1, 2011.

ACI Materials Journal/September-October 2010 515

set-accelerating admixture can exhibit a greater degree of

Kamal Henri Khayat, FACI, is a Professor of civil engineering at the Université de

Sherbrooke, Sherbrooke, QC, Canada. He received his BS, MS, and PhD degrees in cohesion and hence a higher rate of pressure drop.13

civil engineering from the University of California at Berkeley, Berkeley, CA. He is A third approach to evaluate thixotropy is to determine the

Chair of ACI Committee 237, Self-Consolidating Concrete; and a member of ACI

Committees 234, Silica Fume in Concrete; 236, Material Science of Concrete; 238,

structural buildup of the material following a certain period

Workability of Fresh Concrete; and 552, Cementitious Grouting. His research interests of rest by measuring the rate of increase in τ0rest at rest. This

include SCC, high-performance concrete, rheology of cement-based materials, and reflects the coagulation state of the material that enables it to

concrete repair.

regain its shear strength when left at rest. This approach can

Ahmed F. Omran is a Postdoctoral Fellow at the Université de Sherbrooke. He be employed using a rheometer through the concept of

received his BS and MS degrees in civil engineering from the University of Minoufia, measuring yield strain where the material is subjected to

Shibin el Kom, Egypt. He received his PhD from the Université de Sherbrooke. His

research interests include formwork pressure and concrete rheology. minute shear rate (angular velocity) until the initiation of

flow.7,15 The critical stress necessary to mobilize the material

Trimbak V. Pavate is a Visiting Research Professor at the Université de Sherbrooke. from rest is the static yield stress. The rate of structural

He received his BE from the University of Pune, Pune, India; his ME from the Indian

Institute of Technology, Roorkee, Roorkee, India; and his PhD from the Indian buildup at rest can also be evaluated using the inclined plane

Institute of Technology, Bombay, Bombay, India. His research interests include test, which measures a yield angle (critical angle) necessary

electrochemical processes of solid-liquid systems. to initiate the flow of a thin layer of material placed on an

inclined plane. This approach is described in more detail in

the following and has been successfully used to assess the

consolidation during the placement of the top layer.5-9 SCC structural yield stress at rest of various gels, clay suspensions,

mixtures with a high degree of thixotropy can lead to a faster bentonite slurries, soft glassy materials, mud flow, snow

increase in shear-strength properties (internal friction and slides and, more recently, flowable cement-based materials.3

cohesion) after casting, thus precluding the development of The inclined plane approach has been used to demonstrate

high lateral pressure against the formwork. This can enable the interplay between the static yield stress and thixotropy.2,3

the design of a more cost-effective formwork system For any material that is considered to be thixotropic, once the

without the need to reduce the casting rate of the highly critical slope is reached in the inclined plane, the sample

flowable materials. starts flowing. Thixotropy leads to a decrease in viscosity,

A number of approaches have been used to determine the and therefore the flow accelerates, resulting in an avalanche

thixotropy of cement-based materials based on the structural of the flow. During aging, it is the reverse of an avalanche

breakdown or structural buildup approach. Typically, these that occurs, resulting in increased viscosity and decreased

measurements require a rheometer capable of measuring shear rate.16 Aging becomes easier at low shear rates.

shear stresses at various shear rates. By using shear stress Normally, rebuilding time varies depending on the composition

versus shear rate data, hysteresis loops can be plotted. The of cementitious materials and dosage of chemical admixtures.

shape of such loops can progressively change, that is, shear The study presented in this paper aims at expanding the

thinning or shear thickening according to the composition of knowledge base of the inclined plane technique for estimating

the concrete and mixing history.10 Variations in the shape of the structural buildup of highly flowable self-leveling mortar

the down-curve of the hysteresis loop can be related to the and SCC systems. Such knowledge is important to the design

structural buildup as it corresponds to the rate of stiffening of and control of the rheological properties that affect the initial

the cement-based material.11 lateral pressure exerted by SCC on formwork systems and

A second approach to evaluate thixotropy consists of the rate of pressure drop in time.

determining the structural breakdown of the concrete due to

shearing action. This approach to evaluate thixotropy RESEARCH SIGNIFICANCE

consists of fixing the rotational speed, N, of a coaxial A novel technique aimed at determining the rate of structural

concrete rheometer and recording the variations in structural buildup of SCC is presented. The inclined plane approach is

breakdown of the material with respect to time.12,13 For each a simple test method enabling the determination of the static

rotational speed, a peak yield stress, τi, corresponding to the yield stress of flowable cement-based materials after a given

initial structural condition, and thereafter shear stress decay time of rest. Such a technique can be employed to design

with time toward a minimum value, τe, corresponding to an SCC with a high rate of structural buildup to enhance static

equilibrium condition that is independent of the shear stability and also to reduce formwork pressure without

history, are noted. The area comprised between the initial hindering the casting rate. Similarly, SCC can be optimized

flow curve (τi versus N) and the equilibrium flow curve (τe to exhibit low thixotropy to mitigate loss of bond (green

versus N) is calculated to quantify the amplitude of the thixo- strength) between successive layers in the absence of mechanical

tropic phenomenon (structural breakdown area). Using this consolidation between two successive concrete lifts.

approach, it is shown that the initial lateral pressure exerted

by SCC and the rate of pressure drop after casting determined INCLINED PLANE TEST FOR

using a 2.8 m (9.2 ft) high polyvinyl chloride (PVC) column FLOWABLE MORTAR AND SCC

measuring 200 mm (8 in.) in diameter are directly related to Schematic details of the inclined plane are shown in Fig. 1.

the structural breakdown area determined at different time The inclined plane test setup consists of two plates: a bottom

intervals.14 The increase in coarse aggregate content (lower horizontal nonmovable plate and an upper movable plate.

paste volume) was shown to increase the structural breakdown The bottom plate is fixed by a pair of hinges to the upper

area and decrease the lateral pressure exerted by SCC, which plate so that it can be easily moved upwards to any inclination

is attributed to the increase in internal friction and collision and can also be locked by tightening screws. A protractor can

resulting from the increase in aggregate volume.13 On the be held or fixed between the joint of the horizontal and

other hand, the rate of drop in lateral pressure following inclined plates to measure the inclination of the plane.

casting can mainly depend on the development of cohesion The flow mechanism of the material down an inclined

with time. SCC containing higher binder content and/or a plane lifted at a particular critical angle (angle at which the

516 ACI Materials Journal/September-October 2010

downward flow at the upper layer starts) can be explained

phenomenologically by fundamental physical concepts. For

one-dimensional analysis, let mass m be kept on an inclined

plane making angle θ, as shown in the free body diagram in

Fig. 2. Two types of external forces affect the downward

momentum of the system: 1) the gravitational force Fg =

m·g·sinθ; and 2) the frictional force fk, where g·sinθ is an

acceleration due to the gravity resolved along the inclined

plane. The force that initiates flow is then taken as the

difference between these two forces: m·g·sinθ – fk. The fk

force in Fig. 2 exists between the bottom of the block of mass

m and the top surface of the inclined plane when the entire

block begins to slide down the inclined plane. To eliminate Fig. 1—Schematic of inclined plane test.

sliding of the mass, the surface of the inclined plane is

roughened using a suitable sandpaper laid over the entire

surface of the plane. Shearing can then occur near the top of

the sample when the inclined plane is slowly raised until the

top material begins to flow downwards. Keeping in view the

mobility of the flowing mass after shearing at a particular

inclination, only the gravitational force triggers the downward

flow of the material. The sheared mass of the cementitious

material on the plane with an angle of θ and an effective

height of h begins to flow downward due to gravitational

acceleration. Considering ρ as density of the material, the

shear stress τ0rest, due to the downward force, is given by

τ 0rest = ρgh sin θ (1)

With increasing rest time, the critical angle increases, and Fig. 2—Free-body diagram of mass m kept on inclined

hence the corresponding τ0rest. An increase in τ0rest with plane with slope angle θ.16

respect to rest time reflects the structural buildup of the

cementitious material with time.

To conduct the tests efficiently using the inclined plane very small for cement mortar, even though the container had

approach, many preliminary tests were conducted to formulate given good results for bentonite slurries that were initially

a protocol of testing that can reflect the flow characteristics tested. The next type of containers to be used were conical

of highly flowable mortar and SCC. Tests were first carried

hopper containers of a truncated cone shape measuring 70 mm

out with bentonite slurry so as to formulate a protocol for

proper use of the inclined plane approach. The test protocol (2.75 in.) in lower diameter, 55 mm (2.17 in.) in upper diameter,

that was finally adopted in this investigation for the inclined and 70 mm (2.75 in.) in height. They also proved to be of

plane test for SCC is presented in Appendix A. marginal utility in the case of mortar and concrete. Finally,

Initially, for the development of this test, the inclined cylinders of 60 mm (2.36 in.) in diameter and 120 mm (4.72 in.)

plane was coated with a commercial resin and fine Ottawa in height opened at both ends were selected. They are filled

sand. Uniformity of surface roughness was difficult to with mortar to a marked height of 100 mm (3.93 in.), and to

obtain, however. The next attempt aimed at using commercial the top in the case of SCC. The use of different heights for

waterproof sandpapers. These are designated by the size of fluid mortar is for practical convenience so that the spread of

the grit, which is defined with reference to the number of flowing material after lifting the cylinder would be within

abrasive particles per 1 in. (25.4 mm) of sandpaper. A lower the width of the inclined plane.

grit number indicates higher roughness of the sandpaper and,

conversely, a higher grit number refers to a smoother sandpaper. EXPERIMENTAL PROGRAM

Initially, sandpapers with lower grit numbers (grit numbers The investigation was carried out on 29 SCC mixtures and

200 and 400) were tried. This measure proved to be less aimed at comparing the rheological properties of SCC

effective given the high friction with the tested sample; when

mixtures determined using the inclined plane method to

the inclination of the upper surface was increased to initiate

flow, the whole sample began to slide without any shearing those obtained using a concrete rheometer. Measured

at the top surface. A superfine sandpaper having a grit responses included the τ0rest determined at four successive

number of 600 was finally selected and gave satisfactory rest periods up to 60 minutes, necessitating four inclined

results. The selected sandpaper is made of aluminum oxide plane setups. The rate of increase in τ0rest at rest was also

abrasive material and is waterproof, necessitating changes determined using a coaxial vane rheometer on concrete

every 10 to 15 tests. samples subjected to four successive rest periods. One of the

To fill the known quantity of mortar or flowing concrete, SCC mixtures (SCC20) was repeated four times to determine

different types of containers were tested. Initially, small the variations of τ0rest measurements carried out between 15

cylindrical containers of 20 mm (0.78 in.) in diameter and and 60 minutes of rest measured using the inclined plane test

40 mm (1.57 in.) in height were used. The size proved to be and concrete rheometer.

ACI Materials Journal/September-October 2010 517

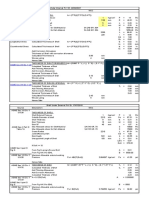

Table 1—Ranges of mixture designs of 29 tested SCC mixtures

Range From To

Type GU cement 295 (497) 422 (711)

Type HE cement 352 (593) 352 (593)

Cementitious materials, kg/m3 (lb/yd3) Type MS cement 500 (843) 500 (843)

Type GUb-S/SF cement 353 (595) 560 (944)

Class F fly ash 85 (143) 168 (283)

Total cementitious materials, kg/m3 (lb/yd3) 393 (662) 560 (944)

3 3 139 (234) 267 (450)

Water, kg/m (lb/yd )

w/cm 0.34 0.47

Sand (0 to 5 mm [0 to 3/16 in.]), kg/m3 (lb/yd3) 560 (944) 995 (1677)

2.5 to 10 mm (1/8 to 3/8 in.) 685 (1154) 830 (1399)

3 3 5 to 14 mm (3/16 to 9/16 in.) 732 (1233) 985 (1660)

Coarse aggregate, kg/m (lb/yd )

5 to 20 mm (3/16 to 3/4 in.) 812 (1368) 812 (1368)

PCE HRWRA 1.7 (0.046) 10 (0.27)

VMA 0.5 (0.0135) 4.1 (0.111)

Admixture, L/m3 (ft3/yd3) SRA 0.54 (0.0146) 0.9 (0.024)

WRA 0.82 (0.221) 0.96 (0.026)

AEA 0.11 (0.003) 0.11 (0.003)

Paste volume, Vp, L/m3 (ft3/yd3) 290 (7.83) 498 (13.45)

S/A, by volume 0.44 0.55

Slump flow, mm (in.) 560 (21.8) 720 (28.1)

MATERIALS Table 1. The cementitious materials content varied from 395 to

The 29 SCC mixtures (SCC1 to SCC29) were proportioned 560 kg/m3 (665 to 945 lb/yd3), and the volume of coarse

with various constituent materials covering a wide range of aggregate ranged between 270 to 330 L/m3 (7.3 to 8.9 ft3/yd3)

mixture designs, including SCC for precast, prestressed to secure different thixotropic values. The w/cm varied from

applications and structural cast-in-place SCC for building 0.34 to 0.47, and the initial slump flow ranged from 600 to

construction and for infrastructure repair. Several types of 720 mm (23.6 to 28.3 in.), except for Mixtures SCC4 to

binders were used for the mixtures shown in Table 1, SCC7, where the slump flow consistency was limited to

including a general use cement (CSA Type GU), a high- 560 mm (22 in.).

early-strength cement (CSA Type HE), a moderate sulfate The mixing procedure for the SCC mixtures consisted of

cement (CSA Type MS), and a ternary cement made with homogenizing the aggregate with one-third of the mixing

approximately 25% slag and 5% silica fume. The mixtures water for 1 minute. The cementitious materials were then

made with Type GU or Type HE cement included 25% Class F added, followed by the HRWRA diluted with one-third of

fly ash replacement by mass of total cementitious materials. The the mixing water. After mixing for 3 minutes, the remaining

Blaine fineness values of Type GU, HE, and MS cements one-third of the water was introduced with the VMA (whenever

and the fly ash are 385, 475, 390, and 410 m 2/kg (1880, applicable), and the material was mixed for 2 minutes.

2320, 1905, and 2000 ft2/lb), respectively. Crushed lime- Following 2 minutes of rest, the material was remixed for

stone aggregate with a maximum aggregate size of 10, 14, and 30 seconds. The ambient temperature during mixing and

20 mm (0.39, 0.55, and 0.79 in.) and siliceous river-bed sand

testing was maintained at approximately 22°C (72°F).

were used. The grain-size distributions of the sand and coarse

Following the end of mixing (7.5 minutes after the initial

aggregate are within CSA A.23.1 standards. The limestone

contact of cement with water), the slump flow was determined,

fine aggregate did not contain any fines passing 75 μm (No. 200).

and then the rheological parameters were evaluated in

The bulk specific gravities of the three coarse aggregates are 2.70,

parallel at predetermined periods using four sets of inclined

2.70, and 2.73, respectively, and that of the sand is 2.70. The

planes and a concrete rheometer.

absorption rates of the three coarse aggregates are 0.57%, 0.38%,

and 0.36%, respectively, and that of the sand is 1.16%. As Fifteen minutes after the contact of water and cement,

indicated in Table 1, a number of chemical admixtures cylinders placed on the upper plate of the inclined planes

were incorporated in the investigated SCC mixtures, such as were filled, then lifted one by one and covered until the time

polycarboxylate ether (PCE)-based HRWRA. The solid of testing. The rest periods for the SCC samples ranged

content and specific gravity of the HRWRA are 22% and between 15 and 60 minutes. Shorter periods were employed

1.04, respectively. A liquid-based VMA (39% solid content) for concrete mixtures exhibiting high thixotropy with a

was used. relatively fast rate of gain in structural buildup at rest.

Yield stress at rest was also determined using the modified

MIXTURE COMPOSITION AND TESTING concrete rheometer. A four-bladed vane rotating coaxially

The 29 SCC mixtures were tested using both a coaxial was used for the impeller. The testing procedure consisted of

concrete rheometer and the inclined plane test to correlate imposing a low rotational speed (N) of 0.03 rps to the vane

the results. The ranges of the mixture proportioning impeller immersed in a fresh sample of concrete subjected to

employed for Mixtures SCC1 to SCC29 are summarized in a certain rest period and recording the resulting increase in

518 ACI Materials Journal/September-October 2010

torque as a function of time.15 The shear growth test when tested with the inclined plane approach. Examples of such

involved the determination of the maximum yielding torque an increase in τ0rest for selected mixtures, including the SCC20

(Tmax) before torque decayed toward a steady-state region. mixture that was repeated four times, are given in Fig. 3.

The τ0rest was calculated from Tmax given the geometry of For the SCC mixtures, the initial dynamic yield stress values

the yield surface and shear-stress distribution on the surface, varied between 10 and 970 Pa (1.45 and 141 × 10–3 psi) and the

which was assumed to be uniform17 initial plastic viscosity values ranged from 35 to 745 Pa.s (5 and

108 × 10–3 psi.s), respectively. The initial τ0rest measured with

τ0rest = Tmax /K (2) a concrete rheometer using the shear growth approach ranged

between 120 and 1300 Pa (17 and 189 × 10–3 psi).

where K = πD3/2[L/D + 1/3], L is the height of the vane, and To determine the repeatability of the inclined plane test,

D is the diameter of the vane. the variations of τ0rest with different resting periods deter-

The concrete sample was lightly sheared at low rotational mined for the SCC20 prepared four times were evaluated, as

speed during the shear growth test for 8 seconds per test. The shown by the dashed lines in Fig. 3. The repeatability was

sample was then homogenized by hand and covered until the evaluated statistically by determining the relative error (RE)

following shear growth test. Depending on the degree of corresponding to a 95% confidence interval using the

thixotropy of the concrete mixture, the rest period between Student’s distribution factor, as follows

successive shear growth test measurements varied from 5 to

15 minutes to enable four measurements within 1 hour. Unlike σ

COV = ---100 ( % ) (3)

static yield determined with the concrete rheometer, tests x

carried out with the inclined plane approach were performed

on four undisturbed (virgin) samples taken from the same

σ

concrete batch used for testing with the concrete rheometer. RE = 3.1824 ---------- 100 ( % ) (4)

The second rheological property obtained from the modified x n

concrete rheometer was the drop in apparent viscosity at

rotational speed, N, of 0.7 rps (Δηapp@N = 0.7rps). The where 3.1824 is a coefficient representing the 95% confi-

Δηapp@N = 0.7rps was measured for each of the four rest dence interval for the Student’s distribution for a number of

times. To determine the Δηapp@N = 0.7rps, the concrete was observations (n) equal to four, n is the number of observations,

sheared at a high rotational speed of 0.7 rps until it reached COV is the coefficient of variation, σ is standard deviation,

an equilibrium state. The maximum initial shear stress (τi) and x is mean value of the observations.

and stress at equilibrium (τeq) were then determined. The The values of RE estimated for the τ0rest readings at

drop in apparent viscosity was expressed as the difference various resting times are given in Table 2. The RE of the

between these two stresses divided by the shear rate that

corresponds to the 0.7 rps.18

The third rheological property obtained using the modified

concrete rheometer was the breakdown area (Ab1). To obtain

the Ab1 values, the testing protocol consisted of applying

constant rotational speeds of 0.3, 0.5, 0.7, and 0.9 rps and

determining the initial shear stress (τi) and equilibrium shear

stress (τeq) at each rotational velocity. For each speed, the

spread between τi and τeq was determined and plotted

against shear rate. The integration of the area between curves

of τi and τeq versus shear rate was known as the “breakdown

area” (Ab1) and was used to quantify thixotropy.15

TEST RESULTS AND DISCUSSION

Structural buildup measurements with inclined

plane and concrete rheometer

All of the investigated SCC mixtures tested exhibited a Fig. 3—Typical results of variation of static yield stress with rest

steady increase in τ0rest during the 10- to 60-minute rest period time obtained using inclined plane test for various SCC mixtures.

Table 2—Repeatability results of SCC20 mixture using inclined plane and modified concrete rheometer

Static yield stress, τ0rest, Pa (psi) Statistical characteristics

Rest time,

Test minutes SCC20A SCC20B SCC20C SCC20D x, Pa (psi) σ, Pa (psi) COV, % RE, %

15 395 (0.057) 385 (0.056) 390 (0.057) 345 (0.050) 380 (0.055) 22 (0.003) 6 9

30 500 (0.073) 480 (0.070) 490 (0.071) 445 (0.065) 480 (0.070) 24 (0.003) 5 8

Inclined plane test

45 600 (0.087) 575 (0.083) 590 (0.086) 540 (0.078) 575 (0.083) 27 (0.004) 5 8

60 700 (0.102) 670 (0.097) 695 (0.101) 635 (0.092) 675 (0.0980) 30 (0.004) 4 7

15 470 (0.068) 430 (0.062) 480 (0.070) 410 (0.059) 445 (0.065) 33 (0.005) 7 12

30 630 (0.091) 600 (0.087) 630 (0.091) 555 (0.080) 605 (0.088) 34 (0.005) 6 9

Modified concrete rheometer

45 790 (0.115) 770 (0.112) 780 (0.113) 705 (0.102) 760 (0.110) 39 (0.006) 5 8

60 950 (0.138) 940 (0.136) 930 (0.135) 855 (0.124) 920 (0.133) 45 (0.007) 5 8

Note: x is average; σ is standard deviation; COV is coefficient of variation; and RE is relative error corresponding to 95% confidence limit.

ACI Materials Journal/September-October 2010 519

Fig. 4—Correlation between initial static yield stress Fig. 6—Static yield stress after 15 minutes of rest obtained

obtained with concrete rheometer and inclined plane test at using inclined plane versus breakdown area (Ab1) obtained

15 minutes of rest for SCC1 to SCC29 (1200 Pa, 0.174 psi using concrete rheometer for Mixtures SCC1 to SCC29.

corresponds to maximum possible value with inclined plane).

Fig. 7—Relationship between time-dependent static yield

stresses obtained with inclined plane test and concrete

rheometer for Mixtures SCC1 to SCC29.

Fig. 5—Static yield stress after 15 minutes of rest obtained

using inclined plane versus drop in apparent viscosity at

0.7 rps obtained using concrete rheometer for Mixtures

SCC1 to SCC29. The correlation coefficients obtained between rest times of

15, 30, 45, and 60 minutes for the τ0rest values obtained from

τ0rest values determined at four successive resting periods the inclined plane approach and the concrete rheometer were

varied between 7 and 9%, indicating good reliability of the indeed satisfactory. When all data points are considered for

inclined plane approach. The RE values for the four repetitions the four rest periods of 15 to 60 minutes, the correlation was

of the τ0rest determined with the concrete rheometer were as follows: IP τ0rest = 0.85 × Rheometer τ0rest R2 = 0.78. The

slightly higher than those of the inclined plane, varying correlation presented in Fig. 3 is higher due to the similar

between 8 and 12%. shear history of the samples tested after 15 minutes of rest for

The τ0rest results of the 29 SCC mixtures determined using both the inclined plane and rheometer tests.

the inclined plane approach are compared to those obtained The relationship of Δηapp@N = 0.7rps obtained from the

with the modified concrete rheometer in Fig. 4 to 6. As modified concrete rheometer to τ0rest obtained using the

shown in Fig. 4, τ0rest obtained using the inclined plane inclined plane approach is indicated in Fig. 5. For 16 selected

approach correlate well with data obtained with the concrete SCC mixtures, the Ab1 values were evaluated using the

rheometer (correlation factor, R2 = 0.82). Values of τ0rest modified concrete rheometer and compared to the τ0rest

from the inclined plane approach are, on average, 5% lower obtained after the first rest time using the inclined plane

than those obtained from the concrete rheometer. This is approach. These results are plotted in Fig. 6. Finally, the

mainly due to the basic change in shear phenomena occurring relationship between the time-dependent change of τ0rest or

in the two types of tests. In the modified rheometer, the the evolution of τ0rest with time (τ0rest(t)) expressed in Pa/min.

rotational shear phenomenon is observed, whereas in the obtained using the inclined plane approach and equivalent

inclined plane, the shear phenomenon is unidirectional flow. results obtained from the concrete rheometer are shown in

The shear stresses measured using rotational rheometers would Fig. 7. The τ0rest(t) values were obtained from the slopes of

be higher than those observed in the unidirectional flow.19 lines similar to those shown in Fig. 3 that correlates the τ0rest

520 ACI Materials Journal/September-October 2010

value and time of rest. The relationships obtained in Fig. 4 to on Stability Characteristics of Cement Grout and Concrete,” ACI Materials

7, with their correlation factors and numbers of data points Journal, V. 99, No. 3, May-June 2002, pp. 234-241.

6. Assaad, J.; Khayat, K. H.; and Mesbah, H., “Variation of Formwork

(N), can be summarized as follows Pressure with Thixotropy of Self-Consolidating Concrete,” ACI Materials

Journal, V. 100, No. 1, Jan.-Feb. 2003, pp. 29-37.

IP τ 0rest = 0.95 × Rheometer τ 0rest 7. Billberg, P., “Form Pressure Generated by Self-Compacting Concrete—

(5) Influence of Thixotropy and Structural Behaviour at Rest,” doctoral thesis,

2 School of Architecture and the Built Environment, Division of Concrete

R = 0.82 N = 29 Structures, Royal Institute of Technology, Stockholm, Sweden, 2006,

91 pp.

IP τ 0rest = 1.23 × Δη app@N = 0.7rps + 263 8. Ovarlez, G., and Roussel, N., “A Physical Model for the Prediction of

(6) Lateral Stress Exerted by Self-Compacting Concrete on Formwork,” Materials

2 and Structures, V. 39, No. 2, 2006, pp. 269-279.

R = 0.67 N = 28 9. Roussel, N., and Cussigh, F., “Distinct-Layer Casting of SCC: The

Mechanical Consequences of Thixotropy,” Cement and Concrete Research,

IP τ 0rest = 1.00 × Ab 1 + 189 V. 38, 2008, pp. 624-632.

(7) 10. Banfill, P. F. G., and Saunders, D. C., “On the Viscometric Examination

2 of Cement Pastes,” Cement and Concrete Research, V. 11, No. 3, 1981,

R = 0.85 N = 16 pp. 363-370.

11. Douglas, R.; Gregori, A.; Sun Z.; Bonen, D.; and Shah, S. P., “The

IP τ 0rest ( t ) = 0.6 × Rheometer τ 0rest ( t ) Effect of Ingredients and Shear History on the Thixotropic Rate of

(8) Rebuilding of SCC,” Proceedings of the 2nd North American Conference

2 on the Design and Use of Self-Consolidating Concrete and the 4th

R = 0.93 N = 27 International RILEM Symposium on Self-Compacting Concrete, S. P. Shah, ed.,

Chicago, IL, 2005, pp. 591-596.

Based on the aforementioned results, the inclined plane 12. Lapasin, R.; Longo, V.; and Rajgelj, S., “Thixotropic Behaviour of

Cement Pastes,” Cement and Concrete Research, V. 9, 1979, pp. 309-318.

approach is clearly shown to enable the evaluation of the 13. Assaad, J.; Khayat, K. H.; and Mesbah, H., “Assessment of Thixotropy

magnitude of thixotropy and structural buildup by determining of Flowable and Self-Consolidating Concrete,” ACI Materials Journal, V. 100,

the initial τ0rest at different rest times or the rate of τ0rest growth No. 2, Mar.-Apr. 2003, pp. 99-107.

with respect to rest time (time-dependent change of τ0rest). 14. Assaad, J., and Khayat, K. H., “Influence of Internal Friction and

Cohesion on the Variations of Formwork Pressure of Self-Consolidating

Concrete,” Specal Publication, SP 2002-02, American Concrete Institute,

SUMMARY AND CONCLUSIONS Farmington Hills, MI, 2004, pp. 19-32.

In the present study, an inclined plane test was developed 15. Assaad, J., “Formwork Pressure of Self-Consolidating Concrete—

and used to evaluate the structural buildup at rest of SCC. In Influence of Thixotropy,” doctoral thesis, Department of Civil Engineering,

all, 29 SCC mixtures of different mixture designs were used Université de Sherbrooke, Sherbrooke, QC, Canada, 2004, 453 pp.

to compare the structural buildup of concrete obtained from 16. Oremus, R. M., “A One Dimensional Model of Dense Snow

Avalanches Using Mass and Momentum Balances,” doctoral thesis,

the inclined plane test to that determined using a concrete Faculty of Humboldt State University, Arcata, CA, May 2006, 64 pp.

rheometer. Based on the results of this study, the following 17. Dzuy, N. Q., and Boger, D. V., “Direct Yield Stress Measurement

conclusions are drawn: with the Vane Method,” Journal of Rheology, V. 29, No. 3, 1985, pp. 335-347.

1. The inclined plane test is shown to be a useful and 18. Omran, A. F., “Formwork Pressure Exerted by Self-Consolidating

convenient method for the evaluation of thixotropy in the Concrete,” doctoral thesis, Department of Civil Engineering, Université de

Sherbrooke, Sherbrooke, QC, Canada, 2009, 315 pp.

case of flowable cementitious mixtures. 19. Barnes, H. A., A Handbook of Elementary Rheology, Institute of

2. The critical angle at which the flow commences on an Non-Newtonian Fluid Mechanics, University of Wales, UK, 2000, pp. 155-156.

inclined plane increases with rest time, reflecting an increase

in the degree of structural buildup of the material. Smaller APPENDIX—PROTOCOL FOR INCLINED

critical angles are indicative of lower structural buildup behavior. PLANE TEST METHOD

3. Similar results are obtained by the inclined plane and by 1. Arrange the inclined planes on a level table. Fix waterproof

the modified concrete rheometer. sandpapers of grit No. 600 onto the top surface of the incline

4. The inclined plane can therefore be proposed to evaluate plane plate. To position the sample in the center of the plane,

thixotropy and structural buildup of flowable concrete and mark the center line and write the distances from one edge of

can be easily used in the field and in the laboratory. the plane to the other edge using a permanent color felt

marker. These markings help to evaluate the distance of the

ACKNOWLEDGMENTS front flow (nose of the flowing material) of the material at

The authors would like to acknowledge the support of the National Ready the critical angle of the inclined plane.

Mix Concrete Education and Research Foundation and the Strategic

Development Council (SDC) of the American Concrete Institute, as well as

2. Spray a small layer of water onto the surface of the

several member companies of SDC for their financial support. sandpaper. Fill the first cylinder measuring 60 mm (2.36 in.)

in diameter and 120 mm (4.72 in.) in height to the 100 mm

REFERENCES (2.54 in.) mark in the case of mortar, and up to the top in the

1. Moller, P. C. F.; Mewis, J.; and Bonn, D., “Yield Stress and Thixotropy: case of SCC. The filling time is noted with respect to initial

On the Difficulty of Measuring Yield Stress in Practice,” Journal of Material water addition time, which corresponds to the first contact

Chemistry, V. 16, 2006, pp. 274-283. between cement and water in the mixture.

2. Coussot, P.; Nguyen, Q. D.; Huynh, H. T.; and Bonn, D., “Avalanche

Behavior in Yield Stress Fluids,” Physical Review Letters, V. 88, No. 17, 3. Slowly lift the cylinder so that the mixture flows

2002, 4 pp. uniformly onto the flat surface of the upper plane. Cover the

3. Coussot, P., and Boyer, S., “Determination of Yield Stress Fluid mixture with a wide cylindrical container covered by a wet

Behaviour from Inclined Plane Test,” Rheologica Acta, V. 34, No. 6, 1995, cloth so as to avoid any evaporation from the mixture during

pp. 534-542.

the rest time.

4. Tattersall, G. H., and Banfill, P. F. G., The Rheology of Fresh

Concrete, Pitman Advanced Publishing Program, Boston, 1983, 356 pp. 4. Determine the density of mortar or concrete, as the case

5. Khayat, K. H.; Saric-Coric, M.; and Liotta, F., “Influence of Thixotropy may be.

ACI Materials Journal/September-October 2010 521

5. The mixture’s first time of rest on the plane, under where ρ is density of the mixture (concrete or mortar), g

covered conditions, can be approximately 10 minutes after is the gravitational acceleration, and h is the thickness or

the first spread. When the time of rest is over, remove the wet height of the spread of mortar or concrete at the horizontal

cloth and the covering container, and measure the spread of position.

the sample. Find the height of the spread by averaging five 7. Repeat Steps 1 to 6 at other rest periods using other

measurements near the central area. Slowly lift the first incline plane setups with virgin, undisturbed samples. The

inclined plane until the flow of the mixture starts. time duration between subsequent tests can vary between 5 and

6. Measure the angle of inclination of the inclined plane 15 minutes depending on the degree of structural buildup of

with a protractor that is either fixed to the plane or removable. the material. Typically, three τ0rest measurements would be

Knowing the critical angle (θ) (the angle at which downward required to determine the rate of structural buildup of the

flow commences), the static yield stress (τ0rest) can be mortar or concrete at rest from the slope of the τ0rest versus

calculated as follows rest time data.

8. Clean the sandpaper using a moist towel at the conclusion

τ 0rest = ρgh sin θ (A1) of each test.

522 ACI Materials Journal/September-October 2010

View publication stats

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- How An Electrical Circuit Is REALLY Powered - Bearden For DummiesDocument8 pagesHow An Electrical Circuit Is REALLY Powered - Bearden For Dummiesberencsi2616No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Solutions For All Social Sciences GradeDocument49 pagesSolutions For All Social Sciences Gradesibusiso dzivaNo ratings yet

- AFF2 Stellar AdventuresDocument130 pagesAFF2 Stellar AdventuresRhys1100% (1)

- Pipe Solved ProbsetDocument115 pagesPipe Solved ProbsetRemae Garci100% (1)

- Creep Test Complete PDFDocument8 pagesCreep Test Complete PDFKalKatu MaLam50% (6)

- L7A - Slope Stability by FEMDocument21 pagesL7A - Slope Stability by FEMOng Tai BoonNo ratings yet

- Concrete Technology: Yassin Ali Ibrahim Erbil Polytechnic University Erbil Technology Institute 2020-2021Document112 pagesConcrete Technology: Yassin Ali Ibrahim Erbil Polytechnic University Erbil Technology Institute 2020-2021Salih MohayaddinNo ratings yet

- Heat TransferDocument292 pagesHeat TransferahmedalishNo ratings yet

- Practice Questions - Unit 4.4: Multiple ChoiceDocument13 pagesPractice Questions - Unit 4.4: Multiple Choiceapi-288922072No ratings yet

- Salih Samer Muhyiddin G6 G B: Point B.S I.S F.S Rise Fall Elev. RemarkDocument1 pageSalih Samer Muhyiddin G6 G B: Point B.S I.S F.S Rise Fall Elev. RemarkSalih MohayaddinNo ratings yet

- Building & Construction Department Concrete Laboratory: Water Cement RatioDocument5 pagesBuilding & Construction Department Concrete Laboratory: Water Cement RatioSalih MohayaddinNo ratings yet

- Ceramic IndustryDocument90 pagesCeramic IndustrySalih MohayaddinNo ratings yet

- Point B.S I.S F.S Rise Fall Elev. RemarkDocument1 pagePoint B.S I.S F.S Rise Fall Elev. RemarkSalih MohayaddinNo ratings yet

- Construction-Oriented Design For Manufacture and Assembly (Dfma) GuidelinesDocument25 pagesConstruction-Oriented Design For Manufacture and Assembly (Dfma) GuidelinesSalih MohayaddinNo ratings yet

- 4-Vee-Bee Time Test ReportDocument3 pages4-Vee-Bee Time Test ReportSalih MohayaddinNo ratings yet

- A Novel Test To Determine The Workability of Slipform Concrete MixturesDocument14 pagesA Novel Test To Determine The Workability of Slipform Concrete MixturesSalih MohayaddinNo ratings yet

- Compacting Factor Test: Building & Construction Department Concrete Laboratory Weekly Test ReportDocument2 pagesCompacting Factor Test: Building & Construction Department Concrete Laboratory Weekly Test ReportSalih MohayaddinNo ratings yet

- 4-Vee-Bee Time Test ReportDocument3 pages4-Vee-Bee Time Test ReportSalih MohayaddinNo ratings yet

- Concrete TechnologyDocument112 pagesConcrete TechnologySalih MohayaddinNo ratings yet

- Roofing Maintenance Software Review: "The Art of Roofing Condition Inspections" (First Report)Document17 pagesRoofing Maintenance Software Review: "The Art of Roofing Condition Inspections" (First Report)Salih MohayaddinNo ratings yet

- Gym Plan: Week 1: Full-Body SplitDocument7 pagesGym Plan: Week 1: Full-Body SplitSalih MohayaddinNo ratings yet

- Lara Kosrat AdelDocument2 pagesLara Kosrat AdelSalih MohayaddinNo ratings yet

- Fineness Test For Gypsum: Experiment No.:4Document1 pageFineness Test For Gypsum: Experiment No.:4Salih MohayaddinNo ratings yet

- Pile Foundation Design: A Student Guide: Introduction To Pile FoundationsDocument79 pagesPile Foundation Design: A Student Guide: Introduction To Pile FoundationsSalih MohayaddinNo ratings yet

- Parameter Study On Tracer Flow Test: February 2019Document8 pagesParameter Study On Tracer Flow Test: February 2019Salih MohayaddinNo ratings yet

- Mid Term Pract - Assess.laraDocument1 pageMid Term Pract - Assess.laraSalih MohayaddinNo ratings yet

- Answer Some of The Following QuestionsDocument3 pagesAnswer Some of The Following QuestionsSalih MohayaddinNo ratings yet

- Conducting Flow Measurement Laboratory Test WorkDocument8 pagesConducting Flow Measurement Laboratory Test WorkSalih MohayaddinNo ratings yet

- Chain and Tape Survey Gelb 109 Topograph PDFDocument14 pagesChain and Tape Survey Gelb 109 Topograph PDFSalih MohayaddinNo ratings yet

- Atomic Structure & The Periodic Table Unit 1Document15 pagesAtomic Structure & The Periodic Table Unit 1Mikaelia NesbethNo ratings yet

- Lab 3-To Measure The Absolute Porosity of A Given Core Sample GravimetricallyDocument13 pagesLab 3-To Measure The Absolute Porosity of A Given Core Sample GravimetricallySunny BbaNo ratings yet

- Thermal ExpansionDocument5 pagesThermal ExpansionParis ParyNo ratings yet

- XS-2321 Peak Performance DC MotorDocument64 pagesXS-2321 Peak Performance DC MotorromachNo ratings yet

- Fusion Bonded Joint - A Fatigue Friendly Connector For Cost Efficient Plastic Lined Pipe Installation and OperationDocument16 pagesFusion Bonded Joint - A Fatigue Friendly Connector For Cost Efficient Plastic Lined Pipe Installation and OperationMubeenNo ratings yet

- The Atom SongDocument1 pageThe Atom SongSheena BelmonteNo ratings yet

- Electronic Devices and Circuits S Salivahanan Full ChapterDocument51 pagesElectronic Devices and Circuits S Salivahanan Full Chapterwilliam.mcguire766100% (6)

- How To Download Quantum Computation and Quantum Information 10Th Anniversary Edition Ebook PDF Version Ebook PDF Docx Kindle Full ChapterDocument36 pagesHow To Download Quantum Computation and Quantum Information 10Th Anniversary Edition Ebook PDF Version Ebook PDF Docx Kindle Full Chapterrichard.talbott508100% (28)

- Lec 4 Hydrostatic Pressure On SurfacesDocument7 pagesLec 4 Hydrostatic Pressure On SurfacesJUSTIN JAMES ADANNo ratings yet

- Singly Reinforced BeamDocument3 pagesSingly Reinforced BeammariyaNo ratings yet

- Tilak Slides PDFDocument72 pagesTilak Slides PDFDarsh MenonNo ratings yet

- Ulaby Exercise Solutions (1) 240228 065636Document24 pagesUlaby Exercise Solutions (1) 240228 065636omonginib38No ratings yet

- Phy 121Document24 pagesPhy 121Suresh SaiNo ratings yet

- QUICKCHECK Webline Bro en 87113900 02Document8 pagesQUICKCHECK Webline Bro en 87113900 02badusha vpNo ratings yet

- CrimpinformationsheetDocument12 pagesCrimpinformationsheetTrần Long VũNo ratings yet

- Symmetrical Form of The Four-Suffix Margules Equations For Quaternary SystemsDocument2 pagesSymmetrical Form of The Four-Suffix Margules Equations For Quaternary Systems1940LaSalleNo ratings yet

- Non-Invasive Anomaly Diagnosis For Hydro Electrical Generators Rotor Inter-Turn Short-Circuit Detection Using Stray Flux and The VAEDocument7 pagesNon-Invasive Anomaly Diagnosis For Hydro Electrical Generators Rotor Inter-Turn Short-Circuit Detection Using Stray Flux and The VAEhamidrezaNo ratings yet

- Oil Feeding System Design For 132Kv U/G Oil Filled Cable Circuit 8092-8123Document6 pagesOil Feeding System Design For 132Kv U/G Oil Filled Cable Circuit 8092-8123Muhammad MahmudNo ratings yet

- Logic and Social ScienceDocument19 pagesLogic and Social ScienceSherlinNo ratings yet

- Asme Sec Viii Div 1 Ug-27Document17 pagesAsme Sec Viii Div 1 Ug-27vipul gandhiNo ratings yet

- Result Chapter Test-1 - Class-11th-A-Lot (CTY-2325) - 10-05-2023Document21 pagesResult Chapter Test-1 - Class-11th-A-Lot (CTY-2325) - 10-05-202310A31 Irfan HashmiNo ratings yet

- Engr. Marabelle R. Del PradoDocument14 pagesEngr. Marabelle R. Del PradoArin ParkNo ratings yet