Professional Documents

Culture Documents

Frigoscandia Spiral Freezer, Chiller & Proofer: Gyrocompact 60

Uploaded by

Karthik BhandaryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frigoscandia Spiral Freezer, Chiller & Proofer: Gyrocompact 60

Uploaded by

Karthik BhandaryCopyright:

Available Formats

Frigoscandia GYRoCOMPACT ® 60

Spiral Freezer, Chiller & Proofer

New compact design, reduced power consumption

Fans located on dry side of evaporator.

Optimised air velocity through

evaporator.

Increased production uptime, greater

freezing capacity, increased reliability.

Maximum heat transfer and frost pick-

up. Easy cleaning. Optimised fan/motor

combinations give a maximum production

capacity with the lowest possible energy

consumption.

Optimised drive system leading to

significantly less drive power for the belt

and reduced need for lubrication.

Pre-assembled wall-mounted control

panel pretested from assembly factory.

Featuring PRoLINK™ control system with

state of the art PLC and HMI system.

Fully seal-welded, stainless steel floor

design, open from door to door under

conveyor and evaporator.

Improved hygiene, instant inspection, easy

access, faster cleaning.

A new machine, from start to finish.

We’ve retained the best features, and added some new ones.

Many evaporator combinations

in 1–2 blocks.

Match any freezing needs precisely.

Easy access and easy cleaning. Optimised

base load.

Simplified outfeed unit without

drive arrangement. Less belt wear,

less maintenance and less energy

consumption.

Simplified belt take-up, with less

winding. Absolute minimum of tension

on the return rail.

Even longer belt life. Easier access for

cleaning.

Sloped floor and fully seal-welded

drains in each corner of the freezer, with

bevelled edges. Elevated floor-to-wall

joint.

Effective drainage where it’s needed,

faster cleaning and less downtime.

No bacterial traps.

Stands fully welded to the floor.

Horizontal stand structures with solid

rods.

Design allows for thermal expansion and

contraction. No horizontal hollow sections

to collect contamination. No caulking to

crack or damage.

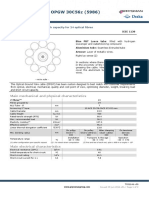

Technical data (SI-system)

Conveyor belt

Type Frigoscandia FRIGoBELT® Nova Conveyor

Link height (mm) 80 100 120

Vertical clearance for product (mm) 65 85 105

Mesh M6-1.5, M9-1.7, M13-1.5, M20-1.5

Width, total (mm) 670

Width, net (mm) 615

Width, between infeed covers (mm) 600

Number of tiers (min–max) 16-42

Length per tier (m) 11.2

Effective belt conveyor area per tier (m2) 5.7

Conveyor belt speed (m/min) 3.5–30 (standard speed range), 2.0–15 (optional speed range)

Electrical data

GC 60 / 2 GC 60 / 2B 1)

Normal power consumption (kW) 2) 5)

28 14

Main voltage 3 x 380–480 V / 3 x 575 V, 50 / 60 Hz

Refrigeration data

GC 60 / 2 GC 60 / 2B 1)

Base load (kW) 6) 31 16

Standard design R717 (Ammonia): Pump circulation ratio = 4–6 times evaporator

Defrosting system

Defrosting media Hot gas or potable water

Water consumption (L/min) at 300 kPa = 3 bar, min 1 bar 3) 150

Subject to change without notice.

Minimum / maximum water temperature (°C) 3) 4) +15 / +25

Noise emissions

According to EC Machine Directive Maximum 80 dB(A)

Application data

Rectangular products: 1.7 x product length

Normal loading distance on straight belt conveyor

Round products: 1.5 x product diameter

B 3220-EN-1509

1)

Low energy alternative.

2)

Does not include dimensioning of power supply fuses/cables. Refer to customer drawings for maximum power requirement..

3)

Must be potable water.

4)

Make sure refrigeration system is safe for water temperature in use.

5)

All consumption values are calculated for a nominal case. Customer specific values available on request - contact sales support.

1700 7650

705

4350

705

687 413

www.jbtfoodtech.com

North America Europe Asia Latin America

JBT John Bean Technologies AB John Bean Technologies Ltd. John Bean Technologies

1622 First St. Rusthållsgatan 21, Box 913 159/26 Serm-Mit Tower, Room no. 1602-3 Máq. Equip. Ind. Ltda.

Sandusky, OH 44870 SE-251 09 Helsingborg Sukhumvit 21 Road, Klongtoey Nua Sub-district Av .Eng. Camilo Dinucci 4605

USA SWEDEN Wattana District, Bangkok 10110, THAILAND 14808-900 Araraquara, São Paulo,

Phone: +1 419 626 0304 Phone: +46 42 490 4000 Phone: +66 2257 4000 BRAZIL

process-solutions@jbtc.com info-europe@jbtc.com infoasia-jbtfoodtech@jbtc.com Phone: +55 16 3301 2000

latinamerica.info@jbtc.com

You might also like

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- FrigolandiaDocument4 pagesFrigolandiagamunozdNo ratings yet

- Gyrocompact m9 ScreenDocument4 pagesGyrocompact m9 ScreennascasNo ratings yet

- Ficha Tecnica Ingersoll Rand DD-24Document2 pagesFicha Tecnica Ingersoll Rand DD-24Javier Hernandez Abril67% (3)

- Spiral Freezer & Chiller: Frigoscandia Gyrocompact 40Document4 pagesSpiral Freezer & Chiller: Frigoscandia Gyrocompact 40Gerardo Sepulveda ToledoNo ratings yet

- DD-24 & DD-30: Vibratory CompactorsDocument2 pagesDD-24 & DD-30: Vibratory CompactorsHenry RosadoNo ratings yet

- 122 KW (164 HP) : Zaxis - Dash-3Document28 pages122 KW (164 HP) : Zaxis - Dash-3lmn_grssNo ratings yet

- System Information Idler Set DataDocument98 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- PramonnoDocument1 pagePramonnoHariyono Rudi NovantoNo ratings yet

- Inbound 140989936258214395Document2 pagesInbound 140989936258214395Emir KunalićNo ratings yet

- DM900 - 9.00 kVA: ModelDocument3 pagesDM900 - 9.00 kVA: ModelMohamed HusseinNo ratings yet

- 8270 - T44pdfDocument4 pages8270 - T44pdfriscorenan22No ratings yet

- Wacker - RT82 - Trench - Roller - SPECSDocument2 pagesWacker - RT82 - Trench - Roller - SPECSRojasNo ratings yet

- CDP Mini Split Quick ReferenceDocument7 pagesCDP Mini Split Quick ReferenceMiguel GomezNo ratings yet

- List of Silo System For PT SUBUR - FAMSUNDocument5 pagesList of Silo System For PT SUBUR - FAMSUNAquinas ThomazNo ratings yet

- Manual de Servicio y Reparacion IR Blaw Knox PF6110Document756 pagesManual de Servicio y Reparacion IR Blaw Knox PF6110Ruben Raygosa100% (4)

- 9.5in OntrakDocument2 pages9.5in OntrakPaul Ticona SNo ratings yet

- Chocolatos 2Document1 pageChocolatos 2Hariyono Rudi NovantoNo ratings yet

- Datasheet Kleemann Mco9 EVO enDocument4 pagesDatasheet Kleemann Mco9 EVO enGemma KemalNo ratings yet

- m-4 ReportDocument47 pagesm-4 ReportHasan arif KısaalioğluNo ratings yet

- Simulation Summary of Horizontal EconomizerDocument1 pageSimulation Summary of Horizontal EconomizerHariyono Rudi NovantoNo ratings yet

- ASLH-D (S) B 48 NZDSF (A20SA 53 - 7,3) : Optical Ground Wire (OPGW)Document1 pageASLH-D (S) B 48 NZDSF (A20SA 53 - 7,3) : Optical Ground Wire (OPGW)AHMED YOUSEFNo ratings yet

- RicisDocument1 pageRicisHariyono Rudi NovantoNo ratings yet

- dt820 Specification Sheet EnglishDocument4 pagesdt820 Specification Sheet Englishburak tiryakiNo ratings yet

- GR BluePro Brochure enDocument4 pagesGR BluePro Brochure enabdu taliaNo ratings yet

- Brochure dd70 dd70hf t2 en 21 20000257 CDocument4 pagesBrochure dd70 dd70hf t2 en 21 20000257 CJoshwa SimamoraNo ratings yet

- Output Summary for Air-Cooled Heat ExchangerDocument7 pagesOutput Summary for Air-Cooled Heat ExchangerVu TranNo ratings yet

- OPL Washer 30022VRJ 2016Document2 pagesOPL Washer 30022VRJ 2016Paul GageNo ratings yet

- 518 HV SL VFD (ATEX) - Equipment Data Sheet (Rev 06)Document2 pages518 HV SL VFD (ATEX) - Equipment Data Sheet (Rev 06)Gerard HoffardNo ratings yet

- Truck-Mounted Concrete Pump With 4-Section Placing BoomDocument4 pagesTruck-Mounted Concrete Pump With 4-Section Placing BoomMichael MichaelNo ratings yet

- NSB Ups BatteryDocument4 pagesNSB Ups BatteryLast Juan StandingNo ratings yet

- DD-14S & DD-16: Vibratory CompactorsDocument2 pagesDD-14S & DD-16: Vibratory CompactorsFer GonzalezNo ratings yet

- GTB v6Document7 pagesGTB v6Chan Shiaw SyanNo ratings yet

- Plugin 739129Document2 pagesPlugin 739129Sohaib AbidNo ratings yet

- Aph6585vibratoryplatesellsheetmss 1062 07 En200305Document2 pagesAph6585vibratoryplatesellsheetmss 1062 07 En200305Apo ghasan Al shargapiNo ratings yet

- Gfps 2581 Datasheet Flowtramag Meter Flow Sensors enDocument8 pagesGfps 2581 Datasheet Flowtramag Meter Flow Sensors enasghar khanNo ratings yet

- XMT 304 CC CVDocument4 pagesXMT 304 CC CVroxanaNo ratings yet

- m-1 ReportDocument58 pagesm-1 ReportHasan arif KısaalioğluNo ratings yet

- 4-Way Standard Cassette - 14,00 KW - R410A - VRF MMU-AP0484HP1-E enDocument3 pages4-Way Standard Cassette - 14,00 KW - R410A - VRF MMU-AP0484HP1-E enAllan FreitasNo ratings yet

- VST - Axial Flow Catalog - 2021.R010Document6 pagesVST - Axial Flow Catalog - 2021.R010Jaydeep PanchalNo ratings yet

- ChocolatosDocument1 pageChocolatosHariyono Rudi NovantoNo ratings yet

- m-3 ReportDocument72 pagesm-3 ReportHasan arif KısaalioğluNo ratings yet

- Optical Ground Wire cable specificationsDocument1 pageOptical Ground Wire cable specificationsDorcioman AndreiNo ratings yet

- Technical Data Sheet: 3stutor® 90/4.5Document1 pageTechnical Data Sheet: 3stutor® 90/4.5duongNo ratings yet

- RTHD Series-CatalogueDocument40 pagesRTHD Series-CatalogueRobecal GeneralNo ratings yet

- DG VL 150 SeDocument1 pageDG VL 150 SevinodhharshiNo ratings yet

- En PS-50-65 200 260 330TP2Document4 pagesEn PS-50-65 200 260 330TP2blueee archiveNo ratings yet

- downhole-vantage-logging-head-psDocument2 pagesdownhole-vantage-logging-head-psLuisNo ratings yet

- Ficha Tecnica - Empalmadora de Mano EX39 - KomshineDocument7 pagesFicha Tecnica - Empalmadora de Mano EX39 - KomshineluisfernandortNo ratings yet

- 9851 3586 01 - Cop MD20Document4 pages9851 3586 01 - Cop MD20Guifo salvadorNo ratings yet

- 9851 3586 01 COP MD20 BrochureDocument4 pages9851 3586 01 COP MD20 BrochureEduardo MassainiNo ratings yet

- Prysmian ES - OPGW 70sqmmDocument2 pagesPrysmian ES - OPGW 70sqmmwan kenobiNo ratings yet

- IMESA STC Commercial-Sheet LM-40-55 Evo - Line ENG R00Document2 pagesIMESA STC Commercial-Sheet LM-40-55 Evo - Line ENG R00Jayantha SenevirathnaNo ratings yet

- En-Dhm-T72x10 FS (BW) - 545-560WDocument2 pagesEn-Dhm-T72x10 FS (BW) - 545-560WNicolae BarcaruNo ratings yet

- High-Efficiency Push Factor For Moving Rock and IceDocument2 pagesHigh-Efficiency Push Factor For Moving Rock and IceIT Account50% (2)

- FISA TEHNICA DAH FULL SCREEN DHM-T60X10 FS (BB) - 455W (All Black) - IanDocument2 pagesFISA TEHNICA DAH FULL SCREEN DHM-T60X10 FS (BB) - 455W (All Black) - Ianc75553157No ratings yet

- Conveyor design for EUROCHEM KOVDORSKIY GOK M-2 projectDocument62 pagesConveyor design for EUROCHEM KOVDORSKIY GOK M-2 projectHasan arif KısaalioğluNo ratings yet

- TG 73-200 - en PDFDocument7 pagesTG 73-200 - en PDFSheril ChandraboseNo ratings yet

- ARR 1575 Brochull de Venta InglesDocument2 pagesARR 1575 Brochull de Venta InglesKerbin Enrique NuñezNo ratings yet

- Memcor UF Product Data Sheet CPII MemRackDocument2 pagesMemcor UF Product Data Sheet CPII MemRackDio MiNo ratings yet

- Live animal import duty ratesDocument337 pagesLive animal import duty ratesKarthik BhandaryNo ratings yet

- Slicer 305 Basic: Simple SlicingDocument2 pagesSlicer 305 Basic: Simple SlicingKarthik BhandaryNo ratings yet

- 915 MH Microwave Batch Machines: DescriptionDocument2 pages915 MH Microwave Batch Machines: DescriptionKarthik BhandaryNo ratings yet

- Slicer 405: Hygienic, Powerful, VersatileDocument4 pagesSlicer 405: Hygienic, Powerful, VersatileKarthik BhandaryNo ratings yet

- Vested Advisory AgreementDocument14 pagesVested Advisory AgreementKarthik BhandaryNo ratings yet

- Ball Control Bc237: The Smart Answer To Convenience ProductsDocument2 pagesBall Control Bc237: The Smart Answer To Convenience ProductsKarthik BhandaryNo ratings yet

- Travel ItineraryDocument2 pagesTravel ItineraryKarthik BhandaryNo ratings yet

- Product sensory evaluation formDocument2 pagesProduct sensory evaluation formKarthik Bhandary80% (5)

- The Power of Steam: CERTUSS Junior TC Steam GeneratorsDocument24 pagesThe Power of Steam: CERTUSS Junior TC Steam GeneratorsKarthik BhandaryNo ratings yet

- Logo Guidelines: We Proudly Serve StarbucksDocument12 pagesLogo Guidelines: We Proudly Serve StarbucksMamphayssou N'GUESSANNo ratings yet

- GSO-1016-2015-E Microbiological Criteria For FoodstuffsDocument33 pagesGSO-1016-2015-E Microbiological Criteria For FoodstuffsKarthik Bhandary71% (7)

- Netherlands Visa Application CenterDocument3 pagesNetherlands Visa Application Centermyfriend2meNo ratings yet

- Script Movie DefSec DoctorsDocument5 pagesScript Movie DefSec DoctorsKarthik BhandaryNo ratings yet

- GSO-1754!2!2013-E Edible Vegetable Oils - Part 2Document14 pagesGSO-1754!2!2013-E Edible Vegetable Oils - Part 2Karthik BhandaryNo ratings yet

- DEFSEC DOCS Video Script ONE With Comment On VideoDocument5 pagesDEFSEC DOCS Video Script ONE With Comment On VideoKarthik BhandaryNo ratings yet

- Global Retail Trends UAE PDFDocument10 pagesGlobal Retail Trends UAE PDFKarthik BhandaryNo ratings yet

- Orders Dashboard for Hectare's WordPress WebsiteDocument6 pagesOrders Dashboard for Hectare's WordPress WebsiteKarthik BhandaryNo ratings yet

- GSO-1754!1!2015-E Edible Vegetable Oils - Part 1Document19 pagesGSO-1754!1!2015-E Edible Vegetable Oils - Part 1Karthik Bhandary100% (1)

- Steel CompaniesDocument2 pagesSteel CompaniesKarthik BhandaryNo ratings yet

- Ben Neuwirth - Dlight PresentationDocument31 pagesBen Neuwirth - Dlight PresentationKarthik BhandaryNo ratings yet

- Script Movie DefSec DoctorsDocument5 pagesScript Movie DefSec DoctorsKarthik BhandaryNo ratings yet

- Orders Dashboard for Hectare's WordPress WebsiteDocument6 pagesOrders Dashboard for Hectare's WordPress WebsiteKarthik BhandaryNo ratings yet

- 중형 보울컷터Document8 pages중형 보울컷터Karthik BhandaryNo ratings yet

- ScopeDocument3 pagesScopeKarthik BhandaryNo ratings yet

- A4 FlyerDocument1 pageA4 FlyerKarthik BhandaryNo ratings yet

- Conference Lecture2 1217646379629881 9 PDFDocument47 pagesConference Lecture2 1217646379629881 9 PDFKarthik BhandaryNo ratings yet

- Maldives Airport Representative: Ms. Naajy Phone: Airport Representative: Ms. Anoosha Phone: Airport Counter Number: 32Document1 pageMaldives Airport Representative: Ms. Naajy Phone: Airport Representative: Ms. Anoosha Phone: Airport Counter Number: 32Karthik BhandaryNo ratings yet

- Seven Keys to Improved Customer ExperiencesDocument10 pagesSeven Keys to Improved Customer ExperiencesKarthik BhandaryNo ratings yet

- A4 FlyerDocument1 pageA4 FlyerKarthik BhandaryNo ratings yet

- Domain Logic and SQLDocument23 pagesDomain Logic and SQLatifchaudhryNo ratings yet

- 2020 FMGT 1013 - Financial Management RevisedDocument9 pages2020 FMGT 1013 - Financial Management RevisedYANIII12345No ratings yet

- VampireRev4-Page Editable PDFDocument4 pagesVampireRev4-Page Editable PDFNicholas DoranNo ratings yet

- Project's Estimated Residual Income and Required InvestmentDocument7 pagesProject's Estimated Residual Income and Required InvestmentblueberryNo ratings yet

- Shaw's play about a sculptor and his creationDocument8 pagesShaw's play about a sculptor and his creationEmanuel BurculetNo ratings yet

- 21st Century Literature Quarter 2 Week 7Document5 pages21st Century Literature Quarter 2 Week 7SHERRY MAE MINGONo ratings yet

- Jurnal SinusitisDocument49 pagesJurnal SinusitisAramanda Dian100% (1)

- Cellular ManufacturingDocument61 pagesCellular Manufacturingapi-3852736100% (1)

- Defying Danger RPGDocument9 pagesDefying Danger RPGmondytriggers2944No ratings yet

- Small Events in The Royal ParksDocument6 pagesSmall Events in The Royal ParksTroy HealyNo ratings yet

- Lift Rope Inspection PDFDocument2 pagesLift Rope Inspection PDFcarlosorizaba100% (1)

- Bamuoingaythienquan NguyenduynhienDocument9 pagesBamuoingaythienquan NguyenduynhienFLed NguyenNo ratings yet

- Lec # 10 Earthing and GroundingDocument68 pagesLec # 10 Earthing and GroundingSaddam jatt786No ratings yet

- School Canteen Satisfaction Survey ResultsDocument2 pagesSchool Canteen Satisfaction Survey ResultsElla PastorinNo ratings yet

- E - Efma Rbi Insp Interval Assess Projector - PP SimtechDocument10 pagesE - Efma Rbi Insp Interval Assess Projector - PP SimtechAbhimanyu SharmaNo ratings yet

- FREE BioGeometry Emitter PhotoDocument5 pagesFREE BioGeometry Emitter PhotoNisha Joshi75% (8)

- Bahan Belajar Ujian Akhir SekolahDocument13 pagesBahan Belajar Ujian Akhir SekolahArga AnggaraNo ratings yet

- D 3 Econo SPP 2110 1 eDocument123 pagesD 3 Econo SPP 2110 1 eMargarida MoreiraNo ratings yet

- Photoshop Cheat SheetDocument11 pagesPhotoshop Cheat SheetGiova RossiNo ratings yet

- Kolej Matrikulasi Pulau Pinang Kementerian Pelajaran Malaysia 13200 Kepala BatasDocument9 pagesKolej Matrikulasi Pulau Pinang Kementerian Pelajaran Malaysia 13200 Kepala Bataskelisa157100% (2)

- The Teacher and Student Relationship of Haydn and BeethovenDocument10 pagesThe Teacher and Student Relationship of Haydn and BeethovenVinny MuscarellaNo ratings yet

- Pizza Hut Training Manual FinishedDocument34 pagesPizza Hut Training Manual FinishedEdilson MaziveNo ratings yet

- Full Download Test Bank For Positive Psychology 4th Edition Lopez PDF Full ChapterDocument36 pagesFull Download Test Bank For Positive Psychology 4th Edition Lopez PDF Full Chaptershaps.tortillayf3th100% (21)

- Training ReportDocument56 pagesTraining ReportRavimini100% (2)

- GPSForex Robot V2 User GuideDocument40 pagesGPSForex Robot V2 User GuideMiguel Angel PerezNo ratings yet

- Clarke 1973 Loss of InnocenceDocument13 pagesClarke 1973 Loss of InnocencePaula TralmaNo ratings yet

- Har Rabia Bins Fax Tunisia 2018Document8 pagesHar Rabia Bins Fax Tunisia 2018vacomanoNo ratings yet

- Case Study of Haleeb FoodDocument18 pagesCase Study of Haleeb Foodjazi_4u86% (22)

- Dynamic Bearing Capacity of Shallow FoundationDocument31 pagesDynamic Bearing Capacity of Shallow FoundationLingeswarran NumbikannuNo ratings yet

- Summer Training Report Lean Process OptimisationDocument19 pagesSummer Training Report Lean Process OptimisationKrishna RaoNo ratings yet