Professional Documents

Culture Documents

Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6

Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6

Uploaded by

dhineshbabu rOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6

Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6

Uploaded by

dhineshbabu rCopyright:

Available Formats

_

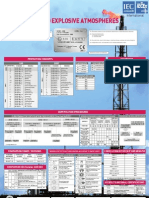

Your Safety Our Reality

NEC 500 Class I, Division 1, Groups A, B, C, D, T6

NEC 505 Class I, Zone 1, A Ex de IIC T6

IEC marking according to ATEX Ex de IIC T6

CENELEC II 2 G Ex* de IIC T6

TYPES OF PROTECTION FOR ELECTRICAL APPARATUS

EQUIPMENT GROUP I (MINING)

IN HAZARDOUS AREAS

Category Sufficent safety Type of protection Diagram Main application Standard

Category M1 by means of 2 protective measures /2 faults

increased e terminal and junction boxes, control boxes EN 60 079 -7 UL 60 079 -7

Category M2 the equipment is intended to be deenergized in the event of an explosive atmosphere for installing Ex-components (with a

safety different type of protection), squirrel-cage

IEC 60 079 -7 FM 3600

motors, light fittings

EQUIPMENT GROUP II (OTHER HAZARDOUS AREAS)

flameproof d switchgear and control station and indicating EN 60 079-1 UL 60 079-1

Category Atmosphere G Atmosphere D Sufficent safety equipment, control systems, motors,

enclosures transformers, heating equipment, light fittings

IEC 60 079-1 FM 3600

(Gas) (Dust)

Category 1 Zone 0 Zone 20 by means of 2 protective measures /2 faults

pressurized p switchgear and control cabinets, analysers, EN 60 079-2 NFPA 496

Category 2 Zone 1 Zone 21 frequently occuring equipment faults/1 fault large motors

enclosures IEC 60 079-2 FM 3620

px = for use in Zone 1, 2

Category 3 Zone 2 Zone 22 during normal operation py = for use in Zone 1, 2

pz = for use in Zone 2

Category (1), (2), (3) = associated electrical apparatus – installation in the safe area

intrinsic safety i instrumentation technology, EN 60 079-11 UL 60 079-11

fieldbus technology, sensors, actuators

IEC 60 079-11 FM 3610

ia = for use in Zone 0, 1, 2

ib = for use in Zone 1, 2

CLASSES AND GROUPS [Ex ib] = associated electrical apparatus

ZONES

ACC. NEC 500 – installation in the safe area

Class Substance Group Dangerous Gas acc. Dust acc.

intrinsically safe systems EN 60 079-25

explosive CENELEC/ IEC/ IEC 60 079-25

Class I (gas) Acetylene A

atmosphere IEC/NEC 505 CENELEC FISCO Ex ia IIC T4 fieldbus intrinsically-safe concept (FISCO) for Zone 1 EN 60 079-27

FNICO Ex ia IIC T4 fieldbus non-incentive concept (FNICO) for Zone 2

Hydrogen B IEC 60 079-27

continously or Zone 0 Zone 20

Ethylene C longterm oil immersion o transformers, starting resistors EN 60 079-6 UL 60 079-6

or frequently IEC 60 079-6 FM 3600

Propane D

likely to/can Zone 1 Zone 21

Mining Methane exist under powder filling q sensors, display units, electronic ballasts, EN 60 079- 5 UL 60 079- 5

Class II (dust) Metal dust E normal operating transmitters

IEC 60 079- 5 FM 3600

conditions

Coal dust F

not likely to Zone 2 Zone 22

Grain dust G occur or for encapsulation m switchgear with small capacity, control and EN 60 079-18 UL 60 079-18

signalling units, display units, sensors

Class III (fibers) Fibers short period IEC 60 079-18 FM 3600

ma = for use in Zone 0, 1, 2

mb = for use in Zone 1, 2

HAZARDOUS AREA ACC. NEC 500

type of n_ all electrical apparatus for Zone 2 EN 60 079-15 UL 60 079-15

protection nA = non-sparking apparatus IEC 60 079-15 FM 3600

Division 1 likely to/can exist under nC = sparking apparatus, in which the contacts

normal operating conditions are protected in a suitable way

nL = energy limited apparatus

Division 2 abnormal condition nR = restricted breathing enclosures

nZ = apparatus with n-pressurization

TEMPERATURE CLASSIFICATION GAS GROUPS ACC. IEC, optical op _ op is = inherently safe optical radiation EN 60 079-28

ACC. NEC 500 CENELEC AND NEC 505 radiation op pr = protected optical radiation

IEC 60 079-28

op sh = optical radiation interlock

Maximum surface Temperature Explosion group Typical gas

temperature classes for gases

I Methane TYPES OF PROTECTION FOR ELECTRICAL APPARATUS

450 °C T1

IIA Propane IN AREAS WITH COMBUSTIBLE DUST

300 °C T2

IIB Ethylene Type of protection Diagram Main application Standard

280 °C T2A

IIC Hydrogen

260 °C T2B protection by tD switchgear and control station, terminal and EN 61 241-1 IEC 61 241-1

connection boxes, control boxes, motors,

230 °C T2C enclosures light fittings

215 °C T2D TEMPERATURE CLASSIFICATION tD A21 = under procedure A for Zone 21

tD B21 = under procedure B for Zone 21

ACC. IEC, CENELEC AND NEC 505

200 °C T3 pressurization pD switchgear and control cabinets, motors EN 61 241- 4 IEC 61 241- 4

Maximum surface Temperature

180 °C T3 A temperature classes for gases

165 °C T3B 450°C T1

160 °C T3C intrinsic safety iD measurement and control technology, EN 61 241-11 IEC 61 241-11

300°C T2 fieldbus technology, sensors, actuators

135 °C T4 200°C T3 iaD = for use in Zone 20, 21, 22

ibD = for use in Zone 21, 22

120 °C T4A 135°C T4 [Ex ibD] = associated electrical apparatus

– installation in the safe area

100 °C T5 100°C T5 encapsulation mD switchgear with small capacity, control and EN 61 241-18 IEC 61 241-18

signalling units, display units, sensors

85 °C T6 85°C T6

maD = for use in Zone 20, 21, 22

Dust: indication of the max. surface temperature in °C Dust: indication of the max. surface temperature in °C mbD = for use in Zone 21, 22

* Ex: from december 2004, EEx: until march 2007 (transition period) ID-NR. 00 006 37 77 0 S-PB-Ex-Plakat-03-en-10/2006

Printed in the Federal Republic of Germany

R.STAHL Schaltgeräte GmbH

Am Bahnhof 30, 74638 Waldenburg, Germany

Phone + 49 7942 943 - 0, Fax + 49 7942 943 - 4333

E-mail info.ex @ stahl.de www.stahl.de

You might also like

- Wet and Dry ContactsDocument7 pagesWet and Dry ContactsKhairul AshrafNo ratings yet

- Basic PV Elite TrainingDocument54 pagesBasic PV Elite TrainingcayovinNo ratings yet

- MindMap RubricDocument1 pageMindMap Rubriccabrera.adolfo1862No ratings yet

- Test Bank For Occupational Safety and Health For Technologists Engineers and Managers 8 e 8th Edition David L GoetschDocument24 pagesTest Bank For Occupational Safety and Health For Technologists Engineers and Managers 8 e 8th Edition David L Goetschjamesaustinckpbxydnqf100% (46)

- PIG Handling TrollyDocument1 pagePIG Handling TrollyAnas Badar100% (1)

- Hazardous Area Chart - StahlDocument1 pageHazardous Area Chart - StahlDanang Prakosa100% (2)

- 3 Ton Load Calculation of Cargo LiftDocument2 pages3 Ton Load Calculation of Cargo LiftTaha ZiaNo ratings yet

- Demag DR Rope Hoist: Without Electrical ControlDocument32 pagesDemag DR Rope Hoist: Without Electrical ControlDante WilliamsNo ratings yet

- Cessna Private Pilot CourseDocument29 pagesCessna Private Pilot CourseSulejman VaticNo ratings yet

- Factories Works Act - Pressure Vessel RegsDocument7 pagesFactories Works Act - Pressure Vessel Regschrissy zee1No ratings yet

- LiftingDocument13 pagesLiftingrichardchiamNo ratings yet

- End-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesDocument6 pagesEnd-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesMuhammad MustafaNo ratings yet

- Steelstrong: Always Strong in Valve WorldDocument32 pagesSteelstrong: Always Strong in Valve WorldBharat Bhushan SharmaNo ratings yet

- Annexure D - For Cable Cellar MVWS SystemDocument1 pageAnnexure D - For Cable Cellar MVWS SystemVaibhav SawantNo ratings yet

- Easyheat s27 - 02 SarcoDocument8 pagesEasyheat s27 - 02 SarcoMarcelo ResckNo ratings yet

- Sheaves & GroovesDocument1 pageSheaves & GroovesJorge Prado DiazNo ratings yet

- Sizing A Hydraulic CylinderDocument4 pagesSizing A Hydraulic Cylinderapi-611379115No ratings yet

- Actuator Catalogue CompleteDocument22 pagesActuator Catalogue Completeprashantsingh0450% (2)

- Global Rail Wheel Market 2017 by Global Growth, Share, Trends, Demand and Analysis Report Forecasts To 2022: Global QYResearchDocument10 pagesGlobal Rail Wheel Market 2017 by Global Growth, Share, Trends, Demand and Analysis Report Forecasts To 2022: Global QYResearchSaurabhNo ratings yet

- Pig Handling EquipmentDocument2 pagesPig Handling Equipmentehsan_baheriNo ratings yet

- Hazardous Area Guide: For Atex & Iecex (Zones/Groups)Document1 pageHazardous Area Guide: For Atex & Iecex (Zones/Groups)Sandra Yadhit Higuera ArchilaNo ratings yet

- Yamaha Part FZR 1000Document76 pagesYamaha Part FZR 1000dario100% (1)

- Study Guide For Med Surg 1Document15 pagesStudy Guide For Med Surg 1desireemaenugentNo ratings yet

- Annexure D - For Cable Cellar MVWS SystemDocument1 pageAnnexure D - For Cable Cellar MVWS Systemsujay AvatiNo ratings yet

- Hafele ArchitecturalDocument797 pagesHafele ArchitecturalDindandut SayNo ratings yet

- Gate ValvesDocument2 pagesGate Valves@sssNo ratings yet

- AEC - 70 KVA Machine SpecsDocument1 pageAEC - 70 KVA Machine Specssamer8saif100% (1)

- ATEC Cyclone Datasheet EnglDocument1 pageATEC Cyclone Datasheet EnglDilnesa EjiguNo ratings yet

- Cooler CatalogueDocument53 pagesCooler CatalogueCărunta-Crista CristinaNo ratings yet

- HAZOP Study Checklist (26092011) - 6 PDFDocument1 pageHAZOP Study Checklist (26092011) - 6 PDFHina ImranNo ratings yet

- Velcon FiltersDocument2 pagesVelcon FiltersLungisani100% (1)

- Hvws System For 10 Mva TransformerDocument26 pagesHvws System For 10 Mva Transformershashi ranjanNo ratings yet

- GL Cargo CraneDocument2 pagesGL Cargo CraneDharmawan100% (1)

- MCQs Surgery 1Document4 pagesMCQs Surgery 1Asim NiazNo ratings yet

- Dual Plate Check ValveDocument1 pageDual Plate Check ValveJEANR77No ratings yet

- Detailed - LESSON - PLAN - GRADE 10 DemonowDocument5 pagesDetailed - LESSON - PLAN - GRADE 10 DemonowShiela Ocho100% (3)

- Commercial Catalogue Jib Cranes Low ResDocument32 pagesCommercial Catalogue Jib Cranes Low Resstalin vNo ratings yet

- Sop GSSDocument3 pagesSop GSSArun MurugaiyanNo ratings yet

- Lcie Bureau Veritas Atex Poster PDFDocument1 pageLcie Bureau Veritas Atex Poster PDFAncaOniscuNo ratings yet

- Dayamas Rotational Molded PE Tank Brochures-09Document4 pagesDayamas Rotational Molded PE Tank Brochures-09Amoolia Ngo0% (1)

- Alvaer DNV2.7-3 PDFDocument23 pagesAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- 1-Piece Instrumentation, 40G and 40 Series: Part NoDocument2 pages1-Piece Instrumentation, 40G and 40 Series: Part Nozidanejason8No ratings yet

- TP-WMS-05967-DAS-A4-D1-K - Biocide DatasheetDocument9 pagesTP-WMS-05967-DAS-A4-D1-K - Biocide Datasheetbmanojkumar16No ratings yet

- Elmar Pannel - BP ColombiaDocument6 pagesElmar Pannel - BP ColombiaFelipe Augusto Diaz SuazaNo ratings yet

- 1V-2V-1315-1325 - Without Tolerance - Out PDFDocument167 pages1V-2V-1315-1325 - Without Tolerance - Out PDFMirang ShahNo ratings yet

- KAT B 5512 HYsec Edition2 en 12 10Document16 pagesKAT B 5512 HYsec Edition2 en 12 10Sathishkumar DhamodaranNo ratings yet

- Separator NadobyDocument15 pagesSeparator NadobyVidyasenNo ratings yet

- LOP For Re-Install FWP B With NPP Nusantara Rev.1Document13 pagesLOP For Re-Install FWP B With NPP Nusantara Rev.1Akbar RahmansyahNo ratings yet

- Rhino Process Equipment: Product DescriptionDocument2 pagesRhino Process Equipment: Product DescriptionMurli ramchandranNo ratings yet

- Bladder TankDocument1 pageBladder TankmuthuvelaaNo ratings yet

- Unidirectional ProverDocument2 pagesUnidirectional ProverGanjar Al Kaspandi100% (1)

- BS5501 2 PDFDocument12 pagesBS5501 2 PDFDasdasd SadasdNo ratings yet

- Ucs 56Document1 pageUcs 56enemesio_85100% (1)

- Asme Sec XDocument1 pageAsme Sec XSARSAN NDTNo ratings yet

- Flow-Switch-RapidropDocument4 pagesFlow-Switch-RapidropNOMANNo ratings yet

- N11 Nozzle CalDocument9 pagesN11 Nozzle Calגרבר פליקסNo ratings yet

- FCI 70-2-2006 PreDocument1 pageFCI 70-2-2006 PreIkhsan LyNo ratings yet

- Iso TS 13725 2001 en FR PDFDocument11 pagesIso TS 13725 2001 en FR PDFAndryNo ratings yet

- Design Analysis and Improvement of EOT Crane WheelDocument4 pagesDesign Analysis and Improvement of EOT Crane WheelIJSTENo ratings yet

- Fire Hydrant Valve Bs 5041: SpecificationDocument2 pagesFire Hydrant Valve Bs 5041: Specificationirrosel4650No ratings yet

- 1905 - Carrier 30 GZ 190 PDFDocument6 pages1905 - Carrier 30 GZ 190 PDFbilal almelegyNo ratings yet

- Coolex Concealed Ducted Split Units R407C 24-60 MBH 50HzDocument20 pagesCoolex Concealed Ducted Split Units R407C 24-60 MBH 50HzAhmed MagdyNo ratings yet

- ControlMaster Select Service ManualDocument46 pagesControlMaster Select Service ManualJoss Maykol Mundaca VasquezNo ratings yet

- Calpeda Pump N SeriesDocument3 pagesCalpeda Pump N Seriesgentleman457No ratings yet

- Pressure VesselDocument7 pagesPressure VesselClarence AG YueNo ratings yet

- Winch Machine Power Operated PDFDocument2 pagesWinch Machine Power Operated PDFSujoy BanikNo ratings yet

- Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6Document1 pageYour Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6And WebNo ratings yet

- Your Safety - Our Reality: Electrical EquipmentDocument1 pageYour Safety - Our Reality: Electrical EquipmentHimanshu ChichraNo ratings yet

- Hazardous Area Chart - BartecDocument1 pageHazardous Area Chart - BartecPutraSumatera100% (1)

- Unionsys TechnologiesDocument2 pagesUnionsys TechnologiesBinit KumarNo ratings yet

- Leac 203Document27 pagesLeac 203Ias Aspirant AbhiNo ratings yet

- Concepts of InternetDocument16 pagesConcepts of InternetYnaNo ratings yet

- Pages ManualDocument10 pagesPages ManualMandy ZibartNo ratings yet

- Straub Catalog PDFDocument24 pagesStraub Catalog PDFAntohi CatalinNo ratings yet

- SPARSH FAQsFinalDocument10 pagesSPARSH FAQsFinalViJaY HaLdErNo ratings yet

- Profit and Loss Projection 1yr March 2018Document1 pageProfit and Loss Projection 1yr March 2018Aqsa SajjadNo ratings yet

- KX91-3 (SN: 20000-29999) : VENDOR: Kubota Section: Engine Diagram: 050100 Water PumpDocument2 pagesKX91-3 (SN: 20000-29999) : VENDOR: Kubota Section: Engine Diagram: 050100 Water PumpMarkiyanNo ratings yet

- ZteDocument32 pagesZteMunandar Kang ArisNo ratings yet

- Strategy Management HitachiDocument23 pagesStrategy Management HitachiDhivya Ram50% (2)

- Weld Probes For Eddy Current TestingDocument4 pagesWeld Probes For Eddy Current Testingkhurram lalNo ratings yet

- Chapter 1: Introduction To CompanyDocument27 pagesChapter 1: Introduction To CompanyarunNo ratings yet

- 3.expannded Battery Treatment Service Guide - TCS BatteryDocument1 page3.expannded Battery Treatment Service Guide - TCS BatteryHICHAM el HAYAOUINo ratings yet

- Rfid Cost BenefitDocument78 pagesRfid Cost BenefitWalid GradaNo ratings yet

- Hindustan Copper Limited: (A Govt - of India Enterprise)Document35 pagesHindustan Copper Limited: (A Govt - of India Enterprise)Tamal SarkarNo ratings yet

- Torque Problems From HoltDocument5 pagesTorque Problems From Holtgiri_sundar5930No ratings yet

- De La Salle Lipa: Authentic AssessmentDocument2 pagesDe La Salle Lipa: Authentic AssessmentMonica ClauorNo ratings yet

- Main Vehicle SpecificationsDocument3 pagesMain Vehicle SpecificationsBoulos NassarNo ratings yet

- Is Nelson Jones's Estimate That A $350,000 Line of Credit Is Sufficient For 2007 Accurate? Forecast Jones Financing NeedsDocument3 pagesIs Nelson Jones's Estimate That A $350,000 Line of Credit Is Sufficient For 2007 Accurate? Forecast Jones Financing NeedsRakesh GyamlaniNo ratings yet

- Nidhi Investment Consultant: Magic Mix Illustration For Mr. AB Prafulbhai (Age 18)Document2 pagesNidhi Investment Consultant: Magic Mix Illustration For Mr. AB Prafulbhai (Age 18)jdchandrapal4980No ratings yet

- The Islamia University of Bahawalpur: Interview Time and Venue Financial Crisis ScholarshipDocument26 pagesThe Islamia University of Bahawalpur: Interview Time and Venue Financial Crisis ScholarshipAbubakar RiazNo ratings yet