Professional Documents

Culture Documents

Sheaves & Grooves

Uploaded by

Jorge Prado DiazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheaves & Grooves

Uploaded by

Jorge Prado DiazCopyright:

Available Formats

TECH TIPS: SHEAVES AND

Tech GROOVES

Tips: Sheaves

Sheaves & Grooves

BACKGROUND

greater specific pressures within the sheave itself—which The Positioning of the Secondary

can lead to accelerated wear of the sheave, wire fatigue Sheave Has A Critical Impact on

and hoist rope breakage. Indeed such wear can be Sheave Wear and Rope Life

very significant as analyses performed using Brugg RLP

(Rope Life Prediction an online application based on the Modern elevator designers are constantly working to

works of Dr. Klaus Feyrer of the University of Stuttgart) create installations that use floorspace more efficiently.

reveal that an undercut of 75°can reduce rope life by These compact designs frequently utilize less massive

60%, while an undercut of 105°reduce rope life by as components, more challenging groove profiles, and often

much as 93.4%. Clearly, the increase in traction provided demand the close placement of secondary, deflector

by undercuts are balanced by a significant trade-off in sheaves and primary sheave. This necessitates the

reduced rope life. implementation of complex roping arrangements and

the use of multiple sets of sheaves.

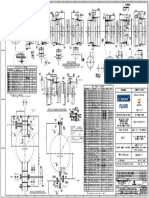

V-Groove/Undercut V-Groove Such conditions often compromise rope performance

Drive Sheave with Undercut dramatically by increasing the number of rope bending

U-Grooves for four ropes Both V and Undercut V-Groove (also known as cycles and creating improper fleet angles. This in turn

the Progressive V-Groove) designs offer even greater leads to greater system operating stresses, which

amounts of traction to installation designers. However can negatively impact sheave surface wear, rope

this design also creates higher specific pressures within performance and hoist rope life expectancy.

the groove, and stresses and distorts the hoist rope.

Naturally this negatively impacts rope life expectancy. Bending Cycles

γ 32°- 40° Many professionals fail to appreciate that hoist ropes

are not single static pieces of wire but are carefully

crafted machines bearing a surprising number of moving

parts.

Each rope is made up of strands of wire. These are

composed of bundled collections of smaller wires that

D D F F are helically wound together. Each rope must work in

In contrast to the Round or U-Groove, the V-Groove's degree harmony with the surrounding equipment. To illustrate

V-Groove Undercut V-Groove of undercut dramatically increases specific pressures placed the complexity of the matter, consider that a single 8

on the hoist rope and creates specific areas of contact that x 19 Seale hoist rope is basically composed of 152

can be identified by pronounced crown wear on the surface

of outer wires.

parts (8 strands, 19 wires per strand). All these parts are

composed of soft steel that must be strong, relatively

The angle for a V-Groove is usually 30° but can go as lightweight and flexible — which poses a real engineering

high as 38°, while an Undercut-V may range between challenge. In addition, bear in mind that hoist ropes are

32-45° (measured as the included angle of both sides constantly in motion; bending over a sheave (frequently

of the groove). V-Grooves are often used for installations multiple sheaves), adjusting to stresses and then

of speeds up to 157.5 ft/m and higher (or less than or straightening out again. And this process is carried on

equal to 0.8 m/s), while Undercut V-Grooves are more often for millions of cycles.

commonly used with slower speed elevators carrying It should come as no surprise that this exponential

heavier loads. Using Brugg RLP (Rope Life Prediction), rise in bending cycles has resulted in a corresponding

studies show that an Undercut V-Groove featuring an increase in elevator breakdowns and decrease in rope

Drive Sheave with Undercut life expectancy.

undercut of 35° can shorten rope life by as much as

V-Grooves for four ropes To address this fact some manufacturers have

94.6%, while a 45°undercut can decrease rope life by

75%. developed new rope designs and are using advanced,

Brugg Lifting • Rome, GA USA • 866.542.7844 • www.bruggrope.com • Brugg Lifting • Birr CH • +41 56 464 42 42 • www.brugglifting.com 43

Brugg Lifting • Dubai UAE • +97 14 813 78 13 • www.brugglifting.com • Brugg Lifting • P.R. CHINA • +86 512 6299 0779 • www.bruggrope.com.cn

You might also like

- EQ Inverter ManualDocument44 pagesEQ Inverter ManualShane P50% (2)

- 203 656 44 Accesorios ElectricosDocument32 pages203 656 44 Accesorios ElectricosJESUSCALVILLONo ratings yet

- Sheave DesignDocument6 pagesSheave DesignZach DockterNo ratings yet

- DIEPA AnswersDocument52 pagesDIEPA AnswersMohamed HarbNo ratings yet

- Crane Vibration Natural Frequency TipsDocument3 pagesCrane Vibration Natural Frequency TipsSACHINNo ratings yet

- HSE Risk Assessment for Wire Rope ReplacementDocument4 pagesHSE Risk Assessment for Wire Rope ReplacementMohamed ElnagdyNo ratings yet

- Bass String Diameters and TensionsDocument6 pagesBass String Diameters and Tensionsbonruiz100% (1)

- SM Pc78uu-6 Pc78us-6 1025-1-45Document45 pagesSM Pc78uu-6 Pc78us-6 1025-1-45Daman Huri60% (5)

- C1 30 - 3 EN Crane Wheel SystemsDocument16 pagesC1 30 - 3 EN Crane Wheel SystemsKovács EndreNo ratings yet

- RT378 379 Spreader Electrical Schematics BRMY ARF 1849-15-21268 70 - ADocument44 pagesRT378 379 Spreader Electrical Schematics BRMY ARF 1849-15-21268 70 - AMIGUEL PEÑANo ratings yet

- Cross Travel Motor Power CalculationsDocument1 pageCross Travel Motor Power Calculationssmarika_16No ratings yet

- Crane Load Chart-D-008 R2 (2) 52Document1 pageCrane Load Chart-D-008 R2 (2) 52sdNo ratings yet

- ABB Drive Selection GuideDocument12 pagesABB Drive Selection Guideprasad_rvsNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationAbhiNo ratings yet

- GM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBDocument1 pageGM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBEduardo Garcia SaraviaNo ratings yet

- SWF RopeHoists CraneKits 09 2012 enDocument21 pagesSWF RopeHoists CraneKits 09 2012 enGogyNo ratings yet

- ManualDocument11 pagesManualfpersiancatNo ratings yet

- DH300 Part SetDocument68 pagesDH300 Part Setfatchur rochman67% (3)

- Timco Sheave DesignDocument10 pagesTimco Sheave DesignAyman SaadNo ratings yet

- SSX40 TrainingDocument20 pagesSSX40 TrainingDavid Adeola OgunyemiNo ratings yet

- SC10876B - Hoist DrawingDocument1 pageSC10876B - Hoist DrawingMotlatjo RakgothoNo ratings yet

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- TGN 08 Crane Rail Selection 2Document3 pagesTGN 08 Crane Rail Selection 2Prasad PatilNo ratings yet

- Seilzug DR 3 - 10 - ENDocument36 pagesSeilzug DR 3 - 10 - ENAmazonas ManutençãoNo ratings yet

- Designing of Cranes With StandardsDocument95 pagesDesigning of Cranes With Standardsank_mehraNo ratings yet

- Passenger and Material Hoist According To TRA 1100 / EN 12159Document2 pagesPassenger and Material Hoist According To TRA 1100 / EN 12159PhanHathamNo ratings yet

- AbusDocument27 pagesAbusMargelatu AndreyNo ratings yet

- Crane wheels with slide bearing DIN 15 074 without gear ringDocument2 pagesCrane wheels with slide bearing DIN 15 074 without gear ringGilmar MenegottoNo ratings yet

- Copperhead Conductor SystemDocument24 pagesCopperhead Conductor SystembhsujanNo ratings yet

- EOT Crane Mechanical Equipment Calculation 1Document17 pagesEOT Crane Mechanical Equipment Calculation 1satendra sharmaNo ratings yet

- Approval Return Status DocumentDocument17 pagesApproval Return Status Documentsatendra sharmaNo ratings yet

- Explosion CraneDocument44 pagesExplosion CraneGolfkung PairojNo ratings yet

- SCU Teach PanelDocument18 pagesSCU Teach PanelMahen PereraNo ratings yet

- Design of TEE Sections in BendingDocument3 pagesDesign of TEE Sections in BendingJimmyNo ratings yet

- KranDocument7 pagesKranMarioNo ratings yet

- How to Replace Wire Rope in 5 StepsDocument7 pagesHow to Replace Wire Rope in 5 StepsBistok MarbunNo ratings yet

- Design and Static Analysis of I Section Boom For Rotary Jib Crane IJERTV3IS080816Document4 pagesDesign and Static Analysis of I Section Boom For Rotary Jib Crane IJERTV3IS080816Evodius RweyemamuNo ratings yet

- 4ductor Engl PDFDocument8 pages4ductor Engl PDFNilesh MahajanNo ratings yet

- Insulated Conductor Rail Single Powerline Program 0812: WWW - Conductix.UsDocument36 pagesInsulated Conductor Rail Single Powerline Program 0812: WWW - Conductix.UsHéctor FuentesNo ratings yet

- Technical Data Hoist Drive GH 5000ADocument1 pageTechnical Data Hoist Drive GH 5000AEricNo ratings yet

- 31 SeriesDocument4 pages31 SeriesJESUSCALVILLONo ratings yet

- Part of My Book of Preventive MaibtenanceDocument5 pagesPart of My Book of Preventive MaibtenanceMohamed Elnagdy0% (1)

- Train Electric PLC 4000 for Programmable Logic ControlDocument13 pagesTrain Electric PLC 4000 for Programmable Logic ControlAbou AyhamNo ratings yet

- W B H in Inches Cable Diam.: Case 1Document4 pagesW B H in Inches Cable Diam.: Case 1RAMSINGH CHAUHANNo ratings yet

- Technical Tips Regenerative Valves: ApplicationsDocument8 pagesTechnical Tips Regenerative Valves: ApplicationsIkeoNo ratings yet

- Wire Ropes: Understanding Bending and Tensile StressesDocument6 pagesWire Ropes: Understanding Bending and Tensile Stressessiddharth Gautam100% (1)

- Wire Rope End Treatments.: Preparation For InstallationDocument10 pagesWire Rope End Treatments.: Preparation For Installationegy pureNo ratings yet

- Design Lifting Beam (80 MT)Document10 pagesDesign Lifting Beam (80 MT)hardeep SinghNo ratings yet

- Winch ControlDocument3 pagesWinch ControlABDUL GHAFOORNo ratings yet

- Cable Drum Hoist Spec 96B PDFDocument16 pagesCable Drum Hoist Spec 96B PDFAmanNo ratings yet

- DH Hoist Brochure PDFDocument22 pagesDH Hoist Brochure PDFMahmoud Allam100% (1)

- Modulift Spreader Beam System ReviewDocument2 pagesModulift Spreader Beam System Reviewmiguelangel314No ratings yet

- DZW position measuring system component partsDocument12 pagesDZW position measuring system component partsBang OchimNo ratings yet

- Steel Wire Ropes For Cranes Problems and SolutionsDocument34 pagesSteel Wire Ropes For Cranes Problems and Solutionsaj3107900% (1)

- ABUS Overhead CranesDocument36 pagesABUS Overhead CranesAya AlgalladNo ratings yet

- Wire Drum DesignDocument8 pagesWire Drum DesignJonathan Lynch100% (2)

- Talhas DCDocument132 pagesTalhas DCCharles SouzaNo ratings yet

- Wirerope Solution Last Updated 3-10-19 4.21PMDocument2 pagesWirerope Solution Last Updated 3-10-19 4.21PMRonnie Ray DumdumNo ratings yet

- DL International Cranes 0710Document2 pagesDL International Cranes 0710sangwoo jungNo ratings yet

- Rope IIIDocument20 pagesRope IIIDhruv ShindeNo ratings yet

- PRO Coiled Rod BR 020322Document8 pagesPRO Coiled Rod BR 020322miguel.casper130No ratings yet

- عیوب بکسلDocument2 pagesعیوب بکسلjahel2002No ratings yet

- Codigos y EstándaresDocument2 pagesCodigos y EstándaresJorge Prado DiazNo ratings yet

- Title Photos TuyeresDocument7 pagesTitle Photos TuyeresJorge Prado DiazNo ratings yet

- Multi-part engineering assembly dimensionsDocument2 pagesMulti-part engineering assembly dimensionsJorge Prado DiazNo ratings yet

- Eclisa 115re 4 Hole-AaDocument1 pageEclisa 115re 4 Hole-AaJorge Prado DiazNo ratings yet

- Gaoxin GAHR Type Rubber Slurry Pump PDFDocument5 pagesGaoxin GAHR Type Rubber Slurry Pump PDFLeobardo DiazNo ratings yet

- 025-R03 - A 26E001AB DetallesDocument1 page025-R03 - A 26E001AB DetallesJorge Prado DiazNo ratings yet

- PG Chapter 3Document6 pagesPG Chapter 3tonisilverNo ratings yet

- Parts List for 5 7/16Document3 pagesParts List for 5 7/16Jorge Prado DiazNo ratings yet

- 024-R05 - A 26E001AB ConjuntoDocument1 page024-R05 - A 26E001AB ConjuntoJorge Prado DiazNo ratings yet

- Modern Equipment LadlesDocument11 pagesModern Equipment LadlesJorge Prado DiazNo ratings yet

- Anillo Laberinto de Cilindro Caja 2 Danieli-Layout1Document1 pageAnillo Laberinto de Cilindro Caja 2 Danieli-Layout1Jorge Prado DiazNo ratings yet

- Wire Rope Install GuideDocument32 pagesWire Rope Install GuideSayed Kassar100% (2)

- Dwg#A-8770 Rev 18Document1 pageDwg#A-8770 Rev 18Jorge Prado DiazNo ratings yet

- DWG#FW 19Document1 pageDWG#FW 19Jorge Prado DiazNo ratings yet

- RevisionsDocument1 pageRevisionsJorge Prado DiazNo ratings yet

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocument8 pagesRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazNo ratings yet

- Mf-156/Astm A532-Llb: Rev Description Date Approved 2Document1 pageMf-156/Astm A532-Llb: Rev Description Date Approved 2Jorge Prado DiazNo ratings yet

- SMICO Shale-Shaker-Manual-COLOR PDFDocument12 pagesSMICO Shale-Shaker-Manual-COLOR PDFmojtaba_m007No ratings yet

- Hardox Uk 400Document2 pagesHardox Uk 400Jackson VuNo ratings yet

- RT 800 WP: The Proven Interchangeable Insert Drilling System With Highest Cutting Performance and Economy - Now WithDocument12 pagesRT 800 WP: The Proven Interchangeable Insert Drilling System With Highest Cutting Performance and Economy - Now WithJorge Prado DiazNo ratings yet

- 6435 Tempest III High Velocity Dual-Fuel Burner: Parts List 6435-5Document2 pages6435 Tempest III High Velocity Dual-Fuel Burner: Parts List 6435-5Jorge Prado DiazNo ratings yet

- Heavy Duty Apron Plate FeedersDocument4 pagesHeavy Duty Apron Plate FeedersAnonymous 8t0V9SNo ratings yet

- Operating Manual: Thule Rigtech VSM 100 Linear Motion Shale ShakerDocument84 pagesOperating Manual: Thule Rigtech VSM 100 Linear Motion Shale ShakerJorge Prado DiazNo ratings yet

- 47143A - COPLA DOBLE BRIDA DIA.85x175MM - 19751 1Document1 page47143A - COPLA DOBLE BRIDA DIA.85x175MM - 19751 1Jorge Prado DiazNo ratings yet

- Dual Bushing Track Reduces Undercarriage Costs by 46Document2 pagesDual Bushing Track Reduces Undercarriage Costs by 46Carlos Alfredo Laura100% (1)

- Grate Cooler CFGDocument3 pagesGrate Cooler CFGfetniNo ratings yet

- Riel LigeroDocument6 pagesRiel LigeroHenrry MendozaNo ratings yet

- Rotary GB enDocument307 pagesRotary GB enadelinciprianNo ratings yet

- Osborn - Apron FeederDocument8 pagesOsborn - Apron FeederAndré Luiz NogueiraNo ratings yet

- Hardox Uk 400Document2 pagesHardox Uk 400Jackson VuNo ratings yet

- Jump Rope Basics: Part 1: PreparationDocument7 pagesJump Rope Basics: Part 1: PreparationJolanta Kamantauskaitė - GvozdovaNo ratings yet

- Godrej SOP for Erecting Poles with HardwareDocument7 pagesGodrej SOP for Erecting Poles with HardwareVIKAS SINGH BAGHELNo ratings yet

- Shop Manual 12V170-2 Series Sebm036601 PDFDocument333 pagesShop Manual 12V170-2 Series Sebm036601 PDFstrong hold100% (3)

- Manual Guincho PullmasterDocument34 pagesManual Guincho PullmasterF. JuniorNo ratings yet

- The Aerial Rope Manual: Rebekah LeachDocument13 pagesThe Aerial Rope Manual: Rebekah LeachRemote Office100% (2)

- MSC.1-Circ.1620 - Guidelines For Inspection and Maintenance of Mooring Equipment Including Lines (Secretariat)Document7 pagesMSC.1-Circ.1620 - Guidelines For Inspection and Maintenance of Mooring Equipment Including Lines (Secretariat)Muhammed SabeehNo ratings yet

- HB RopeDocument104 pagesHB RopeMarko ŠimićNo ratings yet

- CERTEX Wire Rope Terminations LRDocument26 pagesCERTEX Wire Rope Terminations LRAlberto CárdenasNo ratings yet

- JHA On Erection of Temporary ShedDocument15 pagesJHA On Erection of Temporary ShedM8Rskn6wcNo ratings yet

- Deutz Fahr Agrotron108 118 128 Workshop ManualDocument20 pagesDeutz Fahr Agrotron108 118 128 Workshop Manualelbert100% (47)

- Mobil Mobilarma 798 DatasheetDocument2 pagesMobil Mobilarma 798 Datasheetphankhoa83-1No ratings yet

- Tools & Tackles For Transformer ErectionsDocument4 pagesTools & Tackles For Transformer ErectionsBabuNo ratings yet

- Design and Develoment of Vertical Lifting Bridge Ijariie14643Document8 pagesDesign and Develoment of Vertical Lifting Bridge Ijariie14643Anshika MendheNo ratings yet

- 12 132KV DiscDocument3 pages12 132KV DiscArslan AhmadNo ratings yet

- Winch, Manrider (FA150KGi) Product InstructionsDocument16 pagesWinch, Manrider (FA150KGi) Product InstructionsTonyNo ratings yet

- Calculation of Lifting of Screw Pump JWRP (17-02-2022)Document7 pagesCalculation of Lifting of Screw Pump JWRP (17-02-2022)Suresh DNo ratings yet

- Peoria Fire Department Technical Rescue Technician: Skill Performance EvaluationDocument2 pagesPeoria Fire Department Technical Rescue Technician: Skill Performance EvaluationHoracio PeñaNo ratings yet

- Rigging & Lifting AwarenessDocument199 pagesRigging & Lifting AwarenessMuhammad Shahrukh100% (2)

- EOTcrane SafetyDocument54 pagesEOTcrane SafetyRafique AjmeriNo ratings yet

- Ebook - Komatsu Pw140-7 Shop Manual1-Đã M KhóaDocument1,144 pagesEbook - Komatsu Pw140-7 Shop Manual1-Đã M KhóaLâm Trần ngọcNo ratings yet

- Iso 1140 2004Document9 pagesIso 1140 2004Ghulam HussainNo ratings yet

- Ra 08 Safe Mooring PracticeDocument3 pagesRa 08 Safe Mooring PracticeNelum PereraNo ratings yet

- Crosby - Closed Spelter SocketDocument1 pageCrosby - Closed Spelter SocketRobby VillenaNo ratings yet

- Wall Climbing Fundamentals, Competitions & HistoryDocument3 pagesWall Climbing Fundamentals, Competitions & HistoryJusayanChristinaNo ratings yet

- TRede MarinhoDocument176 pagesTRede MarinhoTiago CatuxoNo ratings yet

- Analyzing Water Rescue and Response SituationDocument3 pagesAnalyzing Water Rescue and Response SituationDIANE FAE FETALVERONo ratings yet

- Literature Review of Research On The Technology of Wire Rope Nondestructive Inspection in China and Abroad (PDF Download Available) - Available FromDocument6 pagesLiterature Review of Research On The Technology of Wire Rope Nondestructive Inspection in China and Abroad (PDF Download Available) - Available Frommj recillaNo ratings yet

- Hira - Mobile CraneDocument4 pagesHira - Mobile CraneSantosh SinghNo ratings yet