Professional Documents

Culture Documents

ASTM C 240 Standard Test Methods of Testing Cellular Glass Insulation Block

ASTM C 240 Standard Test Methods of Testing Cellular Glass Insulation Block

Uploaded by

Ryan LasacaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM C 240 Standard Test Methods of Testing Cellular Glass Insulation Block

ASTM C 240 Standard Test Methods of Testing Cellular Glass Insulation Block

Uploaded by

Ryan LasacaCopyright:

Available Formats

Designation: C 240 – 97 (Reapproved 2003)

Standard Test Methods of

Testing Cellular Glass Insulation Block1

This standard is issued under the fixed designation C 240; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ISO Standard:

1.1 These test methods cover the testing of cellular glass ISO 3951 Sampling Procedure and Charts for Inspection by

insulation block for density, water absorption, compressive Variables for Percent Nonconforming4

strength, flexural strength at ambient temperature; preparation 2.3 Military Standard:

for chemical analysis; and thermal conductivity measurements. MIL-I-24244 Specification Insulation Materials with Spe-

1.2 The values stated in SI are generally to be regarded as cial Corrosion, Chloride, and Fluoride Requirements5

the standard. The SI dimensions are to be used for material 2.4 Other Standard:

supplied in metric sizes. The inch dimensions are to be used for NRC 1.36 Nonmetallic Thermal Insulation for Austenitic

material supplied in inch sizes. Stainless Steel6

1.3 This standard does not purport to address all of the 3. Terminology

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1 Definitions—Terminology C 168 shall be considered as

priate safety and health practices and determine the applica- applying to the terms considered in these test methods.

bility of regulatory limitations prior to use. 4. Significance and Use

2. Referenced Documents 4.1 From a general standpoint, these test methods outline

2.1 ASTM Standards: the particular points which have to be taken into account when

C 165 Test Method for Measuring Compressive Properties applying ASTM standard test methods to the case of cellular

of Thermal Insulations2 glass insulating block.

C 168 Terminology Relating to Thermal Insulation2 5. Test Methods

C 177 Test Method for Steady-State Heat Flux Measure-

ments and Thermal Transmission Properties by Means of 5.1 General Sample Preparation—All tests have to be run

the Guarded-Hot-Plate Apparatus2 on dry specimens. In case of need, the sample must be

C 203 Test Methods for Breaking Load and Flexural Prop- unpacked and stored in a dry place in such a way that all

erties of Block-Type Thermal Insulation2 surfaces are exposed to the ambient air for at least one day

C 303 Test Method for Dimensions and Density of Pre- before testing.

formed Block and Broad-Type Thermal Insulation2 5.2 Density—Determine the density in accordance with Test

C 390 Practice for Sampling and Acceptance of Preformed Method C 303. Preferably, the density shall be measured on a

Thermal Insulation Lots2 full block, 450 by 600 mm (18 by 24 in.) by full thickness.

C 518 Test Method for Steady-State Thermal Transmission 5.2.1 It should be noted that density is interesting as such for

Properties by Means of the Heat Flow Meter Apparatus2 calculation of insulated equipment load and because it has

C 871 Test Methods for Chemical Analysis of Thermal some influence on the other important properties of cellular

Insulation Materials for Leachable Chloride, Fluoride, glass. But it should not be considered in itself as a criterion for

--`-`-`,,`,,`,`,,`---

Silicate, and Sodium Ions2 acceptance in the case of cellular glass.

D 226 Specification for Asphalt-Saturated Organic Felt 5.3 Water Absorption:

Used in Roofing and Waterproofing3

1

These test methods are under the jurisdiction of ASTM Committee C16 on

4

Thermal Insulation and are the direct responsibility of Subcommittee C16.32 on Available from American National Standards Institute, 25 W. 43nd St., 4th

Mechanical Properties. Floor, New York, NY 10036.

5

Current edition approved April 10, 2003. Published July 2003. Originally Available from Standardization Documents Order Desk, Bldg. 4, Section D,

approved in 1950. Last previous edition approved in 1997 as C 240 – 97. 700 Robbins Ave., Philadelphia, PA 19111-5094.

2 6

Annual Book of ASTM Standards, Vol 04.06. Available from Director of Regulatory Standards, US Atomic Energy Commis-

3

Annual Book of ASTM Standards, Vol 04.04. sion, Washington, DC 20545.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

C 240 – 97 (2003)

5.3.1 Scope—This test method covers the determination of 5.4 Compressive Strength—Determine the compressive

water absorption of cellular glass insulating blocks by measur- strength in accordance with Test Method C 165 Procedure A,

ing the amount of water retained as a result of complete with the following test parameters and specimen preparation

immersion for a prescribed time interval. Surface blotting is techniques:

used to correct for the water absorbed on the cut surface cells. 5.4.1 Each of the two parallel bearing surfaces of the

5.3.2 Significance and Use—This test method provides a specimens shall be plane. If necessary, rub them on a suitable

means of measuring the water absorption of cellular glass abrasive surface to produce the required flat surface.

insulating blocks under isothermal conditions as a result of 5.4.2 The test specimens shall preferably be one half block

direct immersion in liquid water. It is intended for use in 300 by 450 mm (12 by 18 in.) by nominal received thickness.

product evaluation and quality control. Alternates include a quadrant 225 by 300 mm (9 by 12 in.) or

5.3.3 Equipment and Materials: a full block 450 by 600 mm (18 by 24 in.) by nominal received

5.3.3.1 Balance, with about 1500 g capacity and at least 0.1 thickness. A quadrant specimen shall be taken from any one of

g sensitivity. four equal area quadrants of the preformed block. The mini-

5.3.3.2 Immersion Tank, equipped with inert specimen sup- mum acceptable specimen size is 200 by 200 mm (8 by 8 in.).

ports and top surface weights such as stainless steel. The report shall include the specimen size.

5.3.3.3 Synthetic Sponge, at least 100 by 180 by 40 mm (4 5.4.3 Cap both bearing surfaces of the specimens as follows:

by 7 by 1.5 in.). Sponges found acceptable to use include Coat one surface with molten Type III or Type IV asphalt

cellulosic sponges and fine-pored absorbent synthetic plastic (preheated to 177, + 28, − 14°C (350, + 50, − 25°F)), com-

sponges. pletely filling the surface cells with a small excess. Such a

5.3.3.4 Test Room, with temperature of 21 6 3°C (70 6 coating application rate is approximately 1.0 kg/m2(0.20 lb/ft2)

5°F) and relative humidity of 50 6 10 %. 6 25%. Immediately press the hot coated block onto a precut

5.3.3.5 Distilled Water. piece of felt or paper laying on a flat surface. This is to prevent

5.3.4 Procedure: the asphalt surface from sticking to the compression platten

5.3.4.1 Carefully measure the thickness, width, and length during the test. A lightweight kraft paper is suitable, although

to the nearest 1 mm of a cellular glass block, preferably 50 by traditionally a Type 1 roofing felt paper, commonly called a

300 by 450 mm (2 by 12 by 18 in.) and calculate the volume No. 15 asphalt felt, per Specification D 226 has been used.

and exposed surface area. NOTE 1—A hot asphalt capping is used to simulate field applied

5.3.4.2 Weigh the specimen to the nearest 0.1 g (W1), then systems, which require a high load bearing insulation product, ranging

submerge it horizontally under 25 mm (1 in.) of water from roof applications to cryogenic storage tank base applications.

maintained at 21 6 3°C (70 6 5°F). Inert top surface weights Uncapped material or different cappings will give different values.

are required to keep it submerged. After submerging it for 2 h, Properly capped surfaces should be approximately plane and

set the specimen on end on a damp cotton bath towel to drain parallel. Set the specimens on edge, exposing both capped

for 10 min. After the 10 min, remove the excess surface water surfaces to room temperature for a minimum of 15 min to

by hand with a damp sponge for 1 min per large face and 1 min allow the asphalt to harden before testing.

for the four sides. Wring out the sponge before and once in 5.4.4 The number of specimens to be tested and the sam-

between for each face and pass at least two times on each pling plan shall conform to Criteria C 390 where applicable.

surface. Blot each face of the specimen equally by compressing For the purpose of inspection by user’s representative or

the sponge by at least 10 % of its thickness. Weigh the independent third party, the number of specimens shall con-

specimen immediately (W2) to the nearest 0.1 g. form to ISO 3951 inspection level S-4, 10.0 % AQL using the

5.3.5 Calculation of Results—Calculate the weight of water S method.

absorbed (W 2 − W1) and express it as a function of the exterior 5.4.5 Compress the specimen until failure. The deformation

surface of the sample (g/cm 2). Water absorption can also be at failure will vary, depending on the thickness of insulation

expressed as a function of volume percent, absorbed water and the thickness of the capping materials. Record the loads at

volume divided by specimen volume; or as a function of the failure point or definite yield point. The compressive

weight percent, weight of water absorbed (W2 − W1) divided strength is calculated from this load divided by the specimen

by the dry specimen weight (W1). Such ways of expressing the cross sectional area in accordance with Test Method C 165.

results should be strictly limited to direct comparison of results 5.4.6 The rate of loading will depend on the type of

on specimens of identical sizes. equipment used. With a hydraulic test machine use a constant

5.3.6 Precision and Bias—The precision as determined in load rate of 2200 N/s (500 lbf/s) for half block specimen. With

inter-laboratory tests is given in Research Report RR C16- a screw driven machine use a crosshead speed of 0.1 mm/min.

1007.7 The repeatability or single-laboratory operator precision (0.01 in./min.) per cm (in.) of specimen thickness, within a

is 60.00060 g/cm2 or 60.030 volume % (61S). The repro- tolerance of 625 %. Another alternate testing procedure is to

ducibility or multilaboratory operator precision is 60.00071 reach failure within 30 to 90 s [nominal 16kPa/s (2.3 psi/s)].

g/cm2 or 60.035 volume %. Due to a lack of a standard, no 5.4.7 Due to the sample preparation, with the inclusion of

statement can be made regarding bias. felts and asphalt, the method described in Test Method C 165

to determine compressive modulus of elasticity does not apply

7

for cellular glass as a material by itself.

Supporting data have been filed at ASTM International Headquarters and may

be obtained by requesting Research Report RR: C16 – 1007. NOTE 2—It has been found extremely convenient to employ a partially

--`-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

C 240 – 97 (2003)

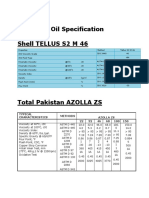

submerged roll (see Fig. 1) for applying the asphalt. 5.6.2 Due to the rigid nature of the material and its open cell

5.5 Flexural Strength—Determine flexural strength in ac- surface, it is preferable to have the thermocouples mounted on

cordance with Test Method C 203, Method I or Method II, the surface of the plates and not adhered to the surface of the

Procedure A, preferably with a test specimen 25 mm thick by specimens.

100 mm wide by 300 mm long ( 1 in. thick by 4 in. wide by 12 5.6.3 For maximum accuracy, it is recommended that the

in. long ). temperature difference between the hot and cold surfaces of the

5.5.1 Measure the distance between the supports from specimens is such that the temperature gradient in the specimen

center to center of the bearing bars. equals or exceeds 900 K m−1(40 F/in.). Avoid specimens made

5.5.2 The number of specimens to be tested and the sam- from several pieces of cellular glass. Joints are prohibited in

pling plan shall conform to Criteria C 390 where applicable. the central measuring area and their number should be mini-

For the purpose of inspection by user’s representative or mized in the guard area.

independent third party, the minimum number of specimens 5.6.4 The number of specimens to be tested and the sam-

shall conform to ISO 3951 inspection level S-3, 10.0 % AQL pling plan shall conform to Criteria C 390 where applicable.

using the S method. For the purpose of inspection by user’s representative or

5.6 Thermal Conductivity—Determine the thermal conduc- independent third party, the number of specimens shall con-

tivity in accordance with Test Method C 177 or Test Method form to ISO 3951 inspection level S-3, 10.0 % AQL using the

C 518. In the case of cellular glass, the following points S method.

deserve special attention: 5.7 Specimen Preparation for Chemical Analysis—When

5.6.1 To achieve flatness and parallelism of the surface as specified in the purchase order or contract, the following

required by Test Method C 177 or Test Method C 518, the chemical analysis results shall be furnished to the purchaser.

--`-`-`,,`,,`,`,,`---

following method is suggested: 5.7.1 Chemical Analysis for Leachable Chloride, (Fluo-

5.6.1.1 By sawing from the original block, prepare a speci- ride), Silicate, and Sodium Ions—Determine leachable chlo-

men with the required dimensions, its thickness being 2 or 3 ride, (fluoride), silicate and sodium ions in accordance with

mm greater than the final thickness should be. Test Methods C 871, MIL-I-24244, or NRC 1.36, with the

following exceptions or additions. The test specimen may be

5.6.1.2 Place the specimen on a flat metal plate slightly

prepared for leaching by either of the following equivalent

larger than the specimen itself and put two machined metal

methods:

bars on the metal plate near two opposite sides of the specimen.

5.7.1.1 Method A—Break about 300 g of the sample into

Insert a uniform sheet of paper with a thickness about 1⁄4 mm

small size pieces about 13 mm (1⁄2 in.) or less. Comminute in

(0.01 in.) between the flat base plate and the metal bars but not

a nominal 4-L (1-gal) mill one-third to one-half full of

under the sample. The metal bars are as thick as the final

appropriate media for about 10 min. Screen out

thickness of the specimen and machined so that their top and

the − 200 + 325 mesh fraction of about 50 g, wash on the finer

bottom surfaces are flat and parallel. Alternatively to machined

screen with 400 to 600 mL of cp methanol using a wash bottle,

bars, one can use cold-rolled steel bars. These bars generally

and dry on the screen to constant weight at 100 to 110°C (212

are sufficiently flat and uniform in thickness.

to 230°F). An appropriate grinding media is flint pebbles or

5.6.1.3 Using a third straight metal bar long enough to lap

alumina pebbles.

metal bars on each side, carefully rub off the upper face of the

5.7.1.2 Method B—Break about 150 g of the sample into

specimen until the scraping bar just contacts the thickness bars.

small size pieces about 13 mm (1⁄2 in.) or less. Comminute

5.6.1.4 Turn the specimen upside down and place it back on

using either a manual or motorized mortar and pestle or a

the flat metal plate and put the two metal bars on the metal

blender, and concurrently screen out the − 200 + 325 mesh

plate near two opposite sides of the specimen, this time without

fraction until about 50 g is accumulated. Wash the fraction on

the sheet of paper under each metal bar.

the finer screen with 400 to 600 mL of cp methanol, using a

5.6.1.5 Repeat the rubbing operation described in 5.6.1.3.

wash bottle, and dry on the screen to constant weight at 100 to

5.6.1.6 If the specimens have to be shipped, provide ad-

110°C (212 to 230°F).

equate protection.

NOTE 3—Alternatively, the sized fraction may be washed in a specially

made small screen by dunking repeatedly into a container of methanol. In

any case, the screens should be washed first with methanol.

5.7.2 All of the other chemical requirements of Test Meth-

ods C 871, MIL-I-24244, and NRC 1.36 are to be followed.

6. Report

6.1 The report shall include the following information:

6.1.1 Density, flexural strength and thermal conductivity

shall be reported as designated in the appropriate method.

FIG. 1 Application of Hot Asphalt to Specimen Surfaces 6.1.2 Water absorption, in g/cm2.

Copyright ASTM International 3

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

C 240 – 97 (2003)

6.1.3 Compressive strength in accordance with Test Method 7. Keywords

C 165, except that the dimensions of the test specimens shall

7.1 breaking load; breaking strength; cellular materials;

also be recorded.

compressive strength; flexural strength; thermal insulating

6.1.4 Chemical analysis results, if required, as specified in

materials-glass; water absorption

purchase order.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`-`-`,,`,,`,`,,`---

Copyright ASTM International 4

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Earth Science: Quarter 2 - Module 1: Exogenic Processes (Weathering)Document19 pagesEarth Science: Quarter 2 - Module 1: Exogenic Processes (Weathering)Mark Allen LabasanNo ratings yet

- Grade 5 - Harmful and Useful MaterialsDocument11 pagesGrade 5 - Harmful and Useful MaterialsCon Aquino100% (1)

- Fluent-Intro 16.0 L07 TurbulenceDocument50 pagesFluent-Intro 16.0 L07 TurbulenceDaniel CastroNo ratings yet

- Solution Manual For Chemical Biochemical and Engineering Thermodynamics Stanley SandlerDocument10 pagesSolution Manual For Chemical Biochemical and Engineering Thermodynamics Stanley SandlerAmalia Rizki FauziahNo ratings yet

- C 367 - 99 - QZM2NWDocument5 pagesC 367 - 99 - QZM2NWElvis Lionel FLORES ROCANo ratings yet

- C 356 - 87 R97 - Qzm1ni1sruqDocument5 pagesC 356 - 87 R97 - Qzm1ni1sruqElvis Lionel FLORES ROCANo ratings yet

- C 302 - 95 - Qzmwmi05nqDocument3 pagesC 302 - 95 - Qzmwmi05nqElvis Lionel FLORES ROCANo ratings yet

- C 208 - 95 - Qziwoc05nqDocument4 pagesC 208 - 95 - Qziwoc05nqElvis Lionel FLORES ROCANo ratings yet

- C 203 - 99 - QziwmwDocument6 pagesC 203 - 99 - QziwmwElvis Lionel FLORES ROCANo ratings yet

- C 165 - 95 - Qze2ns05nq - PDFDocument5 pagesC 165 - 95 - Qze2ns05nq - PDFElvis Lionel FLORES ROCANo ratings yet

- C 195 - 00 - Qze5nqDocument3 pagesC 195 - 00 - Qze5nqElvis Lionel FLORES ROCANo ratings yet

- C 165 - 00 - Qze2nq - PDFDocument5 pagesC 165 - 00 - Qze2nq - PDFElvis Lionel FLORES ROCANo ratings yet

- 242-3f-Ctr Jirsa and Breen 1981Document55 pages242-3f-Ctr Jirsa and Breen 1981Elvis Lionel FLORES ROCANo ratings yet

- Lift On A Moving Sphere Near A Plane WallDocument15 pagesLift On A Moving Sphere Near A Plane WallChukwuemeka JosephNo ratings yet

- Calibration of Near Infrared Dispersive and Fourier TransformDocument9 pagesCalibration of Near Infrared Dispersive and Fourier TransformValentino TurotNo ratings yet

- (Inorganic Chemistry Concepts 10) Prof. Dr. Kozo Sone, Prof. Dr. Yutaka Fukuda (Auth.) - Inorganic Thermochromism (1987, Springer-Verlag Berlin Heidelberg)Document143 pages(Inorganic Chemistry Concepts 10) Prof. Dr. Kozo Sone, Prof. Dr. Yutaka Fukuda (Auth.) - Inorganic Thermochromism (1987, Springer-Verlag Berlin Heidelberg)darkangel9000100% (1)

- Jewellery Investment Casting MachinesDocument7 pagesJewellery Investment Casting MachinesMohammad HassanNo ratings yet

- EvaporationDocument6 pagesEvaporationnoviantari87100% (1)

- Structural Integrity Assessment On Solid Propellant Rocket MotorsDocument75 pagesStructural Integrity Assessment On Solid Propellant Rocket MotorsAzeem KhanNo ratings yet

- Effects of The Column and Mobile Phase Flow in GC: Why Are Modern GC Based On A Capillary Column?Document2 pagesEffects of The Column and Mobile Phase Flow in GC: Why Are Modern GC Based On A Capillary Column?Sartika Nur AisyahNo ratings yet

- TTMA Bulletin #124Document6 pagesTTMA Bulletin #124stevenNo ratings yet

- Net Paper With Solution June 2017 Chemical SciencesDocument40 pagesNet Paper With Solution June 2017 Chemical SciencesDeeksha KumariNo ratings yet

- Climates - Global Warming: by ReadworksDocument5 pagesClimates - Global Warming: by ReadworksSana SohoniNo ratings yet

- Scheme of Work: Cambridge O Level Chemistry 5070Document55 pagesScheme of Work: Cambridge O Level Chemistry 5070Syed Ashar50% (2)

- Core Practical 1 Molar Volume of A Gas (Student, Teacher, Technician Worksheets)Document5 pagesCore Practical 1 Molar Volume of A Gas (Student, Teacher, Technician Worksheets)Esha KamalNo ratings yet

- A Review On Manufacturing Defects and Their Detection of Fiber Reinforced Resin Matrix CompositesDocument24 pagesA Review On Manufacturing Defects and Their Detection of Fiber Reinforced Resin Matrix Compositesenkilee2020No ratings yet

- Determination of Nickel As The Dimethylglyoxime Complex by SpectrophotometryDocument5 pagesDetermination of Nickel As The Dimethylglyoxime Complex by Spectrophotometryevenspase7859No ratings yet

- Williamreynolds 1983Document5 pagesWilliamreynolds 1983Dr. Arijit RoyNo ratings yet

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- Gantry Chain Weight Www-Liftingsafety-Co-Uk-ProductDocument2 pagesGantry Chain Weight Www-Liftingsafety-Co-Uk-ProductMark ManayonNo ratings yet

- Nbs Technical Note 1325Document496 pagesNbs Technical Note 1325Daniel Felipe Parias AnayaNo ratings yet

- Lec-3, EvaporationDocument43 pagesLec-3, EvaporationArsh OmairNo ratings yet

- Introducción WPS ISODocument41 pagesIntroducción WPS ISOCarlos Eduardo Castillo LanderosNo ratings yet

- EMCCDDocument2 pagesEMCCDmythNo ratings yet

- Climatic Phenomenon DLPDocument15 pagesClimatic Phenomenon DLPMaureen Torres CastelNo ratings yet

- ACSEE Physics F5 T4 PropertiesOfMatterDocument4 pagesACSEE Physics F5 T4 PropertiesOfMatterEmmanuel MarijaniNo ratings yet

- GranularesDocument742 pagesGranularesRodrigo LevyNo ratings yet

- Review of Modern Physics Volume 87 Issue 3 2015 (Doi 10.1103 - Revmodphys.87.897) Jones, R. O. - Density Functional Theory - Its Origins, Rise To Prominence, and FutureDocument27 pagesReview of Modern Physics Volume 87 Issue 3 2015 (Doi 10.1103 - Revmodphys.87.897) Jones, R. O. - Density Functional Theory - Its Origins, Rise To Prominence, and FuturegalileoNo ratings yet

- Post Lab QuestionsDocument1 pagePost Lab QuestionsEinsh MonosNo ratings yet