Professional Documents

Culture Documents

EJB UL Enclosures: Certificate NEMA Type 4X

Uploaded by

bader eddine khezamiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EJB UL Enclosures: Certificate NEMA Type 4X

Uploaded by

bader eddine khezamiCopyright:

Available Formats

EJB UL Enclosures Ex Enclosures

Installation: hazardous areas - Zone 1 / 2 (Gases) - Zone 21 / 22 (Dusts)

Classification: Group II - Category 2G 2D

Certificate

NEMA Type 4X

REFERENCE STANDARDS Mechanical characteristics

TERMINAL BOARD / POWER UNITS CONTROL Body and cover marine grade copper free aluminium light alloy

AND SIGNALLING UNITS Screws stainless steel - internal / external

NEC - NEMA 4, 7, 9 Internal plate hot dip galvanized steel / aluminium

Class I - Groups B, C, e D

Fixing galvanized steel stirrups th.10mm

INSTALLATION Class II - Groups E, F, e G

Class III Gaskets O-RING silicon rubber on cover

PROTECTION 4 , 7 BCD , 9 EFG

PROTECTION DEGREE IP66

AMBIENT TEMPERATURE -20°C ÷ +40°C

UL Standard 1203 - 4° Ed.

(15 Sett. 2006)

CERTIFICATION AND

Explosion-Proof / Dust-Ignition-Proof

COMPLIANCES

Electrical Equipment for Use in

Hazardous (Classified) Locations

Directive 2014/34/EU

( II 2 G) Ex db IIA or IIB or IIB+H2 T6…T3

( II 2 G) Ex db [ia/ib IIA or IIB or IIC Ga]

EXECUTION IIA or IIB or IIB+H2 T6

( II 2 D) Ex tb IIIC T85°C…T200°C

( II 2 D) Ex tb [ia Da/ib] IIIC T85°C

EN/IEC 60079-0; EN/IEC 60079-1;

RULES OF COMPLIANCE

EN/IEC 60079-11; EN/IEC 60079-31

EC Type-Examination Certificate INERIS 13 ATEX 0022X

PROTECTION DEGREE IP66

AMBIENT TEMPERATURE -60°C ÷ +80°C

OTHER AVAILABLE CERTIFICATES IECEx: IECEx INE 13_0070X

NEC 505: UL 20141204-E302348 -

Type rating NEMA 1, 12, 4 and 4X

On Request Accessories:

• External epoxy painting (any colours)

• Internal anticondensate painting orange RAL-2004

• O-Ring gaskets on cover

• Drain and breather valves

• Stainless steel AISI-316L hinges

1 BARTEC FEAM - Catalogue 01

EJB UL Enclosures Ex Enclosures

Technical Features

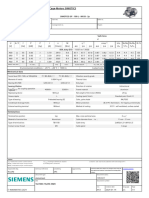

A B C D E F G H I L INT. PLATE WEIGHT

CODE DETAIL

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] X-Y [mm] [Kg]

EJB21-UL 320 280 177 189 180 233 121 214 174 13 180 - 140 13,50 A

EJB31-UL 450 350 248 260 294 287 191 341 241 13 325 - 225 27,00 A

EJB51-UL 600 400 266 278 360 333 195 481 281 13 460 - 260 52,50 A

EJB61-UL 710 500 389 397 500 460 277 566 356 12 560 - 360 114,00 A

EJB63-UL 710 500 259 267 500 460 147 571 362 12 560 - 360 92,00 A

A B C D E F G H I L INT. PLATE LIBRE

CODE DETAIL

[Inch] [Inch] [Inch] [Inch] [Inch] [Inch] [Inch] [Inch] [Inch] [Inch] X-Y [Inch] [Lbs]

EJB21-UL 12,60 11,10 7,00 7,50 7,10 9,20 4,80 8,50 6,90 0,60 7.10 - 5.60 31,00 A

EJB31-UL 17,80 13,80 9,80 10,30 11,60 11,30 7,60 13,50 9,50 0,60 12.80 - 8.90 62,00 A

EJB51-UL 23,70 15,80 10,50 11,00 14,20 13,20 7,70 19,00 11,10 0,60 18.20 - 10.30 121,00 A

EJB UL

EJB61-UL 28,00 19,70 15,40 15,70 19,70 18,20 11,00 22,30 14,10 0,50 22.10 - 14.20 262,00 A

EJB63-UL 28,00 19,70 10,20 10,60 19,70 18,20 5,80 22,50 14,30 0,50 22.10 - 14.20 212,00 A

Reference details

2

A

D

C B F

L

G

E

A

HxI

Body enclosures drilling layout

AREA FOR ENTRY INSTALLATION (LONG WALL SIDES) AREA FOR ENTRY INSTALLATION (SHORT WALL SIDES)

ENCLOSURE

CODE A B A B C D C D

[mm] [mm] [inch.] [inch.] [mm] [mm] [inch.] [inch.]

EJB21-UL 190 80 7,50 3,20 150 80 6,00 3,20

EJB31-UL 320 140 12,60 5,60 230 140 9,10 5,60

EJB51-UL 450 120 17,80 4,80 250 120 9,90 4,80

EJB61-UL 550 260 21,70 10,30 350 260 13,80 10,30

EJB63-UL 550 150 21,70 6,00 350 150 13,80 6,00

Catalogue 01 - BARTEC FEAM 2

EJB UL Enclosures Ex Enclosures

Body enclosures minimum distance between wall entries

MINIMUM DISTANCE BETWEEN WALL ENTRIES (CENTER TO CENTER)

1st ROW [mm] - 2nd ROW [inch.]

4” 139

- - - - - - - -

- (5.47)

3” 115 126

- - - - - - -

M90 (4.53) (4.96)

2 1/2” 101 108 120

- - - - - -

M75 (3.98) (4.25) (4.72)

2” 88 94 102 112

- - - - -

M63 (3.46) (3.70) (4.02) (4.41)

1 1/2” 75 82 88 95 106

- - - -

M50 (2.95) (3.23) (3.46) (3.74) (4.17)

1 1/4” 67 70 77 84 91 103

- - -

M40 (2.64) (2.76) (3.03) (3.31) (3.58) (4.06)

1” 58 63 66 73 80 86 99

- -

M32 (2.28) (2.48) (2.60) (2.87) (3.15) (3.39) (3.90)

3/4” 52 55 59 63 69 79 83 95

-

M25 (2.05) (2.17) (2.32) (2.48) (2.72) (2.99) (3.27) (3.74)

1/2” 46 49 52 57 60 67 73 80 93

M20 (1.81) (1.93) (2.05) (2.24) (2.36) (2.64) (2.87) (3.15) (3.66)

NPT 1/2” 3/4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 4”

Metric M20 M25 M32 M40 M50 M63 M75 M90 -

Reference details

WALL DRILLING AREA

A C

D

B

Cover enclosures drilling layout

MINUMUM DISTANCE COVER DRILLING AREA

AREA FOR OPERATORS

BETWEEN OPENINGS F

ENCLOSURE INSTALLATION ENCLOSURE COVER

(CENTER TO CENTER)

CODE

E F E F

[mm] [inch.]

[mm] [mm] [inch.] [inch.]

EJB21-UL 200 150 7,90 6,00 50 2,00

EJB31-UL 300 200 11,90 7,90 50 2,00

E

EJB51-UL 460 260 18,20 10,30 50 2,00

EJB61-UL 570 370 22,50 14,60 50 2,00

EJB63-UL 570 370 22,50 14,60 50 2,00

3 BARTEC FEAM - Catalogue 01

EJB UL Enclosures Ex Enclosures

Indicative quantity of terminals and relevant section

SEZ. 2,5 SEZ. 6,0 SEZ. 10,0 SEZ. 16,0 SEZ. 35,0 SEZ. 50,0 SEZ. 70,0 SEZ. 240,0 INT. PLATE X - Y

CODE

[sq/mm] [sq/mm] [sq/mm] [sq/mm] [sq/mm] [sq/mm] [sq/mm] [sq/mm] [mm] [inch.]

EJB21-UL 30 x 1 20 x 1 14 x 1 12 x 1 8x1 6x1 2x1 1x1 180 -140 7.10 - 5.60

EJB31-UL 52 x 2 32 x 2 24 x 2 20 x 2 14 x 2 12 x 1 8x1 4x1 325 -225 12.80 - 8.90

EJB51-UL 80 x 2 46 x 2 36 x 2 30 x 2 22 x 2 18 x 2 16 x 1 6x1 460 -260 18.20 - 10.30

EJB61-UL 92 x 3 58 x 3 46 x 3 38 x 3 28 x 3 26 x 2 22 x 2 12 x 1 560 -350 22.10 - 14.20

EJB63-UL 92 x 3 58 x 3 46 x 3 38 x 3 28 x 3 26 x 2 22 x 2 12 x 1 560 -350 22.10 - 14.20

Additional Technical features for NEC 500 only

PRODUCT COVERED

Explosion-proof enclosures for use in Hazardous Locations, Class I, Groups B, C, and D; Class II, Groups E, F, and G; Class III.

These enclosures are Classified as to explosion and fire hazards only in according to Standard UL1203 4° ed.

The explosion-proof enclosures are suitable for Class I, Group B Hazardous Locations only when provided with from M20 to M90, 1/2 in. to 3 in., supply connection openings. If

other supply connection openings are provided, then the enclosures are suitable for Class I, Groups C & D Hazardous Locations only.

The 1/2 in. NPSM operator openings are only suitable for enclosures marked for Class I, Groups B, C & D Hazardous Locations

The enclosures covered by this Certification may have electrical components installed inside. The installation of electrical components shall not reduce the mechanical integrity of

the enclosures.

EJB UL

The enclosures may or may not be provided with hinges for service of the enclosures only.

PROTECTION AGAINST CORROSION

All ferrous-metal other than stainless steel shall be protected against corrosion, except at joint surfaces and conduit threads There shall be no materials

applied to joint surfaces.

GROUNDING 2

Internal Ground Screw – Hexagon head screw M6 x 10 with a stainless steel flat and lock washer provided on the base of the enclosure body.

External Ground – Terminal colored green, marked with the letter or word “G”, “GROUND”, or marked with a grounding symbol.

SUPPLY CONNECTIONS

NPT and Metric Supply Connections - The side walls of the enclosure are provided with conduit openings or none may be supplied, in which case field drilling and tapping

instructions are provided with each enclosure. The entry is drilled and tapped completely through the enclosure wall, and the inside edge is smoothed and well-rounded such that

the conductor insulation will not be damaged when installed. All unused openings are closed with plated steel, plated cast iron or aluminum close-up plugs which are threaded to

match the opening. Closer-up Plugs have to be Listed for the same Class, Group and Division as marked on Enclosure nameplate.

OPERATOR OPENINGS

The cover of the enclosure may be provided with operator openings in the cover only and located only as given in drilling and tapping instructions provided with each Classified enclosure. All unused

openings are closed with plated steel, plated cast iron or aluminum close-up plugs which are threaded to match the opening. Closer-up Plugs have to be Listed for the same Class, Group and Division

as marked on Enclosure nameplate.

REMARK:

Due to the development of the national and international specifications and of the technology, the above technical characteristics showed on this bulletin can be considered as binding on our confirmation only.

Catalogue 01 - BARTEC FEAM 4

You might also like

- 02.ex EnclosuresDocument52 pages02.ex EnclosuresJavier Enrrique Iglesias PelcastreNo ratings yet

- EJB UL Enclosures: Certificate NEMA Type 4XDocument4 pagesEJB UL Enclosures: Certificate NEMA Type 4Xshahbaz AhmadNo ratings yet

- TECHNOR® Brochure EJB ENDocument16 pagesTECHNOR® Brochure EJB ENFabio Henrique Oliveira RochaNo ratings yet

- EJB Flameproof Cabinets Specifications and DimensionsDocument3 pagesEJB Flameproof Cabinets Specifications and DimensionsTTRRTTGFNo ratings yet

- Cable Glands For Non-Armoured Cables: E-OctansDocument4 pagesCable Glands For Non-Armoured Cables: E-OctansMajdi BelguithNo ratings yet

- Spec 01059Document2 pagesSpec 01059NICOLASNo ratings yet

- Bartec EJBDocument4 pagesBartec EJBirfan ptktiNo ratings yet

- 46 Feam Esx EngDocument4 pages46 Feam Esx EngSyed AsadullahNo ratings yet

- EJBC Series Flameproof Enclosures Ex D IIC AluminumDocument16 pagesEJBC Series Flameproof Enclosures Ex D IIC AluminumXavier LefebvreNo ratings yet

- Optimal Performance at High (+60°C) and Low Temperatures (-50°C) - Easy To Install, Low Maintenance Costs - Zone 1, 2, 21, 22Document12 pagesOptimal Performance at High (+60°C) and Low Temperatures (-50°C) - Easy To Install, Low Maintenance Costs - Zone 1, 2, 21, 22Said EltNo ratings yet

- Applications:: Hinge Kits For Field Installation (No Field Machining Required)Document8 pagesApplications:: Hinge Kits For Field Installation (No Field Machining Required)Anonymous zTUWsMNo ratings yet

- ATEX Ebu Cable GlandDocument2 pagesATEX Ebu Cable Glandsamit327mNo ratings yet

- Cable Glands For SWA and AWA Cables: OrionDocument4 pagesCable Glands For SWA and AWA Cables: OrionMajdi BelguithNo ratings yet

- Bimed Ex Stars PDFDocument38 pagesBimed Ex Stars PDFtony6868No ratings yet

- Industrial Dry Coolers for Air Conditioning and Process CoolingDocument2 pagesIndustrial Dry Coolers for Air Conditioning and Process CoolingmoghanmogaNo ratings yet

- BIMED - PRENSAESTOPAS DE POLIAMIDADocument2 pagesBIMED - PRENSAESTOPAS DE POLIAMIDALogistica 2 essaperuNo ratings yet

- Cable GlandsDocument13 pagesCable Glandsharry jangNo ratings yet

- CMP CABLE GLAND CATALOGUEDocument1 pageCMP CABLE GLAND CATALOGUEsubramanyaNo ratings yet

- EVB Series: End-Of-Line Deflagration Flame ArrestersDocument2 pagesEVB Series: End-Of-Line Deflagration Flame Arresterstienhm_pve1553No ratings yet

- CMP Products Cable Gland CatalogueDocument1 pageCMP Products Cable Gland Cataloguesuhaili pedroNo ratings yet

- Double OffsetDocument10 pagesDouble Offsetkrbabu1969No ratings yet

- 1LE1002-1CB02-2AA4 Datasheet enDocument1 page1LE1002-1CB02-2AA4 Datasheet enLance AyoubNo ratings yet

- Series 7 Inline Flame ArrestorDocument4 pagesSeries 7 Inline Flame ArrestorFercomil S.A.SNo ratings yet

- Reference Number: 7.1.1: Ex D: Ex E: Ex NR: Ex Ta: Ip66: Ip68: Class I Div 1: Aex E: Aex TaDocument1 pageReference Number: 7.1.1: Ex D: Ex E: Ex NR: Ex Ta: Ip66: Ip68: Class I Div 1: Aex E: Aex TaHungNo ratings yet

- Te1fu PDFDocument1 pageTe1fu PDFkhaldoun samiNo ratings yet

- Components: For Armoured Cables - Inner and Outer SealingDocument2 pagesComponents: For Armoured Cables - Inner and Outer SealingKarwanNo ratings yet

- EN Double Offset 2E SmallDocument12 pagesEN Double Offset 2E SmallEduardo TapiaNo ratings yet

- Flameproof Enclosures EJB Ex D Iib+H Aluminium & Stainless SteelDocument4 pagesFlameproof Enclosures EJB Ex D Iib+H Aluminium & Stainless SteelTamado JayaNo ratings yet

- Csa/Ah: Type of Protection: Class of Temperature: Protection Degree: CertificateDocument1 pageCsa/Ah: Type of Protection: Class of Temperature: Protection Degree: CertificateAnonymous 9rM4GbfuQKNo ratings yet

- pdfcatalogDocument1 pagepdfcatalogLogistica 2 essaperuNo ratings yet

- 42 GUA-EAHF enDocument2 pages42 GUA-EAHF enSyed AsadullahNo ratings yet

- Polyamide cable glands with lamellar clamping for standard industrial applicationsDocument1 pagePolyamide cable glands with lamellar clamping for standard industrial applicationsşerafettin demirbaşNo ratings yet

- Cable Glands For Armoured CablesDocument12 pagesCable Glands For Armoured CablesFlo MircaNo ratings yet

- LE B-255 H4R: ClassificationDocument2 pagesLE B-255 H4R: ClassificationVivien EmeraldoNo ratings yet

- PAPD Cable glands for hazardous areasDocument2 pagesPAPD Cable glands for hazardous areasGulf Trans PowerNo ratings yet

- 1LE1003-1AA43-4FA4-Z B02 Datasheet enDocument2 pages1LE1003-1AA43-4FA4-Z B02 Datasheet enRefresh DrNo ratings yet

- CMP E1fxDocument1 pageCMP E1fxmohd darusNo ratings yet

- Cortem - Round Junction BoxDocument16 pagesCortem - Round Junction BoxRagu RajanNo ratings yet

- Rotex Solenoid ValveDocument7 pagesRotex Solenoid ValvejoseNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CD3094B Simotics XP - 90 L - Im B3 - 4PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CD3094B Simotics XP - 90 L - Im B3 - 4PToko DownloadNo ratings yet

- Ficha Tecnica Tapón Hexagonal de Polyamide Ex-E Draco, Marca. BimedDocument2 pagesFicha Tecnica Tapón Hexagonal de Polyamide Ex-E Draco, Marca. BimedGiancarloEleNo ratings yet

- 757 METRICDocument1 page757 METRICSamdan NamhaisurenNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2252B Simotics SD - 250 M - Im B5 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2252B Simotics SD - 250 M - Im B5 - 4PrezaNo ratings yet

- Stopper PlugDocument4 pagesStopper PlugChanchai PrugpadeeNo ratings yet

- Appleton Tri-Rated Enclosures FlyerDocument2 pagesAppleton Tri-Rated Enclosures FlyerChen LiuNo ratings yet

- Junction boxes gas group IIC selectionDocument16 pagesJunction boxes gas group IIC selectionkskadryNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 0EB02 2JA4Document2 pagesSilnik - Karta Katalogowa 1LE1002 0EB02 2JA4artur.sowaNo ratings yet

- 38 Feam Ejb EngDocument4 pages38 Feam Ejb EngSaufi YatimNo ratings yet

- Ejb EnclosuresDocument8 pagesEjb EnclosuresMarito VallejitosNo ratings yet

- AE Series Disconnect Switches: Explosionproof, Dust-IgnitionproofDocument2 pagesAE Series Disconnect Switches: Explosionproof, Dust-IgnitionproofMuhamad PriyatnaNo ratings yet

- Caixa Gbox - DocDocument15 pagesCaixa Gbox - Docsimao.bolaNo ratings yet

- Sealconex1 60 PDFDocument64 pagesSealconex1 60 PDFseanll2563No ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- Triple Offset Butterfly Valves Technical OverviewDocument6 pagesTriple Offset Butterfly Valves Technical OverviewBHARGAVNo ratings yet

- Pneumatic Actuator Parts and MaterialsDocument4 pagesPneumatic Actuator Parts and MaterialscvfNo ratings yet

- 52 PAP enDocument2 pages52 PAP enGulf Trans PowerNo ratings yet

- M50-2014 V6Document334 pagesM50-2014 V6Dragan MilosevicNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4nizarNo ratings yet

- Ftae rm001 - en eDocument213 pagesFtae rm001 - en ebader eddine khezamiNo ratings yet

- Advantech Diaganywhere: User ManualDocument46 pagesAdvantech Diaganywhere: User Manualbader eddine khezamiNo ratings yet

- Proces Wp023 en PDocument56 pagesProces Wp023 en PLessing Cárdenas DíazNo ratings yet

- Bristol Openenterprise Reference Guide: Alarm BannerDocument28 pagesBristol Openenterprise Reference Guide: Alarm Bannerbader eddine khezamiNo ratings yet

- Layer 3 48-Port 10G SFP+ + 2-Port 40G QSFP+ + 4-Port 100G QSFP28 Managed SwitchDocument10 pagesLayer 3 48-Port 10G SFP+ + 2-Port 40G QSFP+ + 4-Port 100G QSFP28 Managed Switchbader eddine khezamiNo ratings yet

- PLC Interface RelaysDocument1 pagePLC Interface Relaysbader eddine khezamiNo ratings yet

- Lm-7000H Module Series: Ethernet and Poe+ Modules For The Pt-G7728/G7828 Series and Mds-G4012/20/28 SeriesDocument3 pagesLm-7000H Module Series: Ethernet and Poe+ Modules For The Pt-G7728/G7828 Series and Mds-G4012/20/28 Seriesbader eddine khezamiNo ratings yet

- Intellinet - 561273Document4 pagesIntellinet - 561273bader eddine khezamiNo ratings yet

- MK-DV08: C1 C2 C1 C2 C1 C1 Shunt Shunt Shunt C1 C2 C1 Not Used Not Used Not Used Not Used C1 C2Document1 pageMK-DV08: C1 C2 C1 C2 C1 C1 Shunt Shunt Shunt C1 C2 C1 Not Used Not Used Not Used Not Used C1 C2bader eddine khezamiNo ratings yet

- 02 WholeDocument100 pages02 Wholebader eddine khezamiNo ratings yet

- Data Sheet For SMU01 Controller Module Rev05Document2 pagesData Sheet For SMU01 Controller Module Rev05bader eddine khezamiNo ratings yet

- Victron Ve Direct ProtocolDocument11 pagesVictron Ve Direct ProtocolDefiant OverlandNo ratings yet

- 7.2 DA Patch Install Guide PDFDocument5 pages7.2 DA Patch Install Guide PDFbader eddine khezamiNo ratings yet

- TEOS Data SheetDocument78 pagesTEOS Data Sheetbader eddine khezamiNo ratings yet

- PLC Interface RelaysDocument1 pagePLC Interface Relaysbader eddine khezamiNo ratings yet

- Eds-405a 408a SeriesDocument2 pagesEds-405a 408a SeriesJS168No ratings yet

- SD Summary: 3405 2283405 Sd04-Mdamsfcsnn LF-6240SD4A REV: G 192.168.1.1 4.3.2Document12 pagesSD Summary: 3405 2283405 Sd04-Mdamsfcsnn LF-6240SD4A REV: G 192.168.1.1 4.3.2bader eddine khezamiNo ratings yet

- 6EP19613BA21 Datasheet enDocument3 pages6EP19613BA21 Datasheet ensamim_khNo ratings yet

- 7.2 DA Patch Install Guide PDFDocument5 pages7.2 DA Patch Install Guide PDFbader eddine khezamiNo ratings yet

- 7.2 DA Patch Install Guide PDFDocument5 pages7.2 DA Patch Install Guide PDFbader eddine khezamiNo ratings yet

- 12 Channel Mixed IO Spec SheetDocument5 pages12 Channel Mixed IO Spec Sheetbader eddine khezamiNo ratings yet

- Zener Barrier Protects Circuits in Hazardous AreasDocument2 pagesZener Barrier Protects Circuits in Hazardous Areasbader eddine khezamiNo ratings yet

- 6EP19613BA21 Datasheet enDocument3 pages6EP19613BA21 Datasheet ensamim_khNo ratings yet

- This Datasheet Is Presented by The Manufacturer Dieses Datenblatt Wird Vom Hersteller Bereitgestellt Cette Fiche Technique Est Présentée Par Le FabricantDocument8 pagesThis Datasheet Is Presented by The Manufacturer Dieses Datenblatt Wird Vom Hersteller Bereitgestellt Cette Fiche Technique Est Présentée Par Le Fabricantbader eddine khezamiNo ratings yet

- Zener Barrier Protects Circuits in Hazardous AreasDocument2 pagesZener Barrier Protects Circuits in Hazardous Areasbader eddine khezamiNo ratings yet

- 6EP13322BA20 Datasheet enDocument4 pages6EP13322BA20 Datasheet enLucas Vinícius CostaNo ratings yet

- Delete Top (99) Percent From (Dbo) - (Data - Log)Document1 pageDelete Top (99) Percent From (Dbo) - (Data - Log)bader eddine khezamiNo ratings yet

- Zener Barrier Protects Circuits in Hazardous AreasDocument2 pagesZener Barrier Protects Circuits in Hazardous Areasbader eddine khezamiNo ratings yet

- Assignment 2 Mansi 19001005027Document20 pagesAssignment 2 Mansi 19001005027MansiNo ratings yet

- CLEAT DISTRIBUTION CONTROLS ON THE SULPHUR CONTENT OF THE MIOCENE COAL SEAMDocument11 pagesCLEAT DISTRIBUTION CONTROLS ON THE SULPHUR CONTENT OF THE MIOCENE COAL SEAMSabar Itu AgusNo ratings yet

- Leica DM-500 Microscope - User ManualDocument44 pagesLeica DM-500 Microscope - User ManualluroguitaNo ratings yet

- Gpa 2145Document15 pagesGpa 2145Sergio David Ruiz100% (1)

- Trex 01192Document186 pagesTrex 01192OSDocs2012No ratings yet

- Chemical Protective ClothingDocument8 pagesChemical Protective Clothingguest81No ratings yet

- Indian Patent Law - RNPDocument40 pagesIndian Patent Law - RNPRishikesh ChakorNo ratings yet

- Food Technology XLDocument113 pagesFood Technology XLSubhankar MaityNo ratings yet

- Re 91401Document20 pagesRe 91401JozefNo ratings yet

- ASTM D 3113 - 92 (Reapproved 1998) Sodium Salts of EDTA in WaterDocument4 pagesASTM D 3113 - 92 (Reapproved 1998) Sodium Salts of EDTA in Wateralin2005No ratings yet

- Chapter 19 NMRDocument126 pagesChapter 19 NMRMuchammad RofiiNo ratings yet

- Chem Cuprammonium RayonDocument6 pagesChem Cuprammonium RayonAnjali MenonNo ratings yet

- Experiment 3Document4 pagesExperiment 3Mama ChoiiNo ratings yet

- Guide to Safety Aspects of Manual Metal Arc Welding (MMAWDocument157 pagesGuide to Safety Aspects of Manual Metal Arc Welding (MMAWAsad Bin Ala QatariNo ratings yet

- Lecture Notes On Separation of Stable IsotopesDocument31 pagesLecture Notes On Separation of Stable IsotopesKaranam.Ramakumar100% (1)

- Extraction of Acids, Bases & NeutralsDocument7 pagesExtraction of Acids, Bases & Neutralsjp1923No ratings yet

- HPD ColoRex SD EC Tile (Exp. 2024.03.25)Document6 pagesHPD ColoRex SD EC Tile (Exp. 2024.03.25)Marco RaptusNo ratings yet

- Safety Data Sheet: Ac 9 Long Life Organic CoolantDocument5 pagesSafety Data Sheet: Ac 9 Long Life Organic Coolantraza239No ratings yet

- The Kinetics of Electrode ProcessesDocument8 pagesThe Kinetics of Electrode ProcessesLmm GPNo ratings yet

- Membrane Separation (MS)Document16 pagesMembrane Separation (MS)Walter CarguaNo ratings yet

- Sizing An Ion Exchange SystemDocument14 pagesSizing An Ion Exchange Systemgnino2No ratings yet

- Optimal Tech Coating News Vol 20Document2 pagesOptimal Tech Coating News Vol 20Javeria Ahmed100% (1)

- Hse Plustwo Chemistry Systematic Analysis of Simple Salts Anil HssliveDocument2 pagesHse Plustwo Chemistry Systematic Analysis of Simple Salts Anil HssliveGopakumar K0% (1)

- Large Cap Fan Coils PD2010Document6 pagesLarge Cap Fan Coils PD2010Mohd AdieNo ratings yet

- Concrete NotesDocument4 pagesConcrete NotesdaleemaNo ratings yet

- NM1 MassaDocument11 pagesNM1 MassaShandy ArmandoNo ratings yet

- Types of Electrical CablesDocument41 pagesTypes of Electrical CablesAbdullah NasirNo ratings yet

- Dossier Guanghua Casting PipeDocument58 pagesDossier Guanghua Casting PipeAlejandro C OlivaNo ratings yet

- TDC For Plates - SA 516 65Document3 pagesTDC For Plates - SA 516 65Renny DevassyNo ratings yet