Professional Documents

Culture Documents

Bevcon Grizzly Feeder

Bevcon Grizzly Feeder

Uploaded by

DxFx0 ratings0% found this document useful (0 votes)

77 views2 pagesvibro feeders

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentvibro feeders

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

77 views2 pagesBevcon Grizzly Feeder

Bevcon Grizzly Feeder

Uploaded by

DxFxvibro feeders

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

__BENCON WIBRATING GRIZZLY FEEDERS

Highlights of Bevcon Vibrating Grizzly Feeders

Bevcon Vibrating Grizzly Feeder has greater versatility & adaptability

for increase in Production / Products. The rugged design &

construction, smooth vibrating mechanism helps in reliable operation,

long durability and helps to lower maintenance costs. It is suitable for

continuous, uniform feeding of raw material into the crushers &

equipments while screening its soil / rejects away. It is widely used in

crushing and screening plants of Mineral & Mining Industry,

Construction material, Silicate, Power sector, Steel sector, Cement

industry, Chemical industry and Foundaries etc.

[Aggregates & Construction

}# Stee! Sector

*Power Sector

| Mineral & Mining Industry

+ Cement Industry

+ Chemical industry

+ Foundaries...

Market Leadiors since 1990 in

Material Handing Sereening - Crushing

veveor

BEVCON WAYORS PVT. LTD.

bevcon]

= | NIBRATING GRIZZLY FEEDERS

Sa

Sa

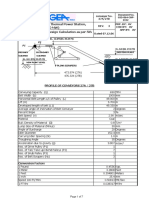

nas Hopper Size ‘Wax Feeding Size Electric Power Wain shaft Speed

{em x men) en) (ow) (om)

BWGF - 0725 750 X 2500 300 45X2 1000

BWGF - 0530 900 x 3000 450 372 1000

BWGF - 1036 1000 x 3600. 500 S5X2 1000

BWGF 1242 4200 X 4200 600 75X2 1000

BWGF - 3896 3800 x 960, 500 i 350 - 800

BWGF - 4996 4900 X 960 500 5 350 600

BWGF - 3641 3600 X £100 500 i 350 600

BWGF - 4911 4800 X 1100 580 s 7350-600

BWGF - 4913 4800 X 1300 850 2 750

BWGF = 5811 5900 X 1100 600 2 350-800

SN

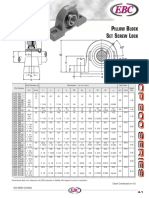

‘Step Grizzly feeder Scalping Grizzly feeder Inclined Grizzly feeder

SS RESET

‘Angle of throw can be adjusted due to the vibrator mechanism 7 Welded steel box construction.

design. * Reinforced feeder pan.

‘7 Grizzly bars are adjustable due to their bolted design, rather than pat

the competition's typical welded design. 2 Bolt-on ARS side liners.

‘> Screen section can be bolted under the grizzly section. 9 Large spherical self-aligning roller bearings

Value-Added

Greater Versatility & Adaptability for More Production Rugged Design & Construction for Lower Maintenance Costs

+ Optimum stratification of material in the feed hopper. 1 Stronger frame with less deflection of the lateral supports.

Better material separation across the grizzly section. 1 Protection of the feeder hopper against wear.

1 Increased primary crusher efficiency due to the fines bypassing

the primary crusher.

Greater Versatility & Adaptability for More Products.

9 Ease in changing the amount or the size of material sent through OTE: Specifications and other d

the primary crusher

27 Ease in making different products through the primary circuit

‘Quality Material Handling, Crushing & Serecning Equipment From

© Ease of replacing the side wear liners.

9 Longer bearing and mechanism life.

5 are subject to change

without notice because of continuous improvements.

Website waw bevconwayorscom

Corporate Office ; G. F., Kavya Apts, Madiuranagar, Hyderabad - 500 038, A. P., INDIA

WA Ic\ : 040-2373 7643, 2373 2628, Fax : 040-2375 0435, 2373 3626, E-Mail : info@beveonwayors.com

une * Chennai > Kolkata + New Delhi + Raipur» Jamshedpur + Coimbatore + Bhubaneshwar « Ahmedabad

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gas Pipe SizingDocument1 pageGas Pipe SizingDxFxNo ratings yet

- Screw T-Up2 PDFDocument1 pageScrew T-Up2 PDFDxFxNo ratings yet

- Et 3173 M 45003 - BDocument15 pagesEt 3173 M 45003 - BDxFxNo ratings yet

- Alwasy Step Ahead in TechnologyDocument4 pagesAlwasy Step Ahead in TechnologyDxFxNo ratings yet

- ET-3100-M-45008 1/15 Sohar Pelletizing PL Ant Pellet System-General Technical Specification of Vibrating Feeder Detailed Engineeri NG ADocument15 pagesET-3100-M-45008 1/15 Sohar Pelletizing PL Ant Pellet System-General Technical Specification of Vibrating Feeder Detailed Engineeri NG ADxFxNo ratings yet

- Alwasy Step Ahead in TechnologyDocument6 pagesAlwasy Step Ahead in TechnologyDxFxNo ratings yet

- Screw Take-Up Device UR6: Conveyor ComponentsDocument1 pageScrew Take-Up Device UR6: Conveyor ComponentsDxFxNo ratings yet

- E.VAIN001-IE1-0001 Revisions: Oman Industrial Complex - Phase I Project Rules & Guideline Interface ConceptDocument14 pagesE.VAIN001-IE1-0001 Revisions: Oman Industrial Complex - Phase I Project Rules & Guideline Interface ConceptDxFxNo ratings yet

- Screw Take-Up Device Ur1 Ur7: Conveyor ComponentsDocument1 pageScrew Take-Up Device Ur1 Ur7: Conveyor ComponentsDxFxNo ratings yet

- Alwasy Step Ahead in TechnologyDocument6 pagesAlwasy Step Ahead in TechnologyDxFx100% (1)

- FMC Syntron Vibrating FeedersDocument36 pagesFMC Syntron Vibrating FeedersDxFxNo ratings yet

- TRF Unbalance Motor Feeder & ScreenDocument4 pagesTRF Unbalance Motor Feeder & ScreenDxFxNo ratings yet

- Conveyor Design DraftDocument25 pagesConveyor Design DraftDxFxNo ratings yet

- Is.12213.1987vibro Feeder PDFDocument9 pagesIs.12213.1987vibro Feeder PDFDxFxNo ratings yet

- Calculating Idler L10 LifeDocument8 pagesCalculating Idler L10 LifeDxFxNo ratings yet

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocument7 pagesProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADxFxNo ratings yet

- Manual Calculation - Con36eDocument2 pagesManual Calculation - Con36eDxFxNo ratings yet

- Babu Soft Braking Solution PDFDocument19 pagesBabu Soft Braking Solution PDFDxFxNo ratings yet

- P B S S L: Illow Lock ET Crew OCKDocument2 pagesP B S S L: Illow Lock ET Crew OCKDxFxNo ratings yet

- 1732 - Square BarDocument6 pages1732 - Square BarDxFxNo ratings yet

- Novel 20 MW Downhill Conveyor System Using Three-Level ConvertersDocument9 pagesNovel 20 MW Downhill Conveyor System Using Three-Level ConvertersDxFxNo ratings yet