Professional Documents

Culture Documents

Manual Transmission Troubleshooting Guide

Uploaded by

Ugratara AutoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Transmission Troubleshooting Guide

Uploaded by

Ugratara AutoCopyright:

Available Formats

www.WorkshopManuals.co.

uk

MANUAL

TRANSMISSION

Click on the applicable bookmark to selected the required model year.

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk 22-1

MANUAL

TRANSMISSION

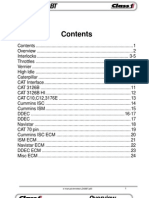

CONTENTS

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . 2 4WD Detection Switch Continuity Check

<V5MT1> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 High/Low Detection Switch Continuity Check

<V5MT1> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SEALANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TRANSMISSION CONTROL <V5MT1> . . . . . . . 8

SPECIAL TOOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TRANSMISSION CONTROL <V5MT3> . . . . . . . 9

TROUBLESHOOTING <SS4 II> . . . . . . . . . . . . . 3

TRANSMISSION ASSEMBLY . . . . . . . . . . . . . . 10

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 6

Transmission Oil Check . . . . . . . . . . . . . . . . . . . . . . . 6 4WD INDICATOR-ECU/TRANSFER-ECU . . . . 17

Oil Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Purchased from www.WorkshopManuals.co.uk

22-2 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - General Information/Lubricants/Sealants/Special Tool

GENERAL INFORMATION

Items Specifications

Transmission model V5MT1 V5M31

Engine model 4D5 4D5 4M4 6G7

Type 5-speed, floor-shift

Gear ratio 1st 3.918 3.952 4.234

2nd 2.261 2.238

3rd 1.395 1.398

4th 1.000

5th 0.829 0.819 0.761 0.819

Reverse 3.925 3.553

Transfer type 2-speed

Gear ratio High 1.000

Low 1.925 1.900

LUBRICANTS

Items Specified lubricants Quantity L

Transmission oil Hypoid gear oil SAE 75W-90 or 75W-85W conforming to 3.2

API GL-4

Transfer oil Hypoid gear oil SAE 75W-90 or 75W-85W conforming to 2.5

API GL-4

SEALANTS

Items Specified sealant Remarks

Oil filler plug 3M ATD Part No. 8660 or equivalent Semi-drying sealant

Oil drain plug 3M ATD Part No. 8660 or equivalent Semi-drying sealant

SPECIAL TOOL

Tool Number Name Use

MD998464 Test harness Inspection of lever position sensor

(4P, square)

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Troubleshooting <SS4 II> 22-3

TROUBLESHOOTING <SS4 II>

For items other than the following service procedures, refer to GROUP 23 - Troubleshooting <SS4 II>.

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis Diagnosis item Reference page

code

21 Lever position sensor (LPS) system <4D5> Open circuit/Malfunc- 22-3

tion of sensor

INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Code No.21 Lever position sensor (LPS) system <4D5> Probable cause

If the LPS output voltage becomes 0.2 V or less at idling, code No.21 will be D Malfunction of the LPS

set as open circuit or maladjustment of the LPS. D Malfunction of harness or connector

D Malfunction of transfer-ECU

D Malfunction of the glow-ECU

OK Intermittent malfunction

MUT-II Data list

D No.1 LPS (Refer to GROUP 00 - Points to

OK: Refer to P.23-5, DATA LIST Note for Transient Malfunctions.)

REFERENCE TABLE.

OK

Check the LPS. NG

Replace

(Refer to GROUP 17 - Emission

Control System)

OK

Check the following connector: NG

B-02 Repair

OK

NG OK

Measure at LPS connector B-02. Measure at glow-ECU connector Check the following connector: D-114

D Disconnect the connector and D-114.

measure at the harness side. D ECU terminal voltage OK NG

D Voltage between 2 and earth measurement

(Ignition switch: ON) D Ignition switch: ON Repair

OK: 4.8 - 5.2 V D Voltage between terminal 7 and

earth Check the harness wire between the

LPS and the glow-ECU, and repair if

OK: 4.8 - 5.2 V

necessary.

NG

NG

Check the following connector: D-114 Repair

NG

OK

Repair

Check the harness wire between the NG

LPS and the glow-ECU, and repair if Repair

necessary.

OK

OK

NG

Check the trouble symptoms. Replace the glow-ECU.

To the next page

Purchased from www.WorkshopManuals.co.uk

22-4 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Troubleshooting <SS4 II>

From the previous page

OK

(1),(2) NG

NG

Measure at LPS connector B-02. Check the following connector: D-114 Repair

D Use the test harness

(MD998464) to connect connector OK

terminals No. 1, No. 2, No.3

only, and measure at the pick-up Check the harness wire between the

harness. LPS and the glow-ECU, and repair if

D Ignition switch: ON necessary.

(1) Voltage between terminal 3 and (3)NG

earth NG

Adjust the LPS. Adjust

OK: 0.5 V or less (Refer to GROUP 17 - Emission

(2) Voltage between 2 and earth Control System)

(Ignition switch: ON)

OK: 4.8 - 5.2 V OK

(3) Voltage between terminal 1 and

earth OK

OK: Accelerator pedal fully re- Check the following connectors: Check the harness wire between the

leased E-113, E-105 LPS and the transfer-ECU, and

800 - 1,000 mV repair if necessary.

Accelerator pedal fully de-

pressed

3,700 - 4,900 mV

OK

NG NG

Measure at transfer-ECU connector Check the following connectors: Repair

E-105. E-105, E-113

D ECU terminal voltage OK

measurement

D Ignition switch: ON Check the harness wire between the

D Voltage between terminal 5 and LPS and the transfer-ECU, and

earth repair if necessary.

OK: Accelerator pedal fully OK

closed Check the following connector: E-105

800 - 1,000 mV

Accelerator pedal fully de- OK

pressed NG

3,700 - 4,900 mV Check the trouble symptoms. Repair

NG

Replace the transfer-ECU.

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Troubleshooting <SS4 II> 22-5

DATA LIST REFERENCE TABLE

Data Check item Check conditions Normal condition

list No.

1 Lever position Engine: Stopped Accelerator pedal: Fully closed 800 - 1,000 mV

sensor (LPS) Selector lever position: Accelerator pedal: Depressed Gradually increases from

<4D5> P the above value.

Accelerator pedal: Fully open 3,700 - 4,900 mV

CHECK AT TRANSFER-ECU TERMINAL

Ter- Check item Check conditions Standard value

minal

No.

5 Lever position sensor Accelerator pedal: Fully closed (engine stopped) 0.8 - 1.0 V

(LPS) <4D5> Accelerator pedal: Fully open (engine stopped) 3.7 - 4.9 V

Purchased from www.WorkshopManuals.co.uk

22-6 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - On-vehicle Service

ON-VEHICLE SERVICE

TRANSMISSION OIL CHECK

Filler plug hole

Transmission oil 1. Remove the oil filler plug.

2. Oil level should be at the lower portion of the filler plug

hole.

3. Check that the transmission oil is not noticeably dirty,

and that it has a suitable viscosity.

4. Tighten the filler plug to the specified torque.

Tightening torque: 32 ± 2 N×m

Transmission OIL REPLACEMENT

<V5MT1>

Oil filler plug 1. Remove oil filler plug and oil drain plug.

2. Drain oil.

Oil drain plug 3. Apply sealant to the oil drain plug threads.

4. Tighten the oil drain plug to the specified torque.

Tightening torque:

V5MT1 39 ± 5 N×m

V5M31 32 ± 2 N×m

Transfer 32 ± 2 N×m

Specified sealant:

Transmission 3M ATD Part No. 8660 or equivalent

<V5M31>

5. Fill with specified oil till the level comes to the lower portion

Oil filler plug

of oil filler plug hole.

Specified transmission oil:

Hypoid gear oil SAE 75W-90 or 75W-85W

Oil drain plug conforming to API GL-4

Quantity:

Transmission 3.2 L

Transfer 2.5 L

6. Apply sealant to the oil filler plug threads.

Transfer 7. Tighten the oil filler plug to the specified torque.

<V5MT1>

Oil filler plug Tightening torque: 32 ± 2 N×m

Specified sealant:

3M ATD Part No. 8660 or equivalent

Oil drain plug

Transfer

<V5M31>

OilOil filler

filler plug

plug

OilOil

drain plug

drain plug

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - On-vehicle Service 22-7

4WD DETECTION SWITCH CONTINUITY CHECK

<V5MT1>

Check the continuity between terminals of the black connector

indicated in the illustration.

Transfer lever position Terminal No.

1 2

2H

4H

HIGH/LOW DETECTION SWITCH CONTINUITY

CHECK <V5MT1>

Check the continuity between terminals of the gray connector

indicated in the illustration.

Transfer lever position Terminal No.

1 2

4H

4L

4H-4L

Purchased from www.WorkshopManuals.co.uk

22-8 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Control <V5MT1>

TRANSMISSION CONTROL <V5MT1>

REMOVAL AND INSTALLATION

Pre-removal Operation Post-installation Operation

D Shift the Transmission Control Lever to the N Check the Operation of the Transmission and Transfer

Position. Control Levers and the Movement in Each Lever

D Shift the Transfer Control Lever to the 4H Position. Position.

5

1

3

2

3

Transmission control lever Transfer control lever assembly

assembly removal steps removal steps

D Indicator panel (Refer to GROUP 52A D Indicator panel (Refer to GROUP 52A

- Floor Console) - Floor Console)

1. Retainer plate 1. Retainer plate

2. Shift control boot 2. Shift control boot

3. Snap ring 3. Snap ring

4. Transmission control lever assem- 5. Transfer control lever assembly

bly

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Control <V5MT3> 22-9

TRANSMISSION CONTROL <V5MT3>

REMOVAL AND INSTALLATION

Pre-removal Operation Post-installation Operation

Shift the Transmission Control Lever to the N Position. Check the Operation of the Transmission and Transfer

Control Levers and the Movement in Each Lever

Position.

2 5.0 ± 1.0 N×m

1

3 7

4

11 ± 2 N×m

Transmission control lever Transfer select switch assembly

assembly removal steps removal steps

D Indicator panel (Refer to GROUP 52A D Indicator panel (Refer to GROUP 52A

- Floor Console) - Floor Console)

1. Transfer select switch assembly 6. Transfer select switch

2. Retainer plate 7. Transfer select switch bracket

3. Shift control boot

4. Snap ring

5. Transmission control lever assem-

bly

4HLc 4H

INSPECTION

4LLc 2H TRANSFER SELECT SWITCH CONTINUITY CHECK

Switch posi- Terminal number

tion 1 2 3 5 6

2H

4H

4HLc

4LLc

Purchased from www.WorkshopManuals.co.uk

22-10 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Assembly

TRANSMISSION ASSEMBLY

REMOVAL AND INSTALLATION

Caution

The rear propeller shaft is made of fiber-reinforced plastic tube, so always refer to GROUP 25

prior to its removal.

Pre-removal Operation Post-installation Operation

D Transmission and Transfer Control Lever Removal D Front and Center Exhaust Pipe Installation (Refer

(Refer to P.22-8.) to GROUP 15 - Exhaust Pipe and Main Muffler)

D Transmission and Transfer Oil Draining (Refer to D Front and Rear Propeller Shaft Installation (Refer

P.22-6.) to GROUP 25 - Propeller Shaft.)

D Front and Rear Propeller Shaft Removal (Refer to D Transmission and Transfer Oil Filling (Refer to

GROUP 25 - Propeller Shaft.) P.22-6.)

D Front and Center Exhaust Pipe Removal (Refer D Transmission and Transfer Control Lever

to GROUP 15 - Exhaust Pipe and Main Muffler) Installation (Refer to P.22-8.)

D Transmission and Transfer Control Lever Operation

Check

<4D5 with V5MT1>

9 24 ± 5 N×m

35 ± 6 N×m 5

11

10

6

48 ± 6 N×m

35 ± 6 N×m

53 ± 5 N×m

24 ± 5 N×m

23 ± 3 N×m

35 ± 6 N×m

44 ± 10 N×m

48 ± 6 N×m

8

4

3 35 ± 6 N×m

44 ± 10 N×m

2

35 ± 6 N×mm

1 7

44 ± 10 N×m

26 ± 4 N×m

35 ± 6 N×m

9.0 ± 2.0 N×m

44 ± 10 N×m

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Assembly 22-11

<4D5 with V5M31>

24 ± 5 N×m

9 35 ± 6 N×m 5

11

10

6

35 ± 6 N×m

53 ± 5 N×m

48 ± 6 N×m

24 ± 5 N×m

23 ± 3 N×m

44 ± 10 N×m

8

35 ± 6 N×m

48 ± 6 N×m

44 ± 10 N×m

4

3

35 ± 6 N×m

2 35 ± 6 N×m

1 7

44 ± 10 N×m

26 ± 4 N×m

35 ± 6 N×m 44 ± 10 N×m

9.0 ± 2.0 N×m

Removal steps

1. Clutch release cylinder 7. Transmission mount center member

2. Space rubber assembly

3. Bell housing cover 8. Transmission mount insulator assem-

4. Starter motor bly

5. Dynamic damper assembly AA" 9. Transmission wiring harness connec-

6. Tension wire bracket tor connection

D Support the transmission with a "AA 10. Transmission assembly

transmission jack 11. Tension wire

Purchased from www.WorkshopManuals.co.uk

22-12 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Assembly

<4M4 with V5M31>

Pre-removal and Post-installation Operations

D Skid Plate and Under Cover Removal and Installation D Front Exhaust Pipe and Catalytic Converter Removal

D Transmission Fluid and Transfer Oil Draining and and Installation (Refer to GROUP 15.)

Refilling (Refer to P.22-6.) D Radiator Shroud Lower Cover Removal and

D Front and Rear Propeller Shaft Removal and Installation (Refer to GROUP 14.)

Installation D Intercooler Removal and Installation (Refer to GROUP

(Refer to GROUP 25.) 15)

24 ± 5 N×m 35 ± 6 N×m 9

13

15

10

7 14 35 ± 6 N×m

53 ± 5 N×m

24 ± 5 N×m

48 ± 6 N×m

8

44 ± 10 N×m

11 ± 1 N×m

48 ± 6 N×m

12

44 ± 10 N×m

6

1

3

5 11

44 ± 10 N×m

26 ± 4 N×m

48 ± 6 N×m

4 2

44 ± 10 N×m

Removal steps

1. Clutch release cylinder 4. Battery cable connection

(Refer to GROUP15) 5. Spacing rubber

2. Clutch dumper assembly 6. Dust cover

(Refer to GROUP15) 7. Heater hose connection

3. Exhaust support bracket 8. Starter motor

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Assembly 22-13

9. Dynamic damper AA" 13. Transmission harness connector con-

10. Tension wire bracket nection

D Support the transmission with a AB" D Clutch release bearing disconnection

transmission jack "AA 14. Transmission assembly

11. Transmission mount center member 15. Tension wire

assembly

12. Transmission mount insulator assem-

bly

Purchased from www.WorkshopManuals.co.uk

22-14 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Assembly

<6G7 with V5M31>

Pre-removal and Post-installation Operations

D Skid Plate and Under Cover Removal and Installation D Front Exhaust Pipe Removal and Installation

D Transmission Fluid and Transfer Oil Draining and (Refer to GROUP 15.)

Refilling (Refer to P.22-6.) D Radiator Shroud Lower Cover Removal and

D Front and Rear Propeller Shaft Removal and Installation (Refer to GROUP 14.)

Installation (Refer to GROUP 25.)

12

24 ± 5 N×m

35 ± 6 N×m 8

14

9

13

35 ± 6 N×m

53 ± 5 N×m

7

74 ± 10 N×m

24 ± 5 N×m

30 ± 3 N×m

5

4

44 ± 10 N×m

11

1

44 ± 10 N×m

89 ± 9 N×m

5.9 ± 0.9 N×m 10

44 ± 10 N×m

11 ± 1 N×m 6 11 ± 1 N×m

36 ± 5 N×m 26 ± 4 N×m

44 ± 10 N×m

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Assembly 22-15

Removal steps

1. Clutch release cylinder D Support the transmission with a

(Refer to GROUP15) transmission jack

2. Heater hose connection 10. Transmission mount center member

3. Cover assembly

4. Starter motor 11. Transmission mount insulator assem-

5. Starter cover bly

6. Oil pan connection bolts AA" 12. Transmission harness connector con-

7. Battery cable connection nection

8. Dynamic damper AB" D Clutch release bearing disconnection

9. Tension wire bracket "AA 13. Transmission assembly

14. Tension wire

<V5MT1> G J K REMOVAL SERVICE POINT

AA" TRANSMISSION WIRING HARNESS CONNECTOR

P

DISCONNECTION

1. Lower the transmission to a position where the

transmission harness connector can be disconnected,

and then disconnect the connector.

2. Place the disconnected transmission harness so that it

stays on the vehicle body.

Code Connector name

E F G

D H A Transmission wiring harness and battery wiring

<V5M31> I harness combination

B Select rail switch <4M4>

C

B C 1st and 2nd rail switch <4M4>

A

D 4LLC (Direct low range 4WD) switch

L E 2WD operation detection switch

M

O

N F Rear propeller shaft speed sensor

P G Vehicle speed sensor

Q H Oxygen sensor (Rear)

R

I Shift actuator

S

J High range/low range detection switch

K 4WD operation detection switch

L 2WD/4WD detection switch

M 4H (Full time 4WD) switch

N Center differential lock detection switch

O Front propeller shaft speed sensor

P Back-up lamp switch

Q Oxygen sensor (Front)

R Back-up lamp switch <4M4>

S 3rd and 4th rail switch <4M4>

Purchased from www.WorkshopManuals.co.uk

22-16 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Transmission Assembly

AB" CLUTCH RELEASE BEARING DISCONNECTION

1. Remove the service hole cover at the clutch housing.

2. Operate the release fork, and push the release bearing

towards the clutch side.

3. Insert the flat-tipped screwdriver to separate the release

bearing.

Release

fork

Release

bearing

INSTALLATION SERVICE POINT

D

"AA TRANSMISSION ASSEMBLY INSTALLATION

L

The sizes of the mounting bolts are different. So be sure

<4D5> not to confuse them.

A A

Starter <4D5>

motor

Bolt Diameter (D) x Length (L) mm

B

A 10 x 45

C

C

B 8 x 30

E

C 10 x 80

D D

D D D 10 x 25

<4M4>

C C

A E 10 x 35

A

<4M4>

A

Bolt Diameter (D) x Length (L) mm

Starter B

B A 12 x 25

motor

B B B 10 x 45

A A

<6G7> A A C 10 x 50

A

<6G7>

A

Starter

motor Bolt Diameter (D) x Length (L) mm

B

B

A 12 x 40

B 12 x 55

Purchased from www.WorkshopManuals.co.uk

www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - 4WD Indicator-ECU/Transfer-ECU 22-17

4WD INDICATOR-ECU/TRANSFER-ECU

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Indicator panel, Floor console front panel removal and

installation

(Refer to GROUP52A - Floor console)

4WD indicator-ECU

Bracket

4.9 ± 1.0 N×m

Transfer-ECU

4.9 ± 1.0 N×m

INSPECTION

4WD INDICATOR-ECU

1. Measure the voltage with the control unit and harness

View A still connected.

2. Earth terminal (8) and then measure terminal voltage.

Purchased from www.WorkshopManuals.co.uk

22-18 www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - 4WD Indicator-ECU/Transfer-ECU

Terminal No. Inspection item Inspection condition Inspection condition Terminal voltage

1: Ignition switch 2: Transfer lever position

1 Free wheel engage ON 2H System voltage

switch

4H*1 0V

2 4WD detection ON 2H System voltage

switch

4H, 4L 0V

3 Ignition switch (IG1) OFF - 0V

ON - System voltage

6 HI/LOW detection ON Shifting from 4H to 4L System voltage

switch or vice versa

2H, 4H, 4L 0V

7 Free wheel clutch ON 4H, 4L 0V

changeover solenoid

valve 2H*2 System voltage

10 4WD Indicator lamp ON 2H 0V

4H, 4L System voltage

NOTE

*1: When vehicle has been moved once.

*2: Shift the lever from 4H to 2H, and then turn the ignition switch to OFF and then back to ON.

TRANSFER-ECU

Measure the terminal voltage (Refer to P.22-3).

Purchased from www.WorkshopManuals.co.uk

MANUAL TRANSMISSION - Gneral/Troubleshooting <SS4 II> 22-1

www.WorkshopManuals.co.uk

GROUP 22

MANUAL TRANSMISSION

GENERAL

OUTLINE OF CHANGE

With additional vehicle with Emission Regulation Step III compatible 4D5 engine, the service procedure

different from service adjustment procedure of the vehicle with 4D5 engine has been established.

TROUBLESHOOTING <SS4 II>

INSPECTION CHART FOR DIAGNOSIS CODE

Diagnosis Diagnosis item Reference page

code

21 Accelerator pedal position sensor (APS) system Open circuit/Malfunc- 22-1

<4D5> tion of sensor

INSPECTION PROCEDURE FOR DIAGNOSIS CODE

Code No.21 Accelerator pedal position sensor (APS) Probable cause

system <4D5>

Code No.21 is output to indicate an open circuit in the APS or an incorrect D Malfunction of APS

adjustment when the APS output voltage drops below 0.2 V while the engine is D Malfunction of harness or connector

idling. D Malfunction of transfer-ECU

D Malfunction of engine-ECU

OK Transient malfunction

MUT-II Data List

D No. 1 APS (Refer to GROUP 00 - Points to

OK: Refer to P.22-2 (Data List Note for Transient Malfunctions.)

Reference Table).

NG

NG

APS check Replace

OK

Check the following connector: NG

Repair

D-135

OK

NG OK

Measure at APS connector D-135 Measure at engine-ECU connector Checkthefollowingconnector:D-112

D Disconnect the connector and D-112.

OK NG

measure at the harness side. D Measure at ECU terminal.

D Voltage between terminal 8 and D Ignition switch: ON Repair

earth D Voltage between terminal 60 and

(Ignition switch: ON) earth Replace the engine-ECU.

OK: 4.8 - 5.2 V OK: 4.8 - 5.2 V

NG

NG

Check the following connectors: Repair

D-135, D-112

NG OK

Repair D Check the harness between the NG

APS and the engine-ECU. Repair

OK OK

To the next page NG

Check the trouble symptoms. Replace the engine-ECU.

Purchased from www.WorkshopManuals.co.uk

22-2 MANUAL TRANSMISSION - Troubleshooting <SS4 II>

www.WorkshopManuals.co.uk

From the previous page

OK

(1), (2)

NG NG

Measure at APS connector D-135. Check thefollowing connector: D-112 Repair

D Use the test harness to connect

only terminals 6, 7 and 8, and OK

measure at the pickup harness.

D Ignition switch: ON D Check the harness between the

(1) Voltage between terminal 7 and APS and the engine-ECU, and

earth repair if necessary.

OK: 0.5 V or less

(2) Voltage between terminal 8 and (3) NG

earth APS adjustment

OK: 4.8 - 5.2 V

(3) Voltage between terminal 6 and

earth Check the following connectors:

OK: Fully close the accelerator E-113, E-105

985 - 1,085 mV

fully open the accelerator OK

4,000 mV or more

Check the harness between the APS

and the transfer-ECU, and repair if

necessary.

OK

NG NG

Measure at transfer-ECU connector Check the following connectors: Repair

E-105 E-105, E-113

D Measure at ECU terminals.

D Ignition switch: ON OK

D Voltage between terminal 5 and Check the harness between the APS

earth and the transfer-ECU, and repair if

OK: Fully close the accelerator necessary.

985 - 1,085 mV

fully open the accelerator OK

4,000 mV or more NG

Checkthefollowingconnector:E-105 Repair

OK

Check the trouble symptoms.

NG

Replace the transfer-ECU.

DATA LIST REFERENCE TABLE

Data Check item Check conditions Normal condition

list No.

1 Accelerator ped- Engine: Stopped Accelerator pedal: Fully closed 985 - 1,085 mV

al position sen

sen- S l

Selector lever

l position:

ii

sor (APS) Accelerator pedal: Depressed Gradually increases from

P the above value.

<4D5>

Accelerator pedal: Fully open 4,000 mV or more

CHECK AT TRANSFER-ECU TERMINAL

Ter- Check item Check conditions Standard value

minal

No.

5 Accelerator pedal

p position

p Accelerator pedal: Fully closed (engine stopped) 0.985 - 1.085 V

sensor (APS) <4D5>

4D5 Accelerator pedal: Fully open (engine stopped) 4.0 V or more

Purchased from www.WorkshopManuals.co.uk

You might also like

- Transmision 42re PDFDocument130 pagesTransmision 42re PDFMarcosneco100% (6)

- Allison ManualDocument58 pagesAllison ManualMauricio Gomez Gomez100% (1)

- Allison HD4060 Service Manual PDFDocument83 pagesAllison HD4060 Service Manual PDFthomas100% (2)

- Workshop Manual Pajero, MonteroDocument137 pagesWorkshop Manual Pajero, MonteroOlga Plohotnichenko90% (10)

- Daewoo Lift Truck Fault Codes de FalhasDocument4 pagesDaewoo Lift Truck Fault Codes de FalhasM L D R100% (1)

- ZF Ecomat 4 PDFDocument36 pagesZF Ecomat 4 PDFEndrit100% (2)

- PajeroDocument137 pagesPajeroLily Anwar88% (8)

- 1K 2K In-Chassis Maintenance 4th GenDocument86 pages1K 2K In-Chassis Maintenance 4th GenMuhammad Fahmi MahmudNo ratings yet

- 1K 2K In-Chassis MaintenanceDocument76 pages1K 2K In-Chassis MaintenanceLiviu Neda100% (1)

- VK540Document211 pagesVK540VladislavDultsevNo ratings yet

- Automatic Transmission Specs and Troubleshooting GuideDocument43 pagesAutomatic Transmission Specs and Troubleshooting Guidedudurez50% (2)

- Ecomat Opertors ManualDocument36 pagesEcomat Opertors Manualryanswj50% (2)

- Cleaner Production of Essential Oils by Steam DistillationDocument7 pagesCleaner Production of Essential Oils by Steam Distillationhagung100% (1)

- General Question Related To Coiled Tubing UnitDocument4 pagesGeneral Question Related To Coiled Tubing UnitBOy GeologErNo ratings yet

- Technical-Specification-Rmu-Frtu (Bses) PDFDocument55 pagesTechnical-Specification-Rmu-Frtu (Bses) PDFSanjay Kumar100% (1)

- Automatic Transmission: Click On The Applicable Bookmark To Selected The Required Model YearDocument137 pagesAutomatic Transmission: Click On The Applicable Bookmark To Selected The Required Model Yearsled novaNo ratings yet

- In Chasis Maintainance 1000 2000 PDFDocument78 pagesIn Chasis Maintainance 1000 2000 PDFMauricio Gomez Gomez100% (1)

- HF23Document60 pagesHF23izzywaanNo ratings yet

- Manual Transmission (FR)Document130 pagesManual Transmission (FR)adialfian2306No ratings yet

- Allison 1000 2000 Product Families in Chassis MaintenanceDocument7 pagesAllison 1000 2000 Product Families in Chassis Maintenanceregina100% (43)

- 23Document70 pages23Autof FerreiraNo ratings yet

- SCORPIO VLX DIAGNOSTIC MANUAL mHAWK Rev1Document178 pagesSCORPIO VLX DIAGNOSTIC MANUAL mHAWK Rev1Marcelo Gutiérrez lopezNo ratings yet

- 22sPACE WAGONDocument16 pages22sPACE WAGONrafaelcruzgjaNo ratings yet

- Throttle Information Reference Guide PDFDocument24 pagesThrottle Information Reference Guide PDFJohn Rivera100% (1)

- HỘP SỐ DRF100.Document21 pagesHỘP SỐ DRF100.Nguyễn Văn Hùng100% (1)

- VIS MotorsDocument6 pagesVIS MotorsnofakarNo ratings yet

- 23 PDFDocument72 pages23 PDFrafaelcruzgjaNo ratings yet

- Auto TraDocument84 pagesAuto TraAjnmalNo ratings yet

- RX1510-CI Service ManualDocument58 pagesRX1510-CI Service ManualJim Campbell De CastroNo ratings yet

- vị trí kiểm tra động cơ 1240-1250veDocument35 pagesvị trí kiểm tra động cơ 1240-1250veNguyễn Văn HùngNo ratings yet

- Xtype Power Train DTC SummariesDocument53 pagesXtype Power Train DTC Summariescardude45750No ratings yet

- Kalmar DRF 450 TranmissionDocument24 pagesKalmar DRF 450 Tranmissiontuấn anh nguyễnNo ratings yet

- Engine: ENGINE 2 - . - . - . - . - . - .Document14 pagesEngine: ENGINE 2 - . - . - . - . - . - .Mauriicio BakNo ratings yet

- User's Manual for Dual Channel Temperature ControllerDocument30 pagesUser's Manual for Dual Channel Temperature ControllerAhmedNo ratings yet

- Raup Iom 0705 PDFDocument35 pagesRaup Iom 0705 PDFritoNo ratings yet

- 03 Engine (4G9-MPI) 3 - SMDocument37 pages03 Engine (4G9-MPI) 3 - SMAtanas DimovNo ratings yet

- Land Rover Bosch GS8.87 Transmission Management (D2 & RR P38)Document13 pagesLand Rover Bosch GS8.87 Transmission Management (D2 & RR P38)ZM OhnNo ratings yet

- 117 - Rear Drive AxleDocument84 pages117 - Rear Drive AxleGedas GvildysNo ratings yet

- Damper Motor HoneywellDocument4 pagesDamper Motor HoneywelljesusNo ratings yet

- Powertrain DTC SummaryDocument71 pagesPowertrain DTC SummaryplanelNo ratings yet

- Accent P0011 Camshaft Position-Timing Over-AdvancedDocument6 pagesAccent P0011 Camshaft Position-Timing Over-Advancedflash_24014910No ratings yet

- OMF391184_POD_unlockedDocument162 pagesOMF391184_POD_unlockedeliminar348No ratings yet

- 4 Tec Diagnostic ProceduresDocument26 pages4 Tec Diagnostic ProceduresDiego Lozano G.No ratings yet

- AMI-GFV Manual KW 903-SP Doc No: AMI-GFV TM903-SP Issue: 1 CLASSIFICATION: Commercial in ConfidenceDocument18 pagesAMI-GFV Manual KW 903-SP Doc No: AMI-GFV TM903-SP Issue: 1 CLASSIFICATION: Commercial in ConfidenceMohamed ElhossenyNo ratings yet

- Data ErrorDocument2 pagesData Errorcristian faundesNo ratings yet

- 2009-12-27 171410 XtypeDocument98 pages2009-12-27 171410 XtypeDeni WardiniNo ratings yet

- Intake and Exhaust: Click On The Applicable Bookmark To Selected The Required Model YearDocument42 pagesIntake and Exhaust: Click On The Applicable Bookmark To Selected The Required Model YearCao LanNo ratings yet

- Emissions Control: EMISSIONS 3.7L/4.7L/5.7LDocument36 pagesEmissions Control: EMISSIONS 3.7L/4.7L/5.7LProducto DigitalNo ratings yet

- Aw03 PDFDocument15 pagesAw03 PDFamazonagirl19No ratings yet

- SM 6 PDFDocument162 pagesSM 6 PDFcarlosm6669No ratings yet

- Gap Transporter Maintenance ManualDocument11 pagesGap Transporter Maintenance ManualFelix MelendezNo ratings yet

- Rexroth 28250 Pump and Service ManualDocument40 pagesRexroth 28250 Pump and Service ManualRonit Manojcumar88% (8)

- 6727DFDocument89 pages6727DFVaworkerNo ratings yet

- Motion Control ReportFrom EverandMotion Control ReportRating: 4 out of 5 stars4/5 (1)

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- Amberjet 1200 H LDocument2 pagesAmberjet 1200 H LIraida MorosNo ratings yet

- QB 5 - Basic NDT - LT QBDocument5 pagesQB 5 - Basic NDT - LT QBprabhakaran.SNo ratings yet

- SOP For Boiler Light Up ChecklistDocument9 pagesSOP For Boiler Light Up Checklistpradeep.selvarajan100% (1)

- Metiche AnalDesign FRP Poles PDFDocument26 pagesMetiche AnalDesign FRP Poles PDFMojtaba Mohammad PourNo ratings yet

- RY780030A Parts ManualDocument4 pagesRY780030A Parts ManualAntonio MartinoNo ratings yet

- ESP ButtonDocument17 pagesESP ButtonDamjan MilanovićNo ratings yet

- Cr-Mo Steel Vessel Repair ConsiderationsDocument7 pagesCr-Mo Steel Vessel Repair Considerationsromanosky11No ratings yet

- Evaluating Strength of Brazed JointsDocument7 pagesEvaluating Strength of Brazed JointssutrimoNo ratings yet

- INKALUMDocument110 pagesINKALUMjasasegaladesainNo ratings yet

- The Rheology Degradation Processing and Characterization of ReDocument261 pagesThe Rheology Degradation Processing and Characterization of ReDeidra CadeNo ratings yet

- A513A513M-15 Standard Specification For Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingDocument13 pagesA513A513M-15 Standard Specification For Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingChuthaNo ratings yet

- 32LC818 Lcd26v88amDocument53 pages32LC818 Lcd26v88amDaniel AvecillaNo ratings yet

- Flexible grid coupling selection guideDocument18 pagesFlexible grid coupling selection guidechavico113No ratings yet

- Leaflet Uniswitch CBCDocument2 pagesLeaflet Uniswitch CBCFahmi CumiNo ratings yet

- Virtualengine Brochure 2016 Web 20160401Document2 pagesVirtualengine Brochure 2016 Web 20160401Vusumzi MzimvubuNo ratings yet

- Research Papers On Polymer NanocompositesDocument4 pagesResearch Papers On Polymer Nanocompositespxihigrif100% (1)

- Celda de Carga Tipo Z Sensortronics - 60050 (Molinos de Pasta)Document1 pageCelda de Carga Tipo Z Sensortronics - 60050 (Molinos de Pasta)Schiraldi BonillaNo ratings yet

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesDocument40 pagesJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemNo ratings yet

- GE Turbine Fuel SpecsDocument24 pagesGE Turbine Fuel SpecsA H RanaNo ratings yet

- Sony Dsc-w630 Ver1.1 Level2Document25 pagesSony Dsc-w630 Ver1.1 Level2Alberto MorenoNo ratings yet

- AURORA KN95 Face Mask Introduction 2020Document23 pagesAURORA KN95 Face Mask Introduction 2020victorcamposNo ratings yet

- Chapter 2 (Lecture 3)Document25 pagesChapter 2 (Lecture 3)SchaieraNo ratings yet

- General BrochureDocument1 pageGeneral BrochurerayscrubberNo ratings yet

- Geberit Silent-PP Pipe With One SocketDocument2 pagesGeberit Silent-PP Pipe With One SocketeneajataganiNo ratings yet

- Astm D 6184Document3 pagesAstm D 6184김인식No ratings yet

- 154 Loesche Mills For Cement Raw Material E 2016Document28 pages154 Loesche Mills For Cement Raw Material E 2016faheemqcNo ratings yet

- Lec-2 Structural Steel PropertiesDocument10 pagesLec-2 Structural Steel PropertiesRifat HasanNo ratings yet