Professional Documents

Culture Documents

Aluminium Slurry Measurement: Application Note

Uploaded by

Fabian SolanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Slurry Measurement: Application Note

Uploaded by

Fabian SolanoCopyright:

Available Formats

Product

APPLICATION NOTE

Pressure

Magnetic

Aluminium Slurry Measurement Vortex

Industry: Mining Coriolis

Product: Magnetic Flowmeter ADMAG AXF, CA

Keywords:Stable Measurement in Slurry Application

Reduced Maintenance Cost T

Temperature

Industry

Introduction Application challenges Yokogawa’s solution

Oil & Gas

-Liner abrasion ADMAG AXF

The slurry measurement is one of the most challenging -Slurry noise -Dual frequency excitation

applications for flow measurement. In the aluminum refining (Enhanced dual

process, there are many difficult applications such as Abrasive

frequency(<=200mm))

abrasive slurry, adhesive slurries that contains corrosive Slurry Refining

-Ceramic Liner (<=200mm)

chemicals. For these flow measurement, magnetic flowmeter -PFA liner with metal

is the most popular flowmeter, and the performance and hat(>200mm)

robustness of magnetic flowmeter the key to maximize the

High Liner and ADMAG CA (<=200mm)

plant productivities with minimum total cost of ownership.

consistency electrodes are Chemical

In this paper, Yokogawa’s solution and expected benefit in

adhesive insulated by

aluminum slurry applications will be introduced.

slurry fluids adhesion

Application Petrochemical

In the aluminum refining process, there are many tough

applications to measure aluminum slurry and corrosive Food &

chemicals. Following is the major challenges in the Beverage

aluminum application.

- Abrasive aluminum slurry causes the output fluctuation and

damage the liner and electrodes.

Pharmaceutical

- Heavy slurry noise may affect on the measurement

accuracy and stability.

- Shorter replacement cycle because of the mechanical ADMAG CA ADMAG AXF (Remote type)

Pulp &

damage by slurry Paper

- High density red-mud covered on the electrodes requires

frequent maintenance for the cleaning

Dual Frequency Excitation Mining

Solution

ADMAG AXF’s dual frequency excitation has the advantages

Yokogawa’s ADMAG fit-for-purpose solutions deliver stable of both the high and low frequency meters. Dual frequency

and reliable process control in noisy slurry application. At excitation provides, good zero stability, accuracy of 0.35%,

Iron & Steel

the same time, the robust and reliable mechanical design 0.2% as option of reading and immunity to slurry noise.

achieves longer life-time and reduces the maintenance work Further, the “Enhanced Dual Frequency Excitation Method”

and process downtime. is optionally introduced in the ADMAG AXF to cope with

more difficult application such as high concentration slurry

measurement.AXF’s new Enhanced Dual Frequency option Power

provides an even higher excitation frequency of 165Hz for

maximum slurry noise reduction when needed, without

sacrificing zero stability.

W&WW

AN 01E20A01-07EN 2nd Ed: Nov. 2011 http://www.yokogawa.com/fld/

All Rights Reserved, Copyright © 2010, Yokogawa Electric Corporation

APPLICATION NOTE

Leak-free Electrodes and PFA Liners

Non-retained liners (extruded liner), which are commonly used

in conventional meters, are susceptible to failures as a result of Bauxite

vacuum conditions that can be created due to a pump or valve

failure. In addition, meters that have extruded liners generally

have a shorter life due to the aggressiveness of the chemicals Aluminoferric

used. Yokogawa uses an injected molded PFA liner with a Cake

retaining grid. This retaining grid plate, used to reinforce the PFA Aluminum

liner, acts like rebar in concrete.

This rugged construction holds the liner in place and prevents

Aluminoferric cake

the liner from caving in due to vacuum conditions. The thickness

and durability of the injection molded PFA liner provides a flow

tube that is capable of handling the most severe applications.

period that conventional electrode

The ADMAG AXF magnetic flowmeter introduced fluid adhesion

Type magnetic flowmeter needed in every 2-3 months could be

level diagnosis which always monitor the level of insulating

extended to every 12-18 months with electrode-less ADMAG CA

material buildup on the electrodes, which enables maintenance

that can continue the operation even once coated. The build-up

timing can be recognized. In addition, with the utilization of

rate of red mud was well known by customer. And the reduction

ADMAG AXF’s replaceable electrode type flowtube, electrodes

in flow area can be calculated in the DCS and used to correct

can easily be removed and cleaned without removing flowtube

the measured flowrate as indicated in the below picture.

from piping.

Pulsed-DC Type

with Wetted and Capacitance Type

Protruded Electrode with High Frequency

Conventional Electrode ADMAG AXF Excitation

Drift (cm/s)

• Exposed electrode seal • Superior electrode seal Drift of 2

• Extruded liner • Injection molded PFA Zero Point 0.16 0.21

1

• UN-Retained liner • Mechanically retained liner 0

3 8 14 Wall

• Aluminum body • Welded stainless steel body Time (month) Build-up

Thickness (mm)

1 0.8

Thickness of 0.5

0.5

Wall Build-up

Thickness

0

3 8 14

Time (month)

ADMAG CA Capacitance Solution with Mirror

Finished Liner

In red mud application, pregnant Liquor(caustic base) which

quickly forms a thin hard insulating

layer on the pipe walls. This coating can not be removed in-line

by either chemical or mechanical

means. Hence the conventional electrode type magnetic

flowmeter would stop the operation once

coated, because the meter to be removed and the coating was

manually scarped from the walls.

As the actual example of an aluminum plant, the maintenance

AN 01E20A01-07EN http://www.yokogawa.com/fld/

All Rights Reserved, Copyright © 2010, Yokogawa Electric Corporation

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- dpcast_01enhancedphysicalproperties_2019-10-08_2.0Document2 pagesdpcast_01enhancedphysicalproperties_2019-10-08_2.0giakovidNo ratings yet

- Yokogawa Admag AeDocument4 pagesYokogawa Admag Aeadi RukunNo ratings yet

- Tafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TDocument4 pagesTafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TIkhsan LyNo ratings yet

- Surface Treatment20Document2 pagesSurface Treatment20alimesmatparastNo ratings yet

- ARCAP - Grades and PropertiesDocument7 pagesARCAP - Grades and PropertiesEminent RishNo ratings yet

- X Supreme Aluminium Tubing HighresDocument3 pagesX Supreme Aluminium Tubing Highresmd 80No ratings yet

- Flue Gas Desulfurization: Application NoteDocument2 pagesFlue Gas Desulfurization: Application Notelutfi_ismailNo ratings yet

- LMV 803Lr Data Sheet US FinalDocument2 pagesLMV 803Lr Data Sheet US Finaljamil ahmedNo ratings yet

- 131 - 1.9.1.2-01T - Aluminum WireDocument4 pages131 - 1.9.1.2-01T - Aluminum WireDiidaii MontañoNo ratings yet

- Chilled Water in Air Conditioning Unit: Application NoteDocument2 pagesChilled Water in Air Conditioning Unit: Application NoteAnas ShifanNo ratings yet

- EPS2021 - Thin, Flexible ARC For 5G Mmwave Filter - Corning - ZhuangDocument11 pagesEPS2021 - Thin, Flexible ARC For 5G Mmwave Filter - Corning - Zhuangzeadzizo715No ratings yet

- GLOBAL BUSBAR INSULATORSDocument16 pagesGLOBAL BUSBAR INSULATORSKatty CachagoNo ratings yet

- Tomahawk 625Document4 pagesTomahawk 625Marcos GarciaNo ratings yet

- Lexan Margard HLG5 2021Document3 pagesLexan Margard HLG5 2021Jessica RamosNo ratings yet

- RCA-HP E3: Vishay DraloricDocument10 pagesRCA-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- Yokogawa Admag SeDocument3 pagesYokogawa Admag Seadi RukunNo ratings yet

- ASTM F75 CoCr Alloy Material Properties and ApplicationsDocument3 pagesASTM F75 CoCr Alloy Material Properties and Applicationsboni_briantoniNo ratings yet

- Sa3 Sa100 Sar3 Sar100 Electric Actuators With Epac Controls in Sil Version enDocument30 pagesSa3 Sa100 Sar3 Sar100 Electric Actuators With Epac Controls in Sil Version enKiruba EathirajNo ratings yet

- Big Blue 800 Series (Issued June 2023 Index No. ED14.0)Document8 pagesBig Blue 800 Series (Issued June 2023 Index No. ED14.0)Ron Woo Chee ZhengNo ratings yet

- SUN 72M (Sunenergy Monocristalino 370W)Document2 pagesSUN 72M (Sunenergy Monocristalino 370W)grasia77No ratings yet

- BA-50Document2 pagesBA-50MIKEL ERMINANo ratings yet

- SGT A05 GT Brochure 2019 PDFDocument16 pagesSGT A05 GT Brochure 2019 PDFvogid38712No ratings yet

- Product Data Sheet for FabCO 811N1 Flux Cored Gas Shielded WireDocument2 pagesProduct Data Sheet for FabCO 811N1 Flux Cored Gas Shielded WireAlejandroAcuñaMaureiraNo ratings yet

- Pramac GGW200G - 50HzDocument6 pagesPramac GGW200G - 50Hzyudisenna SennaNo ratings yet

- DacrometDocument6 pagesDacrometPeter MangalukiNo ratings yet

- Grafilit IQ: Properties Appropriate Industries & ApplicationsDocument2 pagesGrafilit IQ: Properties Appropriate Industries & ApplicationsFrancisco José Espinosa MásNo ratings yet

- ACP BroucherDocument3 pagesACP BroucherMohammed AhmedNo ratings yet

- Welding Alloys Technical CatalogueDocument15 pagesWelding Alloys Technical CatalogueThanh TamNo ratings yet

- Brochure Mechanical Seals DF Sa Diamondfac PDFDocument6 pagesBrochure Mechanical Seals DF Sa Diamondfac PDFLymeParkNo ratings yet

- Excelam-: Q1400COLD/RS Q1400COLD/RSER Q1600COLD/RS Q1600COLD/RSER Q1600COMBI/RSERDocument2 pagesExcelam-: Q1400COLD/RS Q1400COLD/RSER Q1600COLD/RS Q1600COLD/RSER Q1600COMBI/RSEROdien SalehNo ratings yet

- Description Application: Advanced EngineeringDocument5 pagesDescription Application: Advanced EngineeringGregory BrownNo ratings yet

- Graphene Coatings Improve Friction and Wear of Aluminum AlloyDocument10 pagesGraphene Coatings Improve Friction and Wear of Aluminum AlloyDr Praveen KumarNo ratings yet

- 19 32 - Schunk Products For Steel Industry - 01Document4 pages19 32 - Schunk Products For Steel Industry - 01Daniele QuinteiroNo ratings yet

- AMCRPS - AKILA - InfoSheet - GBDocument2 pagesAMCRPS - AKILA - InfoSheet - GBmigusagoNo ratings yet

- Zaragoza Factory - Our Product - enDocument34 pagesZaragoza Factory - Our Product - enEngr Fahimuddin QureshiNo ratings yet

- SGT A05 Product BrochureDocument16 pagesSGT A05 Product BrochureMario Felpe Dos SantosNo ratings yet

- AMECA - Insert CoilDocument20 pagesAMECA - Insert CoilHector MartinezNo ratings yet

- ARaymond Energies PowAR-Slot Datasheet EE-2019-0312-ENDocument2 pagesARaymond Energies PowAR-Slot Datasheet EE-2019-0312-ENSivaNo ratings yet

- GB 2H Fills For Cross Flow CTDocument2 pagesGB 2H Fills For Cross Flow CTShahab Z AhmedNo ratings yet

- R3 MV 15W-40 Off Highway-Multigrade Heavy Duty Diesel Eng OilDocument2 pagesR3 MV 15W-40 Off Highway-Multigrade Heavy Duty Diesel Eng OilRaden Ardy100% (1)

- Schunk Products For Wind Turbines: Schunk Kohlenstofftechnik GMBH Schunk Bahn-Und Industrietechnik GMBHDocument6 pagesSchunk Products For Wind Turbines: Schunk Kohlenstofftechnik GMBH Schunk Bahn-Und Industrietechnik GMBHdian JaelaniNo ratings yet

- Its Flame Scanner v1 1Document12 pagesIts Flame Scanner v1 1foroNo ratings yet

- Aspect 375 Ac/Dc: Tig Welding MachineDocument8 pagesAspect 375 Ac/Dc: Tig Welding MachineJorge Andy Arce CaricariNo ratings yet

- Zap-Lok System For Pipeline Installation January 2019 PDFDocument35 pagesZap-Lok System For Pipeline Installation January 2019 PDFmutadiNo ratings yet

- Technical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionDocument2 pagesTechnical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionMarjan ArhNo ratings yet

- Stainless Steels: Alloy 904L (UNS N08904)Document1 pageStainless Steels: Alloy 904L (UNS N08904)MV ABNo ratings yet

- DacrometDocument6 pagesDacrometdavideNo ratings yet

- Abrasive Flow Machining AFM An OverviewDocument10 pagesAbrasive Flow Machining AFM An OverviewAntin Aquil RajNo ratings yet

- Duralloy 200 DC Pulse PFC MV Owner S ManualDocument20 pagesDuralloy 200 DC Pulse PFC MV Owner S ManualPascu AurelNo ratings yet

- Executive Summary - Armagel (RESSB)Document10 pagesExecutive Summary - Armagel (RESSB)Yap HSNo ratings yet

- Alma - Turbine-Adriane - Fc006en - HD (1) AdrianeDocument2 pagesAlma - Turbine-Adriane - Fc006en - HD (1) AdrianeMiguel AguirreNo ratings yet

- Omala S2 G 100Document3 pagesOmala S2 G 100AMITNo ratings yet

- Almona CatalogDocument9 pagesAlmona CatalogMahmoud AbouelhassanNo ratings yet

- Shell Rimula R4 15W-40 (CI-4 Plus) : Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Rimula R4 15W-40 (CI-4 Plus) : Performance, Features & Benefits Specifications, Approvals & RecommendationsVimal GopalakrishnanNo ratings yet

- TM25 PDFDocument4 pagesTM25 PDFHendi AfriyanNo ratings yet

- Hanwha Q Cells Data Sheet Qplus L-g4.2 340wDocument2 pagesHanwha Q Cells Data Sheet Qplus L-g4.2 340wtaiNo ratings yet

- Electrodeposition Andreas Tolz PPGDocument14 pagesElectrodeposition Andreas Tolz PPGAndi MusdalifahNo ratings yet

- Surge Arrester PDFDocument5 pagesSurge Arrester PDFSwarup NayakNo ratings yet

- Brochure SA WeldingDocument16 pagesBrochure SA WeldingThương LêNo ratings yet

- GPK Ifvi Tgs Ins Ds 026 1Document2 pagesGPK Ifvi Tgs Ins Ds 026 1Fabian SolanoNo ratings yet

- 20A1000 Pick ListDocument26 pages20A1000 Pick ListFabian SolanoNo ratings yet

- Master Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesDocument2 pagesMaster Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesFabian Solano100% (1)

- Cameron Scanner 2000 Microefm Well Testing Solution BrochureDocument8 pagesCameron Scanner 2000 Microefm Well Testing Solution BrochureAnom Haryanto100% (1)

- MCG2420-3D Transmisor de NivelDocument3 pagesMCG2420-3D Transmisor de Nivelanferluis mendezNo ratings yet

- PDVSA Temperature Measurement GuidelinesDocument3 pagesPDVSA Temperature Measurement Guidelines20jose12luisNo ratings yet

- F7 Drive User Manual: Model: CIMR-F7U Document Number: TM.F7.01Document255 pagesF7 Drive User Manual: Model: CIMR-F7U Document Number: TM.F7.01negrinNo ratings yet

- Control Panel: A World of Energy SolutionsDocument11 pagesControl Panel: A World of Energy SolutionsFabian SolanoNo ratings yet

- k-304 TEMPERATURE MEASUREMENT CRITERIADocument6 pagesk-304 TEMPERATURE MEASUREMENT CRITERIArodolforfNo ratings yet

- How To Cure 7 Common Tank Gauging Headaches PDFDocument12 pagesHow To Cure 7 Common Tank Gauging Headaches PDFReda NariNo ratings yet

- General Instrumentacion Portfolio PDFDocument19 pagesGeneral Instrumentacion Portfolio PDFFabian SolanoNo ratings yet

- PRV 2 Size Quick Start GuideDocument36 pagesPRV 2 Size Quick Start GuideAlcides Llanque ChoqueNo ratings yet

- Yokogawa Ejx530a Gs01c25f01 01enDocument12 pagesYokogawa Ejx530a Gs01c25f01 01enandy175No ratings yet

- K 333 PDFDocument9 pagesK 333 PDFjuanchocazon78No ratings yet

- Temperature Measurement Fabrication DetailsDocument10 pagesTemperature Measurement Fabrication DetailsFabian SolanoNo ratings yet

- Gs01e20d01 01eDocument58 pagesGs01e20d01 01eknightfelix12No ratings yet

- GS01C25B01 01enDocument17 pagesGS01C25B01 01enJR RZNo ratings yet

- IEC 62591 WirelessHART System Engineering GuidelinesDocument112 pagesIEC 62591 WirelessHART System Engineering Guidelinesargix69No ratings yet

- CMP Cable Glands PDFDocument184 pagesCMP Cable Glands PDFShihabudin Qolyubi100% (1)

- PANELDocument2 pagesPANELFabian SolanoNo ratings yet

- Basic Instrumentation Measuring Devices and Basic Pid ControlDocument125 pagesBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiNo ratings yet

- Emerson Control Valve HB Ed 3Document295 pagesEmerson Control Valve HB Ed 3Ahmed SeliemNo ratings yet

- Fci BurndyDocument724 pagesFci Burndycarameloo2012No ratings yet

- Ieee 99-1980Document11 pagesIeee 99-1980juaninjaNo ratings yet

- Engineer's Guide To Level Measurement For Power and Steam MeasurementDocument262 pagesEngineer's Guide To Level Measurement For Power and Steam Measurementvlcmstne04100% (1)

- 7 Habits of Highly Successful Controls EngineersDocument10 pages7 Habits of Highly Successful Controls EngineersAdelChNo ratings yet

- FM6310Document29 pagesFM6310Fabian Solano100% (1)

- Basic Instrumentation Measuring Devices and Basic Pid ControlDocument125 pagesBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiNo ratings yet

- Iom104 2910 PDFDocument132 pagesIom104 2910 PDFFabian SolanoNo ratings yet

- AxSEAM - Scanner-User ManualDocument116 pagesAxSEAM - Scanner-User ManualGhaithNo ratings yet

- Series 60 Crank Seal11-60-04aDocument22 pagesSeries 60 Crank Seal11-60-04aKeyser SözeNo ratings yet

- Infinity SM 225Document2 pagesInfinity SM 225Bmwmotorsport GabriNo ratings yet

- CLORIOUS - ControlsDocument4 pagesCLORIOUS - ControlsRM HaroonNo ratings yet

- High Voltage (HV) Outdoor Termination OHVT-145C (3A) : UP TO 145 KVDocument3 pagesHigh Voltage (HV) Outdoor Termination OHVT-145C (3A) : UP TO 145 KVAntonio Gresia100% (1)

- Faculty Recruitment Test: Mental Ability Test (MAT) Paper - BDocument4 pagesFaculty Recruitment Test: Mental Ability Test (MAT) Paper - BN C NAGESH PRASAD KOTINo ratings yet

- Air Enters The Compressor of A Gas Turbine at 1...Document4 pagesAir Enters The Compressor of A Gas Turbine at 1...Juan DiegoNo ratings yet

- RC Roof Beam DesignDocument5 pagesRC Roof Beam DesignSujay SantraNo ratings yet

- 4f27e 1Document75 pages4f27e 1Andres Daniel Garcia Farquet89% (9)

- 3 D Maxto MayaDocument1 page3 D Maxto MayaRakesh Phani Kumar Sunkara100% (2)

- Master Minimum Equipment List: U.S. Department of Transportation Federal Aviation AdministrationDocument296 pagesMaster Minimum Equipment List: U.S. Department of Transportation Federal Aviation AdministrationZainal AbidinNo ratings yet

- BA 50Z3 6003 en 1000127717Document282 pagesBA 50Z3 6003 en 1000127717Alberto100% (1)

- Ethernet Switch For Universal Multi-Service Aggregation: High Performance CarrierDocument4 pagesEthernet Switch For Universal Multi-Service Aggregation: High Performance Carriersalic2013No ratings yet

- Detroit Ds Pf12v149tDocument2 pagesDetroit Ds Pf12v149tMuhammad rizkiNo ratings yet

- Junior Resume EEDocument1 pageJunior Resume EESudeep AbhyankarNo ratings yet

- Study of Dies and InsertsDocument14 pagesStudy of Dies and InsertstraidenNo ratings yet

- Senior SAS Programmer in San Francisco CA Resume Jay JaffeDocument2 pagesSenior SAS Programmer in San Francisco CA Resume Jay JaffejayjaffeNo ratings yet

- Nebosh D guide report structureDocument2 pagesNebosh D guide report structureNorman AinomugishaNo ratings yet

- Administration Guide-NCC v2 6Document40 pagesAdministration Guide-NCC v2 6timucin.yalcinkayaNo ratings yet

- KRISHNA RAO JAISIM - A Brief ProfileDocument2 pagesKRISHNA RAO JAISIM - A Brief ProfileSusant Kumar67% (3)

- Grand Impianti Washer ExtractorDocument124 pagesGrand Impianti Washer ExtractorredvalorNo ratings yet

- 12655/navjeevan Exp Third Ac (3A)Document2 pages12655/navjeevan Exp Third Ac (3A)madhuramfoods.chiralaNo ratings yet

- Ficha Tecnica MEDIDOR GC310Document3 pagesFicha Tecnica MEDIDOR GC310Diana Isabel VillaquiranNo ratings yet

- New Full Report PDFDocument58 pagesNew Full Report PDFiqbal100% (1)

- Backdoors CT Case Negative - DDI 2015 SWSDocument304 pagesBackdoors CT Case Negative - DDI 2015 SWSseNo ratings yet

- Sylvania KatalogDocument2 pagesSylvania KatalogCk_psihNo ratings yet

- UAP Grading Policy Numeric Grade Letter Grade Grade PointDocument2 pagesUAP Grading Policy Numeric Grade Letter Grade Grade Pointshahnewaz.eeeNo ratings yet

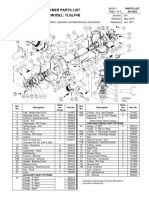

- Blackmer Parts List Pump Model: Tlglf4BDocument2 pagesBlackmer Parts List Pump Model: Tlglf4BRAUL ARMANDO PALOMO CAMPOSNo ratings yet

- Parts List of Engine Assy of FMX 440 (PC-24) - TP-836Document1 pageParts List of Engine Assy of FMX 440 (PC-24) - TP-836Cws0% (1)

- Case Cx50b Mini Crawler Excavator PartsDocument29 pagesCase Cx50b Mini Crawler Excavator PartsWilson CardozoNo ratings yet