0% found this document useful (0 votes)

3K views5 pagesXXXXX: VSD Maintenance Checklist

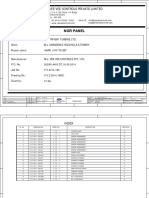

The document provides a maintenance checklist for a VSD unit. It was inspected on August 13, 2009. Key findings include:

1. Backups of parameter settings were performed and no faults were detected.

2. A visual inspection found no abnormal damage. Measurements showed power supplies were within normal ranges.

3. Testing of thyristors and IGBTs found some out of range results that require attention.

Uploaded by

Lim ChsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

3K views5 pagesXXXXX: VSD Maintenance Checklist

The document provides a maintenance checklist for a VSD unit. It was inspected on August 13, 2009. Key findings include:

1. Backups of parameter settings were performed and no faults were detected.

2. A visual inspection found no abnormal damage. Measurements showed power supplies were within normal ranges.

3. Testing of thyristors and IGBTs found some out of range results that require attention.

Uploaded by

Lim ChsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Backing up of Parameter Settings: Covers the procedures for backing up parameter settings before maintenance tasks.

- Measurement of Fan Operation: Describes the verification procedures for fan operation and air chamber state.

- Measurement of Power Supplies: Describes methods for measuring voltage levels and ensuring power supply integrity.

- Record of Readings: Presents recorded data on operational days, faults, and trip timings.

- Details of Thyristor/IGBT Measurements: Provides specific testing data and conditions for Thyristors and IGBT modules.

- Replacement of Parts: Records any parts replaced during maintenance; indicates no replacements needed.

- Remarks and Closing: Final remarks on VSD operating condition and recommendations.